All Activity

- Past hour

-

How do I paint or draw on leather (waterproofed leather)

chuck123wapati replied to c.c.1315's topic in How Do I Do That?

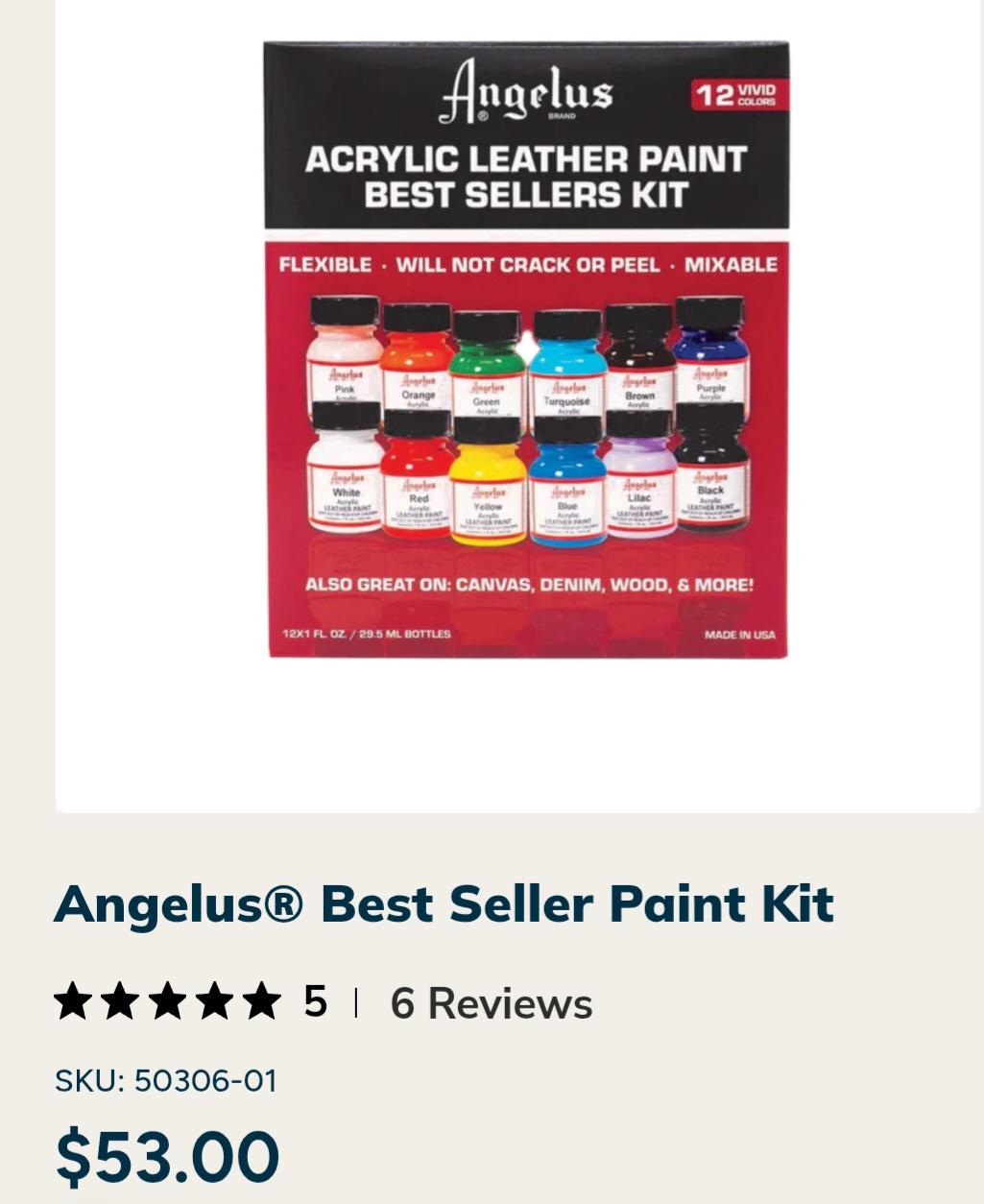

if you've already waterproofed them, then paint probably won't stick. They will have to draw or paint them, then waterproof them, regardless. I use decent artist's acrylic(that's what I have) for my leather work that needs painting, but any acrylic paint will work; it doesn't have to be specific to leather. I'm sure markers would work; never tried them, but a quick test on some scrap would tell you. -

spring flowers and good food

chuck123wapati replied to chuck123wapati's topic in All About Us and Off Topic

Yeah, giving you your own money back and then holding your head under water for getting it back. Don't do it, you don't need to; it just takes some time. I don't know how big your community is, but if it has a good local shopping economy, then you will get recognized and trusted before long and have plenty to do. I have a small garage and am constantly tinkering, building, forging, or just farting around with the door open. I will wave at folks who drive by regularly and they will eventually stop just to see what I'm doing lol, then usually leather comes up in the conversation, and a friend is made at the same time, who tells another friend... Anyway, I figure I have about two years to learn how to put a new heel on these boots. Then I can be the local cobbler, lol, you could be too, it can't be that hard. I'm going with mocs or huarache sandals indoors and for leisure. I'm so done with the Chinese crap footwear. -

How do I paint or draw on leather (waterproofed leather)

DieselTech replied to c.c.1315's topic in How Do I Do That?

-

spring flowers and good food

chuck123wapati replied to chuck123wapati's topic in All About Us and Off Topic

A new hat is a nice treat and supports your fellow countrymen for sure, that's hard to do but needs to be done. I have always been a baseball cap kinda guy, but last spring I bought a nice full-brim canvas job, kind of Aussie outback style, and I'm getting used to it finally. It's funny how you don't know how close your head gets to things until you wear a full-brim hat. I also have a nice black felt Cattlemans style that I turned into a gus style with the wife's steam kettle, but I don't wear it much. My dad was a real cowboy, and my mom was a real cowgirl. I've ridden a bit, stacked a few bales, winter fed cattle, and branded and such but not enough to call myself a true cowboy IMO. So I feel funny, and like I don't deserve to wear a cowboy hat, and I really have no idea why. Clean up that old hat a bit, not much, maybe sew in a new band and some youngster who has never done a day's work under a hat will buy it for the price of a new hat just so he looks like maybe he did lol. - Today

-

A couple of months back . . . had a fellow need a new belt . . . his older one had seen better days. Simple project . . . grabbed a Script font from MSWord . . . wrote his name out . . . on the computer . . . did a screen shot . . . turned it into a *.jpg . . . picked it up with Laser GRBL . . . plotted in on my little 50 dollar laser engraver . . . did a "guesstament" as to the settings . . . darned if it didn't turn out just hunky dory. Laid his belt onto my engraver's table . . . did a couple of test runs for position . . . turned my little laser loose . . . and about 6 or 8 minutes later . . . took the finished project off the table . . . wiped it down with a paper towel . . . dyed and finished the belt. He was happier than a broke out jailbird . . . May God bless, Dwight

-

@Bunb You're welcome to place a proper For Sale ad in our For Sale section: https://leatherworker.net/forum/forum/82-machinery-sewing-and-stitching/ Please review the rules linked below and comply so we don't have to chase you down for further information. They're linked here: https://leatherworker.net/forum/forum/71-items-for-sale/ We're basically looking for a decent description, statement of condition, pictures, location, price and shipping info. We'd all hate to see a sewing machine go to waste. Good luck with it!

-

photonashville joined the community

-

Couple of recent builds off the bench

Hags replied to Hildebrand's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Very nice! I've been wanting to make a case for my old speed 6. -

c.c.1315 joined the community

- Yesterday

-

Source for 12-14 oz quality belt blanks

DieselTech replied to wizard of tragacanth's topic in Suppliers

Buckleguy has Wickett&Craig belt blanks in 10-12oz. -

Tape Measure Carrier

Dwight replied to Hildebrand's topic in Gun Holsters, Rifle Slings and Knife Sheathes

If you saw the right front pocket of most of my work britches . . . you would not wonder why I don't have one. May God bless, Dwight -

Try these folks. They may have what your looking for... https://makersleathersupply.com/collections/leather-by-hermann-oak

-

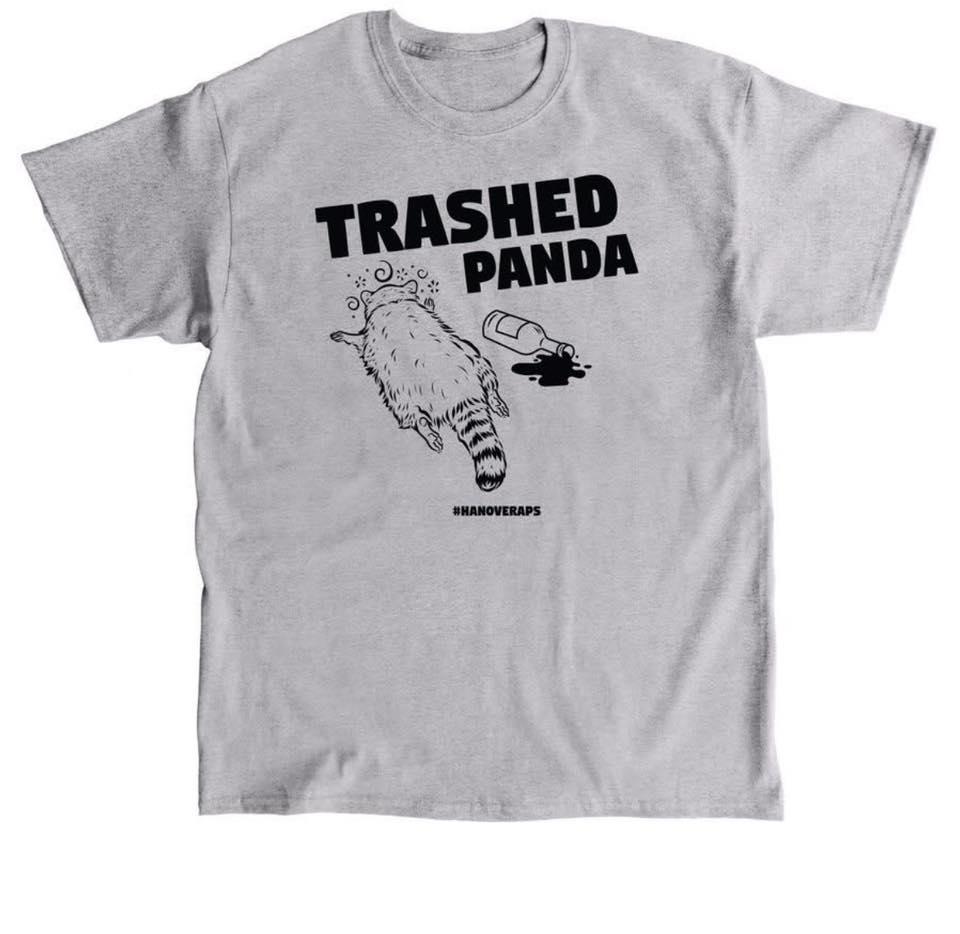

A local wildlife rescue, the Hanover Humane Society, has made T-shirts, and is selling them to raise money!

-

Tape Measure Carrier

chuck123wapati replied to Hildebrand's topic in Gun Holsters, Rifle Slings and Knife Sheathes

And they are ul listed lol. Great idea. -

HS, I saw the article about that on FB today! The whisky brand that the racoon drank is using the event as an advertisement! Unfortunately, I can no longer find that link, but here's a video from Fox News:

-

To start off. i) Which clone?? ii) What are you trying to sew, Fabric or Leather and how thick? If the machine has a walking foot then the simple answer is a roller foot will Not work. Can you give a little more explanation of your curve / turning woes. A couple of photo's of your setup would help considerably. Also what thread and needle combo are you using??? kgg

-

I usually carry a knife and leather man combination when I am working outside or camping/hunting/etc. I have 2 sets one stays on the work pants the other moves depending on what I am doing. Both needed new leather so I took the leather man pattern from the Leather Crafters Journal and modified it to hold both. The scabbard is to carry a single shot pistol in a backpack, you could also carry it on a saddle but I don't have any stock so backpack only. The zipper keeps it pretty weather tight. It is based on the scabbard build in The Art of Making Leather Cases. Todd

-

Fergettit! Walking foot machines are not candidates for conversion to a roller foot. That is pretty much limited to straight stitch machines that have a single foot and bar coming down. Yours is a walking foot machine with two bars to deal with. The first obstacle will be finding a roller foot mounting bracket that will fit into the slot in the center of the presser bar. Most of them are designed to attach to the outside of a round presser bar that may or may not have a flat edge on the left side. The inside foot would have to be removed. Lastly, the feed dog is centered under the inside foot. A roller foot usually sits out on the left of the feed dog. If the roller is too far from the feed dog, it may not be able to feed the leather without the bottom assist. Your only drive would be the moving needle. You are better off buying a straight stitch machine to convert to a roller foot. A large roller has smoother operation and is good for most edge sewing. A smaller wheel is better for sewing designs, or intricate stitching. If you are able to find a roller foot that does fit into the back presser bar, keep the edge of the roller as close to the needle as possible. This will keep the leather from lifting with the ascending needle. The greater the distance from the bottom of the roller to the left side of the needle, the greater the likelihood that you'll get skipped stitches from lifting leather.

-

This topic comes up frequently where to buy the metal portion of the clip to hold the tape measure. I made a holder recently, this one has a pencil pouch also, and decided to try just getting a conduit clip with 2 holes in it and bending it into the right shape. It worked great, they are cheap and easy to bend with just 2 pairs of pliers, I was ready to put it in the vice but they are really pretty soft metal. Todd

-

Bunb joined the community

-

I have a similar machine I’m selling trying not to scrap it

-

CI have a Juki clone machine with basic walking foot set up. I watch too much you tube and I keep seeing people using a roller foot on leather projects. One area I really struggle with is curves and turns on my machine. I have a servo motor and changed pully which slowed it down considerably but I still am terrible on corners and turns. What would be the pros and cons of switching to a roller foot and then small or large roller? Thanks in advance.

-

If it were my project, I may not clean the medallion at all but if I did, I would try a step-by-step solution. First would try dish soap and water with a toothbrush. That may be enough to keep the "heritage" look but not look so rough. If I wanted to go further, I would try to hit just the high-spots using toothpaste (a mild abrasive) on a layer of cotton cloth in my palm and using my other hand to work the medallion around without pressing too hard. This would highlight the letters and the edges of the medallion while leaving darker areas around the lettering and make US stand out. If that wasn't enough, then use buffing compound on a wheel. Nick