All Activity

- Past hour

-

You might want to look at Kevin Lee's stitching irons. Among the sets which are comparable in price to what you note above, he also has inexpensive sets which will help you decide what you like (diamond vs pricking, and so on): https://www.kevinleetools.com/products/basic-diamond-chisel For example, he offers a 1+2+4+6 prong set for 30 dollars. I bought his reverse iron set in 3 mm, to work with my 3mm Japan Goods diamond set. I have used them enough to recommend them as a good starter set for somebody who doesn't want to invest a lot before figuring out if diamond chisels are what they want. They are well-polished right out of the box, which is very helpful. They are light and small, which works for my hands, but big handed folk might find them uncomfortable.

-

help choosing first leather sewing machine

toxo replied to TakashiOkada's topic in Leather Sewing Machines

I think we're getting to the point where all the clones are merging into the same machine. Don't know the specs re needle/thread size but be aware that this price is for head only. Table, motor etc will be extra as will the shipping. - Today

-

Have a good day Be careful and enjoy yourself

-

help choosing first leather sewing machine

TakashiOkada replied to TakashiOkada's topic in Leather Sewing Machines

@RockyAussie I've been browsing alibaba and found a seemingly reputable factory selling a 246 model at a price I can actually afford! what do you think.. should I get this one? the product video shows that the feed dog moves in a circular motion, not just front to back like the 335 https://www.alibaba.com/product-detail/HK-246-Single-Needle-Cylinder-Bed_62558318957.html -

I would start by asking 'Bunkhouse Tools'

-

I am sure the JOG Dial is strong enough. It is essential for for long arm industrial sewing machine that difficult to reach the handwheel. Most long arm sewing machines come with front wheel, but very difficul to turn it. But why use speed reducer? The minimum speed of servo motor is 50 RPM only, if use it on CowBoy CB4500 or other Juki TSC-441 type machines, the sewing speed is about 12 stitches only per miniute!!!

-

Thanks so much. I appreciate every recommendation so I know I'm not missing anything. I'll check out Robert Beard, and I super do plan on some of my own tinkering with some. I have decent files and, in case or extra removal, a diamond (CBN actually) HSS sharpening wheel left over from my prior lathe gouge maintenance, on a slow speed grinder. I wasn't sure of the no.(s) exactly I was looking for, since I don't know all the variations. But it occurred to me to look at the elCheapo-kit stamp that I like the convex nature of... and, looking, she's a 217, so (duh, I forgot to look) I'll look at other makes of 217 as well as others. Thanks for the obvious reminder, sometimes it's been right under my nose. Also I lucked up and hooked up with two Hackbarths (prob. from one of you?) from CountryZach, a 411 and a 414! Thanks again! (P.S. I'll be sure to brush up on my metal sculpting skills & practice on a spare stamp, bolt, or an old printer rod etc. before I take a file or grinder to a new BK)😅

-

I think the Jog dial is pretty lame on a stitcher, unless you have a machine that's a mile's reach to the handwheel. LCD screen with multi function display/features is just as lame, confusing to new users and equally annoying to a seasoned one. So is the typical plastic Chinese made rocker switch/power switch that is good for about 25 cycles. What you need is a basic quality steel toggle switch on/off, a knob that you can twist for speed control (speed control only) and an option for a positioner needle up/down also controlled by basic toggle switches. (flip on, twist flip and done) Those features along with some serious low speed torque and you'd have it. An additional plus, would be one that can actually be compatible with a speed reducer and positioner at the same time and not throw an error at a 4:1 ratio. The problem with the modern programmable servos is that they're made to a price point and expected to function with a wide array of machines of various designs. Lots of functions can be a good thing, but most here that buy a "Cowboy" stitcher or something similar want simple, smooth, easy to use and lots of torque.

-

I'm in search of the perfect hundred-dollar servo motor. I've had two motors, both of them good but neither perfect. Here are some requirements that would make me happy: Distance in degrees between needle-up and needle-down should be configurable Motor should use standard 15mm cylindrical shaft with key hole, since a range of aftermarket pulleys are available for this shaft size There should be a long range of travel in the foot pedal between slow and fast The maximum speed should be configurable When the maximum speed is set to something slow such as "900 rpm", the range of pedal travel should be spread across the entire usable range. Meaning you should have to push the pedal all the way to get to 900rpm if 900 rpm is your max. Slow start, ideally, would be a gradual transition up from 0 rpm into some minimum speed. (The slow start I have used before still immediately jumped from 0rpm to 200 rpm, which was not gradual at all) When you tap the gas pedal to ask for one stitch, you should ALWAYS ALWAYS ALWAYS get exactly one stitch. If you give two stitches instead of one now there's an extra hole in the leather that I hadn't planned on. Also, giving more stitches than asked seems like a safety issue. When you heel-tap to ask for the needle to come up, the needle should come up. It must not do a full turn and then come up. That also puts unwanted holes in the leather and seems like a safety issue. The power switch must be in easy reach of the operator The power switch should light up so we can see when it's powered on When the power switch is turned off, the motor should immediately stop. (Safety) Pressing the gas pedal after the power switch has been turned off should have no effect. (Safety) Instructions for operating the manual should be provided in clear language. (I'd be happy to help you write the instruction manual) Ideally one could limit the amount of torque through the control settings There should be no settings visible in the menus that don't do anything. The settings in the menu should be numbered incrementally. No skipping numbers, as this is confusing. Ideally, needle position sensor would stop within one degree each time. Five degrees may be acceptable, but one would be better. If the gas pedal is pressed down while the power button is turned on, the motor should not start. (Safety) Rather, the motor should wait until the gas pedal is released and then pressed anew before motor starting. Ideally, the minimum speed would be 30rpm. This would alleviate the need for a gear reducer for many people. Though if small pulleys are available, 60rpm may be fine. The factory default maximum speed should be something medium slow like 1000rpm. Let the user increase it through the menu if they need it faster. If the belt slips such that the motor has to turn farther than it expected for the needle position sensor to register one complete cycle, the motor should stay in needle detection mode. Ideally, the needle position sensor should have an LED that lights up when the positioner is in the needle-down position. (Makes for easier setup) Assuming this unit comes with a needle position sensor, the controller should have needle positioning enabled by default.

-

I am trying to make leather necklaces, but I can’t find the right lacing/string/cord/etc. what I’m finding is either too soft and gets twisted or doesn’t seem to be real leather. Looking for something waxed leather style that is similar to the kind of thing we used to get from Abercrombie when I was a kid. Any suggestions of what and where to get it would be hugely appreciated. Thank you.

-

I'm looking for someone to make a custom roller wheel for a belt. I had a guy that was about to do it then went on vacation and never came back. I'm looking for a custom wheel that is placed in a roller machine, with the design imprinted into the leather. Not too sure where to start looking for this. Any help is appreciated.

-

We are trying to delvelop excellent servo motor for leather sewing machine, by now we have reach below features/functions: 1. Low speed: minimum speed 50 RPM only 2. High torque: an awesome 8.6 Nm of torque 3. Soft Start: make the machine far more manageable 4. “Jog-Dial” (suggested by Italian dealer): ectronical needle positioning 5. Speed Controller: allow you to adjust sewing speed in a second 6. Half Stitch (suggested y Sweden dealer) : micro-adjustment stitch length 7. Needle UP/DOWN position Any requirement else?

-

Thank you for this awesomely helpful information Friquant. Great tip on using the tape to mark specific location.

-

help choosing first leather sewing machine

kgg replied to TakashiOkada's topic in Leather Sewing Machines

The thread size for a #12 needle would be probably something like V33 (M80, Tex 30) range. Most of the Juki LS-341 clones will handle down to V46 (M60, Tex 45). True Juki's will handle down to V33 (M80, Tex 30). That said they are not going to be happy and will require a lot of adjustments as V33 has such a low a breaking strength of less then 2 lbs (.9kg). My opinion is that the Juki LS-341 and clones are better suited for a minimum thread size of V69 but prefer V138. kgg -

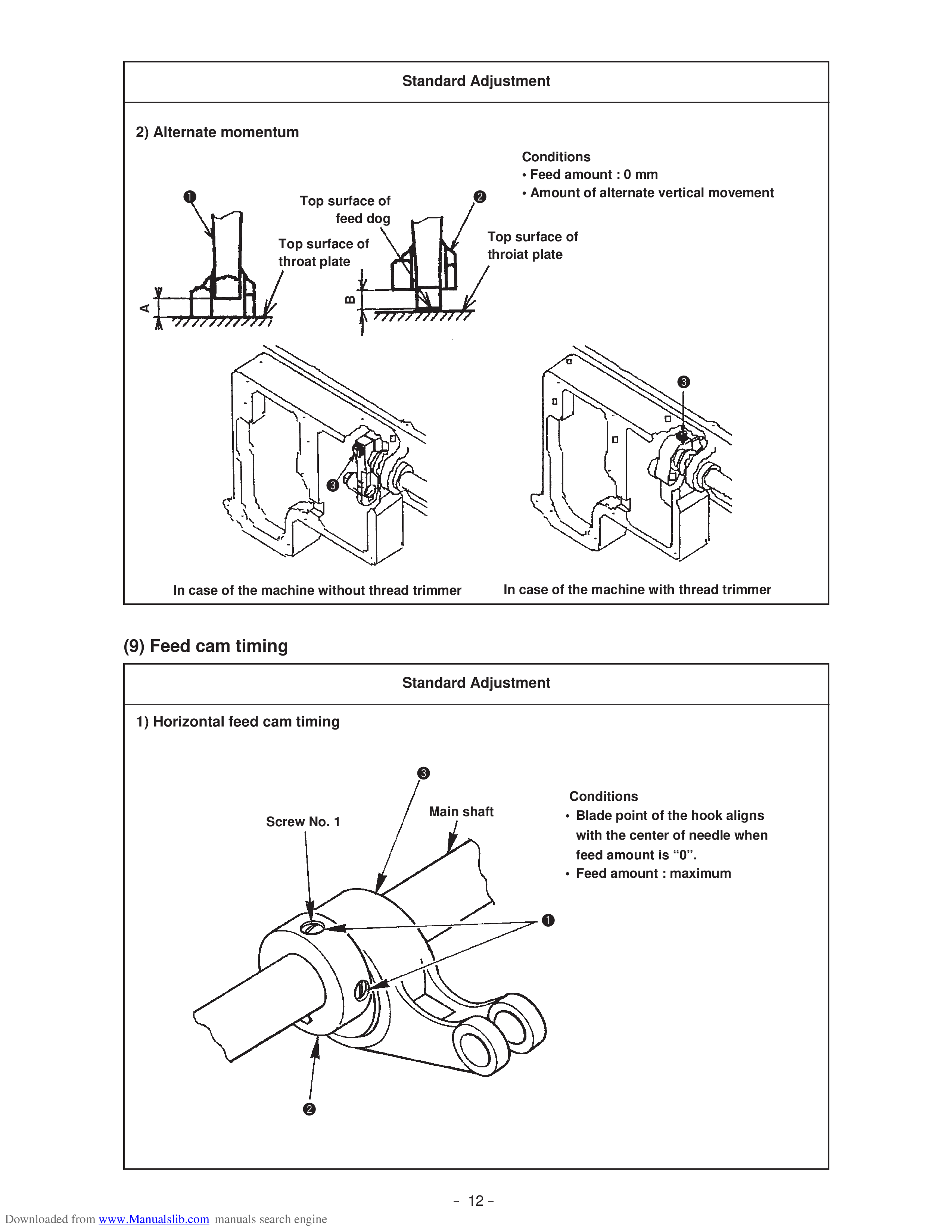

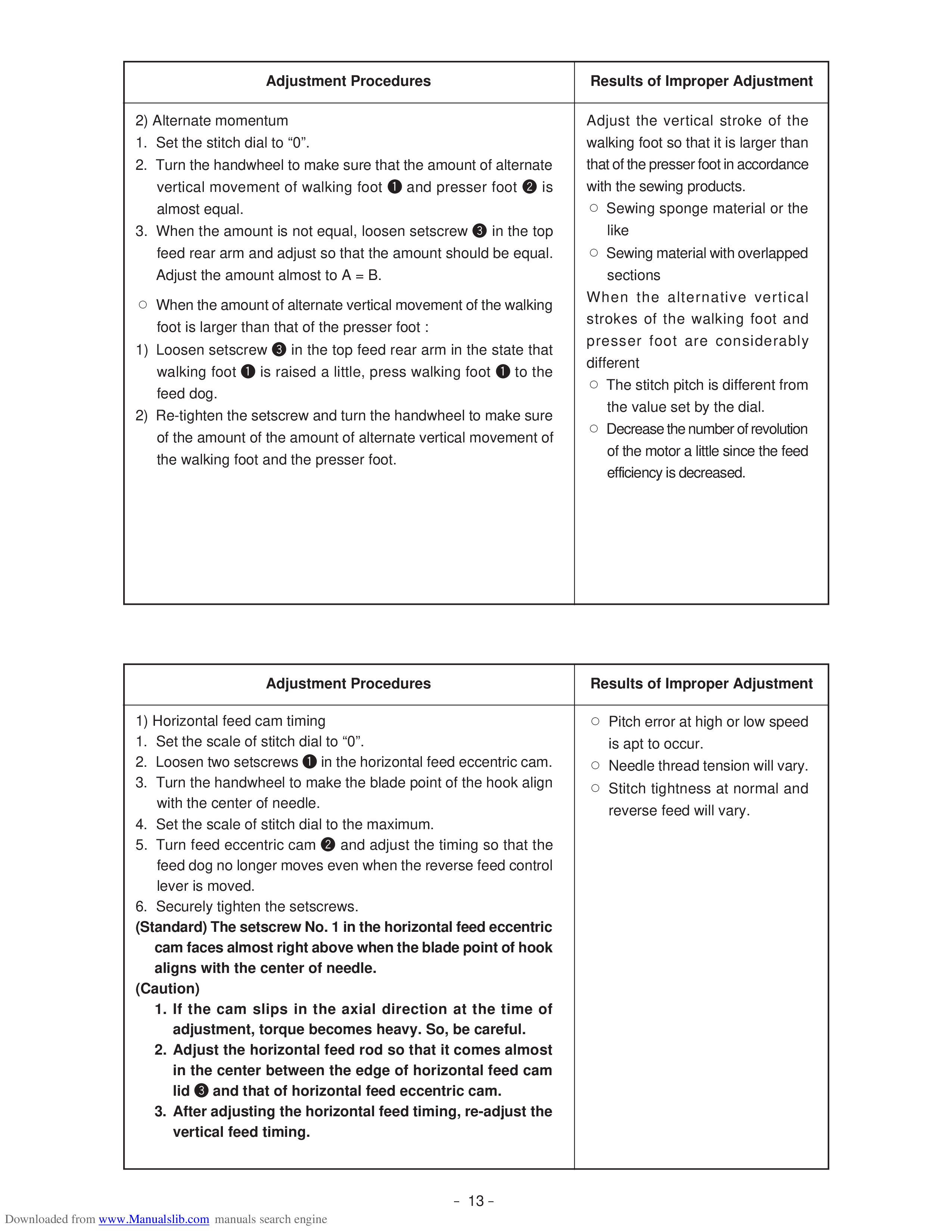

Attaching pages 12 and 13 of the juki 1541 manual. After you adjust section 9 (horizontal feed cam timing), you will have adjusted it so that in a certain position, you can rock the reverse lever back and forth and the feed dog does not move. This is the position you will want to initiate your reverse stitches from. On a machine with a needle position sensor, you can set the position sensor to always stop at approximately that position. Needle positioner or not, I find it useful to have some clear markings on the machine and handwheel showing you when you are in this "reverse magic" position. Here's a picture of my alignment marks in blue tape.

-

@bruce johnson has overstitch wheels in various sizes.

-

I have some beautiful pirarucu pieces and am not sure how to use it. The scales are removed and the scale bases remain, in quadrilateral shapes. These shapes have a ridge around them. The ridges are not firm. They are almost filamentous. You can reach under them, to where the scalers were inserted - tiny pockets, as it were. The ridges can tear off easily if I make anything with the leather as it is now. I have seen pirarucu boots and the scale bases and ridges seem pretty firmly in place. If they were not, they would not last long. How do they reach that stage? I have tried Resolene but that gives too much of a shine and does not stick anything in place. Glue maybe, but sticking each scale base in place is going to be tie consuming, not to speak of the damage to the appearance of the leather. I tried that too though. I have heard suggestions of shellac but that will destroy the texture. If anyone has worked with Pirarucu and can guide me on how to use this beautiful, unusual leather, I would appreciate it. Incidentally, Arapaima is a food source in South America and increasingly, being farmed ethically.

- Yesterday

-

-

Taylor07 joined the community

-

@RockyAussie do any of your skiver video's show you, using the diamond tip dressing tool. I'm curious how they work. I found what you referenced on Amazon, just having trouble envisioning how it's used to not put a grove in the sharpening wheel. Thank you

-

help choosing first leather sewing machine

AlZilla replied to TakashiOkada's topic in Leather Sewing Machines

It's really hard to tell what the specifications are. I'd lay that responsibility off on your dealer, since you have one. I saw someplace that it could handle thread size 20/3 ... whatever in the world that is! It should specify a range. -

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

Tutorial, replacing zippers in riding boots.

Northmount replied to Mulesaw's topic in Shoes, Boots, Sandals and Moccassins

Moved this thread to Shoes, Boots, Sandals and Moccassins -

The more I looked at it, the more I thought it was impossible for a human being to carve it by hand - that’s why I assumed it had to be done with a laser or something. I mean, the forehead - it really looks like metal, like old, pitted cast iron. Mindblowing! Congratulations sir - it's a true masterpiece! Also thank you for your detailed answer, I really appreciate that. Love the trick with coarse sandpaper - I would never have thought of that - thanks for sharing!

-

help choosing first leather sewing machine

TakashiOkada replied to TakashiOkada's topic in Leather Sewing Machines

it says in the video that it can use size #14 to #24 needles, some other places say the smallest needle it can use is #18. I often use size #12 for very thin straps or watch bands and leather accessories with my father's old seiko TF-5. will this machine be able to handle such material/needle? something like this -

Hi, I recently purchased a used Juki 1541 that I now realize was in poor shape. I downloaded the engineers manual and watch a lot of YouTube videos, as well as missing, broken and worn parts. I have timed the hook/needle and adjusted the forward/reverse stitch length to be the same. The issue i have is when testing the forward and backstitch (not using thread), the backstitch will enter the same needle hole for 5 -6 stitches and then start moving further away from the front stitch holes. This is on stitch setting 6. Increasing or reducing the stitch length makes it worse with only the first 2 - 3 stitches going into the same hole. I ran some stitches only forward and then another row in reversed and checked the spacing with calipers and the spacing was equal. Is this normal with the Juki? Or is there a specific time to hold the reverse lever to accurately backstitch in same hole - like only when the needle is down to start the reverse? I was testing on 2mm veg leather. I’m not sure if i need to adjust presser foot or dog to get better results. Thank you in advance for your comments. Jon