All Activity

- Past hour

-

spring flowers and good food

chuck123wapati replied to chuck123wapati's topic in All About Us and Off Topic

I can now make a moccasin. I tried to make my own pattern a couple of years ago and failed miserably, as you can see, they worked but not much more lol. So this time I used a pattern pack from Tandy, "Mountain Man Moccasin Patterns by Gene Noland". I used pattern number three, decided to make it exactly as the pattern, and it was a failure, too. The leather tore out, and the stitching holes were so far apart they looked like crap. The heel and toe had wrinkles that I hate. But the problem I think, was my leather mostly, these moc patterns are made for lighter, more flexible leather than I used, so I had to make a form for the soles, learned that from the first pair. Veg tan won't mold to your foot with time. I used heavy holster leather for both insole and outsole, so the sole is as hard as a decent sandal. I used some 2mm for the vamps, but I still had to oil them before sewing them up, learned that from #2. A good coat of nfo gives the leather enough stretch so you can pull the stitching tight as you go. 3# came together, I think, got the form right, so i dont have puckers , made the vamp three pieces so they dont tear out and fit correctly. Skived the edges of the sole down and moved the stitching up closer and more tidy , took a hammer and pounded out the puckers in the toe and heel. Oh, and changed the top a bit . These i could wear downtown. I used crap leather as these were experiments, but now maybe I'll buy some good bison for the vamps, I kinda like the harder soles now that i can make them repeatable. funny thing the leather I used had been left out in the sun, and part had tanned darker, so now I have a light moc and a darker one lol I guess ones going into the car window for a week or so. -

-

Thank you this is very helpful I try to find this to and didn’t find anything

- Today

-

I have an Adler 220 on which I use 328 needles. I have adjusted/redone the timing. Sometimes I measure the difference in length between the needle systems and adjust the needle bar using a caliper.

-

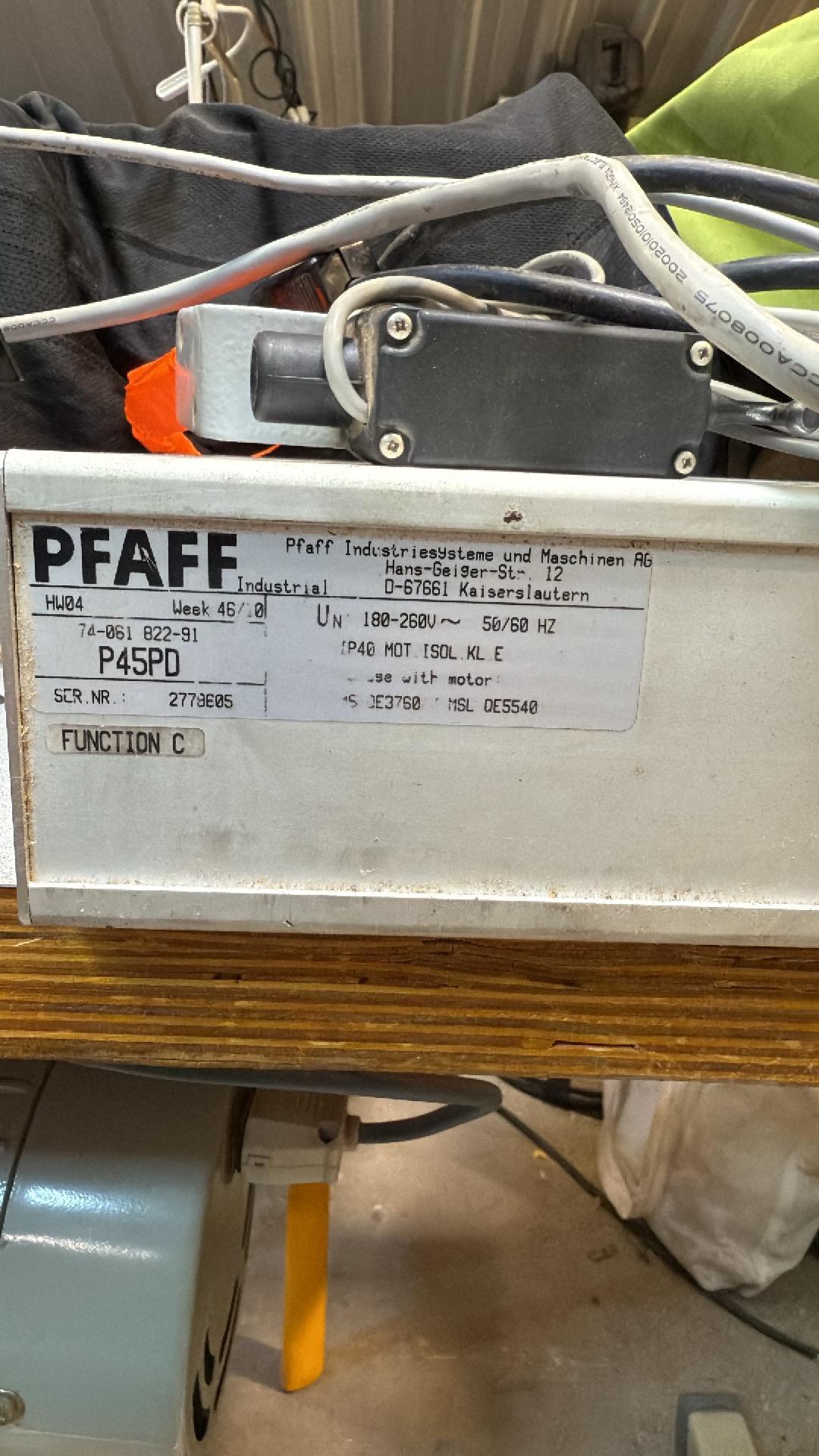

I found this for you (didn't take long) it may be of some help. You could try asking Pfaff about a controller but I suspect the cost would be high - if they have one. The chances of getting one used would probably be low. Pity, it looks like a nice motor. Good luck. picodrive_p40pd.pdf

-

The first link looks correct. I guess I’ll order that and see if it works. Thank you. I have the ones shown in the second link and they’re not the same.

-

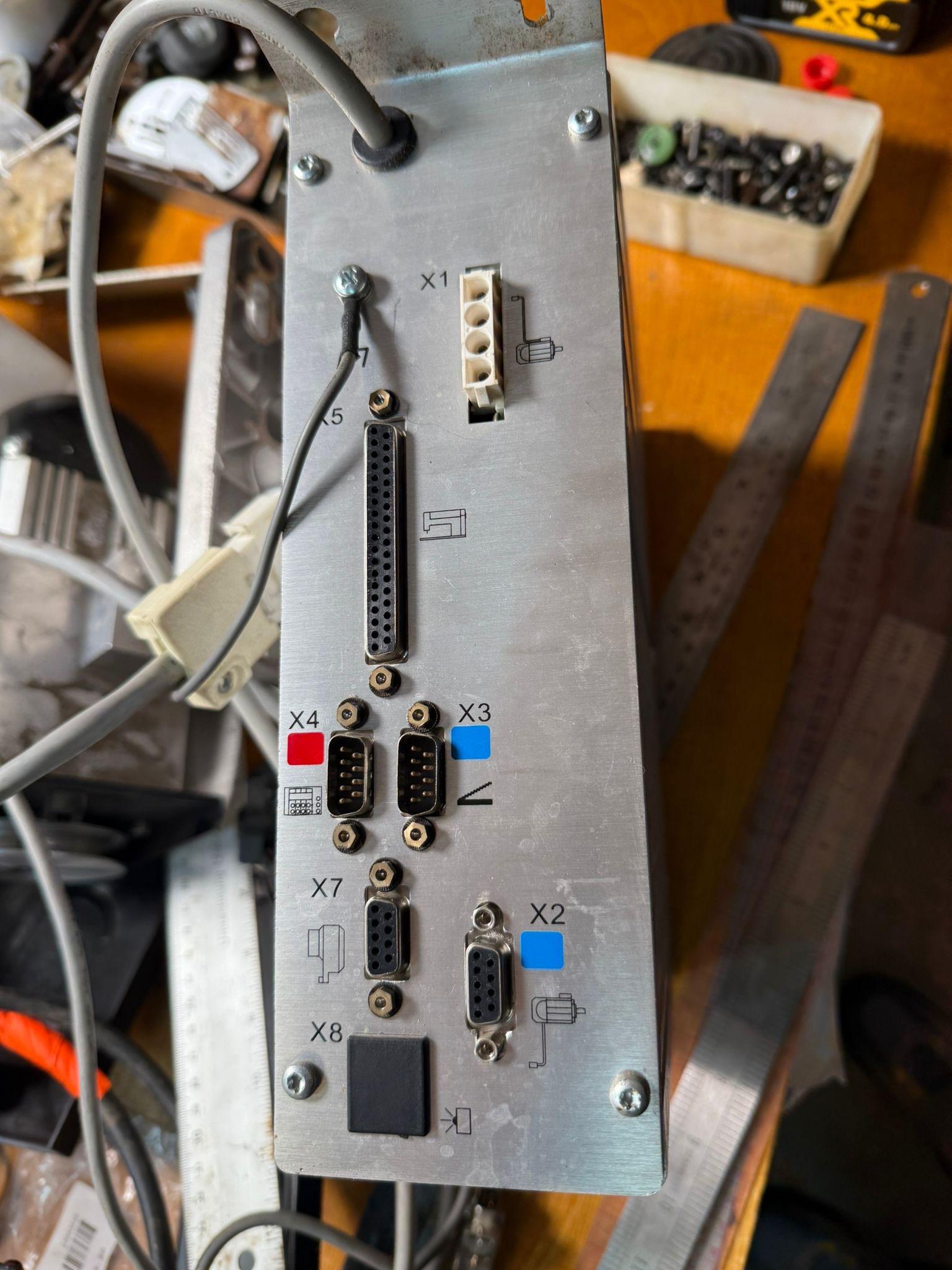

Can we get a photo of the back of the box that says "pico drive"? Also can we get separate photos of each piece that plugs into the back of the motor? I'm not familiar with this model, but trying to see if all the parts are here.

-

Thanks! Generally when I mention The Silmarillion people don't know much about it, this is why it's in a separate clamshell. Everyone knows The Hobbit and Lord of the Rings so it makes sense to have those 4 books in one box. I like to joke The Silmarillion is for the Tolkien nerds lol. Thank you, I really appreciate it. After taking a few product pictures I find that it's missing something to make it more cohesive. On the back cover especially, everything just looks to be floating there. I think a border will bring more balance to it, like putting a picture frame on a photograph. Making the borders gold on all the covers will tie the books together while the other things, like end pages, being different will state that you're in a different part to the story.

-

It mounts in one of these three holes already drilled & tapped in the bed, usually it will be the front one.

-

WOW, there are some very talented people on this site, and you are definitely one of them. Beautiful work.

-

Tim, your work is truly world-class excellent.

-

7x23 are slightly longer IIRC. Minor needle bar height adjustment could be necessary but they may work even w/o adjustment.

-

sure: https://www.ebay.com/itm/234079435236 this is with what the 31K48 came ex factory but roller size may vary. however we have not seen your machine and how it is set up. Could be this type as well https://www.ebay.com/itm/143603133032

-

Thank you very nice thinking on the back stitching I will take it for my next time I will start new project so this time I was trying to sale this machine so I have this seiko and consew for sale and the guy was sure that is do able to sew 207 I told him that is to mach for this machine surprisedly the machine sewed well forward but not backward and any way this guy is not serious and I got off him anyway, and I'm going to sit on these machines and set them up properly from the start thank you very much

-

If you're sewing a few stitches, reversing and then sewing forward again, you're running over the same stitches 3 times. That is going to be messy. Plus the needle hole isn't going to accommodate 3 threads. On my big 441 clone, I start a few stitches from the beginning, reverse 3 holes and then stitch forward again. This gives me 2 locked stitches with 2 threads each. You could try this or follow Hildebrands method, which is how we do it on machines without reverse. I think this is likely your problem. I'd double check that the machine likes that 207 thread. My 111Ws cap out at 138. How about they bobbin thread? What size are you using there?

-

lthr123 joined the community

-

Do you have a photo of this setup? Trying to understand how all of this mounts

-

Yes,same length.

-

Someone can help me I just got this motor it was on pfaff 2545 the guy didn’t want it So he give me motor accelerator pedal and the driver, but it didn't have the controller and I can't find it anywhere. Where can I find one? The motor works for a few seconds and then doesn't continue to work at all. Every time i turn it on, the same thing happens. And there was no needle positioner on this machine. Maybe it's something internal, I don't know.

-

I have a Singer 31K48. I’ve been looking for a roller foot for it. I have the one that came with the machine but it’s worn almost smooth. Is it possible to find a replacement or would some shop be able to resurface the foot that I have? Thinner leather seems to slip a bit as the foot is so worn. Thank you, Bren

-

I have pretty much quit stitching backward. To backstitch when I start, I turn the piece around so I am sewing forward toward the starting point, I usually try to mark about 3 stitches out, then when I get to the starting point I turn the work around and still sewing forward go back over the 3 starting stitches and sew it the rest of the way, when I get to the end I again turn the piece around and backstitch 3 stitches sewing forward along the stitch line. Todd

-

I will try to do some pic maybe tomorrow and a very good technician told me that the tension is different between forward and backward stitching I didn’t know that it most be away to fix it and we try to sew 207 thread with 23# needle that is also not good he said we need needle 24# for this thread and this machine not designed for this big thread

-

Jeeze thats nice work.

-

Super nice clean work - tooling, stitching, and finish are all top notch1

-

Looking good! Nice consistent sewing. Brgds Jonas

-