All Activity

- Past hour

-

How can i activate foot lifter for 45k25

Trox replied to depodarcom's topic in Leather Sewing Machines

These types of stands had knee lifters, but since you don't have one a pedal attached to a tube around the tramp shaft would do the job. -

How can i activate foot lifter for 45k25

AlZilla replied to depodarcom's topic in Leather Sewing Machines

No, I guess I was unclear. OP needs to pull the chain for his foot lift. I'm suggesting he could engineer a pedal similar to what I'm doing to pull down the lever to control the servo motor on my project. -

I've decided to give up on this quest for now. Putting the machine back together and time to get to building something. 🚶♀️

-

How can i activate foot lifter for 45k25

friquant replied to depodarcom's topic in Leather Sewing Machines

Is this to drive the machine or to lift the presser foot? I thought you were going to use the kick drum lever to tell a separate servo to raise the presser foot. - Today

-

How can i activate foot lifter for 45k25

AlZilla replied to depodarcom's topic in Leather Sewing Machines

Just a nothing special bog standard servo from ebay: https://www.ebay.com/itm/356814829633 It says it's 750 watts but I bet when it gets here it's 550. It's got a 2 to 6 speed reducer already. -

Mu first Juki was an LU-563. The reverse stitches were always smaller then the forward stitches Eventually, I discovered the adjustment to get the distances closer. However, as you found out, the faster I sewed, the greater the difference became. This was in the mid 1980s. Since then, I've had various machines with reverse levers, some of which matched at any speed and some of which were flakey, like my old Juki. A Consew 206RB-5 was pretty reliable in both directions. Many of my current crop of sewing machines don't even have a reverse lever. I either sew all around to sew over the starting threads, or spin the work around 180 degrees and perform what I call, "poor man's reverse." In both cases, the stitch length is constant. I sometimes do it on a machine that has reverse simply out of habit.

-

now that you mention jump foot I have a different view of that picture - makes more sense now. Cool machine - love it! 👍 I guess it is using the "common" singer hook as for 153w and so forth. The availability of parts for theses dead old machines always surprise me. Thats why I´m a sucker for vintage Singers. 😉

-

Far from masterful but i appreciate the kind words, Brandon corral at swift hammer is a skull and metal wizard. He does things his own way too, you should look him up.

-

How can i activate foot lifter for 45k25

friquant replied to depodarcom's topic in Leather Sewing Machines

Ooooohhh... Can you post links to the servo you're using for this? -

One problem I have had with digital servo motors vs analog servo motors is the jerky start up. I can understand that lowering the startup speed to 50 rpm will be less jerky than a 100 or 200 rpm startup, it will still engage with a hit. Analog servo motors I have start at zero and smoothly increase in speed as the pedal is pressed. There is no jerk at startup on those motors. I have helped convert several Cowboy and Cobra 441 clones and one Union Lockstitch machine from digital to analog servos for this very reason. Once the change was made, the owners never complained about being able to control the machine or position the needle as needed. I would be happy to have a digital servo motor that started at zero and increased in speed only as I pressed down more on the speed pedal. I don't like motors that start fairly slow, then speed up on their own ("ramp up"). The motor speed should be pegged to your foot position on the speed pedal. If one needs an external speed knob, the same should apply. As the knob is rotated, the speed should increase. Because many servos lack high torque at lower speeds. I can see that the ones having more coils will have more low end torque. I would gladly pay more for an analog servo motor that eliminated to need for a speed reducer. However, when sewing thick veg-tan leather, the faster one sews, the greater the heat that is generated on the needle. I found that when I sewed at 15 stitches per second, smoke came from the needle! This also began melting the bonding agent on the nylon thread. The result was a weakened stitch line. I doubt that I am the only person who prefers to sew slowly to maintain control of the stitch line and needle placement, as well as to keep down the heat on the needle. I typically sew within a range of 1 (for detailed designs) to 6 or 7 (on straight edges) stitches per second. When I sew at higher speeds, I use an edge guide. When the leather is thinner, I can sew faster than when it is very thick. It can be dangerous to sew 3/4 inch at 5 or more stitches per second. If a fast moving needle is deflected by thick layers and breaks, it could embed itself in one's skin! Ask how I know this!

-

Price dropped to $70.00, with shipping included to lower 48 states. PayPal invoice will be sent. Thanks for looking!

-

I think you're seeing the jump foot. I'll get some better pics of the needle area. I got a close enough manual here: https://www.universalsewing.com/parts-lists/singer . I got one for a 21W that has what I need. I had forgotten about that page. Sadly, all the downloads are randomly named so need to be "Save As"ed. I think I'm going to need parts for the left hook assembly but it looks like there are plenty on ebay for the 21W that should fit. It looks like in order to change the spacing of the needles (Gauge) it's going to require a presser foot and needle plate for each width! The good news of that is that very tight spacing between the needles and holes should contribute to a nice stitch. It's waiting for it's servo motor ... patiently.

-

Thanks for the explanation, how about pictures of any current messanger bags.

