Search the Community

Showing results for tags 'tanning'.

-

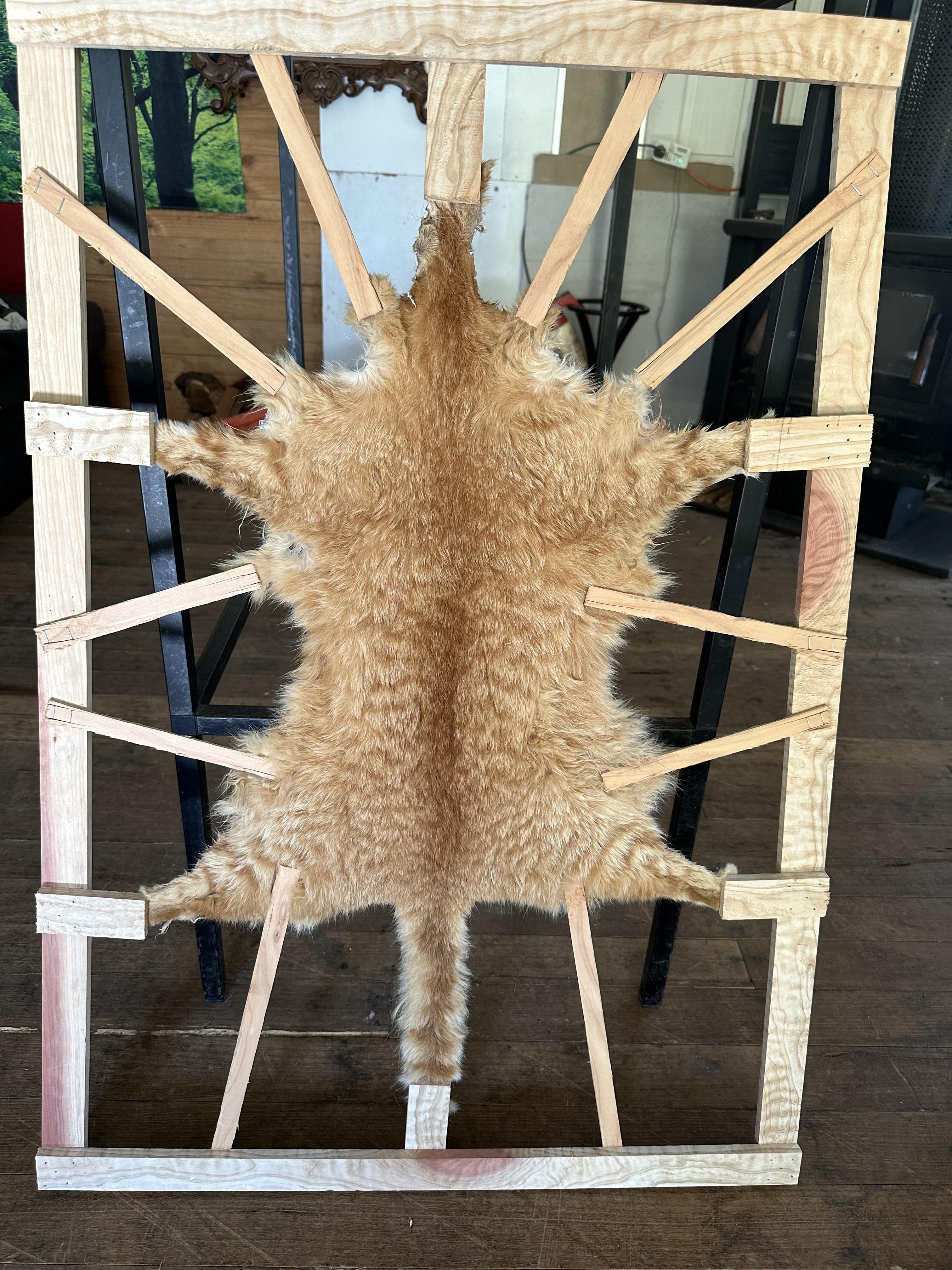

I’m new to this forum, have tanned a few hides and am just about to learn sewing. My dream is to build something out of leather from scratch. This includes harvesting the animal right through to sewing what ever I end up making. I thought joining up here could help me on my journey, well it has already! So far, I’ve chrome tanned at least a dozen wallabies, A Fallow deer and a feral cat. I have also experimented with alum tanning 2 cows. And these worked out ok. Just recently I have purchased a 2nd hand singer 132k6 which I have just rebuilt and have managed to get it to work. I have limited sewing experience but definitely have the passion and patience to figure it all out. Well that’s who I am and why I’m here! Thanks for having me.

