All Activity

- Today

-

spring flowers and good food

Sheilajeanne replied to chuck123wapati's topic in All About Us and Off Topic

What a lovely gift, Darren! And glad to know we have another LOTR fan here! From the sound of it, Chuck, the pressure switch not working was causing condensation to back up in the drain, and that could be why the circuit board got damaged. Anyway, even if the second stage burner isn't kicking in, I'm still nice and toasty again. Another problem was although the furnace is only 3 years old, the AC system is ancient. The condenser coils were mucked up with dust, dirt and pet hair, and he said this was also causing back-pressure on the system. He took a brush to them, and that's when I started noticing the mouldy smell. Sooo, this is where things might get really expensive. The condenser coils may need replacing. And on an AC this old, that might not be possible. The AC is running on freon, which is no longer legal, and there will be a hefty environmental fee for disposing of it, in addition to the cost of a new system. I'm probably looking at $5,000 if that happens. But hey, AC season is quite a few months down the road still. Going to cross that bridge when we come to it! I miss the hot water radiator system our house had when I was a kid. I'm allergic to house dust, and every year when I have to turn the heat on, my allergies go nuts. I had the ducts cleaned when the new furnace was put in, but it didn't help at all. With the old rads, you didn't have that problem, plus they were a great place for drying wet socks and mitts! Older, simpler times... When I was really young, Dad had our furnace converted from coal to oil. I still remember the wooden partitions on the basement floor that held the coal after they shovelled it through a window in the furnace room. I also remember looking into the furnace and seeing the red fire of the burning coal. -

Fender repair...

Brokenolmarine replied to Brokenolmarine's topic in Saddle Identification, Restoration & Repair

I wasn't able to before but may have figured out a way to do it now. I was thinking it would be a good idea because she doesn't take the time to clean, so even glued, that screw might come loose. -

Nice work. They look great.

-

Fender repair...

Cattledude replied to Brokenolmarine's topic in Saddle Identification, Restoration & Repair

Please rivet the D on the flank cinch. If that comes loose there’s a good chance of getting bucked off… -

Not really my impression it is sorta a frankenstein clone of the Juki LS-1341 and Juki LS-1342. The Juki LS-1341 has a no vertical stroke (top knob near the handwheel) and has a wide guage throat plate where as the 1342 has a narrow throat plate. The Kolam 1341 has a wide guage throat plate and vertical stroke knob. With some of the "1341" clones they are using various thread bobbin baskets and some are using PFAFF. It appears to be their "house" brand clone. I could not find: i) any specs on this machine other then $3000 - $3250 USD depending on "style stand" which I assume means table style. ii) Thread/ needle capacity; servo motor size / type (brushless or brushed") , needle positioner or speed reducer. iii) whether they are using Juki compliant parts throughout. iv) is there a table top attachment available v) other then it "comes with a warranty" I could not find what and how long the warranty is good for. Keep in mind some clones spec the thread capacity on what can be stuffed through the max size needle that will fit in the needle bar where Juki rates their machine on what max thread can be used at max rated sewing capacity and there is a difference. Personally I think if you need more sewing capacity (thread size or item thickness) then a LS-341 or clone you need to move to a Class 441 machine (Juki TSC-441 or clone). However it all comes down to what you want/need/desire to sew with what size of thread and how deep your pocket book is. What are you planning on sewing with what size of thread??? kgg

-

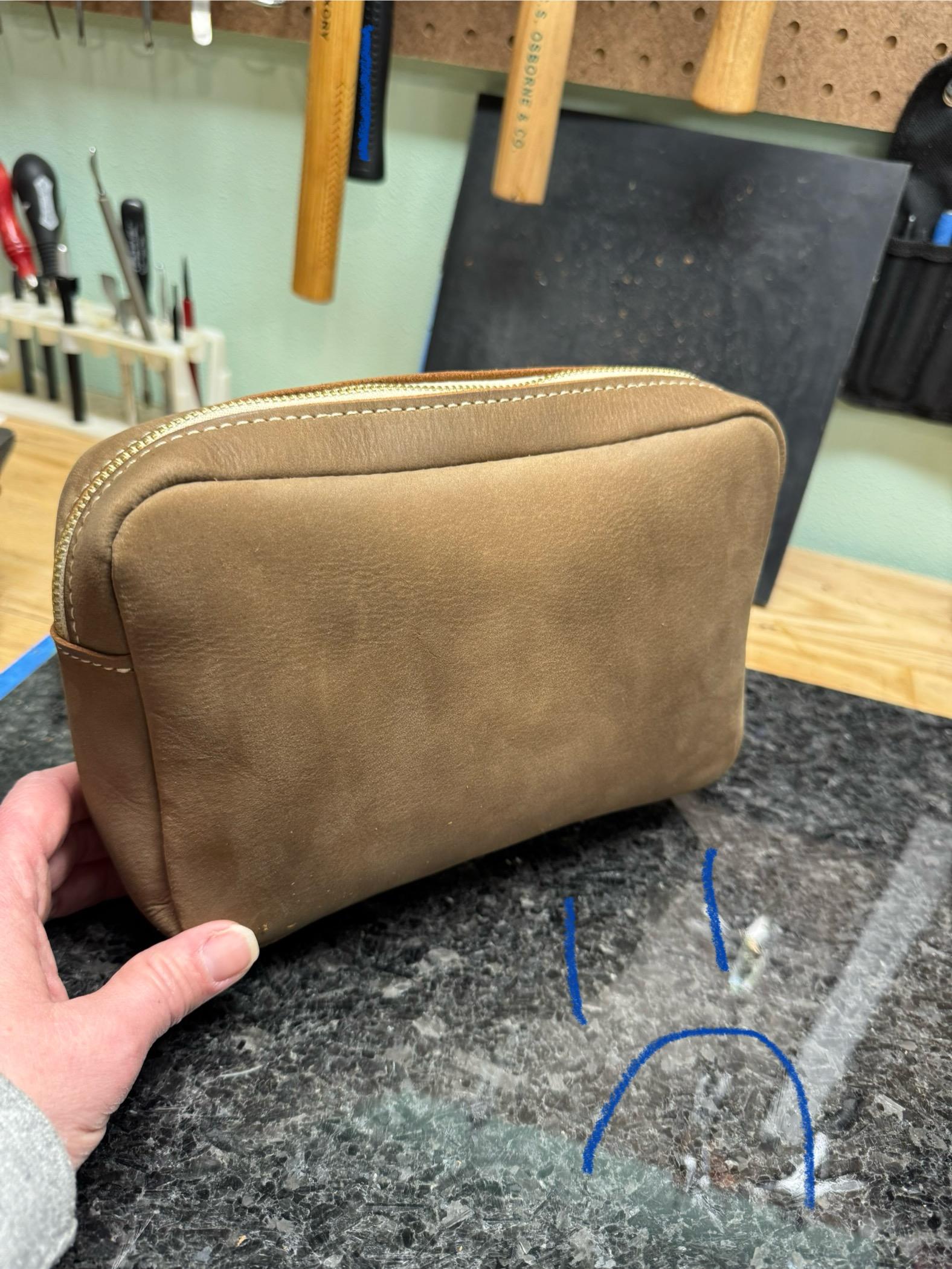

Here’s another pic of a different bag I did in veg tanned leather with the same “flipped up” zipper gusset

-

Hey Everybody! I was wondering if anyone has some tips out there…I’m starting to get into making zippered purses/bags and I’m trying to troubleshoot how to keep the zippered Gusset part flat versus “flipping up” (nothing like being flipped off from your gusset…lol). I have been skiving my edges about .5” in to 3oz thickness, sew at 1/4” seam line, cut excess off and hammer the crease, but flip up it still goes. I’ve used both veg tanned and oil tanned and have the same outcome. Any tips on how to keep it more flat? Thank you!

-

Picked up an older singer machine, got it up and running and used it to make some booties for a friend. Wish I had used a softer leather, getting them inside out was painfull. But I think they turned out okay. Made with 2ozish veg tan.

- Yesterday

-

Hi guys, I'm hoping you can help me decide on what machine / dealer would be best for my circumstance and location. I'm in upstate NY and not too far from Joey Leather Machines in East Berlin, Pa. It looks like he's is caring a Kolam 1341 starting at $3,000 which I imagine is a clone of the Juki 1341. Or I could pay the shipping from Leather Machine Co and get the Cobra 26 for around the same price I imagine. (though I haven't actually checked shipping rates). My other next closest option would be getting a Cowboy cb341 from Toledo Industrial Sewing Machines which I think is somewhere around $2700 right now. Would there be any reason to get the Cobra 26 over the cb341 especially considering that I travel to the Toledo area regularly to see family? The Kolam 1341 would be based off a newer model machine and Joey is closer to me than Toledo Industrial / Leather Machine Co. My main concern with the 1341 is cost and availability of parts in comparison to the older 341 style machines. What have your all's experience been with maintaining and procuring parts for 1341 style machines vs the 341 models? Looking forward to your comments,

-

Helps to evaluate leather thickness in places that a thickness gauge can't reach.

-

Left handed Shoemakers insole/channel knife made by Tina of Germany. Sells new for $219.00 I am selling new out of box for $175.00 plus shipping New TEKTON TOOLS Nipper/Tack puller Made in USA $20.00 plus shipping NEW - LASTING PLIERS $40.00 plus shipping NEW - BRASS SMOOTHING TOOL. Used for smoothing leather toe area of shoes and heel area. I paid good money for this tool. $25.00 plus shipping More later

-

The doctor told me last week I'd have to cut down on my drinking. Only one glass of whiskey per week So far I'm up to the third week of August 2217

-

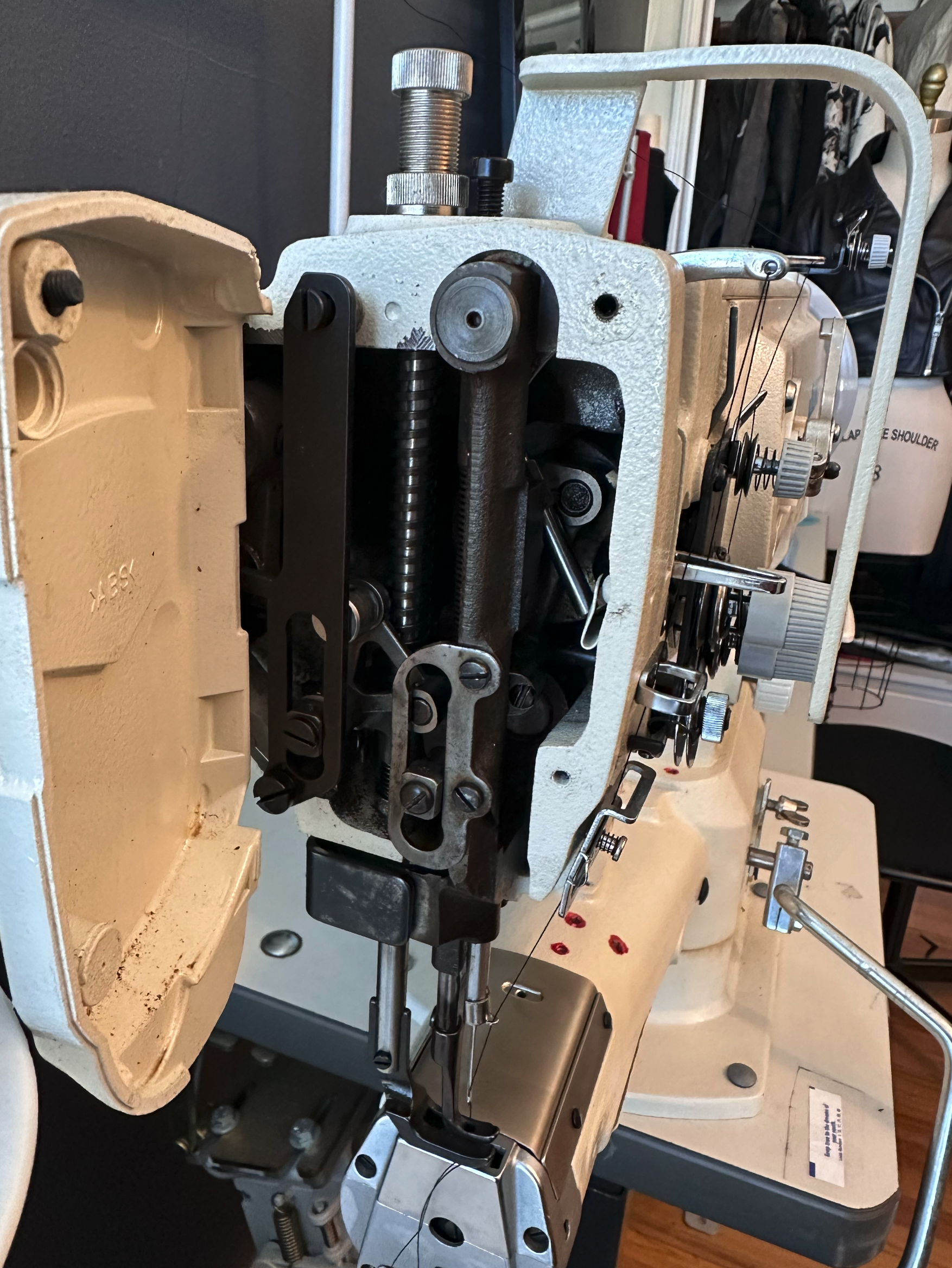

Juki LS1341 - presser foot adjustment

nylonRigging replied to MackProvisions's topic in Leather Sewing Machines

I would imagine that it same as 1541 . there an access plate on backside that you have to get to a screw . It little hidden and you have to look Upward to see it. You have to lift UP the manual press-foot lever to even see and have access to the screw . You also have to make the foot height adjustments with presser-foot lever locked Up position with loosening and then re-tightening the screw . - - - -

I was bitten by a wolf today I had to go to the hospital for treatment The nurse asked me 'Where' I said 'No, just the usual ordinary type'

-

Adam N. joined the community

-

Dale Webb joined the community

-

Pretty slick

-

Used Juki LS 1341. Recently serviced and in good working condition. Originally purchased used but I haven't put it to much use. I believe it is equipped with a speed reducer/smaller pulley (forgive me I don't know too much about these). It can sew very slow, controlled stitches. Selling because it's too heavy duty for my needs. I'm hoping to replace it with a post bed machine instead. Asking $2000 obo for head/table/motor. Pick up in Long Beach CA, or can possibly meet somewhere in LA.

-

As I wandering the lanes of Scotland I heard a farmer shouting I think he was a Rolling Stones fan but he got some of the words wrong He was shouting ' Hey M'Cloud get offa ma you'

-

I'd skive and roll the edge (at least on the 'outside' of the panels), but using contact adhesive. Basting tape will be a pain to stitch through (and also to stick down in curves) and can damage your thread. Notching would depend on the radius and thickness of the (skived) leather; do a test on a bit of scrap first. You can also go for slightly rougher look by skiving the edges of the leather tape really thin and leaving them as-as. And finally you could go for a 'coupé net' where you don't add any leather tape on the edges of the bag panels and seal them with edge paint.

-

Fender repair...

Brokenolmarine replied to Brokenolmarine's topic in Saddle Identification, Restoration & Repair

I also needed to repair the Belly Band, (or whatever it's actually called.) The owner didn't keep the leather clean, it was covered in sweat, dirt, and oils. I cleaned it with saddle soap and a toothbrush. My repair was to replace the broken loop that held a D-ring. Miss T was going to cut back the stitching so I could remove the rivet and the old loop, then replace them. Then I would saddle stitch the removed stitching. She took the band into her shop, pulled about 1-1/2" of stitches and discovered they had glued the two panels together. So I cut a square into the back of the band, and drilled out the rivet. The loop was glued into place as well. I cut out as much of the old loop as possible and made a new loop, and put it on with a chicago screw. Worked well. A closeup of the new loop. Unlike the pics of the fenders, this piece hasn't been treated with Mink Oil yet. I also made new laces so she could wrap the fenders near the blevins like she prefers. I wasn't going to try and recreate that. The project is pretty much done at this point. I'll be back to sheaths and holsters, a belt now and then. -

Fender repair...

Brokenolmarine replied to Brokenolmarine's topic in Saddle Identification, Restoration & Repair

Wow, been away from the topic for a while. Weather. We had ten days of snow and ice and because of my physical challenges the wife won't let me out to go to the shop when the footing is challenging. Thirty surgeries so far and don't need thirty one. LOL. The weather finally turned decent and I was able to get back out and finish the work. I was also waiting for hardware. I had ordered rivets and burrs, but the first set that came in were too short at 1/2", I reordered 1" rivets, and Springfield is a great company, but slow. It took a week. I also ordered more Mink Oil, it was a lot faster coming from Amazon, two days. No matter, stuck in the house ten days. The view of the Fender Assembly from the rear: I didn't remake the stirrup straps, the owner didn't ask for them. I reused the blevins for the same reason. But, everything went together well. The shape of the back pieces is by design, she will curl them and lace them to keep them curled. The view from the front.... For a first attempt, I was happy with the result. My daughter sent her friend pictures and got back a one word reply. "Wow!" I guess she was happy, that's all that matters. -

Juki LS1341 - presser foot adjustment

kgg replied to MackProvisions's topic in Leather Sewing Machines

As a note the difference between a 1341 and 341 is minimal. You probably don't have the manuals for your machine so here a some that will be helpful as well as a needle size to thread size chart link ( https://www.tolindsewmach.com/thread-chart.html ) : kgg Juki LS-1340&42 Servcie Manual.pdf Juki_LS-341N_Engineers_Manual.pdf Juki_LS-341N_Instruction_Manual.pdf -

using glue with leather

stampingdelight replied to stampingdelight's topic in Leatherwork Conversation

@Hags @Handstitched @fredk thanks so much -

does anyone use outside spring calipers/inside spring calipers in leather working or even other tools like those besides wing dividers? if so what is best way to use them?

-

A. short finger nails are a must or latev/rubber gloves to cover them b. run a groover between all the stitching holes before you stitch edit to add; c. dilute any dye you may use and use multiple coats to get the desired colour or finish d. wet the leather before putting on the dye. not soaking dripping wet, just sponge some clean water on .this helps the dye spread thru the leather