All Activity

- Past hour

-

basically that's it but I would check the needle hook timing too - that never can be wrong.

-

Is it enough to lower the needle bar 1mm or ist there more adjusment necessary if i do this? an thanks for the Answers!

- Today

-

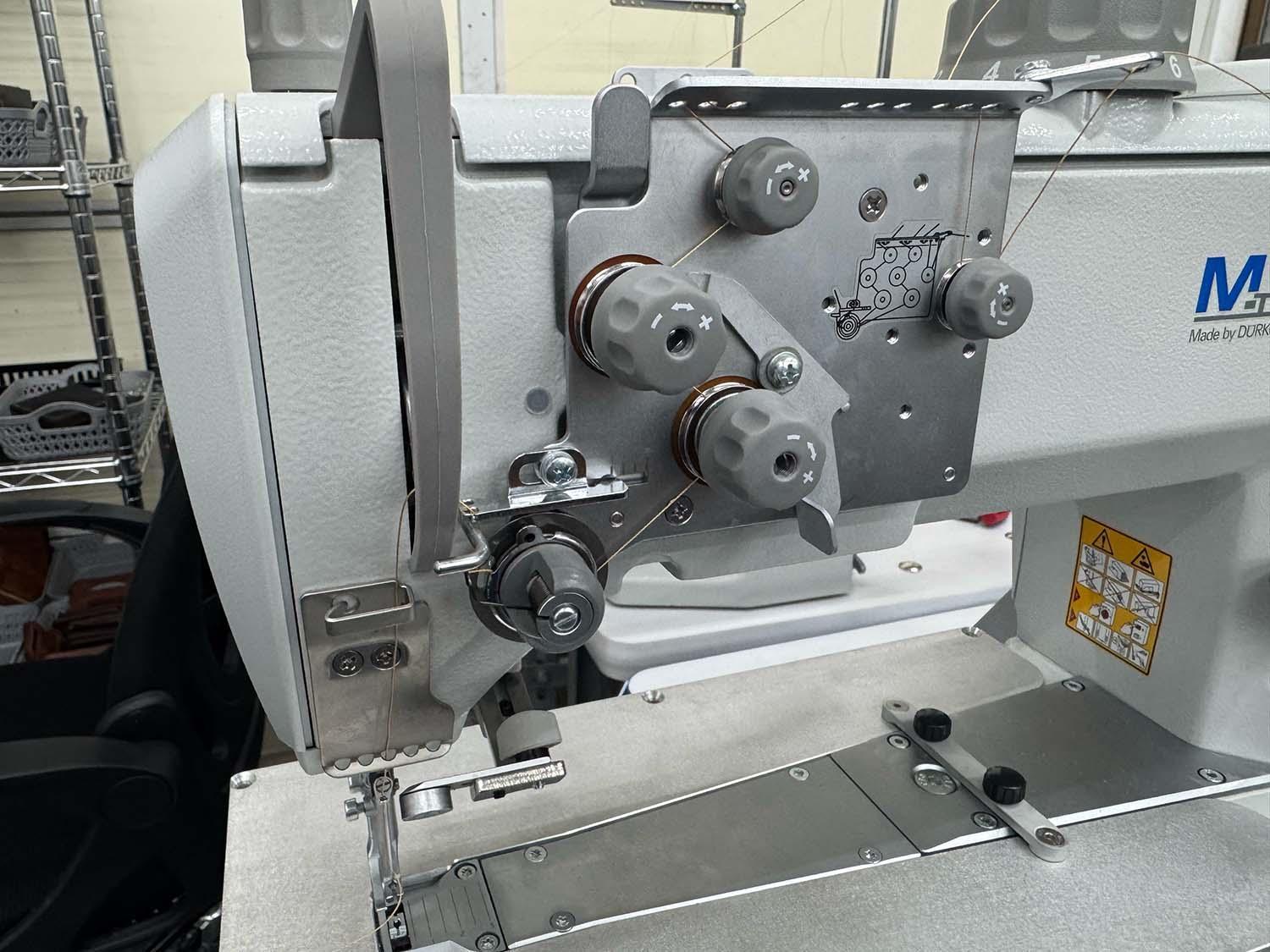

I purchased three brand new Adler 669 sewing machines in November 24. The machines are great but will need to be dialed into what ever leather you are using. I already have three other sewing machines so I purchased these as back-ups. I am selling each one for $1,800. All three have speed reducers, come with a removable tables, have drop down guides, and are mounted to sewing machine desk with rollers. If you are interested please send me a text. Local pick up only. Ernie Contreras, Bull Sheath Leather, Mansfield TX, 817-673-0602.

