Search the Community

Showing results for tags 'adler'.

-

Hello everyone, I am cleaning an Adler 5-27 and I was wondering if it is possible to remove the jump foot? I have removed all the screws, but I can't get it to move a mm. 😅 My guess is that the pin that is visible in the second picture is stuck through the rod. As I don't own the manual I was hoping somebody here is able to help me! Kind regards, IMK

-

Buongiorno, ho acquistato da poco una Durkopp Adler 69 e studiandone il funzionamento mi sono imbattuto nella regolazione della pressione dei piedini; so che la parte filettata più grande serve per regolare la pressione dei piedini ma, nonostante i miei tentativi, non riesco a capire a cosa serva la piccola vite in alto (cerchiata in rosso), quindi chiedo a voi. grazie a chiunque mi risponderà

- 3 replies

-

- sewing machine

- adler

-

(and 3 more)

Tagged with:

-

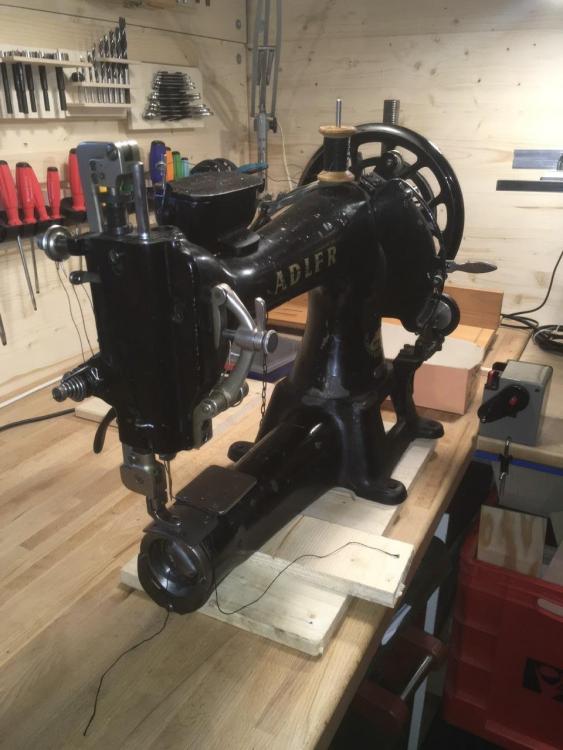

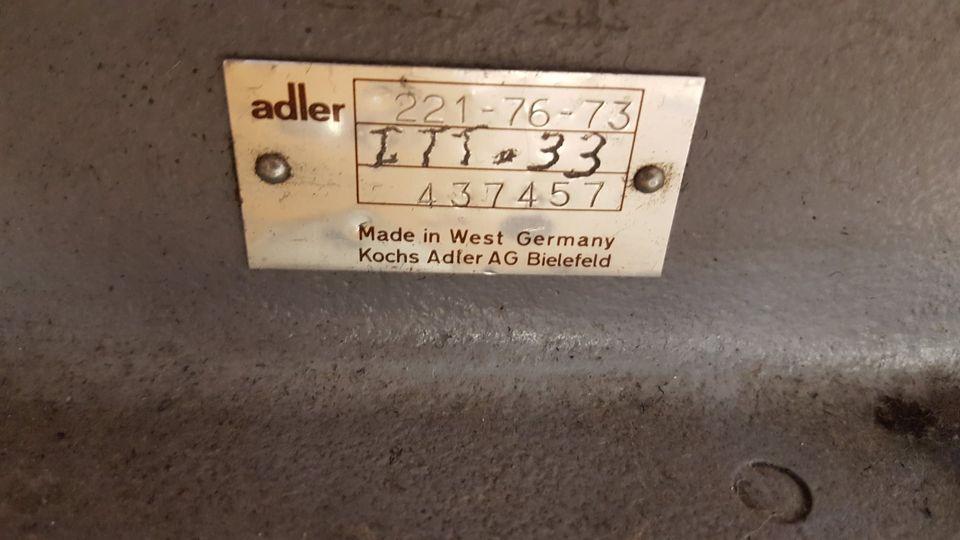

Hi everyone, Yesterday I bought a old Adler leather Maschine at a Atelier closing which need for my studies… it’s been standing for some years so I bought it without really being able to try it out( it was quite cheap). after trying it out I noticed that the bobbin is not turning. Turning the Handweel (which was already very hard) only makes the metal bar in part 2 turn ( referring to the picture provided) the longer bar and everything after is not turning. I tried turning it by force thinking it’s stuck but even after turning it by hand a couple times it didn’t change. I also tried opening the two bolts (2nd picture) but they are too stuck to move. Before I have to carry my machine to the mechanic I thought maybe someone else had had this problem with older, longer not been used Maschines and can help me. I’m usually quite handy and fix all my mashines myself but I’m out of ideas here… thankfull for any help! Thanks

- 9 replies

-

- leathermashine

- adler

-

(and 5 more)

Tagged with:

-

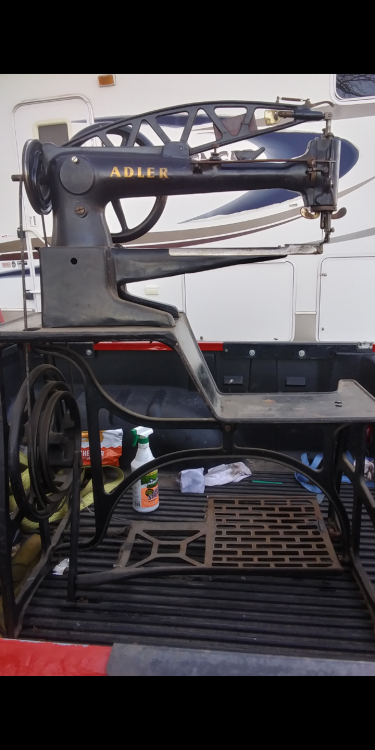

We’ve got several industrial leather machines for sale here in Florida. Actively being used in a working Harness shop and we’re retiring soon Please take a look a share were you can. CONTACT Don Engelking 352-483-6618 Landis 16 $1000 Flat Bed Consew $1000 Adler 205 3500$

-

Hi everyone, This is my first time posting here and I need some expert's advice on this matter. I found an Adler 069-373 cylinder arm industrial sewing machine on eBay and the seller is not far from where I stay - Edinburgh, UK (about 15' drive) The seller is offering to install a silent motor on (instead of the clutch motor) and change the binding attachment you see on the photo for a normal one. His offer is £900 with free delivery and 6 months warranty. This will be my first cylinder arm machine, my only experience with sewing machines is my very old singer 99k. I want to use this machine for waxed canvas and some leatherwork where canvas meets the leather and maybe use it more often for leather straps and/or belts. So I can get this machine or go for the Tysew TY-3600C-1 for £1.300+ (new). They say Adler parts are available in the UK same as for the Tysew, since Tysew is based in UK. I will avoid the good and trusted American brands since I cannot get much support from where I stay, neither parts as far as I am aware. Any expert to help me with this please? Is this a good deal? The seller said he bought it 2 years ago from London and fixed it, but he didn't tell me what he fixed. This is his side hustle he added, buying old machines, fixes them and sells them for some extra money. Shall I go for this deal or go for something else? Thank you

-

I just purchased an Adler K269-373 head only. I have a table on order but need a servo motor. This is my first industrial machine so I'd welcome any input on how to choose the proper servo motor or which brand/model might be best. I've budgeted something under $300 for this component. Tell me if I can make that budget or why I should look at something more costly. Thanks for holding my hand along this learning curve!

-

Hi everyone! I believe the phrase "long time listener, first time caller" is apt here even if we are not on a radio station. I'm a general maker but mainly I'm a leatherworker. I make a plethora of things from wallets to hats. I recently acquired a Sieck 269-373 sewing machine, which I can only assume is a Chinese copy of the Durkopp Adler with the same numbering. So it is fair to say I am new to the august club of sewing machine owners. I have had problems even finding a good manual for the machine so I'm not even sure it's threaded correctly. I have included pictures which show the threading. I am also significantly confused over what thread size this machine can handle. Wherever I look I see different opinions on this matter but as of right now it is (hopefully incorrectly which might make for an easy fix) threaded with TEX 135 bonded Nylon both above and below. I have included pictures of the threading for reference. My problem is mainly the tensioning. I don't know if this is because the thread is too thick or because of a setting. I have tried cranking the tension right up but I get the bobbin thread basically sitting flush and not being pulled into the leather at all. I've included a picture of a flipped over piece of 5 oz veg tan that I tried to put a seam in. I now ask for your help to see if anything stand out as wrong or any ideas that pop up. And please, do not think that anything might be too stupid for me to have done as I am a complete novice with this machine. Thank you.

-

We have an Adler 30-15 treadle sewing machine for sale. Asking $2,000 OBO. Our friend who owned a leather and saddle shop recently passed and we purchased the entire contents of the shop from his estate. We have never used the machine but seen it being used while spending time at his shop. My wife is the leather worker in the house and her bad knees precludes the use of a treadle machine. We are keeping the other modern electric machines that came with the estate. We are located in central Wisconsin so pickup at our location is preferred but I am willing to discuss other possibilities. I know this is my first post so if anyone is concerned I am a scammer, but interested, please message me. I am willing to do whatever to help alleviate those concerns. I have many more photos and higher quality photos I can send interested parties, I wasn’t able to post them here due to the data limit. If there are specific photos of certain parts of the machine you would like, message me, I am more than willing to take more and send them.

-

Hello, I am a newby to leather sewing machines. I am buying an Adler Cylinder Arm 49-2 and would love more information on it. I have been searching the net but no luck. Looking to see if Singer made an equivalent. Looking for a manual. And looking for any opinions. I have attached a picture.TIA

- 10 replies

-

- cylinder arm sewing machine

- adler

- (and 4 more)

-

I need to change the hand wheel to a larger one, I’m starting to get a blister from cranking it for the right needle position :), it’s just too small. Can someone point me in the right direction to get a new larger wheel or one with a handle? Thanks.

-

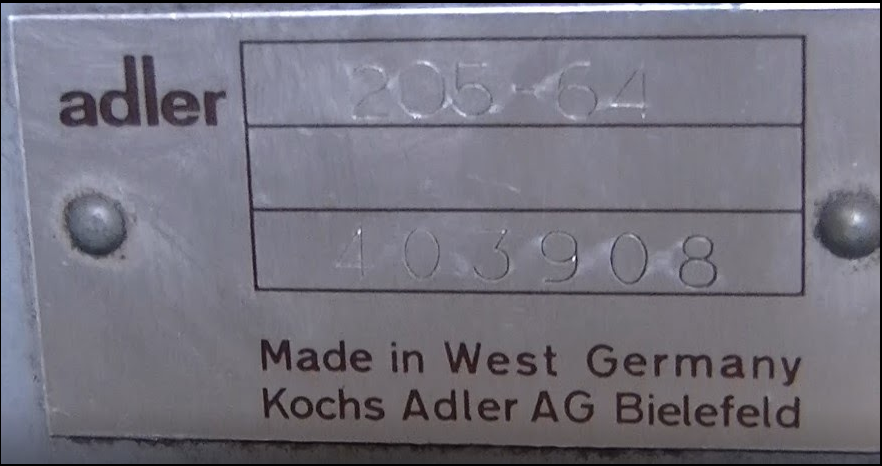

Hi, I am new here on the site. (and i love it) I am looking for Adler 205-64 Sewing machine. I would be happy for some help here! Chen

-

Deluxe Roller Guide for Durkopp Adler sewing machine Hinged, drop down edge guide, right hand Roller and straight guide Adjustable in height by a knulred screw Side adjustment range 0-30mm (1-3/16") Original weaver model not a china copy Fits 204-370 and 205-370 series New Came with Adler Machine never used $195 FREE SHIPPING TO US ADDRESS

-

- roller guide

- sewing machine

-

(and 1 more)

Tagged with:

-

There's an Adler 205-374 for sale in my area for $3680. I'm a novice but I know this model has a good reputation I have a need for a heavy stitcher. The owner doesn't seem to know much about it but it's supposed to be in good working order. I was wondering if this was a good deal or not. I was going to buy a clone but maybe should grab this instead. Thanks in advance. Mike

-

-

Dear all, I asked this morning for a manual of the Adler 4 and 5 series to be shared with me. I have recently gotten a hold of a Adler 5-8 (for free) as I like old machines. But now am faced with trying to make sense of the individual parts and giving it a check that it actually works (according to the person giving it to me it works all right). I was offered a deal: photos for manual. Rationale: apparently there is a lack of images of these old maschineschrieb and spare parts. Ok, if that’s the case: I agreed. So here are the Fotos. any feedback would be appreciated. if you spot things on the machine that seem awkward, let me know. Any guiding is appreciated. As I wrote earlier today, the wheel turns smoothly, the needles is moving up and down and the „ship“ (the „metal surprise egg“ is turning). best MSAdler p.s.: why Do I want to check if it works? Because I won’t spent a lot of time restoring it if the eagle has no wings ...

- 9 replies

-

- restauration

- repair

-

(and 2 more)

Tagged with:

-

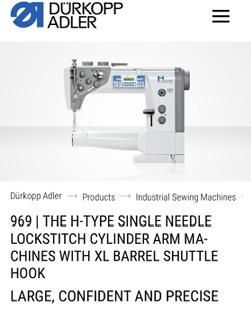

I’ve been looking at the Durkopp Adler 969. From what I’ve found online it looks to be a very capable machine. I’m positive it’s built with the same quality that is Adler, my question is, or my fear is, all the ‘Lectric functions that I’ve spent a lifetime doing manually. Push button tension? Push button everything. Is it worth almost 10 grand in the long run? Anybody had one since they came around in 2013? Opinions? Thanks.

-

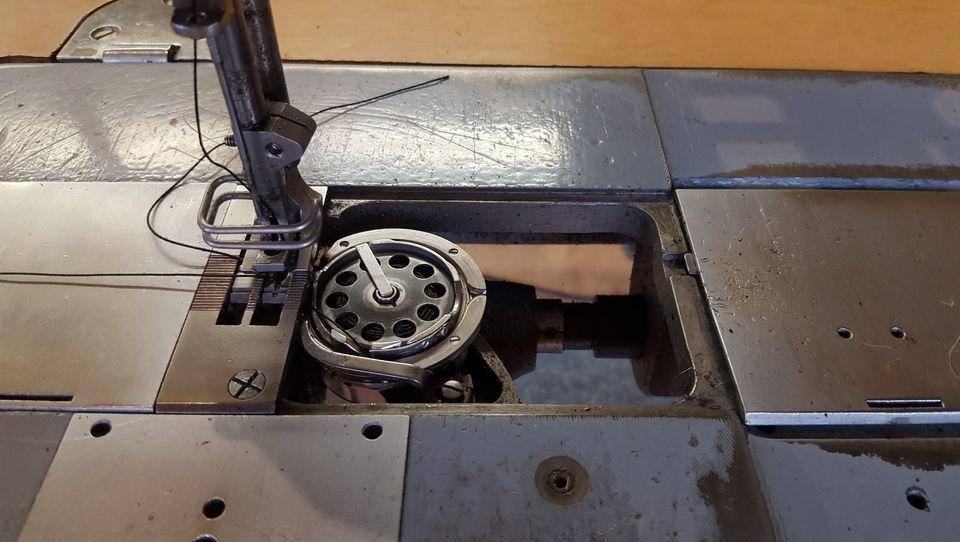

https://photos.app.goo.gl/TbSnNr1nD2n6zpnHA Please see the attached. I've got new bobbin case 0504151380. with shuttle frame 0504151220. However It doesn't fit on 205-64 cylinder arm. Would you help me if I bought wrong parts? or there is still a lack of parts for mechanical repair? 205-64.mp4

- 6 replies

-

- 205-64

- shuttle race

-

(and 2 more)

Tagged with:

-

Hello everybody! I have a DA 169-73 and want to convert this beautiful machine to a binder machine. I have been calling local dealer to try and source the parts but they couldn't really help. I found a topic on this forum where a Hong Kong shop was mentioned that produce spare parts for those machines. The problem is that I can only find parts for DA 269 (needle plate, feed dog, presser feet) and binding bracket for 869 (which they say also fits the 269). I have contacted them but they say that those parts have not been tested on a 169 machine and therefor they cannot guarantee they will fit my machine. My question is, has anybody tried swapping parts from 269 to 169 or vice versa and is this a solution to my problem? I have spoken with a few technicians locally ( I am from Bulgaria if it really matters lol) and they claim that the swap should work but I am not a 100 % convinced. Any information on the matter will be highly appreciated. Thank you in advance! Regards, Georgi

- 23 replies

-

Hello guys, This is my first time writing here. Its been nearly a year i am doing leather goods (wallets, wrist bags, bags, and other small projects). I want to buy a sewing machine, so i can speed up a little bit the process. Found a guy who sell both of them. Any suggestion what to choose?! Adler 69-373 for 350 EUR Adler 269-373 for 450 EUR. And, does they worth the price ?! Thanks in advance !!

-

Saddle shop downsizing >>>> retirement We have a 25 ton 20" x 40" Herman Schwabe clicker press 3 phase for 3200 CAD (will need a new bed) 40 drawer clicker die cabinet 800 CAD Long arm Adler walking foot, a workhorse for any larger materials - 3/4" lift for 4800 CAD - including table & servo motor + new light Artisan walking foot flatbed with very little use. Great for a novice to get going on. 1450 CAD - Includes table with wheels and servo motor Located in Penticton, British Columbia. All machinery is in excellent working order

-

Wanted Adler 205-370, or similar Adler cylinder bed to be set up for heavy duty leather and carpet binding. Top dollar paid for a Adler cylinder bed with a vibrating binding attachment. Prefer head only. Working condition, or free turning mostly complete. Must be able to ship. PayPal preferred payment. Send pictures and contact information to Glynn@ozarksleathersmith.com

-

Hi all, my Dad was a leather craftsman for 55 years (Edinburgh Leather on fb) He sadly passed away suddenly, and I’m looking for some help valuing his machines and where to sell. We have a Wimsew W-8 industrial sewing machine- he bought it recently. A vintage Adler industrial sewing machine An old Brother leather sewing machine - that needs a table. any advice is much appreciated Kerrie

-

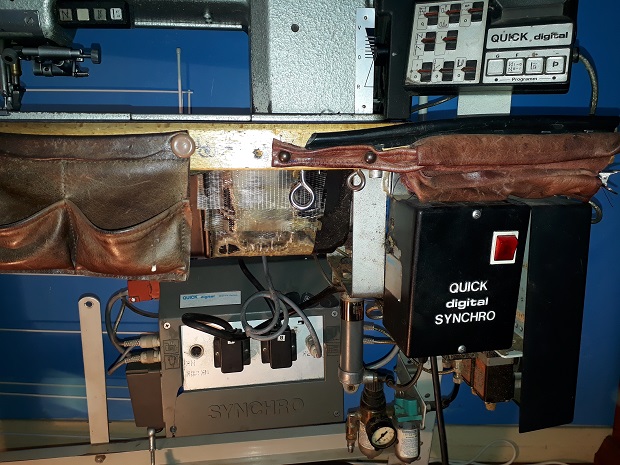

Hi all, I picked up an Adler 767-fa-363 compound feed machine, a parts project. I have the machine set up okay, but need to finish attaching all the electronic connections. I have the sewing machine manual, but not one for the digital motor setup. Not sure which model it is, but it's an older Quick Rotan. I think it might be a Synchro 5040, but not sure. Can't really read the numbers on the various plates, but I've come up with some of these: AB 4/5 1089 0a05aJ A50501, or A50901 Here are some pics. If anyone can steer me toward a manual for connecting all the plugs, I'd greatly appreciate it. I think I have them correct, but when I turn it on, the main switchbox just buzzes, and nothing comes on. Oh, and I'm in New Zealand, so parts aren't exactly plentiful here [grin].

- 21 replies

-

- quick rotan

- eps

-

(and 2 more)

Tagged with:

-

I need a replacement motor for my Adler 30-15 post machine. The motor I had was a Westinghouse, 1/6 hp, 1725 rpm, Frame 145, style 1177109-C, open, AC motor type FH. (placard of motor attached). Please call or email me a price. Demps Bannerman demps@criticalpowersystemsinc.tech 662-401-8831

.thumb.jpg.b3b038d95f8d29d7583c901a4df11280.jpg)