-

Posts

212 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Tequila

-

You’re right the 10 year cost is reasonable, I just don’t know if I’ve got 10 years left in me.

-

Springfield Leather has 2” oblong punches in stock

-

Rifle Buttstock Cover

Tequila replied to Tequila's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I figured -

Rifle Buttstock Cover

Tequila replied to Tequila's topic in Gun Holsters, Rifle Slings and Knife Sheathes

@chuck123wapati no shady deal, he did a huge favor for me, he went 2 hours out of his way to save me 12 hours of driving and I felt I owed him a special thank you. -

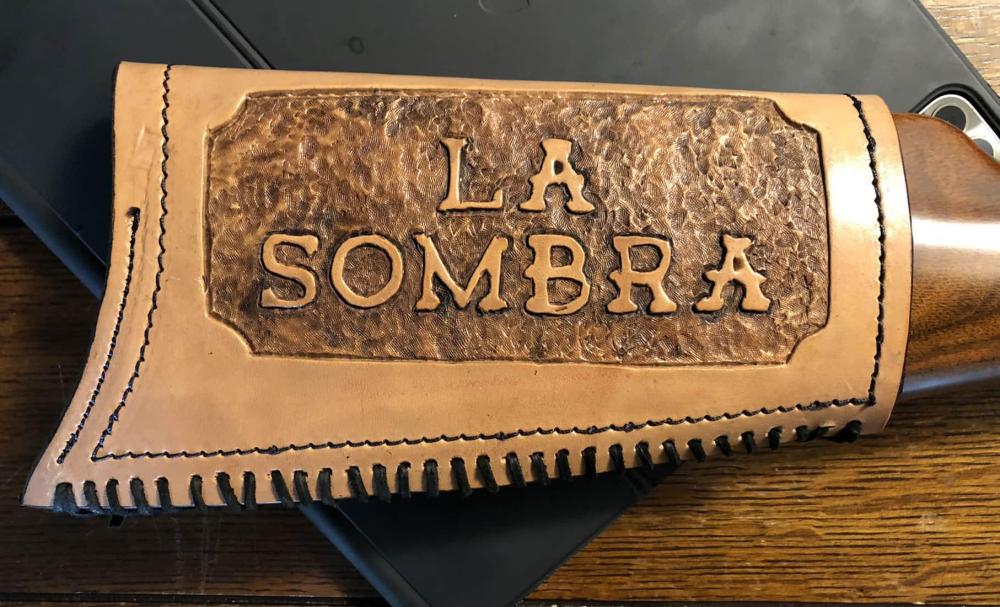

Made this for a friend, “La Sombra” is his SASS alias. Made from 7-8oz HO, I carved his name then backgrounded around it. The leather was left natural, applied a couple of coats of acrylic sealer, then antiqued around his name, finished it off with a coat of leather balm. The cover is lined with black pigskin suede which wraps around the back and under the lacing. And thanks to @bruce johnson for the tips on wet molding the suede it worked beautifully.

-

@PastorBob I like it, just wish it wasn’t so expensive

-

I’ve been using a cheap cutting board (HPDE?) that I got from one of the dollar stores. When I use my round knife with it the blade drags and cuts into the surface. My search on this site for a better alternative got me more confused with all the choices, everything from MDF board to green cutting mat to HPDE board, etc. etc. So, I thought I’d just ask, what cutting surface do you use with a round knife?

-

My latest cross body bag/purse.

Tequila replied to toxo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

If you didn’t say what the difference was I would have never guessed. One day I may screw up the nerve to try to make a bag. I’m with you Bert!! -

I found that thinking of it like shoe polish helped me get my head around how to do it. The longer you let the antique sit the drier it will get, it won’t make it any darker since the Tan Kote is acting like a resist, so I usually let it sit 20-30 minutes before wiping off. When you do wipe it off it’s going to look cloudy (muddy as DG calls it in the video), but once you reapply the Tan Kote it’ll look much better. I would go darker, the antique is meant to enhance the cuts, if it’s the same color as the leather you won’t see it. For fun try some neutral antique mixed with paint, you’ll have to play with it to get the color the way you want and the drying time is a lot longer, but you can get some nice effects.

