All Activity

- Past hour

-

I had a seagull get caught between the mirror and me with the window open in my truck one day at the city dump. damn thing about beat me to death before he/we got loose lol. My son was with me and laughed his ass off, Yellin, get him dad yer winning. Last year, while fly fishing, a pair of geese with younguns sprang out of the brush about ten feet from me. They honk and flap their wings to startle the threat so they can evade, and damn i thought I was a dead man for a minute i turned and they went by me about 40 mph it seemed lol geese look really big when they flair thier wings. Again, my son was watching from afar and rolling on the ground, Whats wrong dad they scare ya?

-

That's amazing. He shouldn't even have to come down off a ladder for lunch lol. Beautiful craftsmanship!!!

- Today

-

You did a beautiful job on that belt. I was just joking, there's so much stuff on that belt I was thinking you could possibly get a holster behind the hammer holder in the small of the back, just joking around. You did a great job on that. I would wear that belt in a heartbeat, my friend.

-

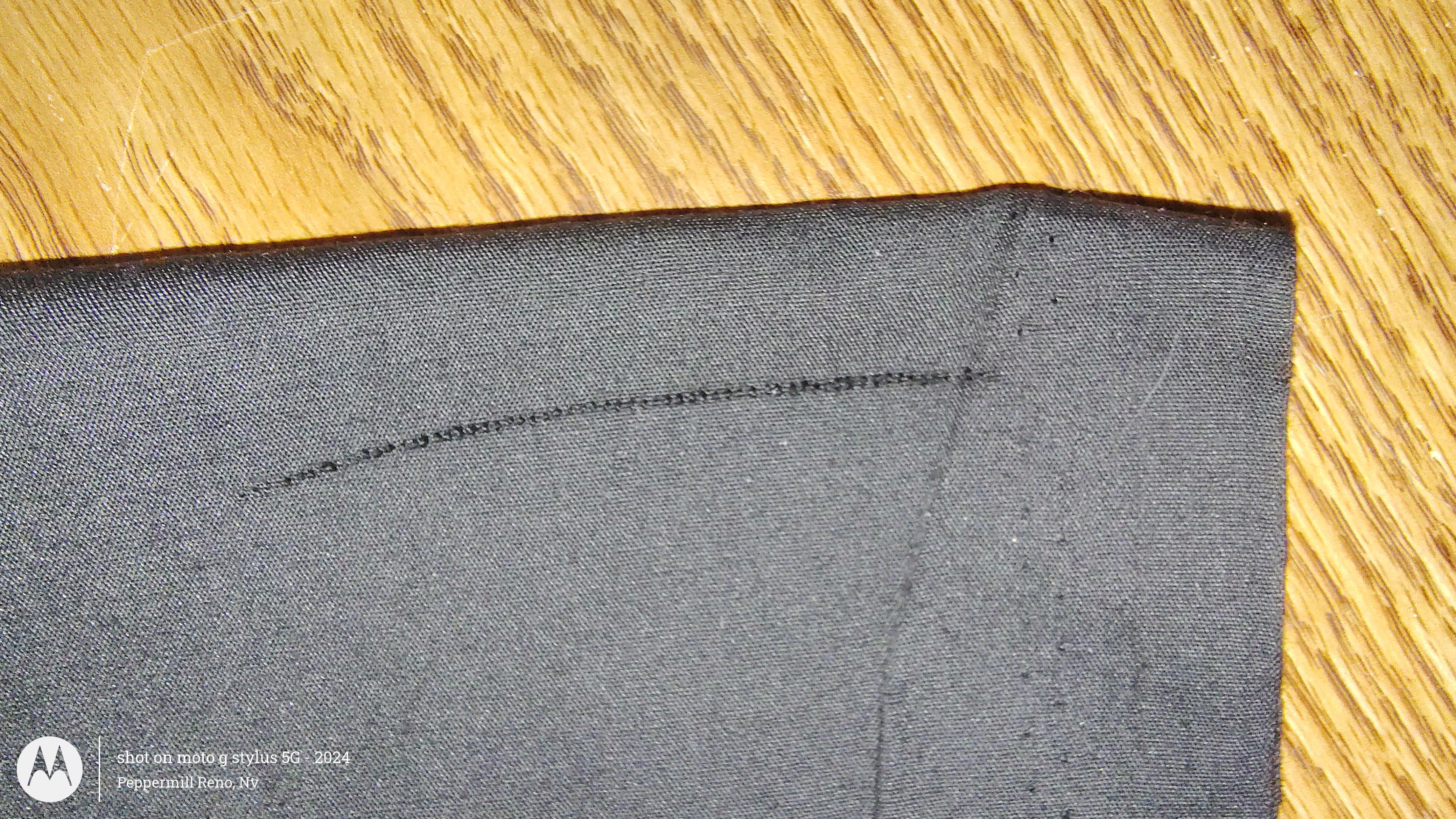

I learned this from you quite some time ago. I wondered what that little wheel looking tool was all about. It does make a huge difference.

-

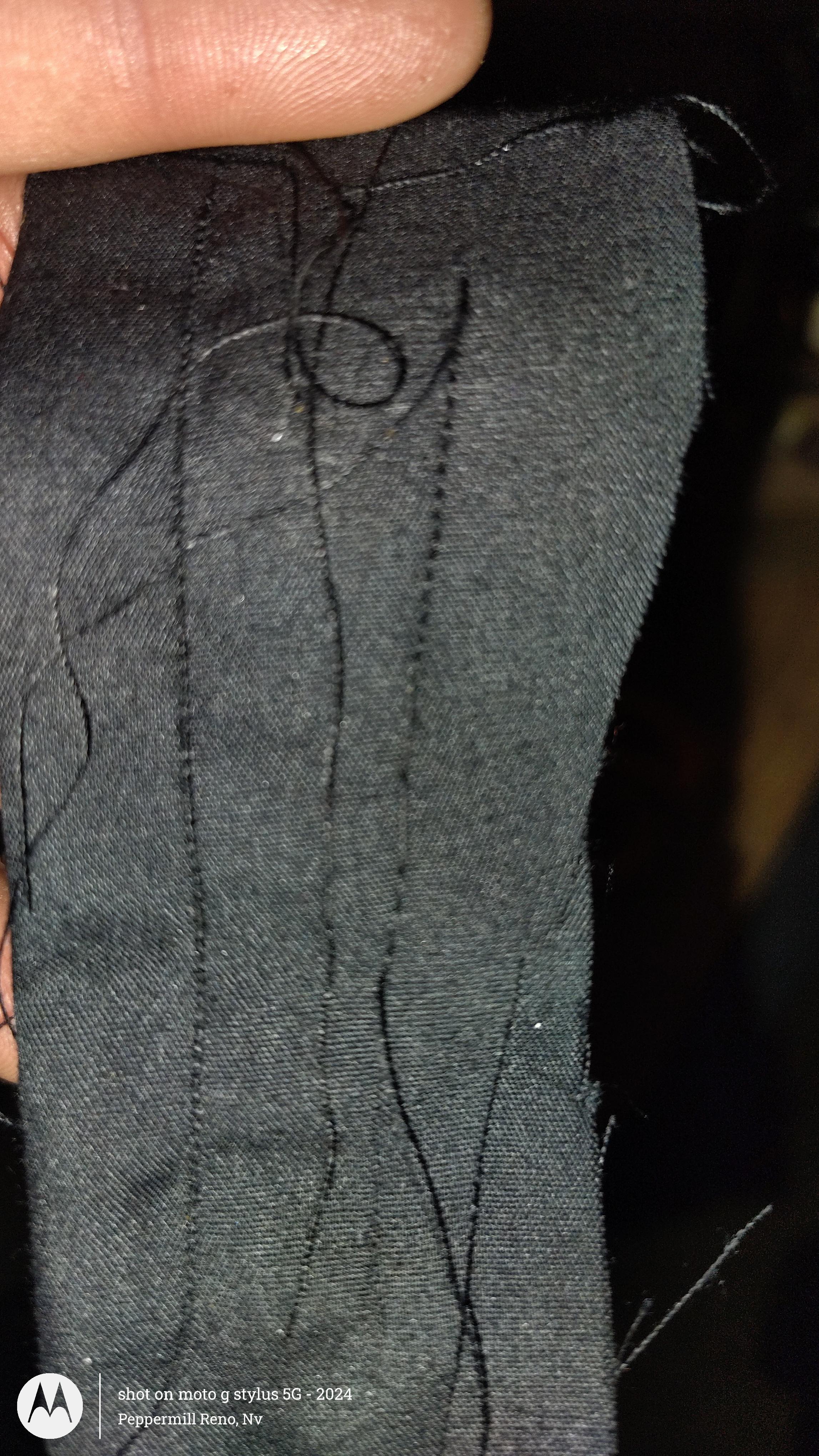

I'm about to head out the door but a couple of quick thoughts ... Sounds like it's hammering. Definitely needs cleaning and oiling internally. Especially the hook area. A dull needle could contribute to that sound. The slow start could also be related to lack of lubrication. But very often that slow start means the motor and/or foot controller need to be serviced. This is all easy stuff to do. I'll recommend going to you tube and looking up Andy Tube he has hundreds of videos, mostly on old Singers but it still applies. Also Vintage Sewing Machine Garage. I'll check in here later this evening and see if we have any updates from you. Oh, the stitching is probably a simple issue as well. It starts with cleaning, oiling, checking your thread path, using new thread and needles, things like that. It's all very Zen. Sit with the machine, go over all the parts of it, study how it works. Become One with the machine . Ommmm...

-

I don't have a photo from the back, but the circular piece has slots. There are two straps and they simply pass through the circular piece. I placed the slots at 90 degrees because it seemed like a good idea. They should be closer to 60 degrees. I'm not sure what you mean by holster. Randy

-

MBurman joined the community

-

I took a video of how it works and sounds. It's amazing the last time I pulled it out the needle was hitting the shuttle. Now it works . I think it still needs to be oiled because sometimes when I hit the peddle I gotta turn the hand wheel to get it go. This time I didn't need to. VID_20260122_002212670.mp4

-

Nothing but beautiful . . . May God bless, Dwight

-

Fender repair...

Brokenolmarine replied to Brokenolmarine's topic in Saddle Identification, Restoration & Repair

They looked pretty bad originally.... but I was told they aren't all the same, and finding matches might be hard. Wouldn't want to have to buy a new set of stirrup straps just because the blevins are ugly, when they aren't seen while riding. (I guess) They can clean them the rest of the way... if they like. -

Fender repair...

Brokenolmarine replied to Brokenolmarine's topic in Saddle Identification, Restoration & Repair

Back at it again, I carefully stamped the tooling pattern around the inside of the border, AFTER I cut the inside line deeper with a swivel knife the blade of which I had re-sharpened and polished. I now had a clearly defined sharp reference to work from. Each stamp was checked before I struck it and EACH strike was firm and careful. I wanted to avoid a glancing blow or a bounce, both of which could ruin the entire line. In the picture below you can see the border, as well as my Maker's Mark at the bottom of the leg on both Fenders. Again, Careful Placement, and then even more careful in the strike. Too much work to blow it now. A closer look at the border pattern. This is what she wanted. I would have gone with a Serpentine Pattern myself, but then... not my saddle. LOL. Next session, I'll work on dressing up the edges in preparation for applying Watco Oil or stain. There are some spots I'll want to smooth out the "Line/Flow" of the edges so that we can burnish the edges. I'll take a couple scrap pieces and make test panels for stains for color comparison. The owner of the saddle finally sent pics to assist with color match, though she isn't too concerned. I like to try. I did get to do some Clean Up work on the blevins, removing old glue, rust, staining... We'll be reusing the old beat up ones. They tell me they can't be seen, So why not. -

