klutes

Members-

Posts

156 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by klutes

-

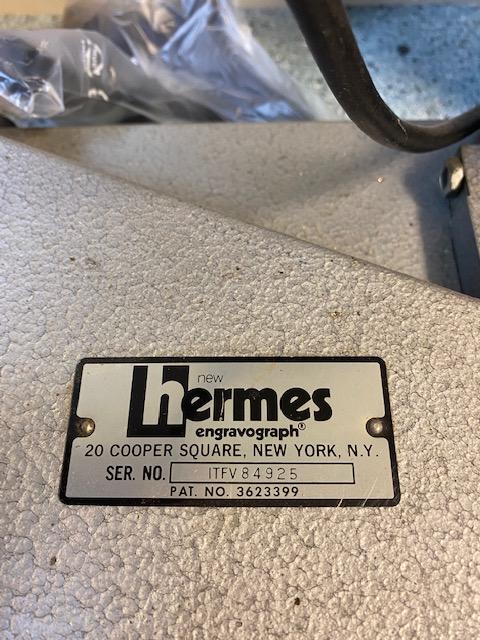

New Hermes engravograph electric engraving machine. Perfect for brass tags for belts and dog collars. This one currently set up two lines of script for 3/4 wide brass tags. Can be set up for single line very easily. This is the one that has a adjustment setting for depth of cut. A really nice feature. I good condition. Pretty heavy for shipping prefer local pickup. Comes with two set of fonts. $475.00 central Ky

-

- belt tags harness tags

- engravers

-

(and 1 more)

Tagged with:

-

Does anyone know where to purchase this belt clip. It is on a phone case and swivels 360 degrees while on the belt. Appears to protrude Thur a hole and is riveted in place with two rivets. Poly

-

For the belt makers that make the belts with brass name tags. I am curious how many people use raw brass tags vs brass tags with a lacquer finish on them. I am have always used the lacquered finished tags. But given some thought to switching. Just curious what the ratio is.

-

Would love to see your work. Welcome aboard

-

Pulling my hair out over tension issues with Consew 206rb

klutes replied to Lokahi's topic in Leather Sewing Machines

Don’t give up on it. They are really good machines. I have and use two of them. One set up with 135 and one with 69. -

Are you glueing two pieces up letting it dry them soaking in water to wet form mold???

-

Wow Shows everyone’s sniffer is different. I find that tragacanth and neatsfoot oil has very little odor. Sorry for you having such issues. Must me rough having that condition.

-

I received the Consew 18 today by fedex. I will have to say I am surprised how great the condition is. Apparently it has been used very very little. I have not found any wear at all. I am going to set it up with a servo motor. Should I set it up with a speed reducer. I am planning on setting it up with small needle and thread for sewing billfolds. Also can someone explain why the machine I set up with dual feed adjustment. One for the bottom feed and one for the top feed. Why would you want these to ever be different. Am I missing something or is this just a way to adjust both feeds to be in sync?? I have heard parts can be sorta hard to fine for this machine. Is there anywhere you can find them in case I ever needed something.

-

Thanks for the information. I am anxiously waiting on it to arrive. Just got it to play with and maybe do really light stuff with small needle and thread. Will it handle 92 thread

-

I have heard this but not sure.

-

Thanks for the info and the link

-

Anyone familiar with the Consew 18 sewing machine. Any info it’s capabilities you could share on it would be appreciated. Thanks

-

Does anyone know where to get heavy duty hook plates for mechanics belts. Need something heavier than what Springfield sells. They are just stamped out of sheet metal. Or do you have any good ideals on how to make one. I have made a couple but always looking for something better

-

Good deal. I personally prefer the wooden forms over the other way. Just me I guess. It’s an almost forgotten way.

-

Email me if you need to

-

Two layers of veg tan around 8 oz each First thing first a form

-

I have used a lot of Weavers English bridle and still like it. But recently switched to WC. WC will take on water for casing the leather better than weavers. I case it for embossing. Plus I typically buy already stained and finished . Part of the reason why one takes on water more than the other. Due to the finishing process I assume. I get sharper embossing imprints on the WC. and no trade secrets for me.

-

Look at the picture posted above. The one with the leather pulled over the wooden stump. That is the first step. Only you have to pull and work the leather down more than he has shown there. Other words about twice as many tack as he shows there. A lot of pulling and working out the wrinkles and water. You will not eliminate all of them. Let it dry for about 24 hours. Now repeat the process with second layer of leather. Flesh to flesh lots of glue. It’s a lot of work to get it worked down. Let it dry for 30-36 hours. Cut and remove. That in its self is a lot of work. Probably close to 200 tacks to remove. Lot of poked holes in the fingers. Finish the top edge as you normally would a piece of leather. Also I always dye to color first. No real apparent reason just the way I do it. It took me a while to get everything figured out. One more thing I forgot to mention. When you finally take it off the form. It is still damp inside the leather. It will feel pliable. Other word set aside for a couple of days and it will finish curing out and get a lot more firmer.

-

Afraid that I have never took pictures of the process to show.

-

-

English bridle