-

My latest cross body bag/purse.

Tequila replied to toxo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

@toxo as long as you like it and more importantly the person getting likes it, well then that’s all that counts. Personally I think it looks good, and I’d love to hear how you did the dye work. -

Dipping my toe into sewing; Advice requested

Tequila replied to Sam83's topic in Leather Sewing Machines

Remember you can always turn a cylinder arm to a flatbed, most have a flatbed add on. Here’s a place in England that sells Typical Machines and exports them JB Sewing Looking at what they offer I’d be looking at either the TW3-P335 or if you can afford it the TW3-441 which looks to be a Juki 441 knock-off, and here’s one on Alibaba: 441- 45 replies

-

- sewing machine

- newbie

-

(and 1 more)

Tagged with:

-

Ok, Ok, I’m officially jealous now.

-

This should help, DG does great work

-

Dipping my toe into sewing; Advice requested

Tequila replied to Sam83's topic in Leather Sewing Machines

@Sam83 I wanted to chime in with a couple of thoughts. I started with a Janome 3000HD and while it will technically sew leather it was a royal pain in the posterior, then I moved on to a Cobra 26, put the Janome away and haven’t taken it out since. Remember that machines like Cobra, TechSew and Cowboy, etc. are Juki knock-offs, doesn’t mean that they’re not as good or any better, so when you compare one to another it may come down to availability or warranty, etc. as to which you decide on. Back to a couple of things to know, threading the Janome was a nightmare compared to my Cobra, same with bobbin winding. The Janome had a lot of stitch options that I never used, the Cobra has one stitch that is fine for 99.99% of leather projects. With the Janome I found it very hard to control the speed and the thicker the leather the faster you had to go or else the machine didn’t have enough oooomph to get through it. My Cobra (and most others) have a servo motor which means that you can slow it all the way down and it doesn’t effect how thick the leather is that you’re trying to sew and it runs quiet. And as @Wizcrafts said you may need 2 machines one for linings and one for leather. Being in Dubai I would’ve thought finding an importer would not have been too big of an issue, but I’m pretty sure you’ll have to pay a good bit for shipping since the leather machines ship on a pallet. Another thought would be to get the head, motor and stuff without a table, that would mean that it could be shipped in individual boxes which could cut down on shipping. Keep us in the loop on what you decide.- 45 replies

-

- sewing machine

- newbie

-

(and 1 more)

Tagged with:

-

I think I’d try taking the belt off and try turning the wheel by hand and make sure that it’s the belt. If you do find that the belt is the problem call TechSew they should be able to set you up with a better fitting belt. Now that’s funny! Gotta love a woman with a sense of humor

-

Hello from Southwestern, PA. IronDrake Studios

Tequila replied to IronDrakeMacGowan's topic in Member Gallery

Wow, sounds like you got a lot of cool toys! Welcome, and don’t be afraid to ask questions there’s a lot of very talented leather craftsmen/women on the forum who are always willing to help someone out. -

@bladegrinder congrats on your new machine. I think you dun did good and you’ll wonder how you ever lived without it!

-

I think you need to post a video using it so we can all get jealous

-

Thanks guys, I’ll pass it along to my friend.

-

A friend bought this hole punch years ago, probably in northern Nevada. He said it has no name on it but it makes tiny holes through thin leather, he said almost as small as a needle hole. I’m never seen one like it, has any else seen one of these or does anyone know anything about it?

-

If you do decide to start a new piece and it was me I’d get a new piece of quality leather like HO or W/C. Keep us up to date on what you decide to do and how it goes.

-

A few duffles in custom SB Foot Leathers

Tequila replied to nstarleather's topic in Satchels, Luggage and Briefcases

Well you did one fine job with it, very nice looking- 14 replies

-

- duffle bag

- duffel

-

(and 1 more)

Tagged with:

-

A few duffles in custom SB Foot Leathers

Tequila replied to nstarleather's topic in Satchels, Luggage and Briefcases

Those are great looking bags! Did you come up with your own pattern or did you find one that’s available to others?- 14 replies

-

- duffle bag

- duffel

-

(and 1 more)

Tagged with:

-

A wee wallet

Tequila replied to GavinO's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

It looks first rate to me, nicely done.