Hi everyone, I’m looking to pull the trigger on my first industrial machine: a refurbished Juki LS-1341 from a local seller. It’s fully overhauled with a digital servo, needle positioner, and compact table. My primary focus is leather bags mixed with outdoor technical fabrics (Cordura, ripstop, canvas) and lightweight liners. I plan to keep my domestic HD machine for very light work, but I want this Juki to handle the 'medium-to-heavy' range. My Confusion: I’m seeing a lot of conflicting information regarding the needle size compatibility for the LS-1341, particularly on the lower end: • Juki Junkies: States a range of #19 to #24, mentioning that anything smaller (like an #18) requires re-timing. • Other Third-Party Dealers: Some list the range as #16 to #24 without mentioning any timing modifications. • Cobra Class 26 (Clone): Rated for #12 to #25, even though it's the same basic design. My Questions: 1. Lower Limit: Can I reliably run a #16 (Nm 100) or #18 (Nm 110) needle for sewing Tex 45 or Tex 70 thread through Cordura/liners without skipping stitches or hitting the hook? 2. Needle Systems: Does the choice between 135x17 (fabric) and 135x16 (leather) impact the timing tolerances for smaller sizes? 3. The 'Re-timing' Myth: For those of you with an LS-1341, have you had to physically move the hook closer to the needle (adjusting the needle-to-hook clearance) just to drop down to a #18? I really want a 'do-it-all' machine for bags, but I'm worried that if I'm forced to stay at #19 and above, I'll be punching 'drainage holes' into my lighter technical fabrics. Any insight from long-term 1341 users would be greatly appreciated And if there are any recommendations for other machines that might fit my needs better im all ears!

-

Fender repair...

Brokenolmarine replied to Brokenolmarine's topic in Saddle Identification, Restoration & Repair

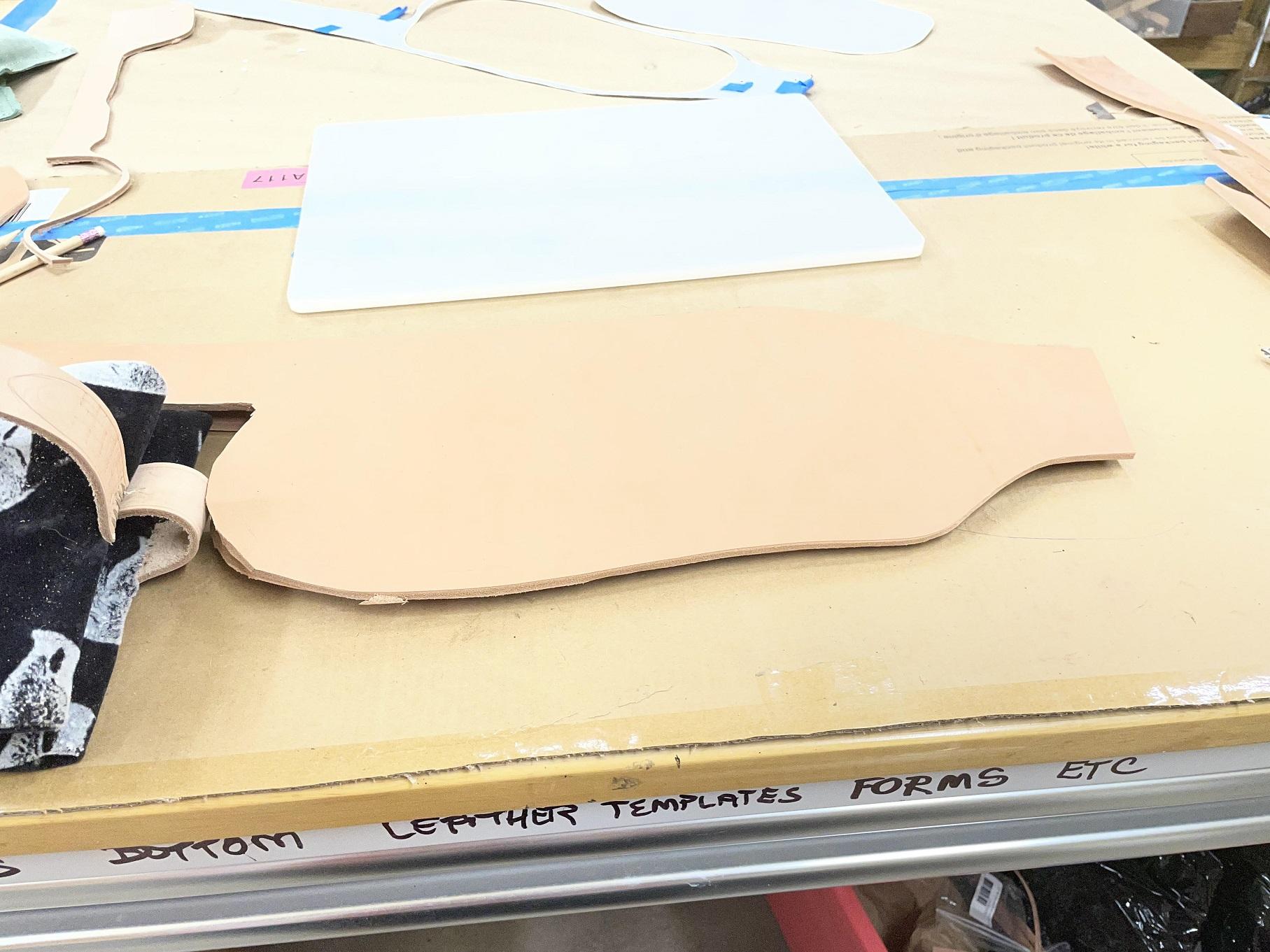

I came out after breakfast the next morning and checked. Success. The Fenders were flat and ready to tool. I used the template to carefully, and LIGHTLY pencil in the pattern. Using a double border swivel knife, I cut in the border. This is detail work, the pucker factor was HIGH. This type makes my arthritis scream, so I was done for the day. BUT, I didn't blow it. Not bad for a Broken Old Marine. I left this to rest while I rested the hands overnight. -

Fender repair...

Brokenolmarine replied to Brokenolmarine's topic in Saddle Identification, Restoration & Repair

I have made some progress in the past few days. I used the original template for the fender, and cut out a border template. It would allow me to insure the border I cut into the one side, matched the border I cut into the other. Why? Since you can't see both fenders at the same time when they are mounted on the saddle? Hey, just the way I do things. I try and do things the right way... or as best I can. However... before I can actually transfer this pattern to the fenders... there is an issue. They still retain a curl from the shipping. As I did with the original fenders, I sprayed them down with a generous mist, and weighted them down on the bench and left them for about six hours, then checked them. They had flattened considerably, but would benefit greatly from a second treatment. I repeated the process and left them overnight. -

Holy moly those are beautiful

-

My thoughts: i) #20 needle is for V92 thread not V69. reference chart ( https://www.tolindsewmach.com/thread-chart.html ). An incorrect sized needle for the thread size can cause skipped stitches as the loop sometimes does not form properly which gives you skip stitches. ii) With a fabric backed material I would try a 135 x 16 x 18 to cut through the vinyl rather the 135 X 17 x 20 rather then punching through with an oversized hole. Think of it more like trying to punch a hole in piece of paper with your finger rather then a needle. The fabric needles are meant to push apart/separate fibres so as not to weaken the fabric where as the fabric on your vinyl is probably more for stability to help it from over stretching. kgg

-

You need to list a price in USD as well as photos and description of their condition. Will you ship, where to, who pays. See the marketplace rules here https://leatherworker.net/forum/forum/70-announcements/

-

Thank you, I really appreciate your impute. Great advice.

-

Swiss Saddler Clam Drawings

ClaimedVacancy replied to ClaimedVacancy's topic in Leatherwork Conversation

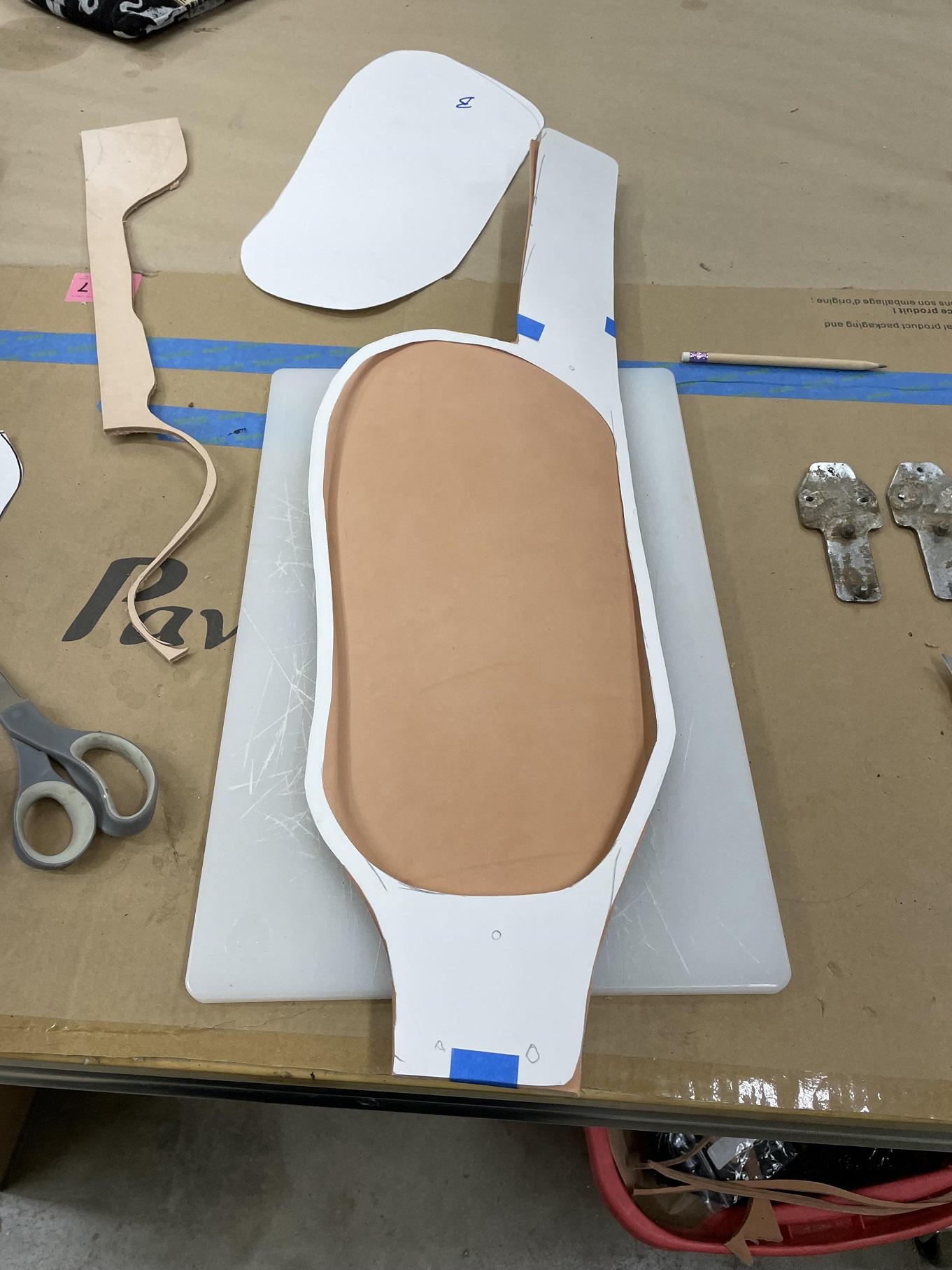

Update: Template has been cut out. Now to cut pieces of birch ply, glue, shape and trim, drill and fixture together. Hopefully everything beds well, but i expect some geometry to be out a bit. Im expecting to use some beryllium bushings for the pivot points such as the right arm and foot lever. That way i can get muchhhh greater life out of the working holes. The left arm is stationary, and the cover plates will affix to them accordingly. Ill need to create the friction lock trip. Ill be making that out of mild steel. Flat stock and just bent at the appropriate areas for the piece on lever. The guide rail at the foot lever ill have to create a mount for that, but its straight forward. The spring at the top, also straight forward. Ill drill holes for a small nub on each arm where the spring will rest. This is what will push the right arm open when the friction lock is disengaged- 6 replies

-

- swiss leather tools

- swiss army leather

-

(and 2 more)

Tagged with:

-

NewbieJason joined the community

-

I just got some new Palo Santo bevelers as a gift, a set of #0, 1, 1+, and 2. Brand new out of the cork, I tried them out on some scrap 6oz veg tan I have and with all four I get this super weird concave bevel. I’ve tried all manner of pressure and angle, and the only thing that even comes close to a rounded profile is if I hold the tool super steep, like almost gouging steep. I can’t for the life of me figure out what’s wrong here. Another user showed the profile I’m getting but that thread didn’t really give me any answers. Here’s the profile sketch, the bottom of the tool, and the edge that it gives. What’s going on here? Gallery of edges

-

I don't see a holster anywhere on that system?

.thumb.jpg.be873fe3cafed424774b187cfb1a470f.jpg)

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)