All Activity

- Past hour

-

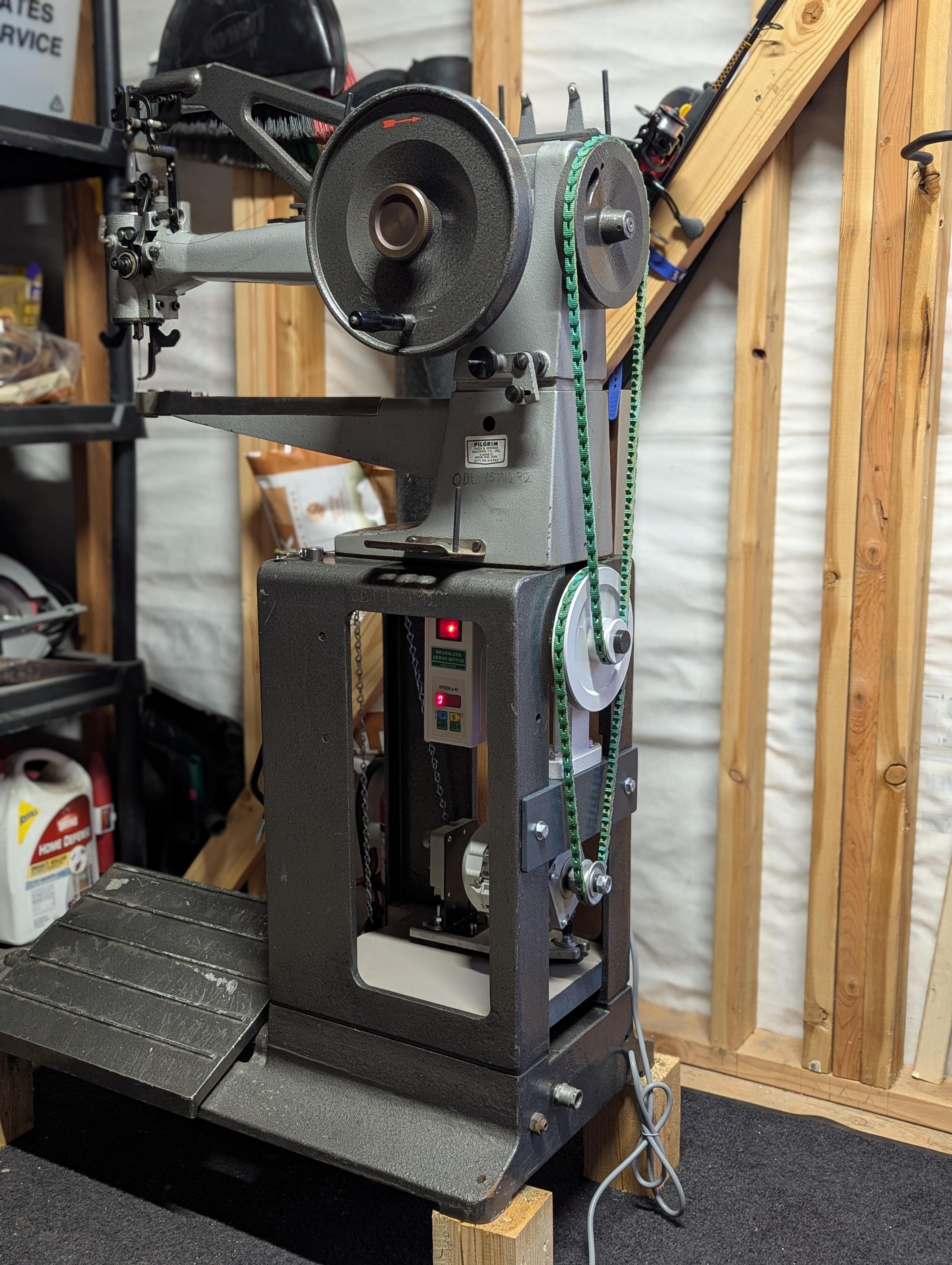

A couple weeks later and she's pretty much squared away. A thin plastic washer in between the motor side pulley and the casing got rid of the clunk I was complaining about earlier. There's still a lot of play in the hand crank but I'm not going to worry about it. I still need to finish up the bobbin winder and tall spool placement. The O-ring for the bobbin winder didn't come with the machine and I can't justify paying $25 for the "bobbin winder rubber" from Landis. BTW, a new shuttle costs $400!?!?! I have two, fingers crossed I never have to pay for a new one! I ordered a new servo motor with needle positioning sensor for my Consew and moved its servo motor over to this machine along with a 3:1 speed reducer. I had to make a couple custom mounts and platforms but enjoyed working through the process. While doing some testing, the machine was running about 32 SPM which is exactly what I was hoping for. I did get some belt slippage when not giving it a running start on some thick leather. I'm wondering if a rubber v-belt would do better than this adjustable fiber chain belt that came with the machine. It was very convenient for setting everything up but it seems to be more "slippery" than what a v-belt would be. Eventually I may get some low profile wheels but for now I think it'll just live on the floor. Thanks for the advice and feedback!

-

Not really a fan of rough out, but man you really made it look great!

- Yesterday

-

Adventures in watch strap making

dikman replied to dirk87's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Well, my efforts were not exactly a success. First leather I tried cracked at the fold for the pin. I then tried kangaroo leather as it is thin and tough, unfortunately it is still too thick, next I tried some chrome-tan as it's thinner but two different types proved to be too soft at the fold. I finally got a piece to stay in place around the pin but it has too much stretch to use as a watchband, I don't think buckle holes will last long. The problem, I finally realised, is the watch, it has recessed parts in the body where the pin/strap fits which severely limits the thickness of the band material. Probably why they use synthetics for all the bands for these I guess. Ah well, it was an interesting experiment. As I have a strap hanging off one side of the watch I'll use it as a fob/pocket watch instead. Me hats off to you, Jim of Calgary. -

Anyone taken a cheap servo motor apart?

