luxuryluke

Members-

Posts

74 -

Joined

-

Last visited

Contact Methods

-

Website URL

Https://instagram.com/luxuryluke

Profile Information

-

Location

Pacific Northwet

-

Interests

Leather, wood, and design

LW Info

-

Leatherwork Specialty

Handstitcher

-

Interested in learning about

Machines and bags

-

How did you find leatherworker.net?

search

Recent Profile Visitors

2,813 profile views

luxuryluke's Achievements

Member (2/4)

-

https://youtu.be/ILIR0jN2lBo well, imagine maintaining that beast. on the other hand, look at what Pfaff has come up with for the shoe industry: 571, 1571 can you imagine making shoes with this dream? (I don’t make shoes, but still, right?) ...as well as this production beast: yep, late night inspiration browsing. have a great night!

-

This is a fascinating thread full of wisdom.

-

Okay so those Groz needles finally showed up and they seem to be the right size, but they’re not TRI for leather. Of the nearly 150 old assorted needles For various thread sizes that came with the machine, most don’t fit Properly or are poorly marked. ...some say *Necchi 140*, some *pfaff 150*. There are even a few *Schmetz 130* or *150*. I’m sewing 135 thread size Exclusively and would love to hear what specific needles you’re using.

- 4 replies

-

- pfaff

- cylinder arm

-

(and 1 more)

Tagged with:

-

looking for a cylinder arm machine

luxuryluke replied to Sturmtrupp702's topic in Leather Sewing Machines

Don’t forget the class 26 for more of an in the middle approach. Otherwise this is all solid wisdom! -

Welcome! I also suggest reading the sticky articles in this Leather Sewing Machines section. I assume since you're on this forum, that it's likely you're working with leather, although that can't always be true. After spending quite a bit of time talking to vendors and other people here on the forum, my best guess is a Leather Machine Co Cobra 26 cylinder arm machine. It'll sew right in the middle of the sweet spot. A little of the light stuff, depending on how many layers, and a little of the heavy stuff, depending on the layers. If you're doing belts and holsters, it's likely that you're stitching thick enough that a 26 would work for you. The 26 is my dream machine. Of course, the capabilities and stats of all of the various machines are important. Take your time, don't think that you've wasted time on research, unless it becomes a rabbit hole. If you're serious about stitching with a machine, figure out your budget. Remember that the more common the machine, the more likely you are to find parts and find help …especially when it comes to videos as there are a few good channels on YouTube. That's my two cents . There are a lot of very helpful people on the forum, and it's well worth your time learning and browsing questions people have. Let us know what you go with!

-

Right. I did that and this required me moving the bar up so high that it touches the inner case at the top of the machine. That’d require me to saw off the top of the needle bar, Lol. No go. Thanks for the tip though! All the same needles is an ideal scenario!

- 4 replies

-

- pfaff

- cylinder arm

-

(and 1 more)

Tagged with:

-

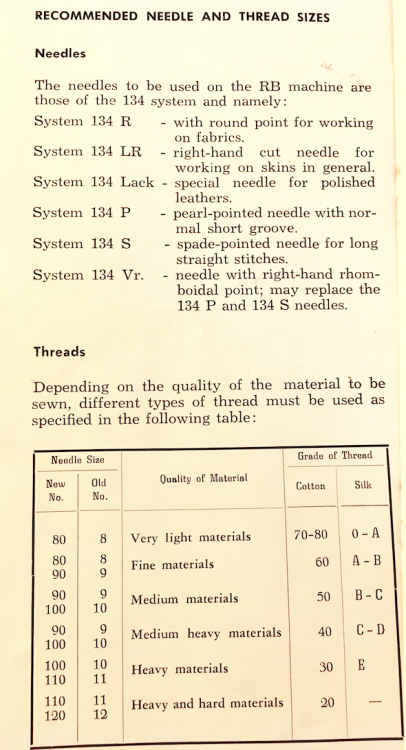

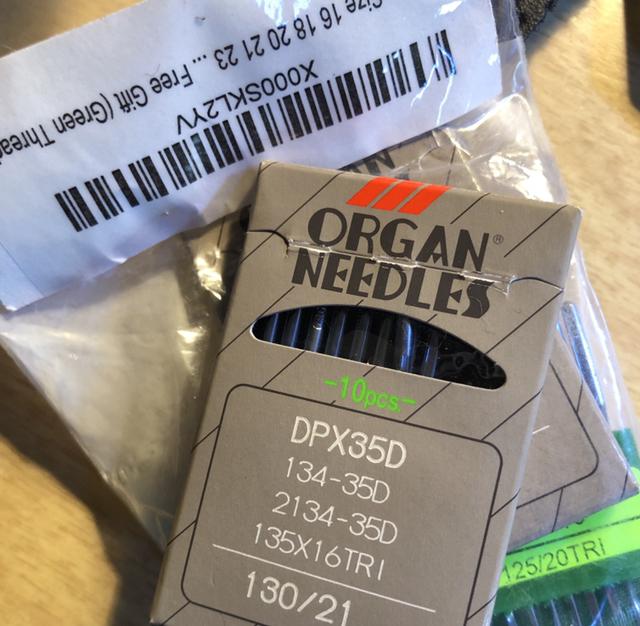

So I finally spent some time trying to understand industrial sewing machine needle sizes and systems. As a reference I’d spent some time going through the information shared on the needles and threads sticky post linked here from 2011: Here has been the main thread for this machine: I bought this machine used (obviously) but the few needles that came with it are nearly unmarked and are about 1.52” long. So I wanted to share with you what I’m doing to find out what size these last few existing needles are that I have that go in my Pfaff 335 clone (it’s a Necchi 840-100 rotating bindery cylinder arm machine). I’d actually purchased a full set of 135 x16 (common needles for walking foot machines for use on the leather, in place of the 135X 17 needles). These are about 1.7” long. These needles were too long. I actually had to adjust the Needle bar very high to allow these larger needles to work. As I adjusted this, the Needle bar eventually touched the top of the machine Case and I realized this wasn’t going to work. I couldn’t find needles that matched the 134 needle system that the Necchi manual described. Eventually I found some! Here are the next set of needles I’m trying: “10 Groz-Beckert Gebedur 134 135X5 DPX5 Titanium Sewing Needles SINGER PFAFF JUKI” https://www.amazon.com/dp/B0759VHZVP/ let me know what you’ve used on this machine or similar. BONUS: if you’ve read this far and you’d like an assortment of 50 various Organ needles for 135x16tri in sizes 16, 18, 20, 21, 23 (I’ve only used two or so) …you can have them! heres a pic of those: dm me your address and I’ll get them shipped! Best first offer or free! Luke

- 4 replies

-

- pfaff

- cylinder arm

-

(and 1 more)

Tagged with:

-

Thank you @RockyAussie and @SARK9! I think I understand it now. I found some Groz Beckert needles of type 134-35 LR , size 21 (or Metrix 130) for my T135 size poly thread. It says it fits Adler and Pfaff machines of a wide range including the 335 and 1245 pfaffs. Let’s hope this works. Now to wait for shipping.

-

Cool project! Watching this thread.

-

Just coming across this too late it seems. I just wanted to add that Techsew has a nice page for just these kinds of questions, in case you hadn’t seen it: https://www.techsew.com/us/learn/cylinder-arm-guide.html?___store=us

-

Latest Purchase Juki LU-563 Never Used in Original Box

luxuryluke replied to JJN's topic in Leather Sewing Machines

That is one beautiful NOS machine, there! -

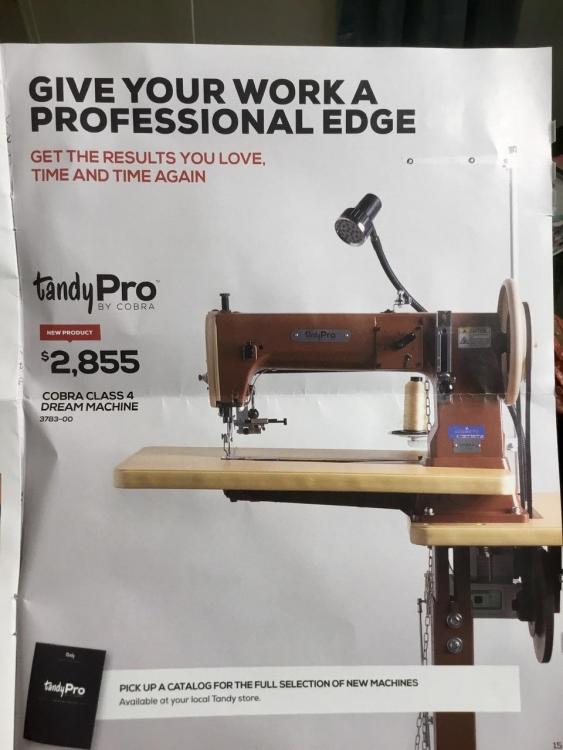

I'd mentioned it the other day when I received the mailer, but in case you hadn't heard, I find it interesting that Tandy is now selling Cobra machines. Not affiliated in any way. Here is the mailer I received last week: This morning I just received an email from Tandy about it on their website, which is new, fyi: https://www.tandyleather.com/en/tandypro-cobra-machines.html Anyway, I really like the Cobra machines, so I found this an interesting twist in the direction Tandy is going.

-

Tandy in Nyack NY now selling cobra sewing machines!

luxuryluke replied to thecruffler's topic in Leatherwork Conversation

-

So, after another semi-thorough cleaning, disassembly, oiling, reassembly, and inspection of the mechanics in the needlebar and bobbin case/hook areas, I did determine that the needle bar could be adjusted to fit the standard walking foot needle size of 135x16L on this machine. After this, I've noticed: At top dead center, the needlebar does top out by kissing the top of the case, so it really can't be raised anymore. At bottom dead center, it doesn't hit the center of the hook assembly inside the needle gap. The needle is now closely aligned to have the hook enter the scarf of the needle at the right timing and sews well with no noise or breakages The result is that the effective stitch length is not near what it was before with the previously installed needle by the previous owner. At the longest stitch setting it went from almost 5 stitches per inch up to around 6+ stitches per inch. I'm sure it's the geometry of the changes a new needle size made to the setup, but I'm not knowledgeable enough to know whether the new setup is better or not for the machine. I do know that this likely isn't the correct needle for this machine, but it's working really well at this point (badump). Below you'll see that the booklet I have specs it as a 134 needle system. Thoughts?