-

How can i activate foot lifter for 45k25

AlZilla replied to depodarcom's topic in Leather Sewing Machines

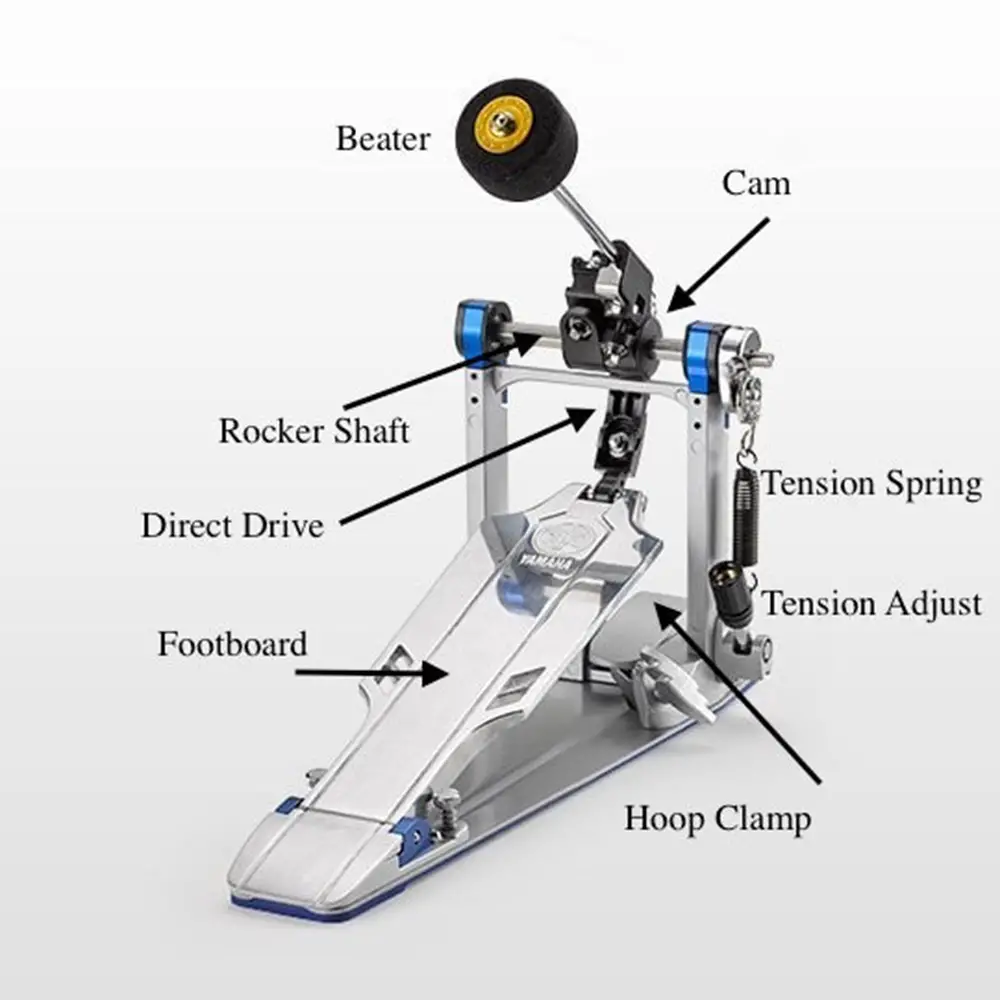

Unless you're going to sit at that machine, I think a knee lift is out. I have a broken bass drum pedal I'm in the process of adapting to operate the servo motor on a sewing machine. The "beater" is broken off, so I'm just going to attach the pedal frame to the table legs and attach the servo motor arm to the pedal. Maybe this pic will inspire something. Edit: I just saw your stirrup idea. That might work, too, if you could keep it from swinging all over the place. Maybe a chain guide of some kind down low, limiting it's swing. Great idea. -

How can i activate foot lifter for 45k25

depodarcom replied to depodarcom's topic in Leather Sewing Machines

Thank you ..This seems good and useful for me. I am also searching for "stirrup" that is used for horse riding.. -

How can i activate foot lifter for 45k25

SARK9 replied to depodarcom's topic in Leather Sewing Machines

The simplest way would be by attaching the chain to a foot pedal, but you would probably have some real estate conflicts putting that on a treadle base. Next would be adapting a knee lift pad similar to the typical ones used on machines like the Consew 206 and several others. There are a few different styles sold as aftermarket kits and you could work out the geometry to suit. A small air cylinder is also an option (I have several on various machines) but they are generally all the way up or all the way down NOW as in "ON/OFF" unless you go full MacGyver on the attachments. The knee lift kits are probably the best bet and can be as cheap or dear as you like. -DC -

thanks. I stopped using Google, so maybe that's why. Thank you for the suggestions.

-

How can i activate foot lifter for 45k25

friquant replied to depodarcom's topic in Leather Sewing Machines

Beautiful table! A foot lift is activated by pressing down with your foot, a knee lift is activated by pressing to the right with your right knee. My Jiang Long came with both, but I had to ask how to install the knee lift. Here is the install video they sent me...the chain actuator reminded me of your singer. 937adbfd78d59f2d56efebcd9d6f1892.mp4 -

Talk about having your cake and being able to eat it! A few thoughts - keep the price comparable to the Reliable or Sailrite (before their price jumped) models so under $200-$250, 12 coil, some sort of trade in program for those that bought analog units from you, made in the USA (that might be tough). Great thoughts - hope it happens.

-

All Y'all have a great 4th of July, don't hold any short fuses when lightning them! Don't give a commie a chance - ALWAYS CARRY!

-

Pirarucu or Arapaima or Amazon bass

SUP replied to SUP's topic in Exotics, Reptiles, Furs and others

It appears that not many have experience working with Pirarucu. When I learn about it, I will post it here for others who might want to know about it as well. -

My cooking skills are a lot better these days than they used to be ,so I'm pretty happy 😊 Peace ✌️ HS

-

help choosing first leather sewing machine

Digit replied to TakashiOkada's topic in Leather Sewing Machines

Ah yes indeed. My cursory glance failed to notice the white lever on white background -

, acetylene cannon !!!! ☺️🍺🍺 life is good. Happy fourth Fred.

-

google custom embossing wheels. i found this in about 5 minutes never tried the product. good luck to you☺️ https://www.infinitystamps.com/products/custom-leather-roll-dies