-

I am looking for help with finding site(s) that deal with home tanning of leather products. I am new to both tanning and leather work in general. Like way too much else on the internet, trying to wade through all of those search results is mind numbing at best. Thanks in advance for any suggestions. Please feel free to move this question to the right section if it's been misplaced. Thanks Ray

-

I am going to begin to start making western chaps. Does anyone know what type of tanning process the ranchers used in the 18th century. I am more interested in natural tanning techniques.

-

Hi Why is the tanning process different in different parts of the world? Is this an apparent difference or a root one?

-

hi I want to open a tannery (traditional tannery), but There are no natural colors in my country. For this reason, I have to produce the colors myself. How do I do this?

-

Hi in winter, sunlight can not be used to dry the skin (in the tanning process). what is the alternative to sunlight?

-

Hi in winter, sunlight can not be used to dry the skin (in the tanning process). what is the alternative to sunlight?

-

Has anyone attempted to tan their own snake skin? I've been researching through youtube mainly and found that practically all the tutorials are on rattlesnakes. I recently purchased three python skins from a taxidermist who only wanted the bones. I am attempting to tan them myself. So far I have only started with one to see if I can figure it out. Has anyone tanned both a rattlesnake and a python? The skins I got were not exactly "tube peeled" and so there is a very large band of tissue running down the spine. I tried to flesh it as best as I could. I got the fascia off for the most part but this band seems to be something else. At times I was able to get a bit lifted up and peeled off but in some areas no matter how much I scraped it would not come up. It was getting to the point where I began cutting some holes in the skin. I ended up leaving it on and I'm hoping that it works out. I put it in the tanning solution (50/50 isopropyl/glycerine), shook it twice a day for a week, and just pulled it out today to dry. In the video I watched the guy mentioned that when I pull it out I shouldn't smell anything but the isopropyl alcohol. I smelled the alcohol but there was also a hint of ... a death smell... not rotting, but dead. Have I totally messed it up? Should that smell have dissipated in the alcohol/glycerin solution? Here's the vid I watched on the solution portion:

-

Good day everybody , I received this sample from local tannery in Egypt ( where I live ) and they claim that's a veg tan leather but I don't really but it as there's a center line with dark grey centered in leather layers .. I tried the boiling water test it didn't curl up but it shrank about 20% of original length .. i don't know why it didn't curl on itself because it's not real veg tan or it's thick layer about 4mm The weird issue that rose is it got burnished very beautiful with glass-like edge with just wooden slicker and water so it got me mad because I can't decide what is that ?! THANKS IN ADVANCE FOR YOUR HELP

-

First of all, I'm new to leather living in Egypt and want to know more about tanning because the gossip here is sky high and everybody claims he's the best but when it comes to picking veg tan leather people get crazy fast I have asked the biggest tannery here and they claimed that they do Vegetable tanning process within a day or so using a drum Since am new to this area so I can't decide is that true or just a scam Also, I'm suffering dealing with too supple leather even my edge beveler ( Not the best quality ) can go as the leather starts to get stretchy and wrinkly so if anyone can help me out i will appreciate it so much Adding to this, when I asked one of the workers in the tanneries he said that they press the leather in the finishing process and he correlated that it has to do with the firmness of the leather in the outcome .. Is that true ? Thanks in Advance

-

Hello everyone, Firstly excuse my English it is not the best. I work with leather and have a question if anyone is able to help. I recieve from friend a old large intact python skin. It is dry, brittle and not in best condition but is it possible to treat for use in some project I have? Any information anyone can give me is big help to me because would be nice to use the skin and not let go to waste. Thank you all :)!

-

Definitely not the first on this board to visit, and probably not the first to post about it, but today I visited the semi-legendary tannery J & FJ Baker's of Colyton, Devon. For the uninitiated they are the last oak-bark pit tannery in England, and possibly Europe. This isn't some rediscovered or retro skill -- the company has been operating essentially unchanged since there was a tan yard in every village. Apologies in advance for the limited and low quality photos. I'm not much of a photographer, I only had my phone with me and we were on a time-scale so I didn't fancy looking like a complete tourist and only took a few snaps as we went round trying really hard not to fall into the liming tank. Baker's has been owned and run by the same family for about 140 years. Today's company director is the 5th Mr Parr. However nobody knows how long the tannery has been here. (There was a tan-yard on this site in Roman times. That's nearly 2000 years, history fans.) The tannery operates in a maze of buildings on the banks of the River Coly, from which it draws water and motive power. (The hides are are agitated in the tan pits by the water wheel which runs in a leat off the river.) These range everything from ancient stone and brick to wriggly tin sheds you might find on a dairy farm. The site has clearly been built and evolved over time, as needs changed to meet a fickle market. One thing that is constant is the impression of age -- a combination of wear from centuries of honest, hard graft and grease which covers every surface. This is what "vintage" dealers aim at and completely miss. Nothing around this site looks old because it's had orange paint daubed on it, been hit with a hammer or rubbed with wire wool -- it's simply been doing its job since it was new. If you've spent time at an industrial site you'll probably know what I'm talking about. Hides arrive as "wet blues" from the slaughterhouse-- just as the got sliced off the cow, except they're covered in salt so they don't rot before they get tanned. They're still hairy and bloody, but that won't last long. First they go into the liming pits. This is an alkali bath which dissolves the fat and little scraps of flesh, loosens the hair, and plumps up the skin. The limed hides go through a couple of machines which dehair and deflesh them, then they're passed to a man who removes any stubborn bits that shouldn't be there. He uses a large knife in a scraping motion. Before machines came about all flesh and hair was removed on the fleshing beam in this way, which was tedious. At this stage it's all still rawhide. After dehairing the leather goes to the tanyard, which is the heart of the operation. Hides are hung in the pits by hand, strung from the oak beams you can see. the beams each hold two hides and fit into wooden frames, which are rocked back and forth by the vertical rods you can see, which in turn are moved by the water wheel. Hides start out in the oldest tanliquor, which is changed by pump each week for a stronger liquor until it's been through the strongest, newest liquor. Talking of tanliquor, Baker's primarily uses oak bark. They have used standard bought-in veg-tannin in the past, and still sometimes do, but these days mostly run oak bark because that's what Baker's is famous for. It's prepared separately in a series of pits underneath the tanyard, with shredded bark left to steep in water for "a while". It's encouraged to ferment before it's ready to be pumped up to the tanyard and the smell is... well let's just say it doesn't smell like a forest. Once the liquor is drained the remaining mulch is sold on as fertiliser. Tanning takes many months and exactly how long I don't know. However the average is 18 months from coming in to being ready for sale. It's this tanning which turns rawhide into leather. Freshly tanned hides are hung to dry in naturally moving air. Once dried, hides are dipped in hot grease and folded in half before they go hard. Later they are put through a hot water bath, laid flat, graded and cut. At this stage their fate is decided -- will it become shoe leather or equestrian leather? Shoulders, backs or butts? Grading is a skilled job but mostly revolves around how many flaws it has -- barbed wire scars matter a whole lot less on a shoe sole than a pair of driving reins. Hides are split to final thickness at this stage. Soling then goes to the butt store but equestrian leather goes on to be curried (dyed, dressed and treated). Most dying is done in a tumble drum these days for speed and uniformity but they still hand-colour some hides. Hides are set out on a stone slab, using a slicker to smooth, even-out and slightly polish the leather. Currying involves the rubbing in of dubbin by hand, which is a mixture of tallow, oil and wax. I didn't get any pictures of the dubbin tank but I think you could submerge an estate car inside it without too much trouble. I've alluded to shoe and equestrian leather and those are the traditional divisions but leathers from these groups is suitable for all sorts of purposes. Baker's sells shoe soling as well as specific cut components like sole blanks, toe puffs, heel stiffeners etc. It can be cut into regular shapes for a beautiful (but rather delicate) flooring material. Soling is also hot fatliquored in a tumble drum to make machinery belting. Equestrian leather is of course traditionally used for riding and driving tack but its use is largely for other goods like belts and bags. Traditional products are bridle and harness in various shades of brown, tan and black. (Some undyed stuff is made, which in England is called russet. That's the sort of thing you might use for tooling.) There's also a certain quantity of lighter weight hides like bag/girth hide, which has an obvious use. Other specialist leathers for making stirrup leathers and girth points on English saddles are available too. Traditional cuts are backs, shoulder, butts and bellies. Backs and butts are sold as pairs or half-pairs (singles). There's also a limited quantity of Russian calf coming out the tannery these days which is amazing stuff. Baker's has been through some rough patches in the past but the quality and beauty of their product is well recognised these days. They're running at full capacity, which is 80 hides per week. It's not the cheapest leather in the world but neither is it the most expensive and I think it's a bargain for what it is. Now I just have to convince my customers the same ;-) You can see some good quality shots of Baker's main products here.