friquant replied to AlZilla's topic in Leather Sewing Machines

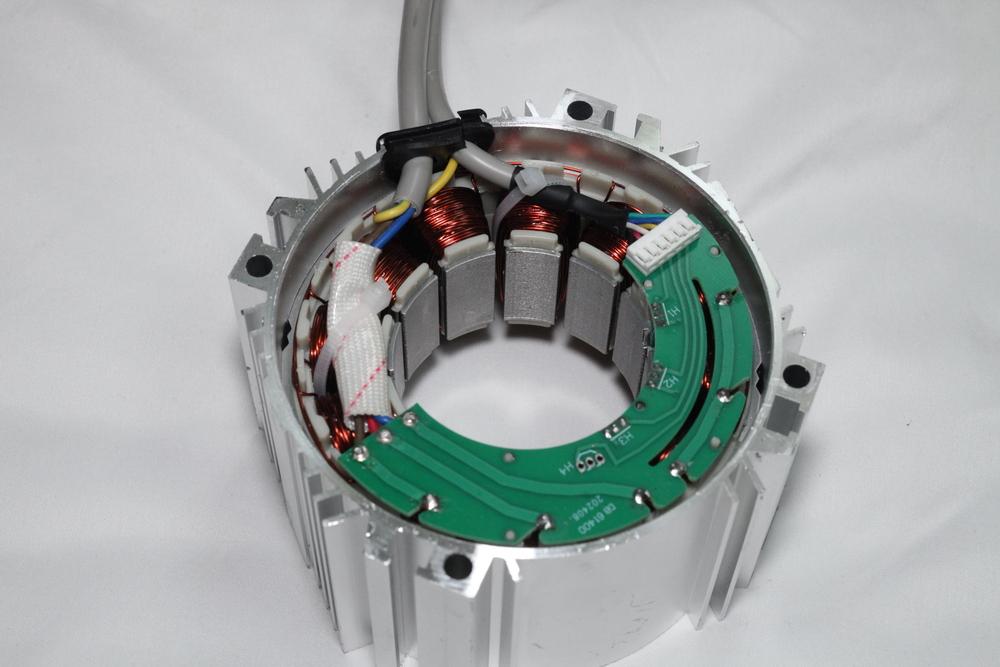

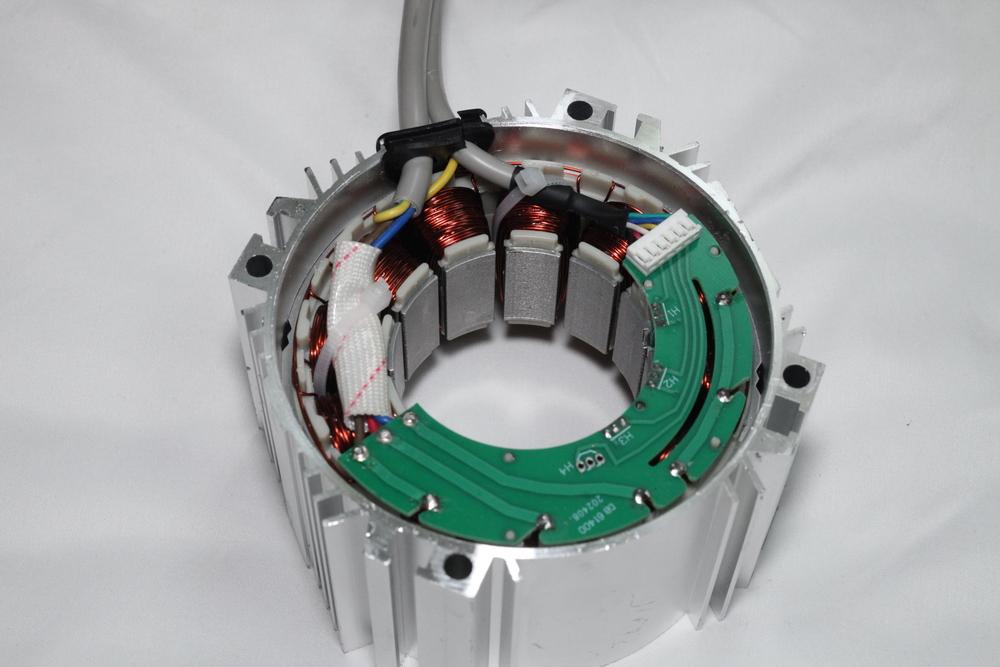

This is the stator and rotor from my "stitchman" digital servo. Only took about fifteen minutes to get it apart with a #2 philips on the screw gun, then a screwdriver and wrench to pry the plates off. Those permanent magnets are no joke! -

Universal motors are all brushed. My universal motor came with extra brushes even. About half the digital servo motors I see advertise as being brushless---the others don't say. I took the motor apart today on my "stitchman" digital servo and verified that it has no brushes. If anybody has a digital servo with actual brushes inside, I'd be interested to hear.

-

https://dn790008.ca.archive.org/0/items/TheAshleyBookOfKnots/the ashley book of knots.pdf Over 600 pages! That's a lot of knots.

-

Ditto!

-

Stitch strength heresy - Lock vs Saddle

Cumberland Highpower replied to AlZilla's topic in Sewing Leather

Ok. -

Tall Post Sewing Machines?

Cumberland Highpower replied to Cumberland Highpower's topic in Leather Sewing Machines

Hey I like that. I guess that's the "Slant 6" of the sewing world? -

I'm wondering if the minimum speed issue is to decrease heat. I've read that 300 is where heat dissipation is adequate (maybe for sustained operation?). Possibly 200 is banking on the user not staying at 200 for longer periods? I've also noticed that some of these cheaper motors have actual cooling fins on the outside of the body, where others just have undulations cast into them. My current motor with a 100 rpm minimum start speed has the cooling fins on the case. I'll have to start noticing if there's any correlation. Also, based on my recent disassembly of a cheap servo, the fan built into the end is just flat paddles running next to the closed end of the motor. No circulation at all. I think a small computer type fan blowing on the motor housing would really up the cooling game. It's on my to do list, even though with my low volume of sewing, I don't think heat is going to be an issue.

-

And maybe there's a distinction between brushed and brushless.

-

The top thread on a machine stitch saws back and forth something like 50 times. Remember that the tension arm way up at the top of the machine is letting it get pulled around the bobbin each rotation and then yanked back up. I was surprised when I first heard it. You are correct about the bobbin thread having an easy time of it. I'm glad this post finally got some traction.

-

Well said Fred.

-

I would dispute that simplistic statement 1. I like to saddlle-stitch. It is NOT for novelty value. Knowing how to saddle-stitch is good for any sort of leather work. I can s/s some items up faster than it takes me to set up any sewing machine 2. Poverty - NOT, I have numerous usable sewing machines and a few speedy-stitchers. The right tool for the right job. All in the leatherworkers armoury. I am neither poor nor rich

-

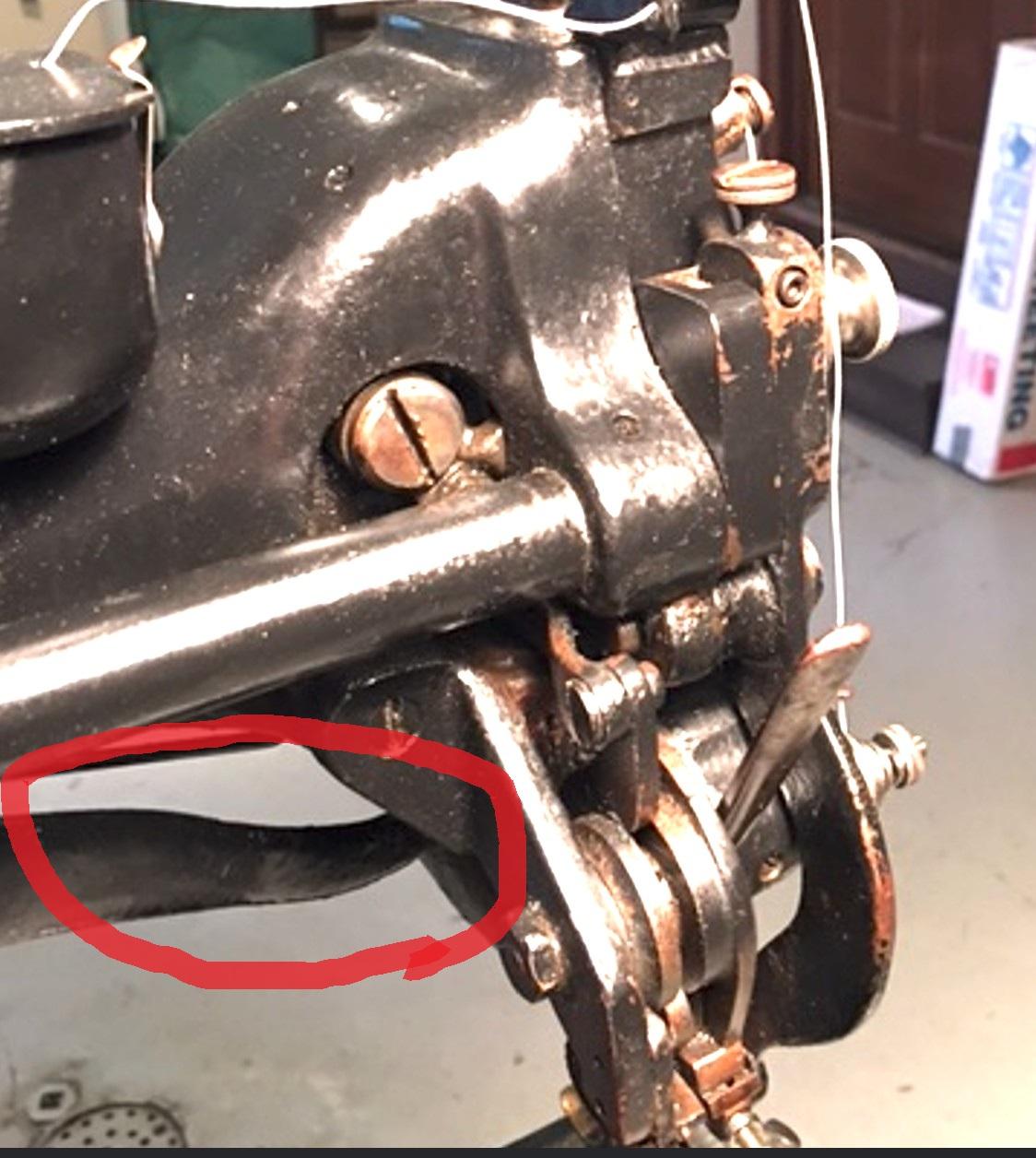

Hello, I have a question about my 45k53 machine, Since I couldnt find parts list for 45k53, I dont know how it would be but, I want to rebuilt foot lifter lever . I have also one 45k25 and I have completed rebuilding for 45k25 . From this topic , I have seen this photo with lever system And also I want to share my machine photos, I just want to learn the shape of part,in order to produce a utilizable replica of it. I think it should be a bit diffrent from the one 45k25.(part code 91716) If possible, Could you please share the photo of foot lifter lever for 45k53 (or part code of it) Thanks

-

Tall Post Sewing Machines?

nylonRigging replied to Cumberland Highpower's topic in Leather Sewing Machines

Not a Tall extra high post, but the slight shim tilt forward modification to the sew head is more comfortable on sitting behind with eye-hand, and you dont find yourself leaning forward as much . - - -

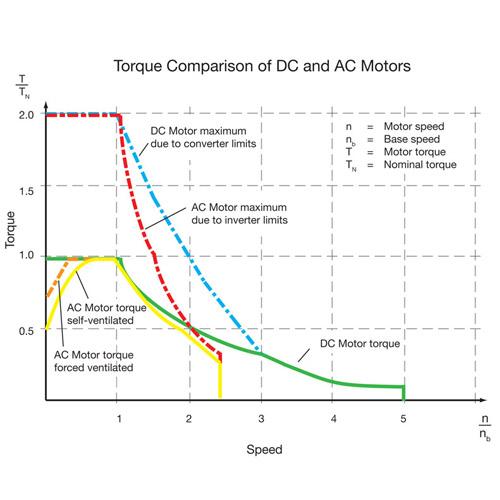

I guess the problem is with the minimum speed to start. Which is I guess an engineering characteristic of the motor, but this is beyond my limited knowledge of electric motors Regarding torque of different types of motor I found this:

-

Nay, with any hand stitching one keeps the thread well waxed to stop any abrasion by the leather and thusly by the thread itself

-

I've started to distinguish between digital servo motors and universal motors with triac speed controllers. Unfortunately, both are marketed as "servo motors".

-

Oddly, most everything I've seen about the cheaper servos is that they lack torque in the low end. I don't know ...

-

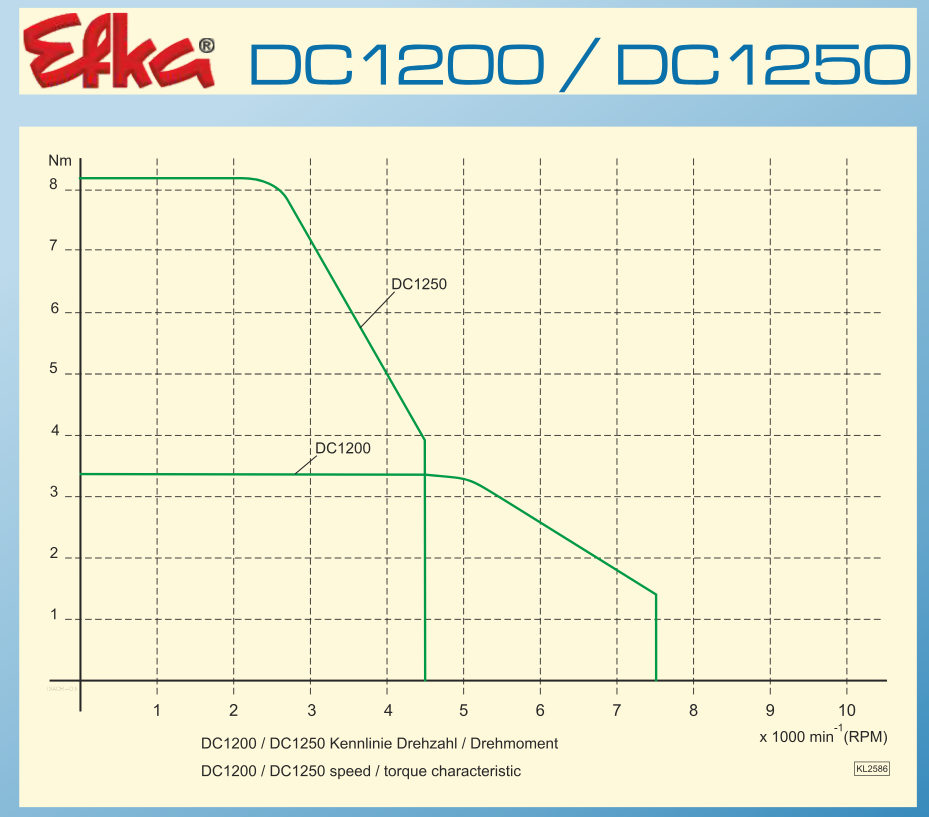

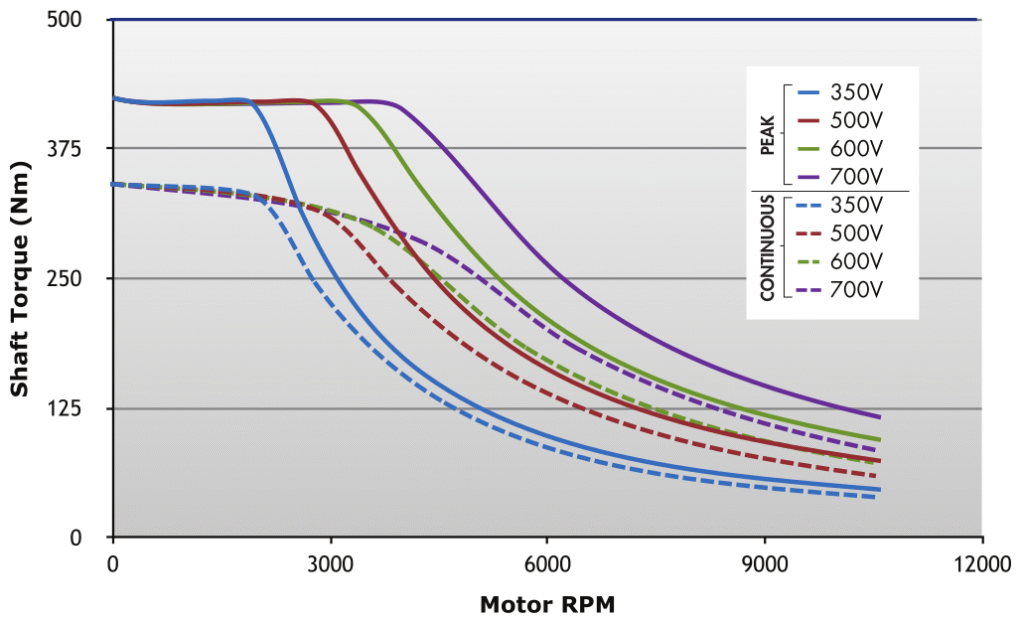

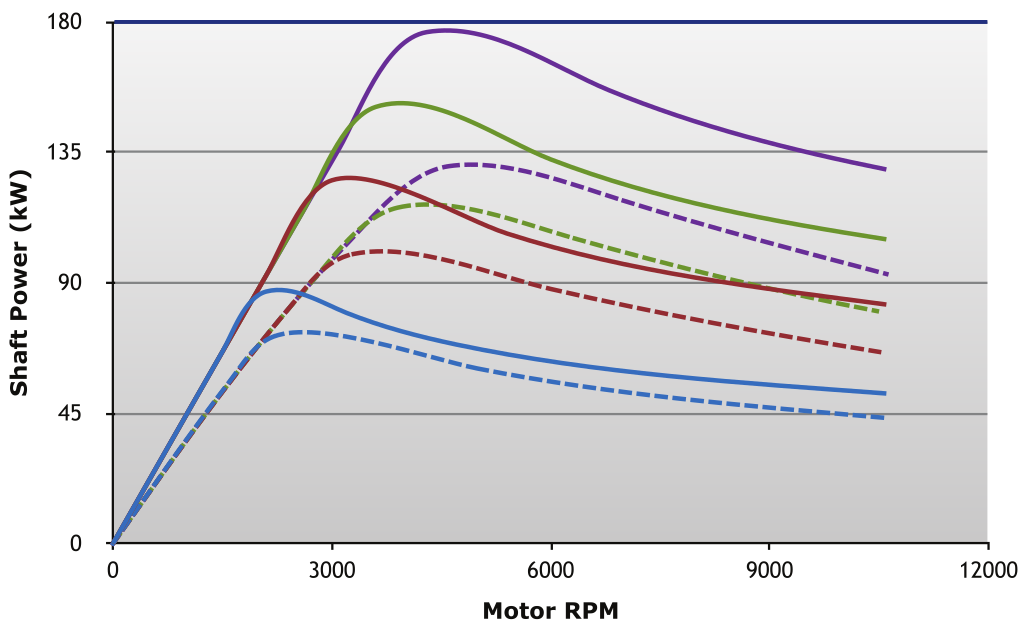

Those are very informative charts. I'd really like to see the same data on lower end servos.

-

of course they have, this is from Efka site: which shows that torque is more or less flat in the lower part of the rpm. It also shows that they have two different servos, one built for speed and the other built for torque. The power is function of speed and torque: P [kW] = (T [Nm] · ω [rad/s]) / 1000 in lower speeds where torque curve is flat the power is increasing constantly with speed. Later it can decrease slightly (depends on the turning curve of torque). Of course when the speed is 0, power is also 0. And because of engineering reasons the motors have minimum speed at which they work.

-

@WMages Good question, I guess it depends on how you want to make your holsters. There is a skiving knife on a 5 in 1 that will make a skived edge alongside a curved edge, so that could be a solution if it is something you already do, or perhaps it could be something that can set your holsters apart from others? The cutting wheel like you mention could potentially help. Could you perhaps borrow the 5 in 1 from your friend, and make a couple of test pieces to see if it is something that would suit you?, make a scabbard and a couple of holsters and try to use it for all those things that you can think of, if the completed item looks better than your normal product, or if you found it easier, then I'd say go ahead. But if it just ad complexity to the process and no real gain, then you have tried it and knows that it won't work for you. Another thing that you might consider, is that you can always try to sell the 5 in 1 again if you don't like it. you might loose a bit of cash, but I think the value of those machines won't change much even if you use it for a couple of months. Brgds Jonas

-

Hey, Dwight! I'm your Huckleberry! I've been sewing patches for bikers for a decade now. I use a patcher, a flat bed and a post machine depending on how the sewing needs to be done. Here's the breakdown. If the patch is on the back, or upper fronts, and there is no pocket or zip open liner behind it, I use a long bed flat bed Singer 139. It doesn't have reverse, but I sew all the way around the patches. No reverse is needed as the starting stitches are covered by at least 6 to 8 going over them. If the vest (cut) or jacket has a pocket to deal with, I use my Adler 30-7 long arm, big bobbin, high lift patcher. It easily gets into pockets and zip open linings. If the sewing is around the vicinity of the arm holes, I tend to use a post machine. It's much easier to turn the vest around the post with the excess hanging down that to fight with a flat bed or patcher. An example of when I use the post machine is when I'm sewing flags or club names, or office positions onto the upper shoulder, in the narrow area between the front and back seams. I use double-sided leather tape from Wawak to hold the patches in place for sewing. If the back is extra flimsy, or is made of denim, I also use a long body office stapler to keep the patch and material lined up. Next, I prefer to use #69 bonded thread with a #18 needle, unless it is on a jacket or padded vest. Then I'll use #92 with a #19 needle. As for the needles, I have learned to use round point needles when sewing any patch that has a serged or embroidered edge. This is because a leather point needle will slice the closely sewn edge thread whereas the round point just goes between them. The leather under the patch doesn't care about the needle. It is garment leather. If your machine takes a needle system that is available in titanium coated needles, buy those whenever possible. This really comes in handy if you are sewing through double-sided tape. I also keep a little can of Goof Off and a dauber near my machines so I can clear any glue or tape residue off the needle. If your patcher has a lube pot, fill it with clear liquid silicon to keep the top thread from sticking to the eye of the needle. While at Wawak, buy some steel thread snips. Put magnets on the body of your machines and let them hold the snips and threaders, bobbins, etc. Wind extra bobbins in advance so you don't have a lot of downtime when you run out of bobbin thread. Prewounds go a long way if they are available for your machine(s). That's all I've got to say about tha-at!

-

spring flowers and good food

Handstitched replied to chuck123wapati's topic in All About Us and Off Topic

If my memory serves, years ago , mum had a few tubs of clay in one of our sheds, 2 different types for different applications. They were hermetically sealed , and still soft ready to use, heat and moisture kept them preserved. I might try to find them . I wonder ? 🤔 I also have her potters wheel, tools etc. Had our last visit to the hospital this arvo (hopefully) just another video conference to go. All that I've been doing seems to have paid off , according to the nurse, can't thank them enough for their help. And yes, not a period to be repeated. Take care HS