All Activity

- Today

-

BOOT TOE BOX REPAIR QUESTION

Drummist replied to Drummist's topic in Shoes, Boots, Sandals and Moccassins

Tozafoot - Thanks for that reply. I'll give it a try. I never thought to try hammering it flat so that just might work! I have this idea that some sort of product like Celastic or a glue of some sort, would help to "stiffen" the inside of the toe box to help it retain the shape after getting it smoothed out. Is this a bad idea? I also thought of using "Tuff-toe" on the exterior, but I'd hate the look of it. D -

I do like your idea of modifying a motor to give you what you would like particularly if you have a motor on hand. I modified what is called a variable speed buffer to do sanding and burnishing. I would be interested in seeing your end result.

-

Typical gc2605 conversion to non-binding machine

nejcek74 replied to TakashiOkada's topic in Leather Sewing Machines

If he is using Pfaff parts, maybe this is a copy of Pfaff 335? Which was often sold as a binding machine. Regarding 2-way (only horizontal) vs 4-way (horizontal and vertical) feed dog movement there was already written a lot about it on this forum. Conversion is possible but it's a mayor work because you need to connect the upper shaft with the lower one that moves the feed dog. You also need parts which are often more expensive than an used machine. My Pfaff 1245 has only 2-way feed dog and it works for me perfectly fine, but I am using it mostly for heavy fabric or combination of heavy fabric and leather. I guess certain, very fine surfaces could be scratched by a feed dog dragging back. -

Typical gc2605 conversion to non-binding machine

kgg replied to TakashiOkada's topic in Leather Sewing Machines

If to changed what appears to be a clutch motor on the used machine out for a servo motor which should cost about $200 the total cost would be about $600. That is of course assuming the used machine is in good working order and mechanically fit. If the machine does the stuff you would like to do then you would have saved $1300 which would go a long ways to other things like needles, thread, attachment, leather, etc. kgg -

Development of best servo motor for leather sewing machine

AlZilla replied to CowBoyOUTLAW's topic in Leather Sewing Machines

I don't know what that's called exactly but it's not what people mean when they say "Clutch Motor". It accomplishes something similar I've got a couple of those and some clutch motors. A clutch motor has something akin to an automobile clutch built right into the end of the unit. Here's Alexander Dyer talking about clutch motors: -

Jonah45 joined the community

-

The foot is held in place with a tapered pin same as the FAV and Fortuna machines. The 1mm washer was needed to allow the sliding lock in thing to position better for holding and angle adjustments.

-

That looks great. I need to make 1 similar, been thinking about buying me a Buck 112 automatic. I might do a bit of wet molding on that sheath/sleeve if I do end up with a Buck 112 auto.

-

They are fantastic , the cat especially. Incredible talent HS

-

Typical gc2605 conversion to non-binding machine

friquant replied to TakashiOkada's topic in Leather Sewing Machines

Jianglong makes a 246 also. (I have the Jianglong 341) You might see what it would cost: https://www.alibaba.com/product-detail/246-Maquina-De-Coser-Cuero-Cylinder_60469774160.html -

Typical gc2605 conversion to non-binding machine

TakashiOkada replied to TakashiOkada's topic in Leather Sewing Machines

okay I'm watching a video from the same guy and the 2603's feed dog has a circular motion, 2605's feed dog only goes forward and backwards. so there's a huge difference after all. I think it's some sort of clone of the 246? I'm strongly considering asking my local dealer to get me this 2603 instead of the 341. I bet it's cheaper, too. -

Typical gc2605 conversion to non-binding machine

TakashiOkada replied to TakashiOkada's topic in Leather Sewing Machines

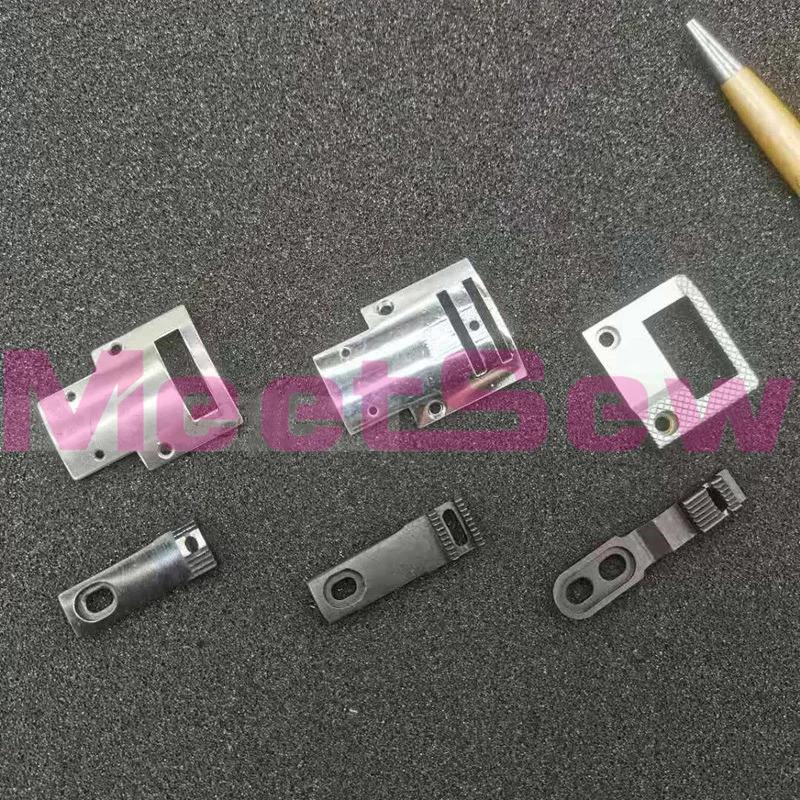

1 - oh so the feed dog and throat plate DO work for that machine, interesting. I think he said they are parts for a pfaff machine? 2 - that's smart. I could design and make a cover plate with acrylic and a laser cutter. 3 - agree TBH today I learned something new, thanks. the translation was a bit rough but it was better than nothing -

Did that yesterday. Made a pocket sleeve for a Buck 301 size knife, a Case 6375 will fit with 1/8 inch exposed. A clip was added to keep the knife in a vertical positio in your front pocket.

-

Nikknik joined the community

-

Typical gc2605 conversion to non-binding machine

AlZilla replied to TakashiOkada's topic in Leather Sewing Machines

Turn Closed Captions on, go to settings and tell it to "Auto Translate" to whatever language you wish. -

Typical gc2605 conversion to non-binding machine

friquant replied to TakashiOkada's topic in Leather Sewing Machines

Three interesting points from that video: The feed dog on the binding machine that he bought has no vertical movement. He wanted to convert it to being a standard machine. It appears that he bought a new feed dog and throat plate for it. In general it works as a standard machine, but the feed dog only goes forward and back. (No vertical movement) He made his own cover plate to replace the binding cover plate that it came with. (The long metal plate that's about 250mm x 30mm that he mentions about 6:55 into the video) He abosolutely loves his swing-down edge guide 😀 -

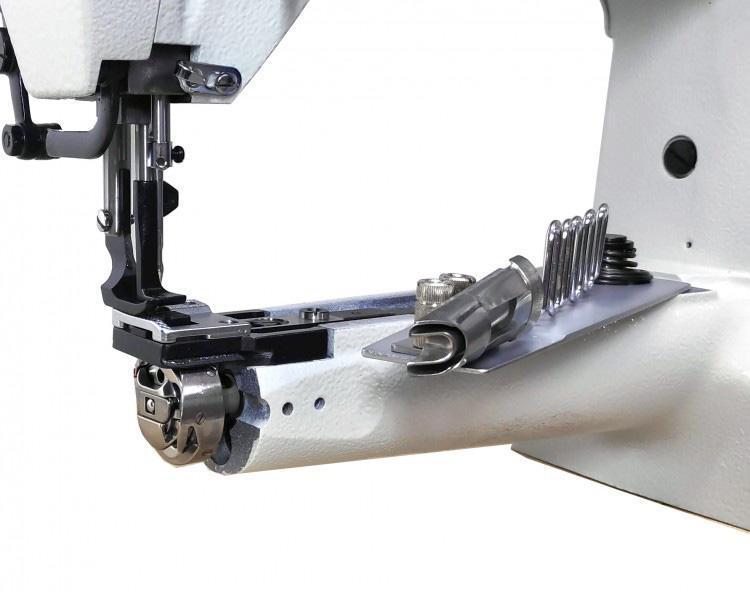

hello, it's me again. I was about to buy the typical 341 you guys recommended to me for 1900$ but then I found an interesting triple feed binding machine in the used market for 400$. it's a typical gc2605. this is the picture of the actual machine for sale, it even has the half table and all! there's a similar model, it's the typical gc2603, which has normal throat plate more suitable for general leather sewing. apparently it's the same machine but with different plates, picture below. the end of both arms seem a bit different. these are the plates for each model. screw holes don't seem to match more pics from the internet for reference according to this picture, both 2603 and 2605 are essentially the same machine? this is a video of a guy with a gc2605 speaking russian (i think) and he's saying something while holding the plate I want to put in the gc2605. can anyone who speaks russian tell me what he's saying?

-

Anyone taken a cheap servo motor apart?

dikman replied to AlZilla's topic in Leather Sewing Machines

Definitely pull it apart, we're all interested now to see what the problem is! - Yesterday

-

BOOT TOE BOX REPAIR QUESTION

tozafoot replied to Drummist's topic in Shoes, Boots, Sandals and Moccassins

I have used a small marble pestle to push out slightly dented toe boxes: can hold the pestle in place with one hand and hit the outside of the toe shape lightly with a small hammer (peen) to smooth out creases in the leather. Not sure about using heat to restore shape: I guess it depends what was used to make the rigid toe shape in the first place. When I make footwear with toe boxes, I soak veg-tan cowhide (~5oz) for several hours before pulling it into place on the last and nailing it on. No heat involved at all, only water, -

Hi, sorry for the late reply's. Thank you for the link, that was certainly cheap. That shape of roller is much better than the long one that followed my machine, much easier to adjust. Mine doesn't equals the shape of the stone roller anymore. I may customize it, cutting away half but the bearing needs to be replaced as well. I will order the one you have but is the hole tapered as on Italian machines (like on mine Alpha SM, FAV etc.) looks like you got a gap there, material thickness different maybe? Thanks Tor

-

Deanobambino joined the community

-

halt joined the community

-

Hey wyatt hereI've been tryingto find suppliers in canada for making some woolie chaps.thanks in advance.

-

Thanks, I already have the foot that Tom E shared a link about. But it has been worn a bit by previous owner, it came with my machine that I bought used many years ago. I guess I can make a new roller for it on my lathe. The roller profile do not longer match the profile of the feed wheel... difficult to adjust for splitting use. The minimalistic guide for turns and stiffer leather makes most skiving tasks in soft leather difficult. I really miss a decent guide. Thanks Tor

-

Thank You, I already have that roller foot that came with my Italian machine. Do Randall have this guide as well? The Italians are notorious difficult to deal with. Even if I'm much closer to Italy, I prefer dealing with USA. Now before Trump's tax are in play. Thanks Tor

-

SunStar KM-380 BL-B cylinder arm consistently leaking oil

kgg replied to Esket's topic in Leather Sewing Machines

The Sunstar KM-380 BL-B can take a max needle size of a #23 needle which basically means you can use a max size thread of V138 ( Tex 135, M20 ) thread in thinner leather. Here is a link to the machines specifications. ( https://www.manualslib.com/manual/970676/Sunstar-Km-380bl.html?page=8#manual ) Here is a link for thread to needle size: ( https://www.tolindsewmach.com/thread-chart.html ) kgg- 12 replies

-

- cylinder arm

- sunstar

-

(and 3 more)

Tagged with: