All Activity

- Today

-

my bad - my feed dog is from a 104-64 - sorry. Anyway, your looks normal to me.

-

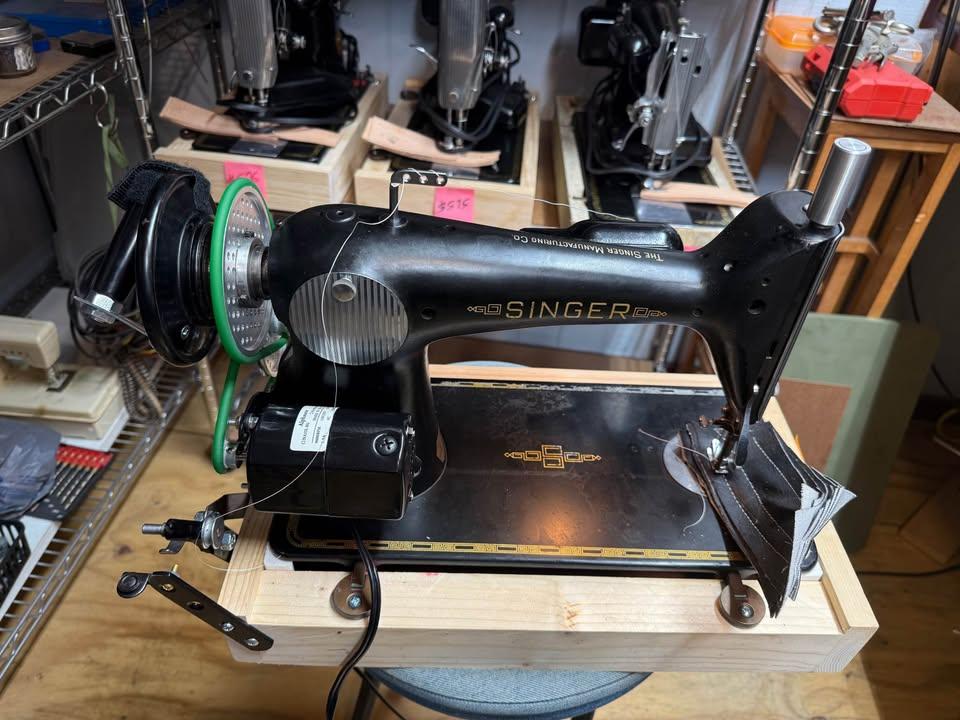

Option E: Domestic Sewing Machine Motor See the parent article: Choosing a Motor A domestic sewing machine motor is a small, compact universal motor that is typically used on domestic sewing machines. 1. What is a Domestic Sewing Machine In this case, “domestic” means “for home use”. But you can think of it as a “dainty” sewing machine. That is, often used for sewing thin materials together with skinny needles, TEX 20 - TEX 70 thread. On this photo you see a common configuration, with the motor mounted directly to the body of the machine. 2. What is a Universal Motor In a nutshell: it’s a motor that can run on AC or DC voltage, and whose speed and torque can be varied together by varying the input voltage. See this page on wikipedia: https://en.wikipedia.org/wiki/Universal_motor Note universal motors always have brushes. Typical universal motors seen on domestic sewing machines draw 1-amp @ 115 volts (or ½ amp at 230 volts), and have a maximum speed of 5000 - 7000 rpm. Some are a little beefier. 3. What Kind of Speed Controller A domestic sewing machine motor typically comes with a foot pedal that has a built-in variable speed controller. Some use a “carbon pile”, meaning a pile of about 50 carbon discs, and when a spring pushes them tighter together, more current flows through them. Carbon piles do get warm in use. Others use a TRIAC speed control. See this page on wikipedia: https://en.wikipedia.org/wiki/TRIAC#Application You can usually replace the foot pedal (speed controller) separately from the motor. So if your foot pedal does not provide a good linear response, try a different one. 4. Is a Domestic Sewing Machine Motor the right Motor for me? Domestic sewing machine motors are a compact, inexpensive alternative for powering your industrial sewing machine. They are intuitive to drive. They will excel in situations where not a lot of torque is required. So pretty much any non-walking foot sewing machine could be a good candidate for a domestic motor, especially if you gear it down. 5. How to Gear Down You can improve the pedal response of a domestic sewing machine motor by gearing it down. This gives the machine better low-end response so it won’t bog when crossing thick material at low speed. The motor pulley that comes with a domestic sewing machine motor usually fits well with 5mm polyurethane “PU” belt, which can be cut to length and hot-fused. You can put an oversize handwheel pulley, see examples: https://leatherworker.net/forum/topic/132445-domestic-motors/ More info on making wooden pulleys: https://preciousww.com/making-big-v-belt-pulleys-from-plywood/ Or you can add an intermediate gear reducer, see example: https://leatherworker.net/forum/topic/132447-glove-sewing-machine-advice/#findComment-789023

-

That's a nice first piece. Stay with it and have fun practicing. Keep your first piece so you can compare later on. My first one has disappeared over the years but I still have the second. It's good to go back and look at it now and then.

-

Well, you can still post to it, but I'd recommend starting a new thread with what you know and what you'd like to know. Pictures always draw attention. It might be interesting to have a thread dedicated to your grandfather.

-

Mine had the oval hole. I raised it all the way up when I was sewing wear leathers on saddle blankets. otherwise - the teeth barely clearing the slot.

-

Great looking work.We have used the 1.5 amp 9000 rpm version of this motor on Singer 29 patchers in the past & they work pretty good.You have to use a stronger foot pedal with it as the motor will fry a standard pedal.

-

Internship and maybe a new start

Sheilajeanne replied to Tove09Tilda's topic in All About Us and Off Topic

As someone who has a science degree, and is very interested in it, it really burns me the number of times women have made really important scientific discoveries, only for men to take all the credit. The best known example is probably the discovery of how the DNA molecule is put together. It was a woman, Rosalind Franklin, who did the x-ray crystallography that revealed the molecule was actually a double helix. Yet scientists Watson and Crick were the ones who received all the credit. In a later edition of the book, The Double Helix, (published 1968) Watson confessed that Franklin did not receive the credit she deserved: Unfortunately, this was many years after Franklin's death from cancer in 1958. -

I have no authoritative answer on the question of lubricants. But I can say that lots and lots of people use kerosene for an initial clean down on sewing machines, followed by sewing machine oil. In the olden days of yore, people would put a quart of diesel fuel in their crankcase and run it a while before changing their oil. I, too, am deeply envious of such a find. Congratulations.

-

I would use kerosene in a spray bottle and a paint brush to clean it and remove all the old brown oil it will also help remove any old gummed up oil Numerous applications will be required . For stubborn grime soak a cloth in kerosene and wrap the cloth around the particular part over night and wipe off or work it with a brush the next day . Start from the top down . Keep in mind that kerosene stinks to high heaven for at least a week so do it outside and under cover . As for oil,a sewing machine white oil will do the job .I use a synthetic motor oil 5W-30W on my outsole stitcher and it seems to love it . you will also have to replace all the rubber belts because they deteriorate over time but they are easy to find in an auto parts shop. Please keep us posted on progress . I love to see an old machine come back to life .

-

creaturecheek joined the community

-

I got it moving. Now, after I get the WD-40 off everything. What type of lube should I use for this machine. I imagine that different parts need different type of lubricant. I keep finding info saying all kinds of stuff from regular sewing machine oil to ATF even kerosene and I'm not exactly sure what info to go with. If there is a consensus on this I'd welcome the info. Thanks PXL_20251209_021619880.mp4

-

does not look worn, it is an oval hole because you can alter the feed doh height I think I have a feed dog to compare I´ll check later today.

-

Thanks for the tips on the hat clamp. A good fitting quality hat can't be beat. Make sure to have one steamed to fit your head by someone in a good hat shop. You can forget it's even on.

-

Hello, I used incorrect terminology when I said walking foot, I think the correct term is the feed dog, I believe that is worn out. I had a chance to mess with it some today. I’m not an expert with this but from what I can tell the screw hole on the dog is enlarged due to useage and I think the screw not being tightened. If I had a new one to compare it to I might know for sure. I was able to get it snugged up by using a cardboard shim and it appears to work. The screw is messed up from being torqued on repeatedly. I was just wanting to see if I could get it to work. I’m think it’s got promise, needs a good cleaning and the new parts. Thanks jonathan

-

How do I paint or draw on leather (waterproofed leather)

Dwight replied to c.c.1315's topic in How Do I Do That?

If you have someone who has a laser burner . . . the mittens could have a flat board pressed into them (to create a flat surface) . . . and if you could get it flat enough . . . and IF the person using the burner is good enough . . . he could just burn off enough of the waterproofing that you would have a rough surface for the paint to adhere to. The acrylic paint itself is waterproof . . . so you should work out good there. But the whole thing hinges on how good your laser burner buddy is . . . May God bless, Dwight -

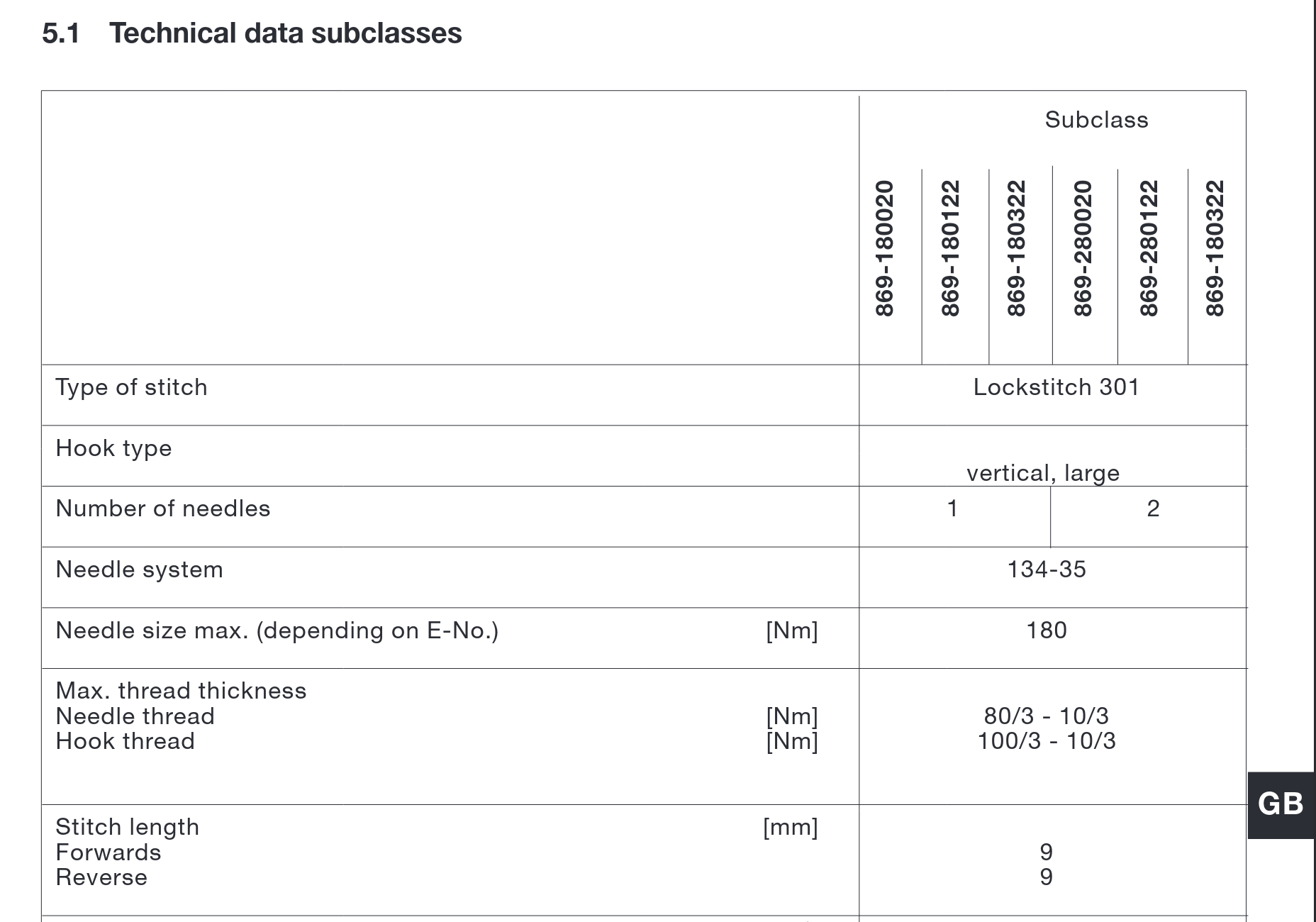

I'm not seeing reference to the "-M" part of the 869. Looking in this user manual: https://partner.duerkopp-adler.com/commons/download/public/869/B_869_DE_EN.pdf on page 89 (as viewed from the pdf reader), or page 9 (as viewed in print from the english section) it shows several subclasses and they are all specified with a max needle size of 180. Here is a screenshot: It also says "(depending on E-No.)" but I'm not seeing reference to "E-No" elsewhere in the manual. 🤷♀️

-

How do I paint or draw on leather (waterproofed leather)

c.c.1315 replied to c.c.1315's topic in How Do I Do That?

Thanks for your input everyone. I won't be making the mittens, just buying them, so I can't help that they are already waterproofed. It's a gift, so I'm hopeful I can get something that will work. -

That is an interesting mod.

-

Rob R joined the community

-

ChicagoJDH joined the community

-

Hi, everyone. I just stumbled upon this site yesterday. I have been trying to find out more about my grandfather's life in the Valley in the 1940s, 50s, and 60s. His name was Gene Hamrick, and I know he lived somewhere on the same property as the SF Valley Saddlery. He worked with horses but also tooled leather. Is this thread still active?

-

Good start, it looks like your leather was a little to dry when you were tooling, there are several good posts on here about casing leather for tooling. Keep practicing and in a month look back at this one and compare it to what you are doing then. Todd

-

Nice. That's a company you keep doing business with.

-

Looking forward to seeing pictures and videos of your solution! In the past I have 3d printed a motor pulley, but have not done the larger hand wheel pulleys. (My printer can print within a cube 180mm on a side) By the way, I took some of my inspiration from this slick item I found for sale on marketplace: https://www.facebook.com/marketplace/item/678066578496084/ That link will likely go stale soon so I'll post the pictures from the ad here for posterity.

- Yesterday

-

That looks like a serious upgrade to me. Nice job!

-

As a project for a relative, I made this replacement piece for his binocular Harness. The original is a rubber like material, and a little short for his longer torso. While it isn't perfect, I'm fairly happy with how it turned out.

-

when spending long hours training outside, I wore a cowboy hat. They are a surprisingly good hat to go sweat outside it. Shouldn't be surprising though. Somehow blocks out all the sky, without limiting vision.

-

Can you upload the user manual? That hopefully will show us how to set the start speed and the maximum speed. Also it may say what the absolute slowest the start speed can be set to. Once you know how slow the motor can go, you can do the math to figure out what pulleys will get you to your goal of 60 stitches per minute when the motor is at its slowest setting. As others have indicated, smaller motor pulley, larger handwheel pulley, and/or gear reducer in the middle are all options to get you to your goal speed. I also like what @nejcek74 said about a needle positioner giving you "as much time in between [stitches] as you want".