-

Singer 107 W1 Stitch Length not changing

Wizcrafts replied to ohLyssa's topic in Leather Sewing Machines

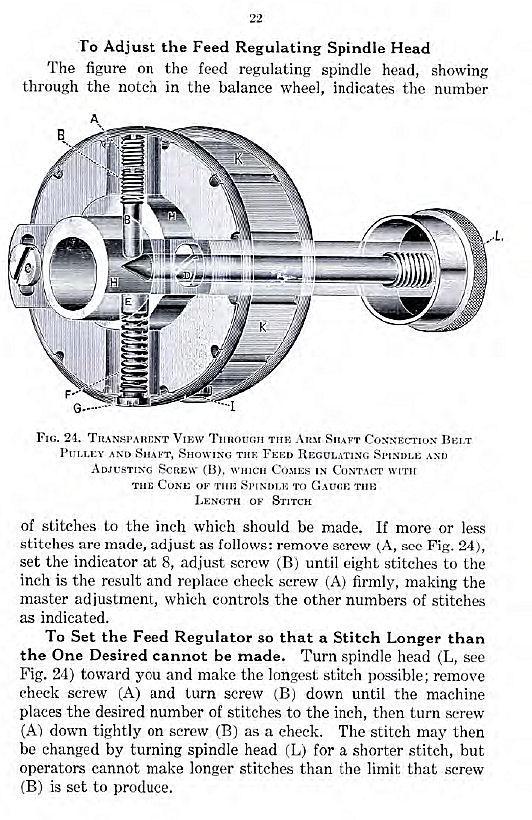

@ohLyssa The taper on the end of the stitch length rod is what does the adjusting. You need to get somebody with a machine shop to turn the rod and recreate a nice long taper that ends in a sharp point. That system is long obsolete. I have the same machine and baby the adjuster any time I move it. -

For tack repairs I match colors by trial and error, testing dye mixtures on a scrap of the same leather I'm using for the repair. I am usually adding a small amount of Fiebings brown dye to their English bridle (yellow-tan) or mahogany (red-brown) dye as a base. The Fiebings brown dyes I've used are, from lightest to darkest, are light/medium/dark brown, show brown, chocolate, and dark chocolate. To my eye, the show brown has a bit more reddish hue than the others. To simplify, I'd get show brown (dark red-brown) and chocolate (dark brown with a black tone) and dilute them in a tan or mahogany base. Based on the picture of your saddle I'd guess that a pinch of show brown in mahogany dye would be an acceptable match. My go-to dye for dark brown Asian tack is 7% show brown in mahogany dye. Your saddle is not that dark. As others have said, oiling and sunlight will also darken the leather to improve the match.

-

Singer 107 W1 Stitch Length not changing

Constabulary replied to ohLyssa's topic in Leather Sewing Machines

are all the parts as shown in your diagram present (See text / parts list)? The tip on your adjustment rod is damaged as you already noticed, tip should be very sharp (see picture below). Not sure how much this affects the stitch length regulation. Is the small stud inside the adjustment knurled knob present? Is the coarse threading at end of the top shaft in good order? Please post some pictures. edit: Quick picture of the stud from my 107w1 rod and the top shaft threading. Stud slides inside the coarse threading. -

I recently inherited a Singer 107 w1 and I am trying to get it all set up. Everything seems to be in working order, except when I turned the dial to change the stitch length, it lengthened the stitches to just over 4 per inch and now it won't change at all. The zig zag still works fine and it's not skipping any stitches. I tried the adjustments it says to do in the manual (pictured below) but that didn't do anything. The only thing a did notice was that the tip of the stitch dial rod is slightly bent (pictured below), but I'm not sure if that is major enough to keep it from adjusting at all. Does anyone have any experience with this machine? I can't find any information online other than adjusting those two screws.

-

Check with Fuchs Elektronik in Germany they have the Quick Rotan Service: http://www.fuchselektronik.de/index.php?vid=302&mid=1&lid=2 However - not sure if they are still in business - looks like an early 2000´s website

-

sleepy-joe joined the community

-

Dear friends I am looking for a manual for the Quick Rotan P70SE motor in english (all three parts). Does any of you have one, I am interested in buying it. Cheers Danish Man

-

I'm no expert but I would sharpen the knife, working slowly/gradually to avoid overheating. Use a marker on the bevel to see that the stone is creating a uniform bevel. I would also polish the foot to reduce drag - use a buffing wheel if you have access to one. Check that the drive roller is round and without gouges/flat spots by shining a bright light to visualize the gap between the roller and the knife.

-

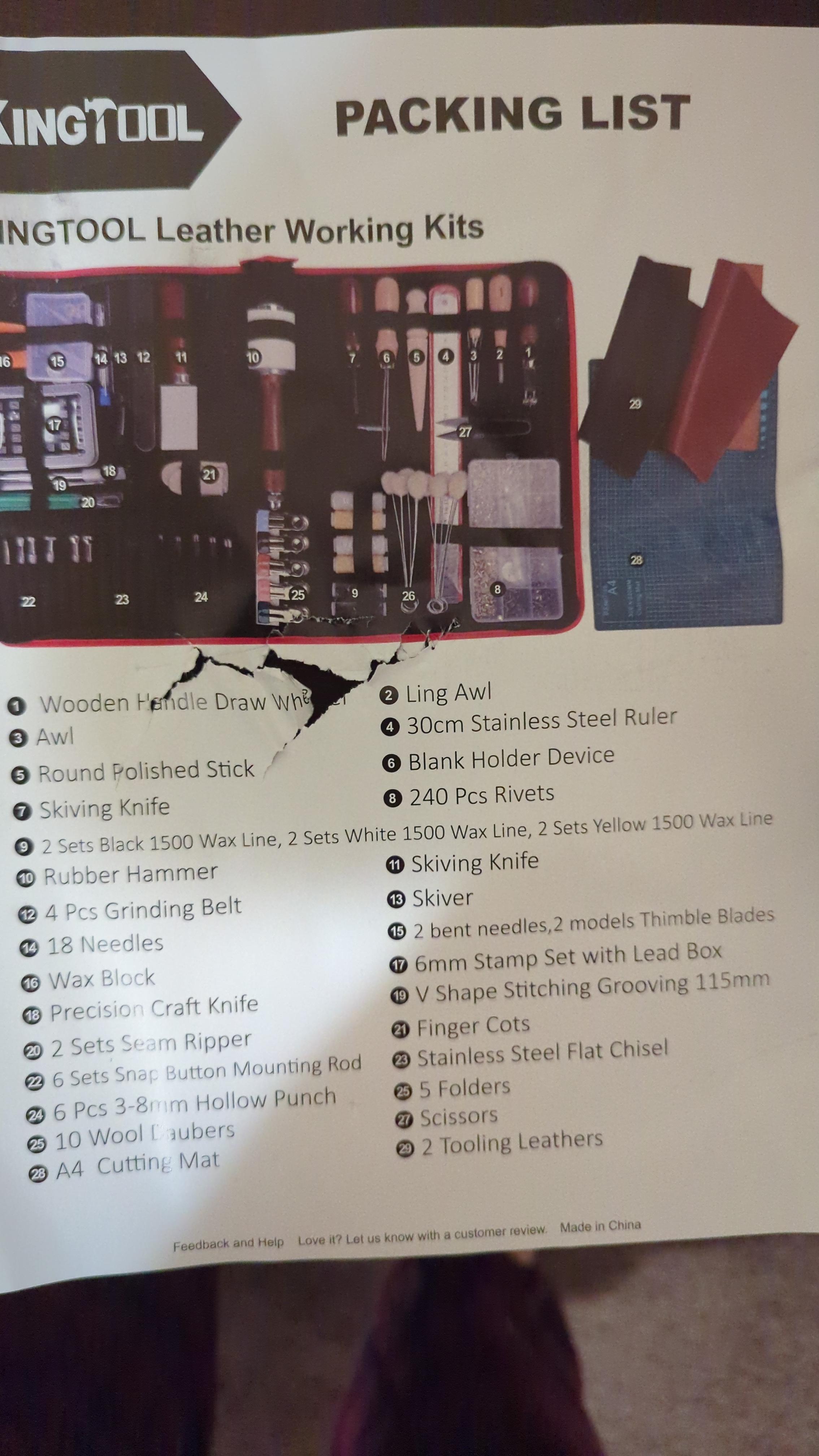

Nice. I don't seem to see a swivel knife. Not necessary unless you want to do carving, like a portrait or a floral pattern on a knife sheath or holster. Yep, understanding the many types of leather available is tough. Vegetable Tanned, or "veg tan" is the type you need to stamp and carve on. Chrome Tan is cheaper and available in an array of gaudy colors but is to be avoided for anything that will contact metal (as a knife sheath or holster). Then there's thickness. Learn the "ounce" system, would be my advice (for which you have not asked). An ounce of leather thickness is 1/64th of an inch. Wallet linings are often in the 2/3 ounce range. The outside can be up to maybe 4/5. Knife sheaths, I usually use 4/5. Many people go heavier. Gun Holsters typically run 8ish to 10 ounce. Belts can be 4/5 up to 12 or more depending on the application, sometimes 2 layers. If you ask 10 people for their thoughts on the last paragraph, you'll get a dozen different answers. For me, I keep 3 hides around, a 2/3 ounce, a 4/5 and something 8 to 10 or so. All undyed veg tan. And then there's a question of brands ... I'm lucky to have a very large leather/fur dealer close by and use whatever they have. Others are very loyal to a given brand (Wickett & Craig, Herman Oak, etc) and would sooner fight a Holy War than change. The Saddle and Tack people are a world unto themselves where types of leather are concerned. Looking forward to your progress.

-

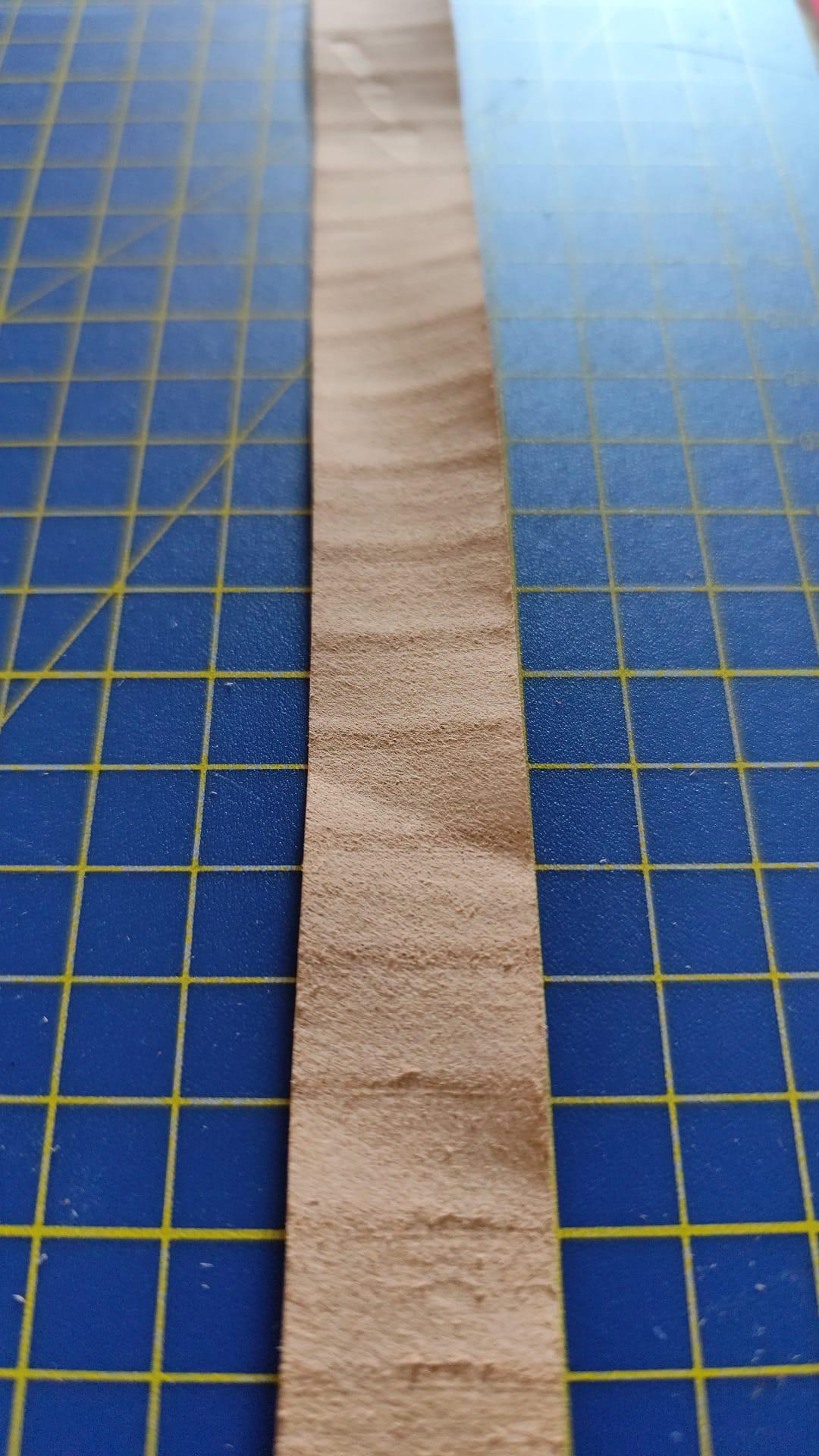

Hello everyone, I recently bought my first skiving machine, it's a used machine, a Sagitta SC75A (for which I'm also looking for the manual) I'm new to skiving so I'm asking you if you've encountered problems like mine and could you explain to me how I can solve them? The big problem is that it flakes unevenly with a wavy pattern, not smooth as it should be. Thank you Ps, I'm attaching a photo to help you understand the problem. It's a 2cm wide and very long strip of leather, stripped from 1mm to 0.5mm.

-

Thanks I just got this kit on Amazon... Now I need to get some leather, seem to have some basic tools I guess . Now I need to get some patterns and some leather to start practicing. Saw I few things on a Renaissance fair that I would.like to some.day be able to make like a dragon mask or a dragon night night helmet. I also already promised my mom to make her a wallet once my skills are up for the challenge.

-

One more detail to add to that picture and description. I put a 1 1/2 inch pulley on the motor.

-

This looks amazing!

-

Saddle making books and DVD’s

AlZilla replied to Bren2736's topic in Books/Patterns/Periodicals/Videos

@Bren2736 We probably need to know if these include shipping and what types of payment you accept. Don't forget we have a global reach so you probably should address international shipping or not. -

I have several Saddle Making DVD’s and books for sale. Stohlman 3 book set “Encyclopedia of Saddle Making $250 Jeremiah Watt 3 DVD set $250 Dale Harwood 2 DVD set $300 Bruce Cheany 4 DVD set $90 Harry Adams Saddlemakers Shop Manual $200 Payment by PayPal invoice. Buyer to pay shipping. I’ll calculate actual shipping at time of purchase. US lower 48 sales only.

-

Thank you for posting it. Hope it helps somebody.

- Yesterday

-

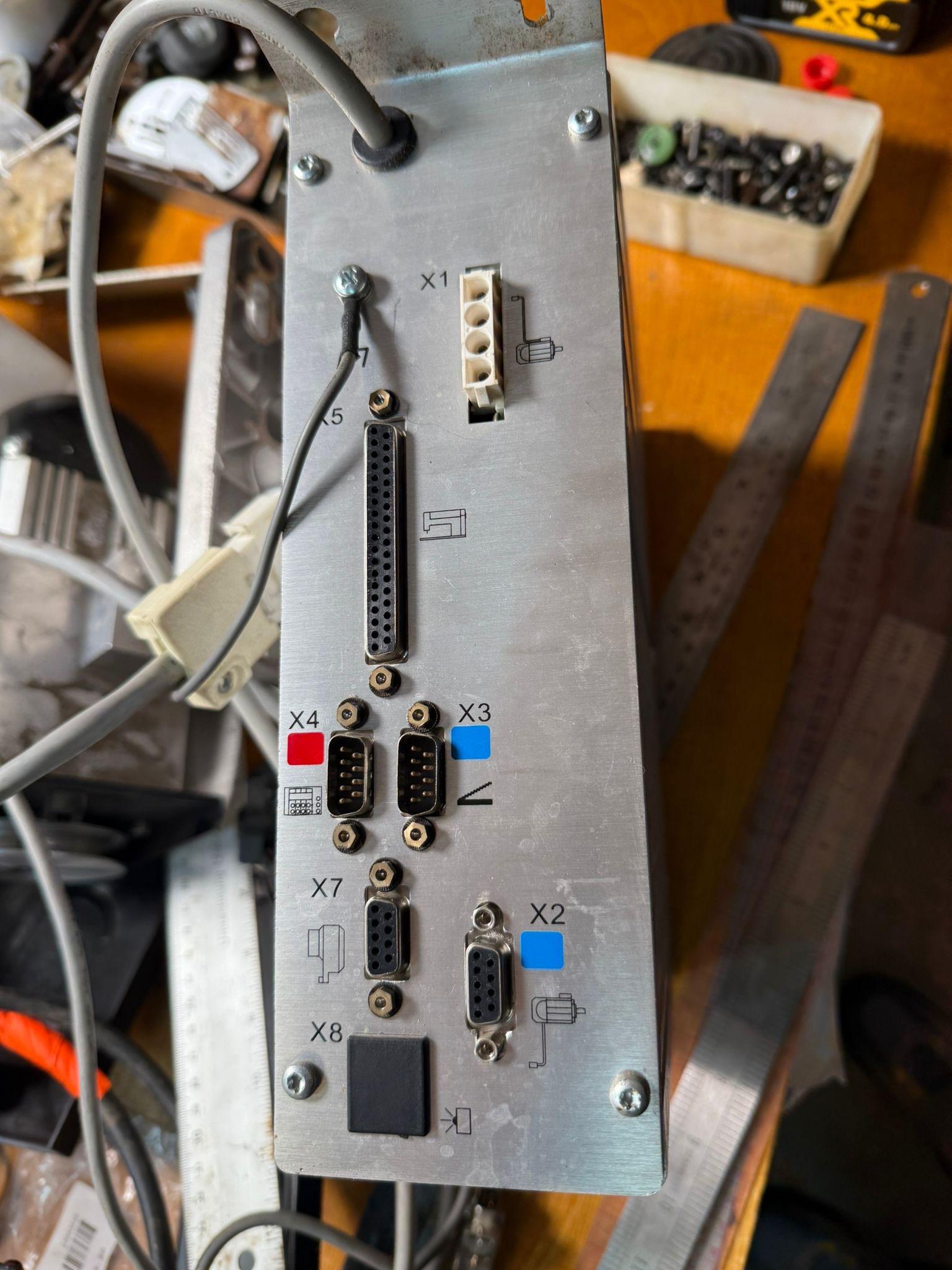

This box looks complex. It has the following ports which are common to a lot of digital servo motors: X1, X2: motor X3: gas pedal X7: needle positioner But then there's additionally X5 (head unit) and X4 (looks like a control panel) that most digital servo motor's don't have. In other words, I'll bet this is a proprietary system and that it will be difficult to buy the pieces individually.

-

You seem to be creating a niche. Not every newbie with an Amazon starter kit is going to be doing this but I don't think it's a big enough market for some Chinese factory to spit out 5,000 before lunch tomorrow. Plus, doing custom bespoke orders for someone's favorite book. You're on to something.

-

spring flowers and good food

chuck123wapati replied to chuck123wapati's topic in All About Us and Off Topic

I can now make a moccasin. I tried to make my own pattern a couple of years ago and failed miserably, as you can see, they worked but not much more lol. So this time I used a pattern pack from Tandy, "Mountain Man Moccasin Patterns by Gene Noland". I used pattern number three, decided to make it exactly as the pattern, and it was a failure, too. The leather tore out, and the stitching holes were so far apart they looked like crap. The heel and toe had wrinkles that I hate. But the problem I think, was my leather mostly, these moc patterns are made for lighter, more flexible leather than I used, so I had to make a form for the soles, learned that from the first pair. Veg tan won't mold to your foot with time. I used heavy holster leather for both insole and outsole, so the sole is as hard as a decent sandal. I used some 2mm for the vamps, but I still had to oil them before sewing them up, learned that from #2. A good coat of nfo gives the leather enough stretch so you can pull the stitching tight as you go. 3# came together, I think, got the form right, so i dont have puckers , made the vamp three pieces so they dont tear out and fit correctly. Skived the edges of the sole down and moved the stitching up closer and more tidy , took a hammer and pounded out the puckers in the toe and heel. Oh, and changed the top a bit . These i could wear downtown. I used crap leather as these were experiments, but now maybe I'll buy some good bison for the vamps, I kinda like the harder soles now that i can make them repeatable. funny thing the leather I used had been left out in the sun, and part had tanned darker, so now I have a light moc and a darker one lol I guess ones going into the car window for a week or so. -

-

Thank you this is very helpful I try to find this to and didn’t find anything

-

I have an Adler 220 on which I use 328 needles. I have adjusted/redone the timing. Sometimes I measure the difference in length between the needle systems and adjust the needle bar using a caliper.

-

ohLyssa joined the community

-

I found this for you (didn't take long) it may be of some help. You could try asking Pfaff about a controller but I suspect the cost would be high - if they have one. The chances of getting one used would probably be low. Pity, it looks like a nice motor. Good luck. picodrive_p40pd.pdf

.jpg.c16d742de7f0f8360a718ea3d7b8a9d2.jpg)