HandyDave

Members-

Posts

200 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by HandyDave

-

To sand the edges or not to sand

HandyDave replied to ThisIsMyFirstRodeo's topic in Leatherwork Conversation

Single edges get sanded to smooth up from cutting out with knife. Layered edges get sanded to level everything out for a better finish. With layered pieces I want the edges to look like one piece or as close as possible. As for grits. I keep a 80 grit on my bench top belt sander it helps to even things up on alot of the thick welted projects I do. And I keep a 120 on the disc. Then any beveling that needs doing and a final once over with 220 by hand. I actually like to very lighty damp the edges before the 220. This I what works for me. -

Here in NC we don't get as cold as Colorado but winter gets cold enough to freeze some of my leather stuff if left in my shop during winter. The alcohol based dyes ain't really a problem but alot of the stuff like paints and finishes and oils and glues I have had problems with. I thought about taking one of my cabinets in shop and insulating it with foam board or something. But what I end up doing was buying me a dedicated tote. I got one of those stackable rolling tool boxes but a cheaper one. It holds all my supplies and keeps them somewhat organized. And it makes it easy enough to just bring in the house with me and roll it out to my shop when I'm working and shop is heated up. I was gonna use a old rolling suitcase that I have laying around and make some dividers for it but found a good deal on the webs for the box I got.

-

Get edges sanded nice and smooth. Then I use a bit of water just to lightly dampen the edges getting burnished. And wood burnisher. Then I rub edge with beeswax and hit it lightly with blowdryer to kinda melt the wax just a bit before burnishing again with a separate wooden burnisher cause I don't want wax build up on my primary burnisher. I hate edge paint. That's not burnishing or finishing a edge that's just covering it up. I've tryed tokenol and a couple other "finishes" but didn't find them to be worth the extra cost over my regular method.

-

Dye woes

HandyDave replied to Yellowhousejake's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Leather is natural material. And even really good leather has differences throughout the hide. Sometimes with lighter colors then pure black your just gonna have uneven areas. You'll save yourself alot of headache if you learn to just let it ride. The variation in finish is just part of it. Even when you buy pre dyed veg tan you can see lighter and darker areas. -

That weldwood contact cement is pretty much all I use. Even a couple odd projects that didn't get sewn after gluing it holds. The trick like alot of other glues is the set time before sticking pieces together. Spread it on both pieces that's going together and let it set for 20 minutes or so till it doesn't even really feel tacky anymore. Then you want be able to pull 2 pieces apart without damage. I buy it by the gallon from lowes or home depot home improvement stores. It's cheaper in store then most places online.

-

I use 4/5 oz for my outsides. 8 will make a thick wallet like has been said. Just got to be easy with carving tooling so you don't blow right through. I use 2/3oz veg tan for my inside pockets.

-

Easiest way to make a bandolier for across the shoulder is cut straight strap the width you need it. Overlap the ends but at a 90 degree to each other. By doing this it creates a curve. The overlapped ends hang at the bottom.

-

I use regular hdpe cutting boards. I sand them with straight or orbital palm sanders with 220ish grit paper. It doesn't melt and clog but makes a super fine dust that sticks to everything if not using dust collection. Definitely wear a mask. Running plastic through a wood planer machine would be terrible on the blades of machine. I have a couple different boards I use. Some for just cutting and some for just punching. Then after sanding them several times and they are just wore out. I grab a couple more cheap ones from the store when I go to town.

-

Keep in mind you may need to cut strip a little wider then 5 inches depending on thickness of leather. Cause when folded you'll lose just a bit of width.

-

This is a good tip. I also keep my modeling spoon handy for same purpose. Just to smooth out any little bumps. As for the op and his carving journey it's already been said but practice practice practice. You'll find that the beveler will want to naturally ride your cut lines. And with time you'll find that sweet spot between speed and consistency.

-

Total noob w/ bullet loop question…

HandyDave replied to Ravenshurst's topic in Gun Holsters, Rifle Slings and Knife Sheathes

You can also add a thin strip below the ammo loops. And even if loops do loosen up a bit over the years they still want fall out from the bottom. You can also adjust where you put the stop strip to get the rounds to set a little higher in the loops making them easier to fetch. I also like to remove my dummy rounds when loops are allmost dry but not quite. Then they draw up a bit more without the ammo in place. Then work the rounds back in the loops once fully dry for a snug fit that's still usable. Here's a pic of a rig I done using the strip under the ammo loops like a stop. This method works good for straight cartridgeslike the 45acp -

Sheath for curved knife?

HandyDave replied to DaleksInc's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Just do a 2 piece sheath with a front and back panel and a welt running all the way around. And it can be whatever shape you need. -

One tip I'll lend for the welt on holsters like this and even knife sheathes. I notice you cut your template for the welt in the shape of the holster. When you have gentle curves like on your holster template you don't need to cut a welt to shape. You can use a straight piece cut to width. Glue it and you can curve the straight piece right along your edge without the extra work of making a special welt.

-

Also when using a 2 piece style mold for molding leather you just got to make sure you have a big enough piece of leather to mold deeper pieces.

-

I like to leave a bit extra meat on my edges where it can be. Then after sewing I can trim edge down and run it across my sander then start edge finish work. Makes getting the edges nice and smooth so much easier which we know for a good finished edge it needs to be good and smooth.

-

About all I use is hand tools and everything I make is hand sewn. The one machine that I do really enjoy having is a bench sander. With belt and disc. And if I could only choose one machine to keep it would be the sander. Before I got it I would cut everything flush as I could with razor then hand sand which worked but boy is it nice to just run the edge of holster or belt or whatever over the bench sander then go back to hand finishing and slicking.

-

painting leather Leather prep before acrylic paint application

HandyDave replied to FrankHester's topic in How Do I Do That?

I use 50/50 resolene or leather sheen thinned down just slightly. Those are the main 2 top coats I use for everything. I've tryed a few other types and brands but those 2 are what I've found to work the best for me. -

painting leather Leather prep before acrylic paint application

HandyDave replied to FrankHester's topic in How Do I Do That?

I do alot of painted details using acrylic paints I get at the hobby store. If you don't allow the paint to cure good it can streak or lift a bit when applying finish of choice. I usually let my painted pieces set for couple days before adding 50/50 resolene or other top coats. Black and white seem to be the most likely to have any issues in my experience. If black paint is used on a light or natural color leather and you don't let it cure good I've had it streak lightly as I've done top coat. If it I cured good then no problems. And I've had plain white kinda yellow after adding topcoat. My fix I've found for this yellowing is I add just a drop or 2 of a super light beige/tan paint to my palette and mix it into the white. It doesn't change the color enough so it's not white anymore but something about adding that slight bit of different pigment and I don't get no yellowing after doing top coat. -

I'm sure you know but there is also grades of leather at most suppliers. So for something that doesn't need to be show ready but still plenty tough and durable go with a lesser grade of leather which usually will save you substantially. Sometimes a grade C can be half the cost of grade A. Nice piece of more rustic looking hide with some branding marks and bug bites and such imo looks better on a real working tool then a shiney spotless hide anyway.

-

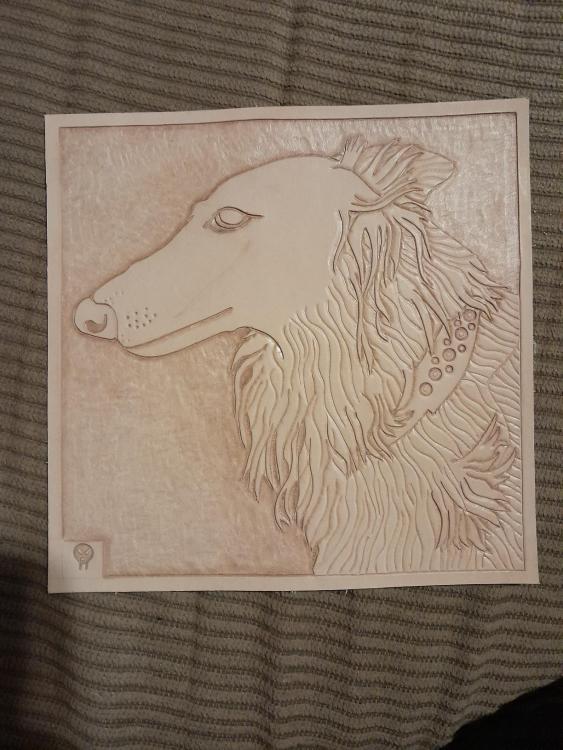

I've done several animals including birds and reptiles and fish. But haven't done a dog until now. I was asked if I could do a memorial piece for a guys Russian wolfhound. He sent me a few pics and I chose one I thought would translate good on leather. I told the guy I hadn't done a dog yet but was up for the challenge. I would also like some feedback from this group on your thoughts.

-

Pieces look pretty good specially for just starting. If your planning on doing alot of key fobs and such smaller items I would suggest looking into some cutting dies. Key fob dies and similar small item dies aren't alot of money and will guarantee you a pile of pieces that are all cut perfectly the same. It is hard to get consistent shapes when cutting stuff like this by hand.

-

"Grade A" HO 8/9 from Springfield looks terrible

HandyDave replied to palehorse's topic in Leatherwork Conversation

A place I have used many times online that doesn't get brought up very often is Frogjelly Leather. They are near fort worth and I think they have a store front. Might be worth checking out -

Another vote for leatherstampmaker.com I've had several custom stamps for a few different companies I do regular work for made by them. I've been very happy with there stamps and my customers was over the top happy. And like said above you can get there heating iron for using stamps for branding purposes.