Search the Community

Showing results for tags 'workshop'.

-

Hey folks, check out my recently finished leather workshop :) https://www.youtube.com/watch?v=G77z3E4Qsp8&t=12s

-

For anyone willing and wanting to support, my fundraiser is live. I am hoping to convert my detached Garage into a dedicated leather shop. Thanks for considering. Caleb https://gofund.me/d9753f5a

-

- fundraiser

- diy

-

(and 2 more)

Tagged with:

-

I thought someone might be interested in seeing my small Leather workshop take shape up until now I have been working in a small space in the house. My first plan was to turn the garage into a workshop but that is now going to be a utility room / laundry. So the Garden was my next option. This is the old shed which was on the property before we moved in, It was really well built and took some removing. 2018-11-19_04-18-08 by my0771, on Flickr This is my first plan for its replacement. Yes it is on the back of an envelope but I don't smoke anymore so did not have a fag (cigarette) packet to draw on. 2018-11-11_10-01-42 by my0771, on Flickr This was followed by a slightly more detailed scale drawing 2018-11-11_10-02-12 by my0771, on Flickr Foundations involved digging some holes. 2018-12-07_09-39-02 by my0771, on Flickr After digging I had to fill the holes with hardcore. 2019-01-06_04-20-33 by my0771, on Flickr The base was made of 4 concrete lintels a little unusual but it is not covered by planning or building regs. 2019-01-16_04-13-52 by my0771, on Flickr The first layer of wood is laid on a mortar bed with a damp proof course below 2019-01-16_04-13-52 by my0771, on Flickr This is very much a simple version of this build there is a more detailed post on my blog I will continue here if anyone is interested

-

Hey y'all, I'm in the middle of negotiating a lease contract and have about 1,500-1,700 sqft warehouse to work with. It has a large garage door and workshop is close to square. There's a good amount of equipment to move in and I'm trying to wrap my head around initial layout. Who out here is working with a shop this size and feels they have a good setup? My thoughts are to make the flow of work move clockwise starting and ending at the door with cutting/assembly tables in the middle so you can bounce back and forth from step to step. Please critique and give your feedback on adjustment to my workflow below. We are expanding to more than just our Boulevard East line to make corporate branded gifts and private label goods so it could be anything from 50 wallets to 1,000 foil stamped notebooks to 5,000 coasters. Not everything we make will use every piece of equipment, but we all know you have to cut before you glue before you sew before you edge paint, etc, etc, etc Here's my workflow moving clockwise around a square-ish room. Try to imagine it in your head b/c I don't have drawings at this time: Inventory racks for incoming leather and raw materials (3-4 large racks) Wall of Clicker Dies and Rolling Tool Chest of Logo Stamps (100+ of each) 25 Ton Pneumatic Clicker (x1) 12" Band Knife Splitter (x1) Bell Skivers (x2) Heat Stamping Station (x2 Kwikprints) "Glue-Up Station" (Gluefast 20 Colonel and a center assembly table for all gluing needs) "Sewing Machine Alley" (x6 --> mix of cylinder arm and standard machines for various needs) "Rivet and Button Station" (foot and hand press) Edge Sanding/Slicking station (Power Edge Slicker Sander) Edge Paint Station (RC-50 edge painter and table for hand painting) "Shipping Station" - 1-2 large racks for packaging materials and 'ready-to-ship' orders **cutting/assembly tables in center of room (x4)** Does this sound like the correct workflow? What am I missing and what do you think needs to move around? POST PICS OF YOUR SHOP!

-

Hi Everyone I am planning to build a small work shop in my garden to get my leatherwork out of our house, I currently have a granite slab 16 in x 30 in and a 2ft x 3ft piece of plywood that I rest on a couple of boxes to work on. My garden workshop will be almost 12ft x 8ft ( we are metric in England) and have some crazy planning laws. I have made some simple drawings to help with the timber order. Where I am looking for help is with the work benches my current thinking is to have a large full width cutting bench across the bottom and two benches up the long sides one for leather work the other for wood and other work. I am not sure of the height for the leather working side as well as the width so if anyone has any advice I would appreciate it

-

Hey all! I'm planning a trip to Florence and Tuscany later this year. Planning to visit the leather school but also want to visit a tannery if possible- maybe even buy some veg tan at the source! Has anyone done this and do you have places to recommend? Thanks!

-

Hello! I have been working out of a small space for quite a while, but recently have the opportunity to move into a 2,000 square foot steel building. Yes I know - I could park a 747 in there. Most of it wont be used for production, but I was wondering how to heat the place for winter? Outside air temps are typically 40 degrees. It's got 18 ft. ceilings and is pretty much a large open space. I was thinking at first - using vented propane radiant tube heating. However, since this is infrared heating and heats objects....does anyone have experience with using this type of heating with leatherwork below? Is it a bad idea? I can hang them fairly high. The other option is forced air via one of those hanging units, or possibly a typical home furnace. That seemed a bit of a waste considering the size of the space and height of the ceiling. All of the hot air would go to the top! Anyhow - just looking to see if anyone has experience heating a space this large, especially for leatherwork and any considerations for it. Thanks!

-

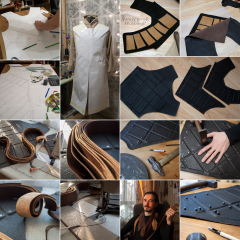

Joh Snow leather armor (replica) WIP

Svetliy Sudar posted a gallery image in Gallery- Our Leatherwork

From the album: Svetliy Sudar Leather Arts Workshop ©

Now we working on a replica of Joh Snow leather armor from "Game of Thrones" TV series. This patterns took longer than we thought ... We needed to keep the proportions of the patterns and at the same time adapt them to required size. It was not so easy and so fast, but we managed). In addition, we needed to make several sets of patterns: for the base and for the top layer (different in size). And now we can say that this is really an exciting project! We're very pleased with how this plates turned out! :) Also you can see here the leather tapes for covering the edges. In total, we needed about 36 ft of these tapes.-

- leatherwork

- leathercraft

- (and 11 more)

-

This video has taken forever to get filmed and uploaded to YouTube. I have a NEW Leather Goods store in L.A. and thought I would show you that you too can start from your living room with two needles, thread, a bit of leather and a dream. It has been a long 4 years of uncertainty, grit and determination. I am posting this to you show all of my fellow leatherworkers that going retail is possible and making a full time career out of this labor of love is both possible and rewarding! I have posted several ads over the past 2 years looking for an apprentice or another leatherworker to come into my shop...still no takers.

- 19 replies

-

- leather workshop

- workshop

-

(and 2 more)

Tagged with:

-

We are a small leather goods shop in San Francisco, California and are currently looking for a skilled leather worker to be an instructor for our twice monthly workshops. If interested in this paid position, you can send send a cover letter, resume noting your experience and any images of your work. Applicants should be skilled, friendly and patient. Workshop size: maximum is 6 students. Leather and tools provided. Workshop duration: 2-3hrs depending on project. Frequency: Twice monthly. Evenings during weekdays or during the day during weekends. Projects will be small simple items for beginners ex. wallet, passport cover, leash and collar etc. Please send me a message. My member name for leatherworker.net is: VLam

- 1 reply

-

- san francisco

- sf

-

(and 7 more)

Tagged with:

-

Just finished some workshop renovations, thought I would share before you can't see it for stuff all over. So this is what happened I got a new surface plate for tooling so new bench for that, which led to new bench for punching and general stuff, which led to new cutting table and light box, which meant rearrangement of sewing machines and stuff. The wife says that she can't remember it ever being clean with nothing on the benches. I have to agree I seems weird looking, but that will change soon.

-

Entire Leather Workshop Must Go. If you live near South Florida (BROWARD COUNTY) and are looking to open or equip your shop, I've can save you thousands! I made beautiful watch straps for Panerai, Rolex, Omegas, etc. and sold them through my Etsy boutique for years, but every hobby must come to an end and this one has run its course for me. I was able to make 300-400 a week doing these straps at night, but it has taken a toll on my family life and now its got to stop. If you are looking to get into or have just gotten into leather work or making leather watch straps, and are looking to take it to the next level... this is the post for you. I have here: -Consew 206RB-5 Leather Sewing Machine (setup specifically for leather work -new table, -new servo motor, -new reducer pully system installed (sews nice and slow for those tight corners), -new rolling glide, -nice small width FLAT BOTTOM walking feet (perfect for leather work), -tons of bobbins.) -Solid Steel Manual Leather Press (for punching) -Solid Wood Stitch Pony (with leather cover) for hand saddle stitching your work -OLFA Cutting Pad -OLFA Rotary Blade and 6 extra new blades -Elfikta Leather Tool Grinder and Edge Smoother (motor powered) -A bunch of custom Plexiglass laser cut leather strap templates - 5 sets of custom made clicker dies for leather watch straps (mostly panerai sizes, 26mm straight, 26/24 taper, 26/22 taper, 24/22 taper, 24 straight.) Must be used with press (listed above) -Solid wood leather tool holder/organizer -Every leather tool imaginable! Just to name a few: Various hammers, leather roller, edge trimmer, edge groove maker, edge burner, Vergez Blanchard solid steel Scratch Compass, heated edge creaser, stitching chisels of different sizes, high quality rotary hole punch, edge paint roller, and much more! -Tons of thread colors, both for the machine stitch and for hand stitch available -Tons of products, high quality and expensive edge stains, water based adhesives, etc. -Also have tons of Horween leather and different exotic leathers to go through if you wish!! -I EVEN HAVE TONS OF GIFT BOXES FOR THE STRAPS, EMPTY READY TO SHIP!!! Contact me via email to make appointment to see: punchapp@gmail.com I I

- 12 replies

-

- watch straps

- workshop

-

(and 4 more)

Tagged with:

-

Here are some pictures of my workshop after I re-arranged it. I needed to re-arrange it and utilize the whole shop due to the increase in business. Let's see some picture of your shops and workbenches. I've seen some forums on there that have workshop and workbench pictures but none of them appear to be recent so I would like to see some of your shops and workbenches to help me utilize my space more efficiently. Thank You!

- 29 replies

-

Here is a video of my work area... I picked up a new camera (GoPro 3 White) and decided I'd try and make some videos of my leatherwork. I am just a beginner, however, I have learned so much from other people (of all skill levels) posting videos that I figured that maybe someone could benefit from my little knowledge or, from my mistakes... I'm new to making vids and new to the GoPro as well so I hope you don't get sea-sick watching! All comments are welcome. (I have thick skin as well as the ability to ignore any non constructive comments.) (Click on the word "video" above to link to YouTube.) Thanks!

-

From the album: A few of my latest...

My workshop area as it is today, with my shop 'supervisor' doin' a photobomb at my cutting table. -

We are very excited to bring the age-old craft of leatherworking to NextFab. This introductory workshop will expose participants to a variety of basic leatherworking tools and techniques and give them a solid base for further exploration of this craft. The first session of this workshop will primarily deal with leather preparation, tooling, lacing, and finishing through brief lectures and demonstrations. In the second session partcipants will be able to choose and complete one of two leather projects from start to finish and take home what they create. Participants in this workshop will learn a variety of techniques including: pattern transfer, pattern carving and pattern stamping. After the demo portion of the class, class members will have the opportunity to try their hand at carving, stamping, stitching, and finishing by completing either a traditional coin purse or money clip project. The coin purse project features a simple yet classic flower design on the back of the piece that will be brought to life with the carving and stamping techniques learned in class. It also features a traditional whip-stitch patten around the perimeter of the piece and a custom monogram on the front of the piece. All in all, students who choose this project will walk away from the workshop with a personalized, stylish, and fully functional coin purse that securely snaps closed to keep coins in place. The money clip project features a more complex vine and flower design on the front of the piece that will have quite a bit of depth and visual interest after carving and stamping. In addition, this project calls for a classic straight stitch around the perimeter of the piece. All in all, students who choose this project will walk away from the workshop with an attractive money clip that utilizes magnets to keep bills secure. This workshop will run 3-4 hours in total. The first hour will be dedicated to discussing the carving and stamping tools included in the leather working kits with short follow-along demos. The following 2-3 hours will be dedicated to completing one of the featured projects. When the workshop is complete, students will get to keep their leather working kits from the class, and will have the opportunity to complete 3 other projects included in the kit at home. Purchase tickets HERE.

-

hi looking for leather carver in the UK willing to give lessons - basics already known, want to progress further - thks

-

Interested in making your own tough and beautiful bridle leather belt? Peter Grove (from Tundra Leather, in Hamilton, Ontario) is instructing a Belt Making Workshop, at Needlework Fabric Shop (Hamilton, Ontario), on June 4th, 2013. Time: 6-9pm. Cost: $65+tax. See the link below to register for this great workshop!! http://iloveneedlework.com/class/leather-belt/ If you have any further questions, please don't hesitate to contact Needlework: Phone: 905-667-5663 Email: hello@iloveneedlework.com Website: http://iloveneedlework.com Or contact Tundra Leather: Phone: 905-527-7745 Email: info@tundraleather.ca Website: http://www.tundraleather.ca

-

- leather

- bridle leather

- (and 5 more)

-

From the album: Workshop Tools

I purchased this leather horse in the late 1970s in Montana when it was already an antique. 35 years later, it is still in use!© Jeannie's Jems

- 1 comment

-

- leather horse

- stitching pony

-

(and 2 more)

Tagged with:

-

From the album: Workshop Tools

I purchased this leather horse in the late 1970s in Montana when it was already an antique. 35 years later, it is still in use! Notice the pock marks where it was obviously used for punching with an awl and the one especially deep hole.© Jeannie's Jems

-

- leather horse

- stitching pony

-

(and 2 more)

Tagged with:

-

From the album: Workshop Tools

I purchased this leather horse in the late 1970s in Montana when it was already an antique. 35 years later, it is still in use!© Jeannie's Jems

-

- leather horse

- stitching pony

-

(and 2 more)

Tagged with:

-

From the album: Workshop Tools

I purchased this leather horse in the late 1970s in Montana when it was already an antique. 35 years later, it is still in use!© Jeannie's Jems

-

- leather horse

- stitching pony

-

(and 2 more)

Tagged with: