kgg

Contributing Member-

Posts

3,350 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by kgg

-

Wholesale hardware suppliers beyond Buckleguy, Tandy, Weaver, Ohio etc.

kgg replied to PheesOriginal's topic in Suppliers

Yes they are still around Harness Hardware Inc ( https://www.harnesshardware.ca/contact ) and about 3 minutes from Arron Martin. kgg -

CB341 having issues with sewing near edge of leather

kgg replied to Chapelworx's topic in Leather Sewing Machines

I agree with @Wizcrafts. I do have a couple of questions: i) are you using a edge guide or free handing? ii) are you using a table top attachment? A lot of machines have a natural pull to the left which can cause wandering which seems to be worse on cylinder arm as the contact surface is very small along with fighting gravity. iii) what size of thread are you using? iv) what size of needle? Here is a link to a good needle size to thread size chart ( https://www.tolindsewmach.com/thread-chart.html ) v) what system of needle are you using? (135 x 16 x needle size) is used for leather while the (135 x 17 x needle size) is used for fabric. I do see blowout on the underside which could indicate you are using a fabric needle. kgg -

Yes you are correct a lot of the "1341" clones are indeed Class 341 machines regardless of what their labels say. My two cents worth and I could be wrong. That said the Juki LS-1341 does not have the vertical stroke knob as it only came with the Juki LS-1342 and the Juki LS-1342-7 (reference: https://www.juki.co.jp/industrial_e/products_e/lether_e/cylinderbed_e/detail.php?cd=LS-1341_LS-1342_LS-1342-7_E ) That said the Jianglong machines are hybrid's being they have the vertical stroke knob of the Juki LS-1342 / LS-1342-7, the larger throat plate of the Juki LS-1341 and older Juki LS-341, the bobbin size used in the Jianglong varies from the 25.4mm ("M") used in the Juki LS-1340 series and older Juki LS-341 to your 28mm which was used in the Juki LU-1508 and older Juki LU-563 along with Durkopp Adler 867 and 868 and is actually a "U" size bobbin that has a larger capacity then the "M" which also means the bobbin case has to be that of maybe a Juki LU-563 or 1508 or a Durkopp Adler (867, 868). I suspect it is more similar to a Durkopp Adler bobbin case as it has a coiled bobbin spring rather then a flat spring and a different shape then the Juki's. kgg

-

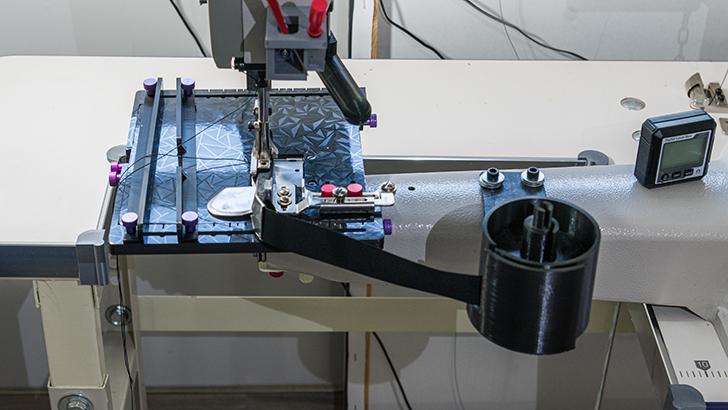

What I done with my cylinder arm machines Class 1341 and Class 441 is I 3D printed table top attachments for three reasons: i) I am a cheap old geezer and there is a considerable cost difference between your standard inline binding attachments vs the 90 degree ones. ii) As I have quite a collection from 1/4" up to 3 1/2" I wanted to be able to use the standard inline binding attachments that I have on all my machines whether they are a flatbed or cylinder arm machine. That said I will coincide you can get tighter bends with a 90 degree binding attachment then with a standard inline. iii) None of the table top attachments for cylinder arm machines that I have seen have the ability to accept standard inline attachments. Here is a sample of what I mean. First photo is a Class 1341 and the second is a Class 441 with a standard inline binding attachment using a swing-away binding attachment. kgg

-

Wholesale hardware suppliers beyond Buckleguy, Tandy, Weaver, Ohio etc.

kgg replied to PheesOriginal's topic in Suppliers

The last time I was there their stock was pretty slim pickings. May have just been between restocking. The place that I would recommend but forgot to include the link is https://en.cuirdizazzo.com/ in Montreal. kgg -

What Machine Do I Need to Sew 12 mm Leather

kgg replied to OscarRush's topic in Leather Sewing Machines

For sewing the 12mm or so of leather as previously stated you need a Class 441 machine like the Juki TSC-441 or clone. Finding Tippmann, Cobra machines on that side of the pond will probably be a chore. Since you are in the UK: For New: I would contact Franklin Co. for Cowboy machines https://www.franklinco.co.uk/about/ For Used: I would contact places like https://leathermachinery.co.uk/ as they seem to have a selection of used machines. Another option would be to import a 441 class clone machine directly from China for probably about the same price as a good used machine would cost in the UK. kgg -

Wholesale hardware suppliers beyond Buckleguy, Tandy, Weaver, Ohio etc.

kgg replied to PheesOriginal's topic in Suppliers

Other sources are Temu and Aliexpress. Depending on the quality and quantity find the item on say Temu and then go to Alibaba. Then you could buy one off say Temu and chances are the manufacturer will have their label on the item then contact that manufacturer directly. Sewing thread: A&E (made in Canada) http://www.amefird.ca/home/ General Items like rivets and Class 441 needles https://aaronmartin.com/ General Sewing Items like needles/zippers/binding for upholstery class machines https://www.wawak.ca/ General Sewing Items like Fieblings Dye, hand sewing thread and needles, hardware https://lonsdaleleather.com . It is cheaper for me to purchase dye from them and pay the shipping then buy it anywhere in Ontario. I'm in Eastern Ontario have purchased most of my leather in Montreal but have purchase on occasion purchased from Zelikrovitz in Ottawa https://www.zelistore.com/en-ca?srsltid=AfmBOooyTM4vv_4UX6qKoAuFBz284O3uiStWwlYvo3ns8cR66VQuM-Jv To narrow your search what kind of items are you looking for???? kgg -

I use single action airbrushes as I just couldn't get the hang of the double action airbrushes, like the Timbertech Airbrush Kit and the Paasche Airbrush that are siphon feed rather then gravity feed with the braided nylon hoses. I would push the pressure probably up to 40 - 45 lbs from my normal of 30lbs. You may have to: i) use a real compressor rather then an airbrush compressor just for the volume of air that maybe required. ii) detail spray gun like the Titan Tools Siphon Feed Detail Spray Gun if the consistency in doing the large pieces isn't what you need and to reduce the number of dye bottle changes. The airbrushes that I have can realistically hold about 20ml while the detail spray gun could probably hold close to 200ml. I have done 2' x 2' pieces of leather using my airbrushes with the airbrush compressor for both oiling (JOJOBA oil) and dying. I would definitely try the inexpensive Timbertech airbrush first, practice on a piece of cardboard of the same size first to get your spray and your rhyme right. This topic on my setup may help.

-

Take bobbin assembly out of 1341 cyclinder arm

kgg replied to TonyD1948's topic in Leather Sewing Machines

Before attempting to removing the bobbin assembly I would remove the bottom cover on the cylinder arm as you have a 50/50 chance that the tip of the needle fell down there. kgg -

Yup. Also another point is how the ink will react with leather that has been oiled etc and the longevity of the ink. The old inks could last twenty plus years with detail and colors still there. Today I see a lot of tattooing that needs to be refreshed after 3 or 4 years. kgg

-

Singer 211G156 vs Seiko STW-8B (Consew 226R) for heavier thread.

kgg replied to beefy's topic in Leather Sewing Machines

My two cents worth in addition to @Wizcrafts comments: Neither. They are upholstery class machines with a rated thread size max of V138 as a top and in the bobbin and typically a max sewing thickness of 3/8". That said depending on how thick you are planning on sewing sometimes you can use v207 in both the bobbin and as a top thread with thinner /softer leather more times you will be able to use v207 as a top thread and v138 in the bobbin. The drawback with using different thread sizes, top vs bobbin, is the strength of the seam will be only as good as the smallest thread size. As a note the brand name machines rated their machines on the thread size it could sew in the max thickness not what size of thread you could stuff through the eye of the needle. All the machines you have listed are rated for a #24 needle which is good for V207 in thinner stuff and V138 in thicker. Doing the conversion to the larger "U" size bobbin is not a simple pop-off and drop-in process which will in reality only get you more bobbin thread. The conversion is not going to get above V207 (limited by needle size) and depending on how thick / tough the leather is you still maybe limited to V138 as the top thread as well as in the bobbin. Is it worth the effort?? I don't know. If you need to sew V207 and above in thick or tough leather consistently these machines are the probably the wrong class of machine. You maybe able to trick the machine by increasing the torque using a speed reducer but chances are over the long haul you are going to damage the internals components of the machine. The term you used "extremely heavy" for thread is a relative thing. Domestic sewers consider V69 to be heavy duty while upholstery class machine users consider V207 to be heavy duty while those using saddle/ holster capable machines consider V415 as heavy duty and then you get into threads that hand sewers use which would be above V415. What is the thickness of leather you want to sew????? kgg -

Airbrushing for both the dye and oiling. kgg

-

The main difference is a clutch motor is running at full rpm's (1450 or 1750) as soon as you turn the power on and like a manual transmission in a vehicle you ease the on clutch. The servo motors don't spin until you depress the "go" pedal. All servo motors have a "startup jump" with the brushless typically having a more noticeable "jump" then the brushed servo motors. You can reduce this somewhat by reducing the pulley on the servo motor, installing a speed reducer and buying a better quality servo motor. Typically the more internal coils the servo motor has the less "jump" experienced but check the startup rating of the servo motor a lot of the cheaper ones have a 500 rpm rating. kgg

-

I would reconsider by the time you change the clutch motor out for a servo barring anything else you are up to about $1100 for a machine that came to the market in 1976. If you need parts they are going to be either hard to fine or expensive. Since you mentioned the Consew 226 which came to the market around 1960 I would go more for a newer Consew 206RB-5 which has a larger bobbin and costs about $1800 new. kgg

-

My 2 cents worth: Problem 1: Yes I agree oiling first will change the color of the leather however you are going to dye it anyway. The upside to dying first is the dye will penetrate deeper in the leather and allow the dye to go deeper as well. Problem 2: If you convert to airbrushing for both the oiling and dying you will, depending on the size of the piece, get a more even streak free dye covering. Also you will use less oil and less dye in the process. Which method of how you are applying the oil and dye to the leather?? Rag, sponge, brush etc.. kgg

-

The .3mm thickness is really thin leather. The .3mm would sort equate to about 3/4 oz in leather which is about the thickness of three sheets of regular copier paper. I suspect the problem is mainly do to the leather thickness. With such thin leather it will lend itself to stretching which will throw consistent stitch lengths off and the leather probably is being sucked / forced down ever so slightly into the needle hole of the feed dog as well as along the outside edges of the feed dog in the space between the feed dog and the needle plate opening. I have seen this type of problem with my Juki DNU-1541S when I am sewing thin flexible items as it has a large needle opening in the feed dog and just loves to suck things down that hole. I have used regular weight copier paper placed on the feed dog side of the items with some success in the past. A couple of questions. Which domestic machine are you using, what thread size are you using and what size of needle? kgg

-

What would your ultimate needle positioner/synchroniser do.

kgg replied to beefy's topic in Leather Sewing Machines

Interesting discussion. I do think it would be an interesting project and would be interested on how it turns out for your application. I'm with @dikman I don't use the needle positioner on the brushless servo motors since I sew slow. I like to keep my setups as simple as possible, brushed servo motor maybe a speed reducer and machine. I do have a couple of machines with the brushless NP compliant brushless servo motor without the NP installed but In reality I can't wait for those to throw in the towel or even a blown fuse so I can justify replacing them with a brushed servo motors. kgg -

I don't hand sew but I would think maybe leather gloves something similar to those used for Cycling, Weight Lifting or Wheelchair use would work. kgg

-

Yes and No. The manuals do show how to wind a bobbin, load/unload a bobbin, what direction the bobbin should turn when the bobbin thread is pulled and what screw to adjust for increasing or decreasing the tension just not how not how to get the tension close to what is needed for a given thread size or what not to do when adjusting the tension screw. Note: 1) Juki LS-1341 can have it's bobbin tension adjust while in your hand and not in the machine and you can do a drop test like a flatbed machine since it is a split case setup. 2) The manuals indicate the bobbin should turn clockwise NOT counter clockwise. Here are three examples from the Juki manuals. Other Brand Name and Clone machines may differ. : i) Juki LS-1341 (compound walking foot cylinder bed)--> threading a bobbin ii) Juki LS-1341 (compound walking foot cylinder bed) --> adjusting bobbin tension iii) Juki DNU-1541S (compound walking foot flatbed)--> threading a bobbin iv) Juki DNU-1541S (compound walking foot flatbed) --> adjusting bobbin tension v) Juki DU-1181N (walking foot flatbed) --> threading a bobbin vi) Juki DU-1181N (walking foot flatbed) --> adjusting bobbin tension kgg

-

The bobbin is the same it's the bobbin case that is different. Here is a good video on doing a drop test on a flatbed machine. The same applies for a Juki compliant bobbin case on a cylinder arm. kgg

-

FEIT DCL-8500N : Stump for Tilting Machine Head

kgg replied to friquant's topic in Leather Sewing Machines

This a typical location for the "tilt stump". Typically just made of plastic, pressure fitted into a hole drilled into the table top and meant as a temporary rest. The machine " slithered off the table hinge and into the drip pan " indicates to me incorrect / damaged hinge and or hinge installation. I have never had a head slip off and with my stubby fingers I am also titling my flatbed machines back to install / remove bobbins. kgg -

Downside I think is getting the bobbin tension adjusted. The Juki style is where the bobbin is placed in the top half part of the bobbin assembly, threaded and tension adjusted while still in your hand and then dropped in place. Personally I like being able to adjust the bobbin tension this way as I can do a bobbin tension drop test. kgg

-

That is correct for the Cobra Class 26 it does not have a Juki compliant bobbin assembly. Here is a video for the bobbin installation. kgg

-

My two cents worth: Notes i) The recommended size of needle for Tex135 (V138) is a 140 (#22) thin material, 160 (#23) medium material and 180 (#24) thick material. ii) Your 130 needle is really meant for Tex90 (V92). A good reference chart is ( https://www.tolindsewmach.com/thread-chart.html ). iii) V45 has a breaking strength of 7.5 lbs iv) V69 has a breaking strength of 11 lbs v) V92 has a breaking strength of 14.5 lbs vi) V138 has a breaking strength of 22 lbs If I'm not mistaken the 269 is cylinder arm and by adding a simple table top attachment you would have sorta kinda a flatbed for versatility. Personally I wouldn't bother changing the thread size and do all the sewing with Tex135 (V138). kgg

-

Yes, I have purchased bobbins and bobbin cases for a Sailrite clone. I purchased them from CKPSMS brand and they were decent quality. I have also bought from Aliexpress. kgg

.jpg.a99f9558247d9363f91a1f848f588421.jpg)