-

Hey all! I'm planning a trip to Florence and Tuscany later this year. Planning to visit the leather school but also want to visit a tannery if possible- maybe even buy some veg tan at the source! Has anyone done this and do you have places to recommend? Thanks!

-

I have an idea for a large tote bag for my daughter in law. The project would be fairly large; about 15X12". Most of my projects have been holsters and such so my leather dying doesn't matter much if it isn't uneven. My concern is with such a large piece, how to I dye it and keep my color consistent throughout the whole piece?

- 22 replies

-

Hi, I'm new to this forum and part of a startup business that seeks to source and promote premier quality leather goods and craftsmanship to a wider audience. I will post a link to our site in the "new members" group. We want to educate people and help them better understand leather so they'll make informed purchasing decisions ― and we want to improve our own knowledge of leather. Those are the main reasons I am now a member here on Leatherworker. We have just finished an article about vegetable vs chrome tanning. I would be most grateful if some of you experts would spare 5 minutes, read through it and comment on it. If you have suggestions for changes or adding more information to the article, please let me know. Thanks!! Anders -- Tanning leather: Chrome or vegetable? The leather that your bag is made of has been tanned. And no, that doesn’t mean that it has been left in the sun to get a bit of colour. Basically, tanning is the process that converts animal skin to leather. How this process is carried out has a very significant impact on the quality of the bag you hope to use for years to come. Will it soften and acquire a patina over time? Or will it look the same until one day it starts to crack? Once an animal skin has been turned into a hide by being degreased and having all its hair removed, the tanning process can begin. An untreated skin would both harden and putrefy as it is an organic material. So, the aim of the tanning process is to prevent this from happening – to turn the hide into leather. This is something human beings have been doing for a very long time. Some evidence suggests that leather tanning was performed as far back as approximately 6,000 BCE in the Indus Valley – one of the cradles of modern civilization. The basic principle has been the same for all these millennia: To modify the protein called collagen, which the skin is made up of. You can actually get a sense of this protein with the naked eye. Collagen molecules like to first line up and then to twist together into “fibre bundles“, that you can easily see if you look closely enough at quality leather. Look closely and on vegetable tanned leathers you will be able to see the collagen fibres that leather is made up of. What tanning does is leave the skin much less susceptible to hydrolysis – the separating of chemical bonds caused by water – which would otherwise cause its degradation. Tanning modifies the molecular structure of the skin. Vegetable tanning For the vast majority of the past thousands of years this modification has been performed by soaking the skin in a solution made up of vegetable tannins. These tannins would most often come from trees such as oak, chestnut or mimosa, but hundreds of tree types and other plants have been used. In fact, the word ‘tannin’ derives from an old German word for ‘fir’. So ‘tanning’ has nothing to do with colouring as in getting your kit off and letting the sun brown your skin. A tannin is a molecule that bonds easily with proteins and will draw liquids out. If you are a wine drinker, you may have had heated debates over a wine’s ‘tannins’ – the ingredient that makes the wine feel dry in the mouth, sometimes to the extent of making both your tongue and gums feel unpleasantly arid and barren. Just as the tannins in wine come from the skin of the grape, the tannins in trees are found in the bark. When tanning hides to make leather, the hides are soaked in a tanning solution. The tannin molecules will enter the hide and displace the water that is bound in the collagen. The water is drawn out, but as the tannins take the place of the removed water, the leather does not grow inflexible as fully dehydrated leather otherwise would. It may sound easy, but it isn’t. The process is complex and the skins require multiple treatments over a period of up to two months in order for the water molecules to be fully extracted and letting the tannin molecules take their places in just the right way. A lot of work from skilled craftsmen is involved too. Mineral (chromium) tanning The complexity, expense and time involved with tanning with vegetable tannins led to the development of using mineral tanning agents instead. The basic principle is the same, removing water molecules from the collagen and replacing them, but the process is much quicker using chrome which by far is the most popular mineral tanning agent today. The whole process can be automated and finished in a day. The process, however, is far less natural than when using vegetable tannins. It involves first placing the hides in acidic salts to better make the chrome fit in between the collagen molecules – and then returning the hides to a normal pH level. This requires the use of acids and other chemicals as well as the chromium sulphates themselves. All these have a negative environmental impact and the industry is under increasing pressure to “clean up”. As opposed to the vegetable tanned variety, chrome tanned leather can’t be recycled either as it is not truly a natural product. Nevertheless, today no less than about 90% of the world’s leathers are chrome tanned – primarily due to the cost. If you buy wholesale leather, vegetable tanned leathers cost about three times as much as chrome leathers. In general, vegetable tanned leather is considered far superior to chrome leather. Look, feel and smell The cost and environmental impact of chrome and vegetable tanned leathers are not the only differences between the two. There are more visible distinctions too. Vegetable tanned leather Because of the way it is tanned, the colours of vegetable tanned leather will be richer and “deeper” and the leather will appear, as it is, natural. Being an entirely organic material, vegetable tanned leather will change over time. It will grow softer and darker, and will acquire a patina depending on its uses. As it is more durable, vegetable tanned leather will last longer than chromium leather – potentially several lifetimes. Bags that are decades old can be highly sought after items. Vegetable tanned leather scratches fairly easily, but unlike chrome leather, scratches can easily be buffed out. Vegetable tanned leather smells natural – the pleasant, sweet smell you probably associate with leather is the smell of vegetable tanned leather. Chrome tanned leather Chrome tanned leather looks a little as if it has been painted – the fibres of the leather not being allowed to show through the way they do on vegetable tanned leather. It is basically a less natural product. Chrome tanned leather will not develop a patina but will continue to look pretty much like it did when it was purchased. Chrome tanned leather will initially be softer and suppler than vegetable tanned leather but will not age well. Over time it will grow prone to breakage. Chrome tanned leather is more resistant to water, stains and extreme heat. Chrome tanned leather will have a slight chemical smell to it. Sometimes disguised by the producer artificially scenting the leather. HOT TIP Blue chrome The chrome tanning process will turn the hides light blue. As they are subsequently dyed, the blue will no longer be visible on the surface of the finished leather. But the leather will later be cut into the pieces needed to sew, say, a bag, and the edges of these individual cuts will show a blue tint. Most producers will use a special paint to paint the edges, but if you see any trace of blue edges, the leather in your hands has definitely been chrome tanned.

- 26 replies

-

- vegetable tan

- chrome tan

-

(and 1 more)

Tagged with:

-

Okay, my gut says there's a short two-letter answer to this, but I can't think of why it wouldn't at least be possible, so here goes: Would it be possible to tan rawhide in veg/bark solution? If not, why not?

-

Hi Everyone....haven't posted in a while cause I've been so busy on making horse tack and tanning hides. So thought I'd stop in and pot some new pictures. The snakes have been crawlin' and I've been taken them out as fast as I can. lol.... These are 3 Timber Rattlers ....and a few of my Diamond Backs and Copperheads

- 18 replies

-

- rattlesnakes

- horse tack

-

(and 3 more)

Tagged with:

-

Hello all! I have a few questions lined up that may have very basic and straight forward answers but to the novice they are quite confusing! What part of the tanning process makes a finished hide soft and luxurious to touch compared to hard? What part of the tanning process makes the flesh side rough or smooth (like the top side)? What part of the tanning process makes the leather firm or flexible and floppy. I have asked some people in the past but have never had a suitable answer, some have said it depends on the thickness of the leather but some leathers can be very thick and very soft to touch and vice versa with thin leathers, or very thick but still floppy or very thin and very firm. Also, what is the difference between bridle leather and harness leather, and do that both have smooth bottom sides? And does anyone have any suggestions for a waxy feel of shell Cordovan from either Horween or Clayton but from a cowhide rather than just the small horse shells? I am making leather wallets and purses and have found that 1.5-2mm or around 3oz is the perfect thickness for what I want to produce without the wallets becoming too bulky, what recommendations would anyone have for leather having the above mentioned waxy feel but with a bridle type flesh side, to avoid bulking up even more with lining. And if I were to line the wallets is pig skin or goats skin the best option, or is it just down to preference? From reading the posts on this forum I've become accustomed to there being no wrong answer but just many individual preferences. I am based in the UK so as well as this long list of queries if anyone had recommendations for suppliers that would be perfect too! Many thanks in advance! Ross

-

I've read a thread about tanning and some articles and they talk about damage to the skin if left untreated for even a shjort time. will the damage go beyond loosening the hair? is there aa timeline on how much damage and uses that can be made of it? above ques if skin has been scraped and salted? what do people use for the scraping anyway? should I grind down something witha special profile? Brain, Bran, Veg, Alum tanning what are the + & - of each method? Brain-some swear by, but what of u don't have Brains available? are there other methods? can I just stretch the skin on a framework in an open shed for drying or is something more needed? will my neighbors complain about the smell? Is ther a "tanning for idiots" book avail?

