-

Posts

483 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by BlackDragon

-

Fender repair...

BlackDragon replied to Brokenolmarine's topic in Saddle Identification, Restoration & Repair

Best way I've found to straighten leather when it comes in to the shop is to dampen it a little and letting it lay flat. You can cut it while it's slightly damp, the knife will go through it easier too. It's not going to hurt the leather just like when you case it for tooling. I like the tooling options 2, 5, and 7 and would be happy with which ever matched my saddle the closest. -

Looks great!

-

Fender repair...

BlackDragon replied to Brokenolmarine's topic in Saddle Identification, Restoration & Repair

One trick I learned about taking a picture of something I want to color match is to take the picture along side of a known color. I would take a colored object like red playing card and take a picture of the item next to the card. When you have the picture and the card in hand you know know the amount of difference between the two. -

Pigskin liners

BlackDragon replied to ThisIsMyFirstRodeo's topic in Exotics, Reptiles, Furs and others

That's one of the issues with gluing in an interior. The wrinkles will even happen with fabric. One way to combat this a little is to glue the liner into the shape of the bend. The issue you'll have with this is that it will be harder to open because the liner won't give when you try to straighten it out. So it's a bit of a balance you can try less of a bend and hope you strike a good balance so when you open it you don't see wrinkle and it's not fighting the user to keep it open. This just came into my shop for a little TLC on the piping and other leathers. Notice the stains and grime. Since I'm removing the piping the liner (cotton canvas) will be free and I may be able to clean it up a little but the ink probably won't come out -

Fender repair...

BlackDragon replied to Brokenolmarine's topic in Saddle Identification, Restoration & Repair

Great beginning! One thing that will make it a little easier for you on the next fender. To remove the rivets on the Blevins buckle I take a large slotted screwdriver and use it like a chisel. I put it in between the leather and buckle and give the rivet shaft a couple of hard wacks and it'll cut right through the rivet. -

Great craftsmanship! My hands were screaming at the thought of hand stitching all of that. lol You can find harness leather split to your liking from Wickett & Craig. I've been using their leather for a while and it's great quality.

-

Pigskin liners

BlackDragon replied to ThisIsMyFirstRodeo's topic in Exotics, Reptiles, Furs and others

I would shy away from lining a purse with animal skin unless it's a specialty purse or a purse that's just a fashion piece. Purses get really dirty on the inside because of makeup and just things that fall into it. Imagine not emptying your pockets for months/years at a time lol. Most purses I make are lined with a cotton material that's easier to clean. With that said I make fashion purses from time that I line with pig suede and it holds up well but it's pretty thin. You can use vegtan pig, lamb, goat as a lining but it'll be pretty thin, it's more expensive, it'll get dirty or stain easily, and it won't get clean. -

Great job! Color matching can be pretty difficult especially when you don't do it often. I went to art school in the early 90's and I still mess it up lol.

-

need help finding hardware

BlackDragon replied to stampingdelight's topic in Leatherwork Conversation

Do you have a photo of the whole item not just the concho? It may help locate the source. -

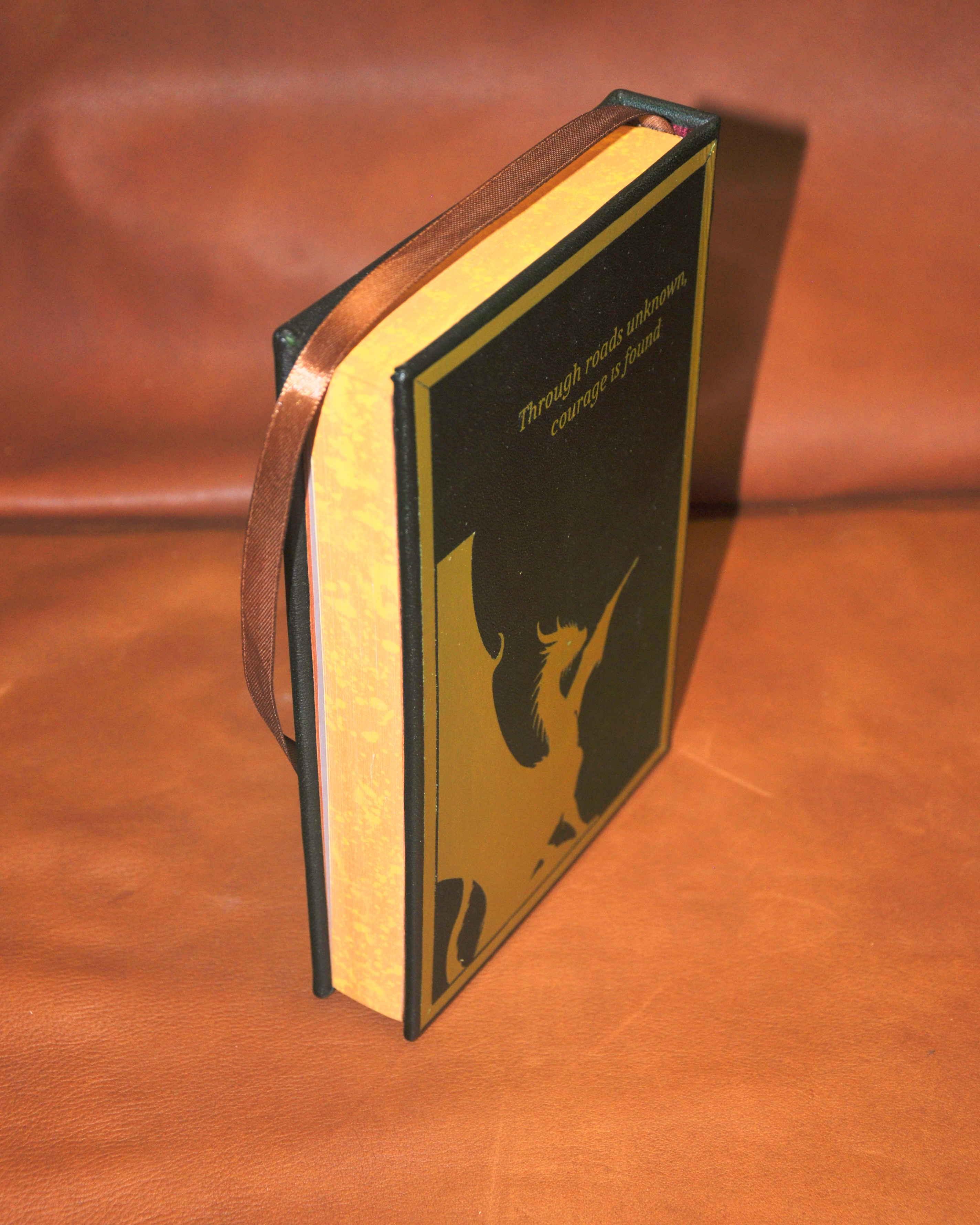

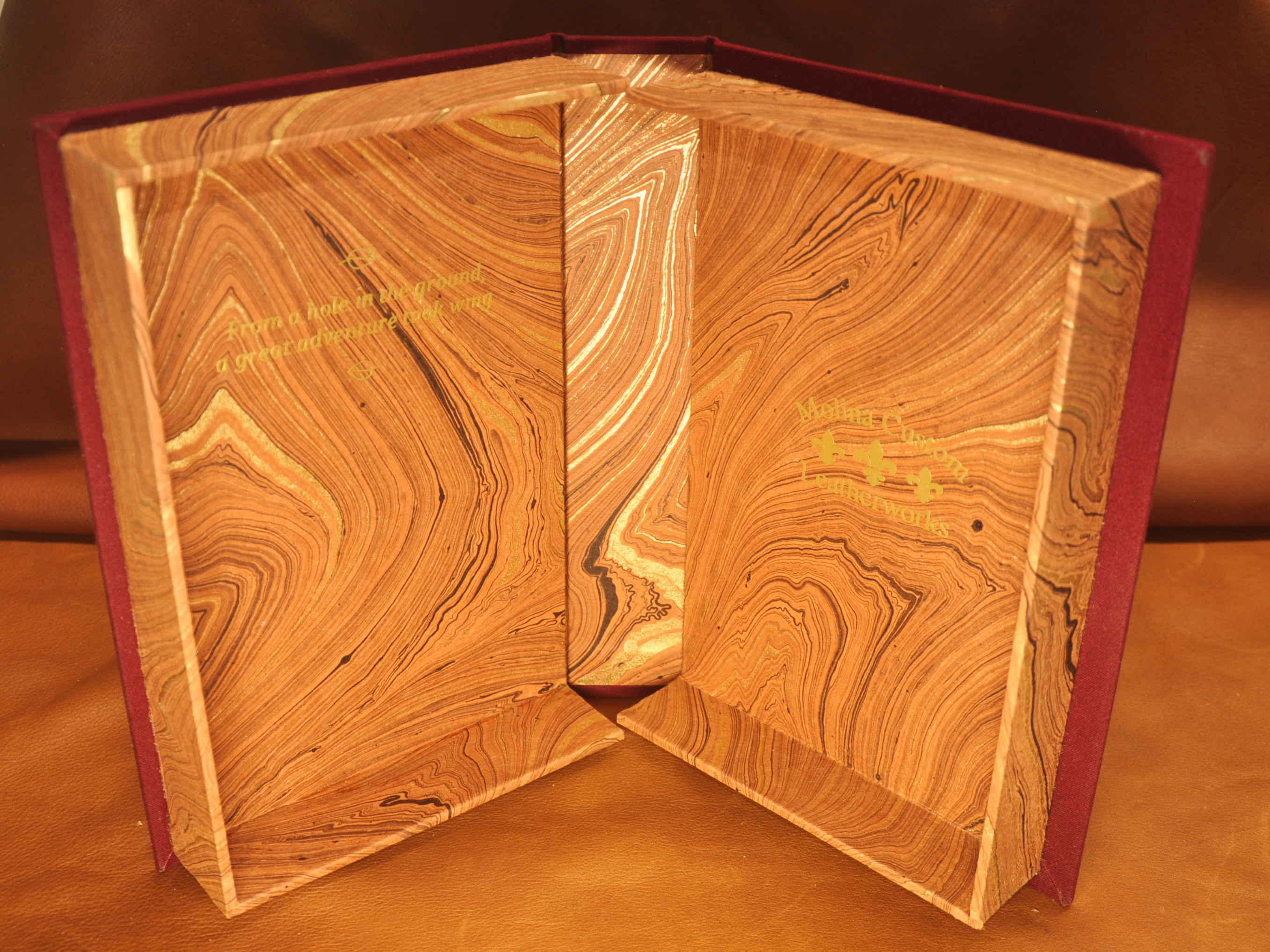

Thanks! I really appreciate the kind words. Next is the LOTR trilogy. The books will be in the same style but the box will be a bit different. It'll be a clamshell/slip cover hybrid so I have to invent it lol. I want to make it so the front opens like a pair of doors with the doors of Durin on the front.

-

Typically they used the Spanish mustangs but later on would trade horses. So they may of had a few different types, plus they would cross breed their mustangs. The Spanish mustangs has Barb and early Andalusian, think of a Spanish war horse. Today's American mustang has very little Spanish and a lot more European blood lines, it's closer to a Quarter horse.

-

Welcome back!

-

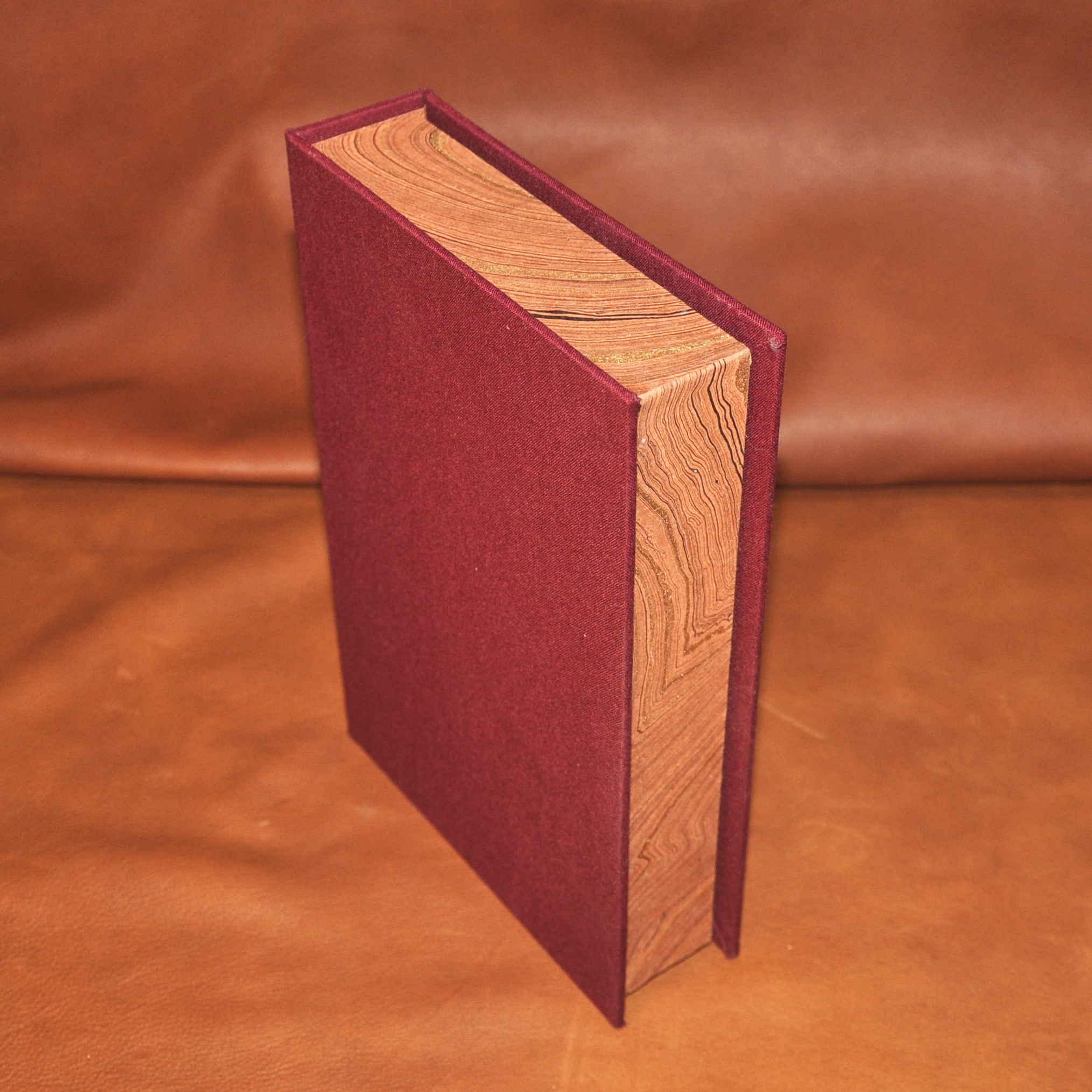

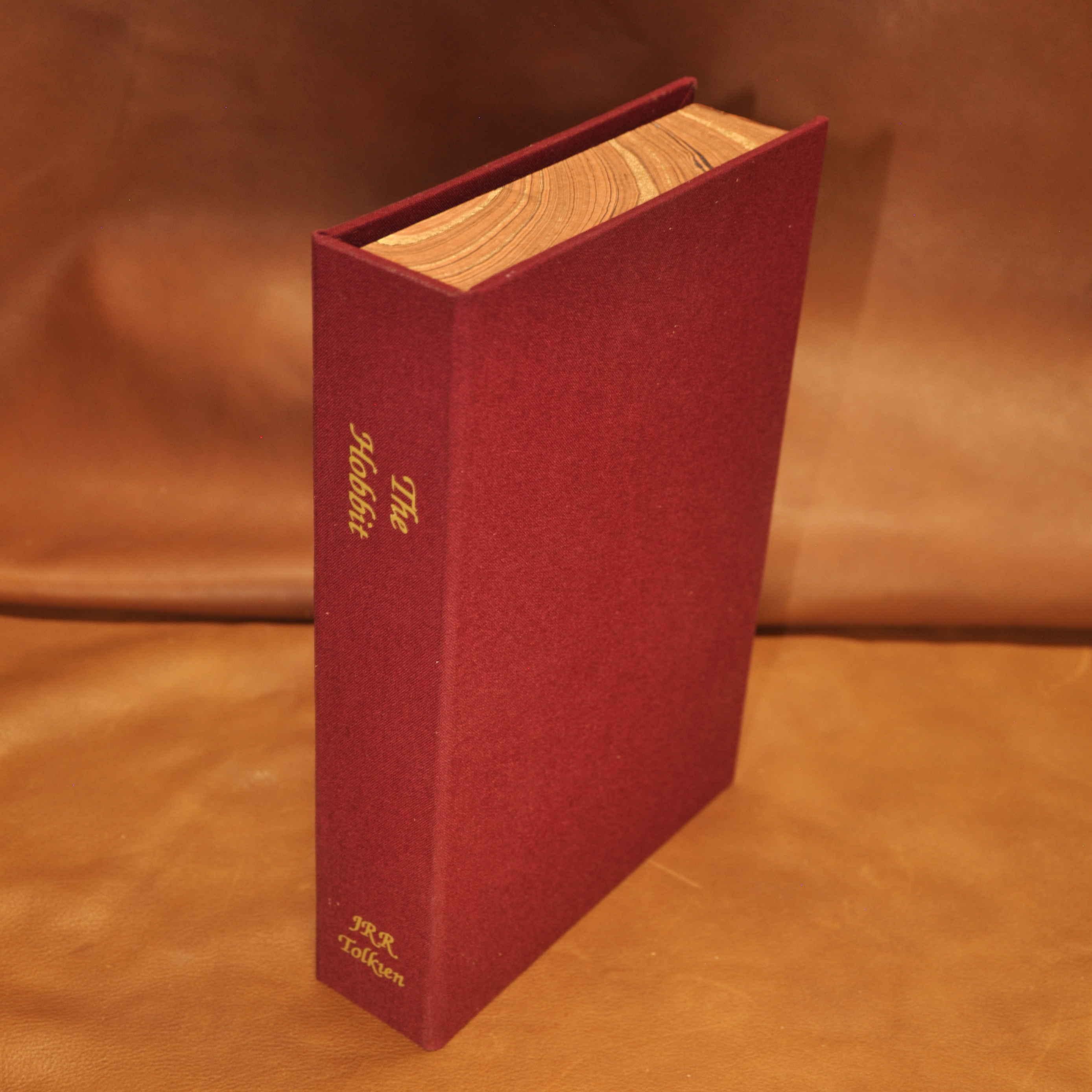

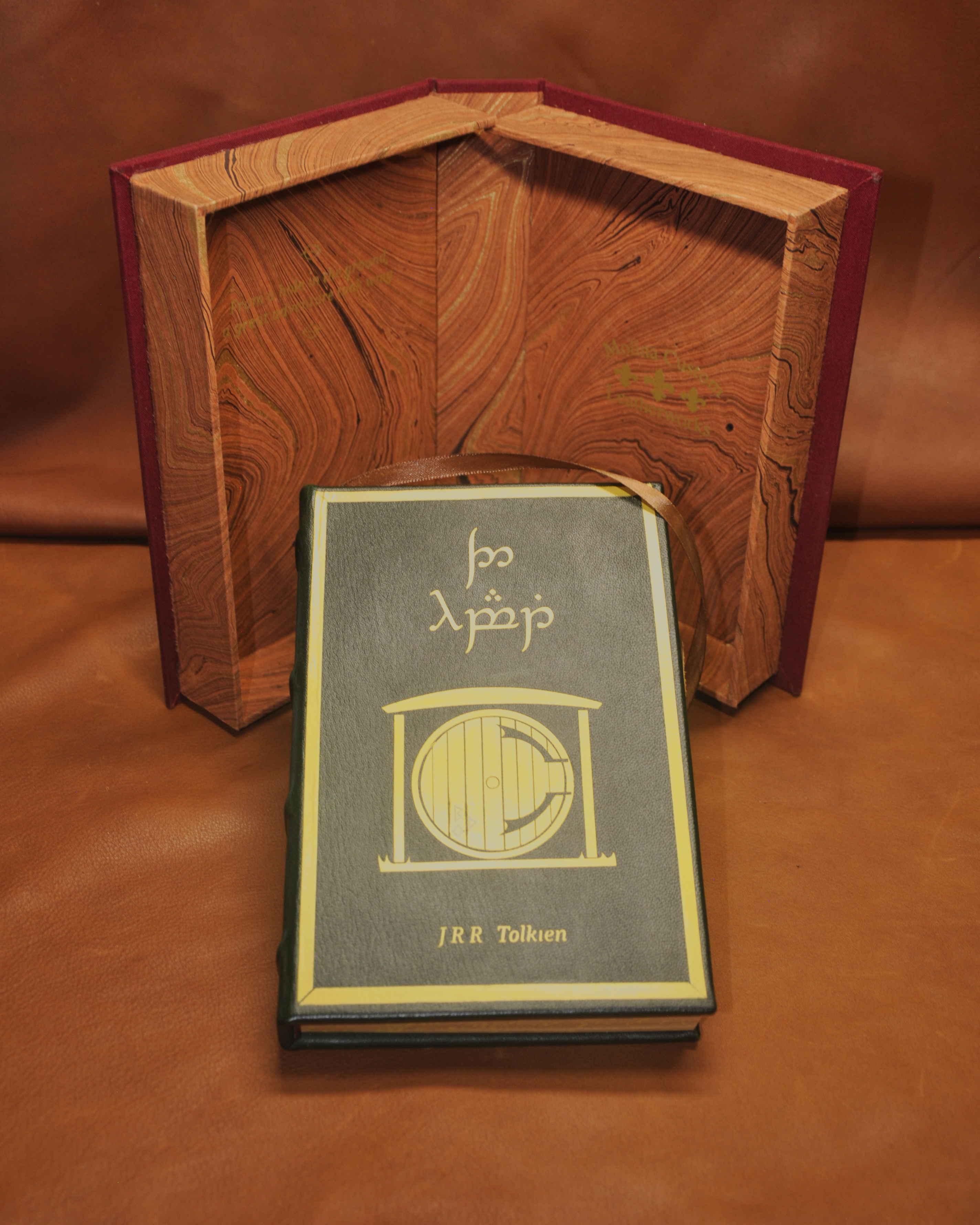

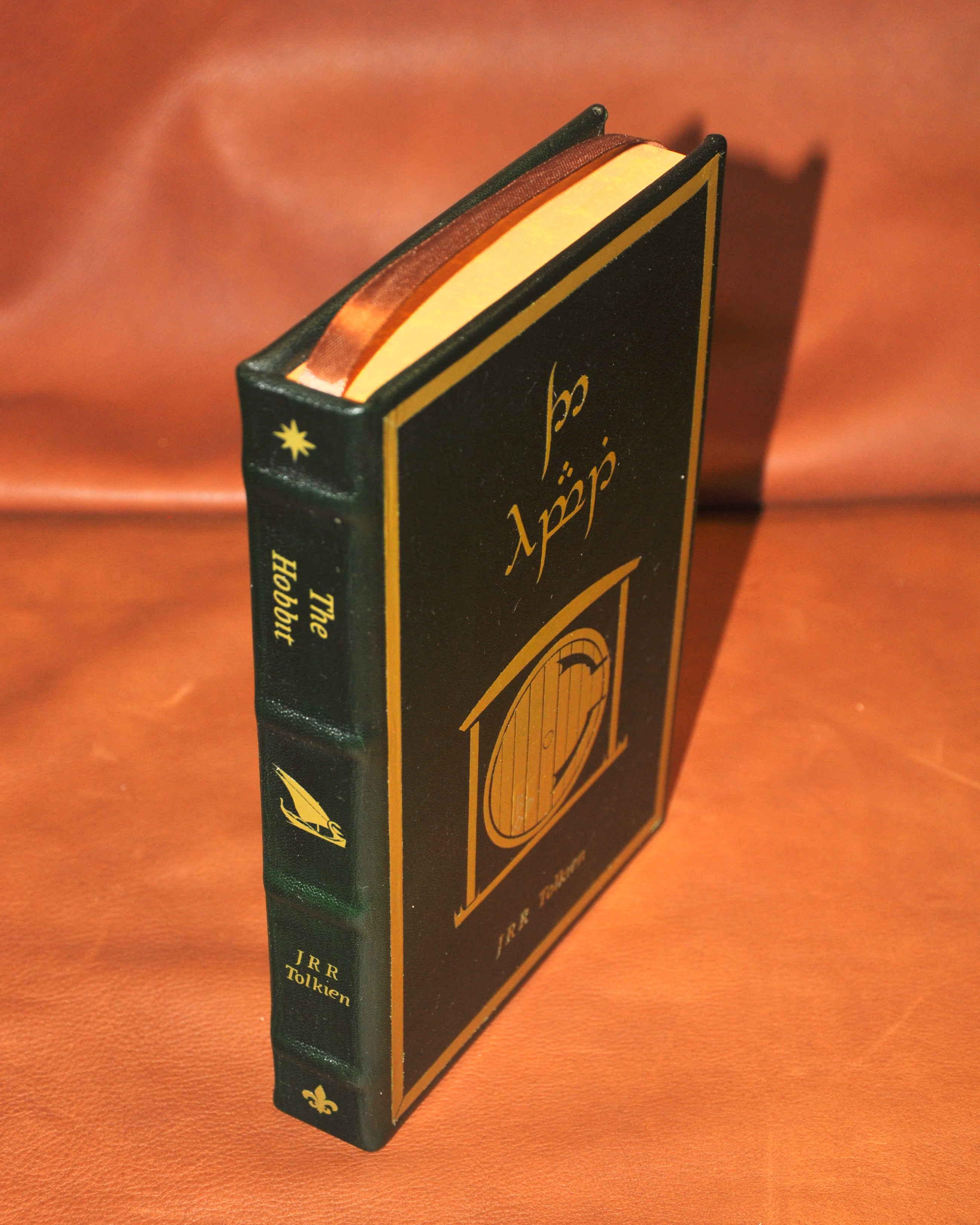

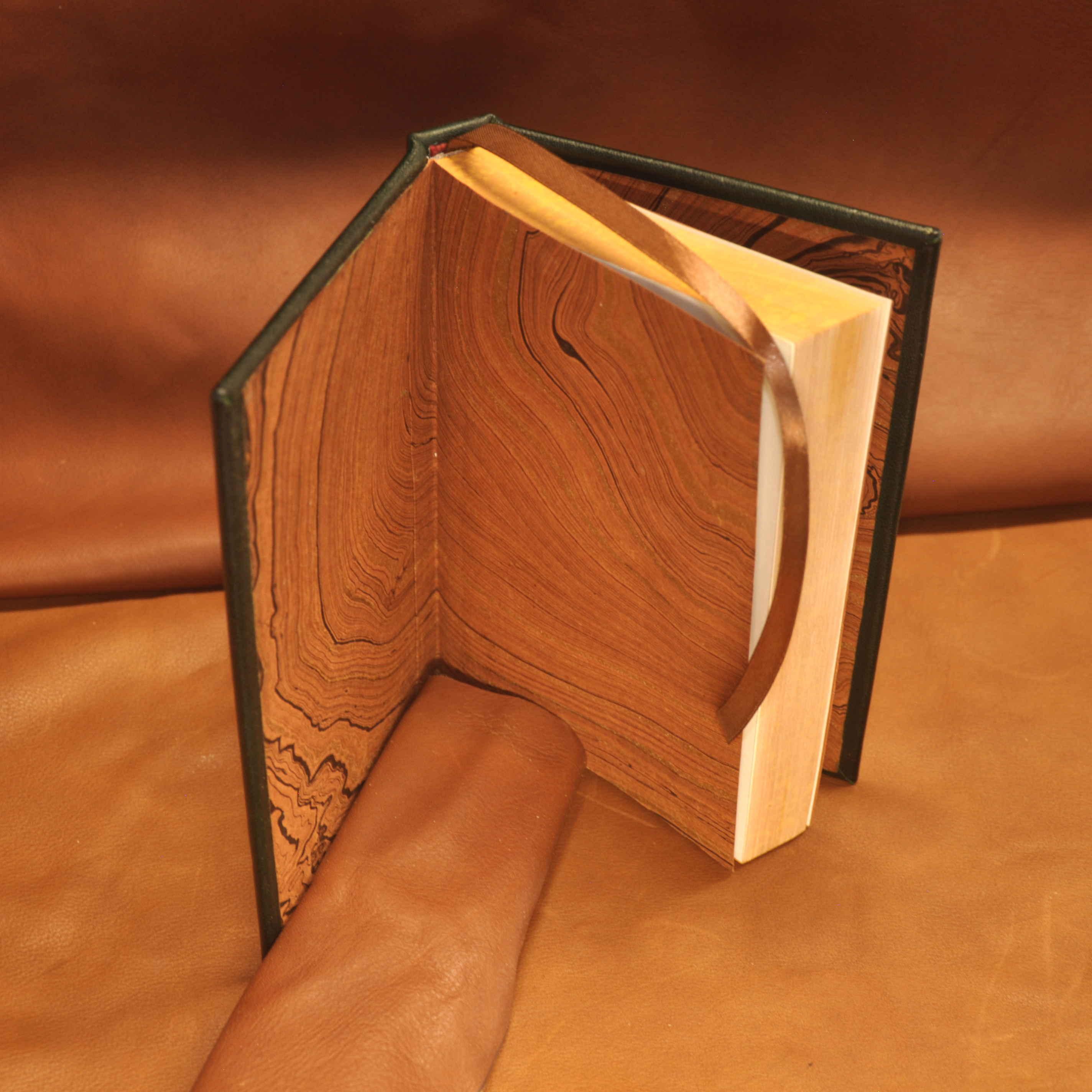

Got back in the shop after the holidays and finished up The Hobbit rebind. This one is going out to the same friend as The Silmarillion rebind I did here: https://leatherworker.net/forum/topic/132484-book-rebind/ This book has the same specs as the last but I added a gold border on the front and back, I think it ties the cover art pretty well. I used holographic htv for the "queer symbol" Gandalf put on Bilbo's door and Smaug's eye on the back cover, which are difficult to see in the pics. The end pages and the book ribbon are earth tones to represent the Hobbits love of growing things in the soil. The page edges are light brown with a dark yellow speckles.

-

I use Ballistol on my rifles and pistols, it's a great product, but I wouldn't use it directly on my holster. You may get some transfer from the weapon to the holster but I'm guessing it extremely minimal if you use it as intended. I use NFO on all my holsters and customer's holsters and never had an issue. Again you use it as intended and you shouldn't have a problem. I'm sad to say I did this to my first cowboy rig and I paid the price. I grit my teeth each time I look at my revolver.

-

Just be aware of how you restore/conserve the saddle. There is a difference in the two and you can ruin an antique saddle if not done correctly.

-

An image I found does show a possible stirrup. It's pretty basic, made out of wood and covered with leather, much like the saddle.

-

I put the saddle into Grok. The information from AI can be suspect but you'll have to do more research to determine if what Grok put out is reliable. This is Grok's result; Based on the photos you shared, this appears to be a Plains Indian woman's saddle from the 19th century, commonly referred to historically as a "squaw saddle" (though that term is now considered outdated and derogatory toward Native American women). A more accurate and respectful name is "prairie chicken snare saddle," named after the shape of the high pommel, which resembles snares used for catching prairie chickens. These saddles were used by tribes like the Blackfoot, Sioux (Lakota), Piegan, Nez Perce, and Crow in the Great Plains and Rocky Mountain regions. ### Key Features Matching Your Item - **Structure**: It's a frame saddle with wooden sidebars (bars) covered in rawhide or leather. The high pommel (front) and cantle (back) are typically made from bent elk or deer antler (softened in water and shaped), forming an arched, U-shaped loop with an open hole at the top. This design provided stability for riders and allowed for securing loads when used as a packsaddle. - **Decorations**: Yours has brass tacks or studs along the edges, which were a common embellishment on Native American gear from the period, often traded from Europeans. While basic versions were undecorated, variations included tacks, beads, or quillwork for aesthetic or status purposes. - **Stirrups and Straps**: The attached leather-covered wooden stirrups and rigging straps (for cinching to the horse) are typical. The overall worn, aged leather suggests heavy use and antiquity. - **Size and Use**: These were lightweight (around 20-25 inches long), all-purpose saddles for women, children, or older men. They doubled as riding saddles for long journeys and packsaddles for hauling buffalo meat, camp gear, or attaching to a travois (a drag sled). They were quick and inexpensive to make compared to pad or full wood saddles. These saddles became widespread in the mid- to late 1800s during the buffalo hunting era but fell out of common use after 1850-1870 as tribes adopted more Western-style saddles. Women in these cultures were often the saddle makers, using local materials like antler, cottonwood, and buffalo rawhide stuffed with grass or hair for padding. If this is authentic (which it looks to be from the craftsmanship and patina), it could have collectible value—similar examples from Crow or Blackfoot origins have sold at auction for $1,000-$5,000 or more, depending on condition and provenance. I'd recommend consulting a Native American artifacts expert or museum (like the Museum of the Plains Indian) for authentication, as reproductions exist. For visual comparison, here are some examples of similar saddles:

-

I thought it was for sheetmetal as well. Could be the cobbler adapted a metal shear to cut leather. Maybe someone gave it to him or he got it cheap and adapted.

-

Merry Christmas everyone!

-

I've been trying to find out about this machine but I'm not finding much. The words "Marca depositata" is Italian for "registered trademark" so it's likely this is Italian made. The possible machine name may be Lince which is Lynx in Italian and Spanish. On the label in front of the L the graphic seems to have a tail and you can see the 2 front legs leading to it being an animal. So (Lince) Lynx may be correct. More than likely, since you got it from a cobbler, it's a sole trimmer. Sort of like a 5in-1 but it's a guillotine cutter and it only does one thing

-

mountain man moccasins pattern #3 By Gene Noland

BlackDragon replied to chuck123wapati's topic in Patterns and Templates

Really cool! Just add some shearling on the inside and you have nice winter shoes. Just watch out for ice lol. -

It's hard to say really. Can the error be viewed by a potential customer as a scratch because of use? I wouldn't worry about it. I tend to focus on my mistakes and I don't like something that's glaring to me. Other's may not see it but I tend to catch it and it bugs me. If I want to show off a purse that I'm selling for $250 I don't want something obvious showing up. It's my name on the bag and the price tag warrants redoing a strap that will cost me $5 to replace.

-

When you say groove line are you meaning an indentation with something like a compass or an actual groover where you're taking off the top layer of the hide? If it's the first one I would do it as Bruce said. You may be able to undue the indent and it won't be noticeable. If it's the second I'd start over. I would keep that belt for myself or someone that doesn't mind a blemish but I wouldn't give that to a customer that's paying top dollar for a belt

-

Thanks! Generally when I mention The Silmarillion people don't know much about it, this is why it's in a separate clamshell. Everyone knows The Hobbit and Lord of the Rings so it makes sense to have those 4 books in one box. I like to joke The Silmarillion is for the Tolkien nerds lol. Thank you, I really appreciate it. After taking a few product pictures I find that it's missing something to make it more cohesive. On the back cover especially, everything just looks to be floating there. I think a border will bring more balance to it, like putting a picture frame on a photograph. Making the borders gold on all the covers will tie the books together while the other things, like end pages, being different will state that you're in a different part to the story.