kgg

Contributing Member-

Posts

3,344 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by kgg

-

Deserves simple answer: NO kgg

-

IMHO: i) If I had purchased a Grade A, B, C or lower I expect the vendor to choose what I purchased if I'm buying it sight unseen. I am relying on their expertise / reputation. ii) If I had purchased the hides as 8 / 9 oz and they measured out with a proper leather thickness gauge or by micrometer to be equal to 7.5 oz I would have returned them regardless. I expect they would be at a minimum of 8 oz everywhere on the hide. Otherwise I would have bought 7/ 8 oz. iii) If I purchased Grade A hides I expect near as possible to perfection over the whole hide, no cuts or wriggles and a consistent colour as I did notice a dark line in your first photo up the length of the hide. I wonder if some of those wriggles going across the width of the hide on the right hand side of the hide in your first photo were cause by it being rolled too tight during storage or shipment to you. As a side question what was the laser measurement on the back side of the hides? Did you do a rough check to see you got the square footage you asked for?? If possible it is always wise to go and select your own hides to avoid the frustrations you are having. Who was the leather produced by, not the vendor? kgg

-

Couple of questions: i) How wide are the belts?? On this side of the pond the typical width is 1 1/2" (38mm) for say jeans while 1 1/4" ( 32mm) is more for dress pants. ii) How thick is the leather, 8 / 9 oz?? iii) Did you glue, staple, sew or rivet the belt loop? kgg

-

lonsdaleleather I did check out the Makers which lead me down the contact cement cost rabbit hole. The cost for i) Makers is $23 USD ($31 CAD) for 16 oz, water based ii) Aquilim 315 for 16 oz is $45 ($62 CAD), water based iii) Weldwood for 16 oz is about $23 USD ($31 CAD), solvent based That said in Canada we can get i) Lepage heavy duty contact cement is $29 ($40 CAD) for 32oz, solvent based ii) L.L. ( Lonsdale) contact cement is $26 ($36 CAD) for 32oz, solvent based which is advertised as using the same "recipe" as Barge. iii) Zelikovitz 1882 contact cement is $39 ($54 CAD) for 32oz, water based My conclusion is the water based contact cements on either side of the border are a fair bit more expensive. Contact cement (water or solvent based) are cheaper in Canada. kgg

-

They are decent enough, better then some I have seen for sale. Suggestion: Add a stitch line along the edge to help reduce stretching. kgg

-

The water based with one coat is Very interesting. The problem with the Aquilim 315 is the cost. It is about 1.6 times the cost of a heavy duty clear contact cement from your local hardware store. kgg

-

I would be interested in seeing the belts. Me I have two belts. A store bought "genuine" leather black dress belt which I figure I have worn maybe a dozen times in the last 8 years and my daily 13 oz medium brown chrome tan. kgg

-

Veg tan tooling with chrome tan projects

kgg replied to Blitz Thunderlungs's topic in How Do I Do That?

I find getting chrome tan to another colour can be a challenge. There are a lot of factors, who the manufacturer of the leather was, the original dying process, the colour you are trying to change, who the manufacturer of the dye is, etc. I have some medium brown pre-dyed 6 1/2 oz chrome tan that I want to redye to a colour close to Oxblood. I have experimented with a few cutoffs with different colours (rouge, wine and oxblood), and dye from three manufacturers. What I finally settle on was oiling first with Promise 100% Pure Organic Jojoba Oil, leaving it for 24 hours to soak in, then wiping the excess oil off and then applying Fiebings Oxblood dye so far is giving me a decent result. kgg -

The centre. Personally I am more hands on then my example. I hand cut my leather with a utility knife, use a standard oblong, round or corner punch with a hammer but I do use templates when I can and I do use a sewing machine as I don't have the temperament needed to sew by hand. Since I am artistically challenged I will use an embosser once I complete building it. To me hand sewn is literally when needles and thread are used manually to create a seam not a sewing machine. kgg

-

Veg tan tooling with chrome tan projects

kgg replied to Blitz Thunderlungs's topic in How Do I Do That?

What I would suggest is that you choose a colour for your chrome tan leather that will go with any colour you decide to use with your veg tan leather. Think of colours like black or grey or use a colour wheel. I wouldn't go with a leather stain as it will probably sit on top of the leather and rub off with use. kgg -

The definition, according to Wikipedia, of Artisan according to (from French: artisan, Italian: artigiano) is a skilled craft worker who makes or creates material objects partly or entirely by hand. The problem then arises would I consider myself a Artisan if I constructed a belt in this manner: i) used a leather cutter machine to cut the length and width of leather ii) used a skiver machine to cut the buckle fold over down iii) used a leather tongue hole punch machine to put the 5 holes in iv) used a levered punch/grommet setter to set the double side rivets that hold the buckle in place v) used a rivet setting machine to install the double sided rivets for the belt buckle vi) used a stapler for the belt loop vii) used a leather embosser machine to put the pattern in the leather viii) used a airbrush to apply the dye ix) used a motorized burnisher to finish the edges x) used a sewing machine to stitch around the edge of the belt The belt would look professional, functional and be able to be consistently repeatable but what part did I make by hand? To me anything with Artisan in it just means expensive. Hand made is in a completely different level / category particularly hand embossed, hand sewn, hand cut, hand dyed, hand burnished, etc... kgg

-

I would suggest: i) use a motorized leather strap cutter ii) contacting the suppliers of motorized leather strap cutters like Campbell Randall ( https://campbell-randall.com/shop/strap-cutting ) iii) once you have the straps cut to the width you need it would be a matter of gluing and sewing them together. Could you possibly cut back the thickness to 9 / 10 oz as you have an easier job finding a manual leather strap cutter like Tandy ( tandyleather.ca ) ??? kgg

-

This is a couple of photo's of the bobbin assembly from a fellow member who recently bought a 341 machine from them. Yours looks like a Juki style. kgg

-

I like that one. kgg

-

Most machines have two spots to hook the return spring into. You should check to see if yours has a second location to give a softer return. Possible solutions: a. The internal rubber wheel that drives the winder needs to be adjusted so it only engages when you want to wind a bobbin. However if you wind a bobbin while sewing it can create a problem of unwinding the thread from the bobbin. There seems to be a couple of versions of this model some with the bobbin winder on the top of the machine and others driven with the main belt. I would just cut to the chase and buy a winder that runs of the main belt which probably would cost about $16 USD off Amazon. The dial should have a set set so you could move the dial to the correct position. Most machines are that way. I know some of those machines came with a smaller top thread pin with only two holes. As a note the hook assembly in the Jianglong 341 seems to come in couple of favours one that looks like the old old Nakajima 341L which was similar to the Singer 111 and another that is like the Juki LS-341. Which one do you have??? Just my thoughts. kgg Juki bought Nakajima and renamed it the Juki LS-341.

-

I use Leather Work to describe what I do. To me it is easier for the average Joe to sorta kinda have a idea of what my hobby is about. To me a "crafter" would be more like "master" as in a master electrician / plumber / tailor etc. having far better skills and knowledge then myself. kgg

-

My posts keep disappearing

kgg replied to DoubleKCustomLeathercraft's topic in Feedback and Suggestions

Post on the front page move down the list as new ones appear but are still in the sub Forum they were created in like a question related to a sewing machine would have been created in the Leather Sewing Machines sub forum but would also appear on the right side of the front forum page. As new topics appear it would move down the list and off the front page but be still listed in the Leather Sewing Machines sub forum. If someone posts a answer to your topic it would reappear on the front page of the forum and then move down the list once again. Your post: Questions on tooling English Bridle is still available in the "How do I do that?" sub forum on page 2 with one response from @TomE. kgg -

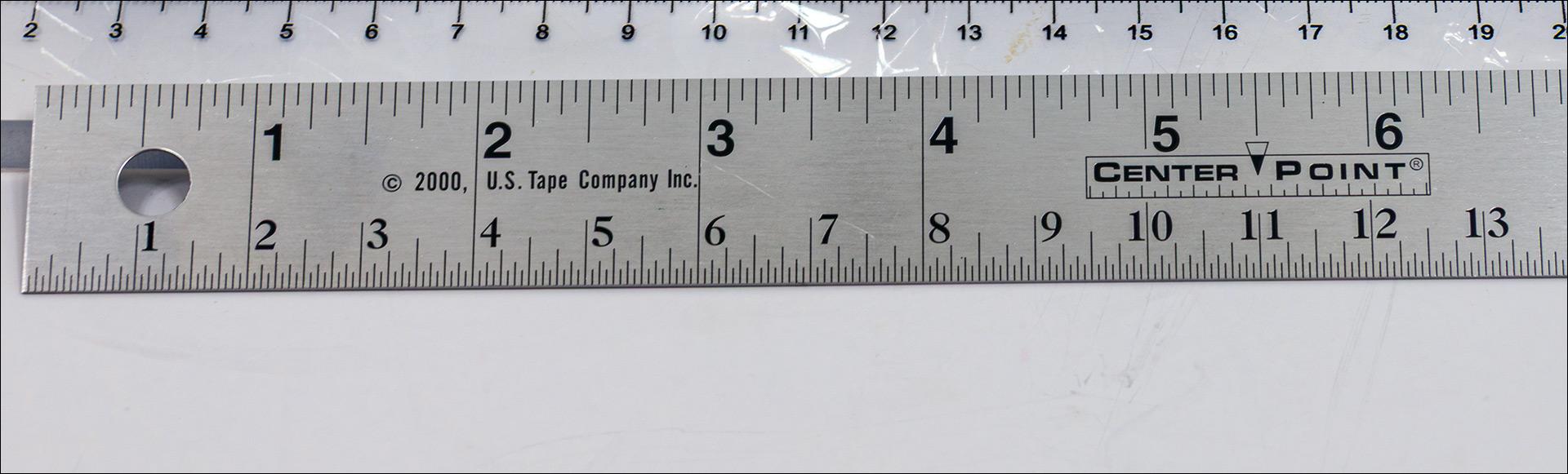

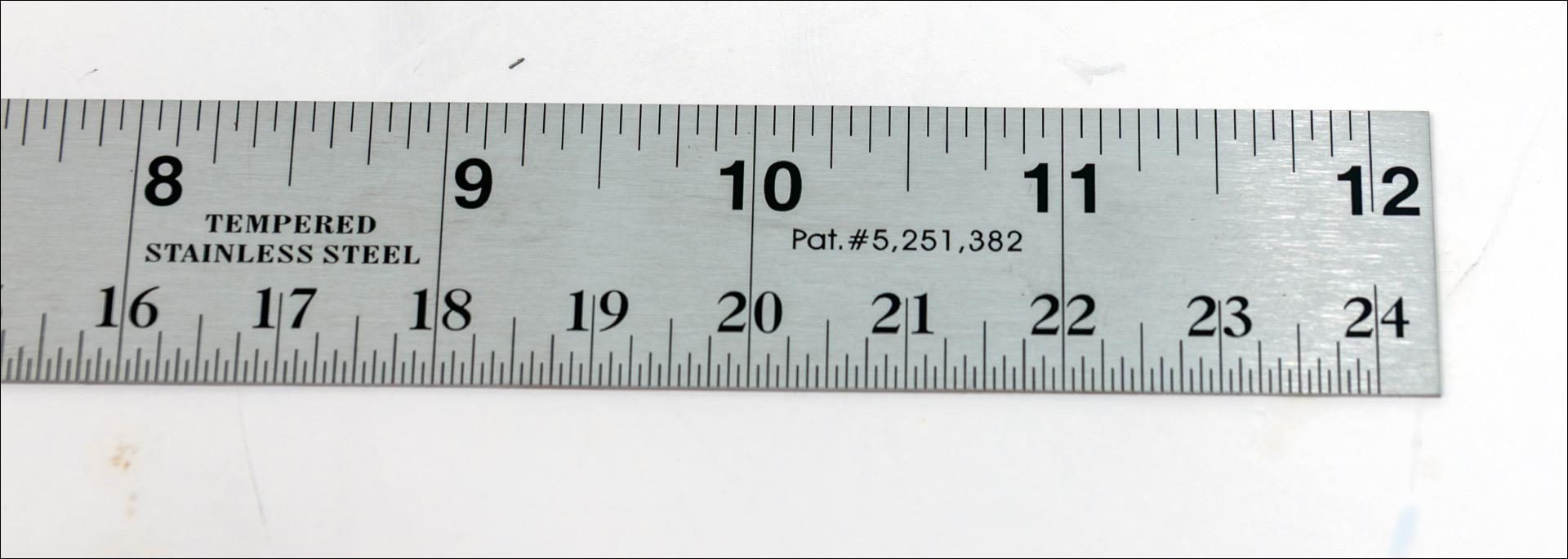

Most times it is not a problem but have a seniors moment, be distracted, tired or whatever and Murphy's Law is always at the ready to kick in. You screw up and you want to kick yourself in the butt as you just screwed up the work piece. Someone else my not notice but you will. @toxo I agree. Having a simple centre point ruler of any configuration is easier and correct everytime. Also the fractional measurements in the imperial system are not as easily divided in half as compared to the metric system. I did have a digital mic that read in both metric and imperial which is typical but this particular mic automatically showed half of the actual measurement. kgg

-

The logo for this ruler is a square with a centre point arrow and the brand name of the ruler is Center Point which is sold by US Tape Company. I figure it was placed at the 5.5" mark just to confuse the hell out of people as it has nothing to do with measurements. kgg Nah, it's a short foot sorta like a short ton (2000lbs). kgg

-

@toxo and @fredk The more options the better. Like when I am doing a dog lead I use a 6' steel ruler. kgg

-

I finally got tired of doing calculations in my head when trying to find the centre of something. Since I was taught, trained and worked in the Imperial and US systems until Canada converted supposedly to the Metric system. Normally the Imperial system is my go to for everyday type measurements. So I finally broke down and bought a 12" centre finding ruler sometimes called a doubling ruler. The ruler: i) Imperial measurements up to 12" or a you can get a larger 24" version ii) Two scales. A measuring scale and a centre point scale iii) Material: Tempered Stainless Steel iv) Sold by US Tape Company (https://www.ustape.com/product/centerpoint-straight-edge-rulers/) v) Made in China vi) patent number: 5,251,382 which is for a tape measure not a ruler???? vii) Status: Expired - Lifetime viii) Cost: I paid $18.90 CAD plus tax for total of $21.35 CAD ( $15.35 ) from Lee Valley This is a very simple design. You just measure the item say 8 1/4" and find 8 1/4" on the bottom scale and that is the centerpoint location. Anyone with a laser or 3d printer could easily make one. To bad they don't have a metric version for better accuracy. kgg

-

Servo motors: You can use either a brushed or brushless servo motor on any industrial sewing machine and it is a straight swap out as the mounting hole pattern is the same. You may have to move the "go" pedal slightly to the left or right. You can buy from a vendor or from Amazon / Temu / Ebay but you are not limited to the dealer should you want / have to change the motor. Brushless servo motors come in typically three puke flavours. Cheap ones have 6 internal coils for the servo motor, mid grade have 9 internal coils and the better ones have 12 internal coils typical wattage ratings of 1/2 hp to 1 hp. The more internal coils the better. Brushed servo motors are simpler to repair with no computer controls, longer lasting with typical wattage ratings of 1/2 hp to 1 hp so less frustration. kgg

-

Carefully and with two people. The strongest one on the heavy end. I would suggest making another table and avoid swapping them back and forth??? kgg

-

I'm glad the you got it freed up. As far as I'm concerned there's nothing better then good old fashion Diesel. It works better then any of the "penetrating oils" just smells a bit. I would now flush/soak the area with synthetic transmission fluid. That will soak in and flush out the old garbage while lubing. Sorry, can't help with the amount of movement you should have. kgg

-

Thank you. Looks uncomfortable but I have never worn one that way, always worn one on the outside. kgg