-

Hey guys. My uncle is having a cow butchered in a month or so (he owns a farm) and i was just wondering if you guys new were i could get the hide tanned? I live in Toronto Canada. Thanks a ton guys! -Peter

-

I came across a really good web site that outlines the history of the tanning and glove making history in Johnstown and Gloversville New York. At one time that area was one of the largest in terms of tanning and glove making. Made for some interesting reading as I grew up in that area. What was real telling was the phone directories from over the decades, from the heyday to present time there was a huge decline in the industry. Having lived there I can attest to the severe damage to the ecology that was done by the tanneries, dumping raw chemicals and runoff into the local creeks. At on me time the Cayudetta creek was one of the most polluted bodies of water in the US. Things cleaned up in the 80's but there are a lot less tanneries now. Gloversville was a glove making machine, still remember the factories on my way to the library. It is interesting looking back in history at how popular ladies gloves were at one time. Take a look at the site, it is worth a few minutes of your time for sure. www.gloversandtanners.com

-

Even in the 21st Century, the manufacture of leather retains an air of the dark arts, still somewhat shrouded in the mysteries of a millennia old, craft based industry. Despite the best efforts of a few scientists over the last century or so, much of the understanding of the principles of tanning is still based on received wisdom and experience. Tanning Chemistry : The Science of Leather Author : Anthony D. Covington Leather is made from (usually) the hides and skins of animals - large animals such as cattle have hides, small animals such as sheep have skins. The skin of any animal is largely composed of the protein collagen, so it is the chemistry of this fibrous protein and the properties it confers to the skin with which the tanner is most concerned. In addition, other components of the skin impact on processing, impact on the chemistry of the material and impact on the properties of the product, leather. Therefore, it is useful to understand the relationships between skin structure at the molecular and macro levels, the changes imposed by modifying the chemistry of the material and the eventual properties of the leather. This book aims to contribute to changing the thinking in the industry, to continue building a body of scientific understanding, aimed at enhancing the sustainability of an industry which produces a unique group of materials, derived from a natural source. The Science of Leather is the only current text on tanning science, and addresses the scientific principles which underpin the processes involved in making leather. It is concerned with the chemical modification of collagen, prior to tanning and the tanning reactions in particular. The subject is covered in the following order: collagen chemistry, collagen structure, skin structure, processing to prepare for tanning, the tanning processes and processing after tanning. The aim of the book is to provide leather scientists and technologists with an understanding of how the reactions work, the nature of their outcomes and how the processes can be controlled and changed. The objective is to synthesise a scientific view of leather making and to arrive at an understanding of the nature of tanning - how the wide range of chemistries employed in the art can change the properties of collagen, making leather with different properties, especially conferring different degrees of stabilisation as measured by the hydrothermal stability. Environmental issues are not treated as a separate theme - the impact of leather making on the environment is a thread running through the text, with the assumption that better understanding of the science of leather making will lead to improved processing. The book also reflects on the ways leather technology may develop in the future based on the foundation of understanding the scientific principles which can be exploited. It also includes a subject index, references and a glossary. The book provides the reader with insights into the role science plays in leather technology and provides fundamental understanding, which should be the basis for scientific and technological research and development for the benefit of the global leather industry. The book is aimed at students, leather scientists and technologists, in both academia and industry, in leather production and in chemical supply houses. The Book "Tanning Chemistry The Science of Leather" is also available online at 1. Amazon.com 2. Indiebound.org 3. Barnesandnoble.com 4. Printsasia (UK)

-

Leather Processing and Tanning Technology Handbook By NIIR Board of Consultants & Engineers The Profitability of Leather Processing is dependent on a good Product and requires the consistent implementation of well under stood process. This book covers latest techniques of leather processing and tanning, so that the Industries involved in this process and new entrants can grow up with new technology. Leather Tanning as an industry has been subjected to evolutionary Forces as Technology makes use of new materials, techniques and concepts. This book has been written having all the aspects in mind. This book is an attempt to fill the need of those desirous of starting leather processing industry. The book is very useful for new entrepreneurs, existing units, technocrats, Technical institutions etc. Browse this book Online at 1. Amazon.com 2. Alibris.com 3. Printsasia.co.uk (UK)

-

- leather

- processing

-

(and 3 more)

Tagged with: