-

Posts

493 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by BlackDragon

-

Don Gonzalez has a couple videos on breaking down a saddle and cleaning. He gets into a lot of detail and shows you the tools he uses, some he made himself. https://www.youtube.com/@DonGonzalesMaker/search?query=breaking down a saddle

-

If you want to remove the dirt and grime you can use warm water, saddle soap, and a sponge. Then wipe off the soap with warm water, let it dry thoroughly, then wipe some neatsfoot oil on all of it. If you add wax after the oil soaks in it will deepen the color and add a little protection. Leather, like your skin, needs to breathe to stay healthy so I don't recommend keeping it in a tote. If you do store it in a tote make sure it's completely dry because wet leather will mold. Most tack stays in a barn or tack room its entire life and as long as it's taken care of it can last decades. Your tack is 100 years old, it's seen heavy use and it's still around. If you're going to keep it on display in the house or tack room just wipe it down every year to remove dust and condition it.

-

The white looks like mineral deposits from sweat. The brown can be dirt or the leather is deteriorating. Since you're retiring the equipment you can wet it and lightly scrape the mineral deposits off. There is quite a bit of cracking, that cracking means the leather is failing and in pic #3 on the left side that degradation is pretty severe. I wouldn't get to deep into cleaning since it's only going to be for display. The deposits just attest to the life and use of the gear. I would just brush it off, wipe it down with a damp rag, let it dry, and add a little oil to preserve it.

-

It's hard to determine what the white is without pictures. It could be mold, sweat, dirt, wax, or some type of chemical. When washing down saddlery it's common for the dye to rub off. Leather becomes soft when wet and can be indented easily, let it dry completely before putting unnecessary pressure. First thing I do when a saddle comes to my shop is to brush as much of the dirt and grime I can. As I'm cleaning I start determining what needs to be replaced or repaired. I can do small repairs and replacement but if the saddle needs to be broken down I don't take on the job. Normally I remove the stirrups completely but these would not come out and if they were going to be this difficult removing they were going to be harder to get back in. I then start to wipe it down with warm water to get any mud off as well as softening any waxes. I then go at it with saddle soap, warm water, and a sponge or toothbrush. I wipe it down with warm water as I go so the soap doesn't dry on the saddle. Once I'm satisfied with how clean the saddle is I let it dry for at least a day. Then I oil it with neatsfoot oil and let the oils soak in for about a day. At this point I determine whether or not to add some dye if to much dye came off while washing it and let it dry. I then wax. I use Fiebing's Leather balm with atomic wax and get great results. Before After washing and letting it dry After

-

How to Lift a Sewing Machine Safely

BlackDragon replied to friquant's topic in Leather Sewing Machines

I see that you're using the same motor for the two machines. If you don't want to add another motor you can put another table so they are back to back and can share the same motor. You'll just have to switch the belt which you'll have to do anyway if you're switching out the heads. -

Show Me Your Stamp Organizer

BlackDragon replied to RidgebackCustoms's topic in Leatherwork Conversation

Originally I had it mounted horizantally on the right side of the bench but I kept hitting the mauls. I mounted it like this now and I like it much better. I'm going to remake it so the holes are at an angle so the mauls don't tip downward. -

Show Me Your Stamp Organizer

BlackDragon replied to RidgebackCustoms's topic in Leatherwork Conversation

There's no such thing lol. My shop is 16'x44' and I need more room. Sometimes I have several saddles needing minor work or deep cleaning. Other days I have an ATV or motorcycle needing either a bag or carb work done. -

Show Me Your Stamp Organizer

BlackDragon replied to RidgebackCustoms's topic in Leatherwork Conversation

-

The holster goes inside the waistband and the only thing sticking out will be the clips. The holster will hang on the waistband and the belt Like this:

-

Thanks! Thanks. I didn't even think about the keyboard I have. I just took it out of the drawer and it's a little to long to fit without the sides getting deformed. So, I'll just continue to use the laptops keyboard.

-

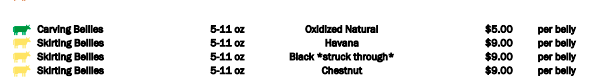

Not sure if you're selling just the bellies but I got an email from Wickett & Craig for bellies at $5-$9

-

Thanks, I really appreciate the compliments.

-

Thanks a lot I made a post about my knife.

-

I have a large laptop with a 17" Screen so I decided to make a bag to fit it. The bag 17"X 11.5"X 4" I used 10oz vegtan for the front and back panels as well as the shoulder strap, 5oz for the center divider. I played around a bit with the shoulder strap attachment points and came up with a different design than what I've seen before.

-

I've gotten orders online for knife sheaths and I don't have the knifes. There are a couple ways I go about it. One: I offer to make a general fit sheath. I'll get basic measurements of the knife then make a sheath that will fit the knife and there will probably be play in the sheath. You could use the sheath for different knives. Its like buying something off the rack in Large, Medium, or Small. Two: You can get the measurements from the knife manufacturer, it's usually right on their webpage. I print a copy of the picture of the knife in the measurements they provide, then I make a wooden knife like Dwight said. And the second way raises the price of the sheath.

-

Thanks!

-

Thanks!

-

Newly crafted set of saddle bags

BlackDragon replied to Wildwest2029leathercraft's topic in Show Off!!

I going to comment on pricing but not the saddle bag itself since this isn't the "Critique My Work" section. Generally speaking I price items based on cost of materials, my time, shop costs, and locality. They look like swing arm bags but I can't tell the size of the bags. I'm going to guess at 12" wide? I round up to the nearest sqft. So if something is 1' x 6" I count it as 1 sqft. 1sqft front, 1sqft back, 1sqft gusset, 1sqft lid. add your thread, glue, dye, hardware, etc. What does it cost to run your shop? Rent, electricity, water, insurance, etc. I'll take those costs and go up to triple. So if all the costs add up to $50 it'll be at $150 Now add in your time. Lets say it took you 8hrs. What are you paying yourself $8hr or $40? This is going to depend on your experience. Hopefully the more experience you have the higher quality you're producing. You'll have to also decide what are the going prices in your area? If the max for a custom leather bag is $300 you're probably not going to get more than that, unless you're selling online and have a broader reach. Sometimes I'll make deals with people. If they buy several pieces I may do I group price. Or if they are veterans, LEO, paramedics, FD I'll knock 10% of the price. -

Thanks!

-

I've been seeing a lot of ratchet belts and a few people have asked me about them. My usual comment goes along the line of "I haven't made any and I'd have to do some research on them". So here I am looking into them. I started looking for ratchet tracks and a lot of companies make the ratchet belts but the tracks are really hard to find. I found a couple people selling them on Etsy and Ebay but they are the same brand. I can't find an actual company that sales them directly. If anyone knows of a direct source I would appreciate that info. The tracks that I ordered through Ebay are pretty good and the seller was great to deal with. I gave him a call when I had a few questions and he was really helpful with tips to mount them and what buckles work well with the track. https://www.ebay.com/itm/277241899676?itmmeta=01K0SQE5R03ZHFJ6Y637CP450F&hash=item408ce7aa9c:g:ycwAAeSwrd1oYYOR The biggest issue I have is that I would like to sew them in instead of gluing then in. I used a #23 needle but the track is too narrow for the needle. I also tried using a pricking iron and I don't like how close to the edge of the leather it is. I put one together with just glue as a test. 5oz black harness leather and 5oz vegtan liner. The area that has to latch onto the leather is skived down to a total of 5oz so the clamp can actually close. I'm looking for buckles that can actually close down on 10oz. So, does anyone know where I can find these tracks wholesale? What can I do different, if anything, to secure the track better?

-

- ratchet belt

- belt

-

(and 1 more)

Tagged with:

-

Thanks! I'm glad I could inspire you!

-

I put together a fork bag for my bike. I guess it's actually more of a windshield bag. I used 10oz vegtan dyed with vinegaroon and used resolene to seal. The bag is 10.5"x 5"x 2.5" (mount point is 13"x 1.5")

.jpg.94484fcd2240f3f790944b598e9fe4d3.jpg)