Silverd

Members-

Posts

489 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Silverd

-

Overwhelmed by leather Sewing machines

Silverd replied to Starwind0's topic in Leather Sewing Machines

Starwind0 At some point if you are interested in advancing your level of participation in leather craft you need to commit to something and take action. These machines are not that costly and can be re-sold if you find it to be not exactly what you want. Certainly you and your efforts are worth the investment. In addition; no matter what machine you buy, you will go through a learning curve that will give you valuable insight that can only be gotten by experience in front of a machine. I like the idea of bringing an antique on-line but if you are more interested in actually making things than you are in fixing things, an entry level new or near new machine is the direction I would recommend based on my past two years of starting from nothing and doing it both ways. Best of luck! Silverd -

Overwhelmed by leather Sewing machines

Silverd replied to Starwind0's topic in Leather Sewing Machines

You may not be too impressed with Tech sew customer service practice and attitude. But if you don't require customer service then yes, certainly they have Canadian branded machines for sale. Best of luck to you. Silverd -

Overwhelmed by leather Sewing machines

Silverd replied to Starwind0's topic in Leather Sewing Machines

My fault entirely I'm afraid. My apologies. Silverd -

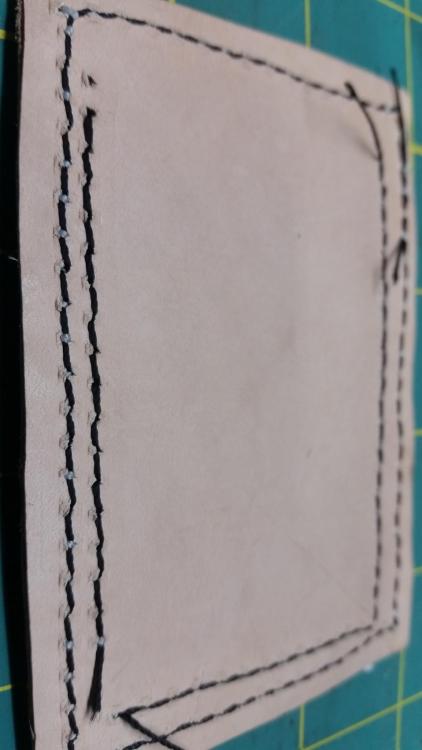

Have spent now several hours attempting to tune this machine into sewing like I expected, and all things considered i have likely gotten it to stitch as well as it is going to but didn't know it. The photo is of the backside stiches from my Chinese 441 thick white thread and this machine. Is this normal for the jukie? If so, I've made a mistake. Silverd

-

My equestrian stitching experience pushes me toward tight stitching. I understand the principle of lock stitch but have no experience on this machine. It's more difficult to tune a machine when you don't know what ito should be doing! I appreciate your attention to this matter. It's been very helpful. Silverd

-

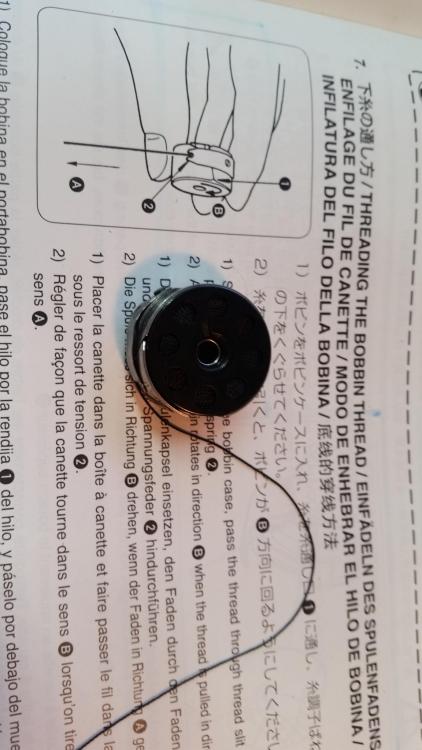

Kgg. Thank you so much for this latest info. Wow. I'm blown away that you took the time to help me. You mentioned in a previous note to make sure bobbin is loaded correctly in bobbin case. Oops! It was not according to the Juki manual and I have since corrected that. I'll re-thread the machine per your latest recommendation and go from there. Obviously the bobbin direction being wrong was the primary cause of my issues but thread tension is also contributing.

-

I'll adjust the top thread tensioner per your suggestion (rotate to 2 O-clock) Bobbin: Counter clock wise rotation of bobbin is how its set-up I have bobbin tension set way high. Will reduce accordingly to your suggestion I only have the needles that came with the machine at this point. They are the correct size 135 X 18, 20, 22, 23 etc but are mostly the 17 series needles for fabric. I have an order in for 16 type needles in all compatible sizes coming. The needle used to sew the sample in my photo is a 16 series. I'll post more photos per your request later today

-

Great story Wizcrafts... I made the purchase of a DNU-1541S with servo & table yesterday. Drove 3 hours both ways to the owners home. Have to say I'm not super happy with the deal that went down. The problem with investing travel time in used equipment is that it suggests you are committed to bringing it home and reduces your ability to negotiate. This machine did not sew when I arrived. I brought thread and sample leather to evaluate it with. Spent 2 hours attempting to get it to make a stitch. Its a newer machine and should work pretty well without a lot of fanfare but that was not to be. Finally got it working and did bring it home but it was a painful experience. Spent the evening cleaning and lubricating. Top tension wire spring and pulley needed fixing, there was no tension release rod for some reason so I made one out of a modified 441 # 27 needle and generally got it work better but it lays down an ugly back side stitch with 138 thread and # 23 needle. Achieving sufficient top tension is challenging. Event after wrapping the thread around and around the guides (as shown in the manual) plus a few more turns and a highly tightened tensioner but still not enough. #T90 thread is in there now and seems like a better fit but I'm still working out the tension details...Really ugly bottom stitch so some further adjusting to be done or is this just how these machines are? Silverd

-

KGG: Very helpful review. Thank you. Most significant relevance to my application regarding the differences may be bobbin size. I understand from reading marketing information that one machine will pick-up the lower thread without removing the work piece should the bobbin run dry midstream... If the 1541S accomplishes this feat it would be a nice alternative to the larger bobbin offered on the 1508. Another nice feature of both these (light version) machines are their 441 compatible needle systems. This simplifies life in my shop to a degree since I own a 441. And lastly my application need is to so sew wallets / hand bags etc and as such either would appear to work. Another short string of questions I have on same topic is with respect to the previous Juki model LU-563. What is the current production equivalent? How does the bobbin size of the 563 compare with the 1541S and 1508? There is not an advantage the 563 has over one of the current production models is there? From a product / manufacture / good business view it would not make sense to redesign a complete new family of products with actual lesser capability or reliability. Yet a well used 563 sells for about the same as a slightly used 1541S. Silverd

-

Nice! Is it a DNU- 1541S. OR 1541? Servo motor?

-

Hi Still available? Silverd

-

Up-Date on this topic: Received all the necessary supplies: Stirrup Butt 1/2 hide Stainless Steel Stirrup buckles Polyester / Cotton Core Spun 18/5 thread Many thanks to all who helped Photos to follow. Silverd

- 14 replies

-

- english saddle

- stirrup leathers

-

(and 2 more)

Tagged with:

-

When can you call yourself a craftsman?

Silverd replied to Handstitched's topic in Leatherwork Conversation

I'm dully impressed with the finish you have obtained and would encourage you to continue as well as exploring other venues that expose your work to more appreciative customers who are looking for and willing to pay for top quality products. Silverd -

Still available? Silverd

-

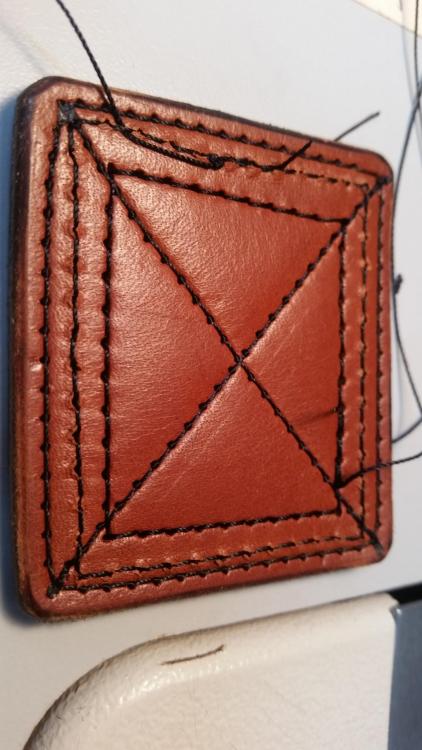

Hi I got up one morning a couple years ago and told my wife..."Honey, I think I'm going to learn to play the Violin". Well that's how I feel trying to learn the leather trade these past two years. It's not an easy assignment and I'm a good student candidate having 40 years experience working in mechanical engineering, product design and manufacturing. Plus i have some OCD going! I'm preparing myself for retirement in a couple of years and dove in pretty deep investing thousands of $ in equipment, tools and shop infrastructure as well as spending all of my free time learning and turning big hides into small pieces most of which I think end up in my scrap box or the trash. But it's been a wonderful journey so far and I'm getting a few customers finally who I haven't completely disappointed! All of it i must say would not be even remotely possible without the help of a leatherworker.net member Sharon of Big Sioux Saddlery who I met on this site. She is the only reason I'm still at it. As a mentor she has the strictest of professional expectations and though thousand miles away has been pretty effective at sharing her 35 + years of experience in the equestrian community. I am blessed to have her looking after me as I fumble my way along. Thank you Big Sioux! Silverd

- 14 replies

-

- by chuck reed

- april

-

(and 2 more)

Tagged with: