All Activity

- Past hour

-

Whilst I do have the actual ammunition for what I've made so far I made up a set of dummy rounds in .38, .44-40 and 12ga, makes it much easier to make belt loops. I also have an assortment of empty rifle calibre cases if I ever need them. I'm guessing you couldn't have them either?

- Today

-

Hello, would you mind trying to send me the manual you have? I have been getting acquainted with my Adler 30-70. I just bought some gun oil and am preparing to clean and oil it. I would like to do this properly if possible but have been unable to find a manual. Thank you. pond.amy17@gmail.com

-

First off using Weaver Leather Thickness Chart ( https://www.weaverleathersupply.com/pages/leather-thickness?srsltid=AfmBOoqzN2JPG7btuXxjAntVnhbq3NjzasVYzvuTwaMaLRu6Y0adRV4J ) 16 oz of leather is going to be 1/4" (6.36mm) and add another 2 oz you are going to be at .281" ( 7.14mm). The max the spec say is 3/8" ( 9.53mm) which is going to give you less then 3/32" (2.39mm) wiggle room. That for me would knock that particular machine out as I would think you would always be pushing it to or near it's max. which I figure would reduce life expectancy. I would suggest looking at other alternatives maybe a Class 1341 cylinder arm machine similar to the Juki LS-1341 (or clone) but I don't do footwear. The Cobra Class 4 is NOT a post bed machine it is a cylinder arm Class 441 clone of the Juki TSC-441. These machines are meant to sew such items as holsters. They use a needle that is visually almost the same size as a 2 1/2" finishing nail. They weight in at about 125lbs for just the head alone verses a LS-1341 at 82 lbs. I would suggest: 1. read 2. either visit / telephone / sending a sample of what you want to sew to maybe someone like Toledo Industrial Sewing Machines ( www.tolindsewmach.com ). There is no one machine that will do everything. Buy a new machine that will do 90% of your items and get a second used machine to cover off the remaining 10 %. kgg

-

Hook to Needle Distance: A Compromise

AlZilla replied to friquant's topic in Leather Sewing Machines

It doesn't seem to be hanging up, really. Just a bit noisy. It's a "clone" of the Juki but with longer stitch lengths, if I recall correctly. Obviously it's not an exact clone, if it has longer stitch lengths. I wonder what they modified to get the longer lengths and if the noise is the price you pay for it? Really, how often are you going to reverse stitch at maximum stitch length? And probably only 2 or 3 stitches just to backtack. -

Look into re-tan veg tan water buffalo.

-

Hook to Needle Distance: A Compromise

friquant replied to friquant's topic in Leather Sewing Machines

In my original post, I reported that after setting the hook-to-needle distance to factory spec it was stitching fine in reverse. Well it's true that the hook is no longer bisecting thread. But it is quite clunky-sounding in reverse with long stitches. Here is a video that shows where it's still hanging up. 😢 This is stitching in reverse at max stitch length. 19-options-36.mp4 -

Hey everyone! First off, I just want to say how much I appreciate all the helpful input from this community. After your advice last week, I've decided to go with a post bed machine for my bootmaking projects. Most of my work involves stitching 16oz leather for work boots, but occasionally I'll be working with thicker combinations up to 18oz when using bison leather. I've been researching the Techsew 830 because it's advertised to handle 3/8" thickness, which seems better than most post beds that max out at 5/16". However, I'm not entirely clear if that 3/8" rating is for stacked denim or if it can truly handle multiple layers of thick veg-tan leather at that thickness. Has anyone here actually tested this machine with dense leather stacks? I'd hate to invest $2K+ only to find it struggles with welted seams or through heavy stacked areas. I'm also curious about alternatives - have any of you had success with other heavy-duty post beds like the Cobra Class 4 or used industrial Jukis? I'm trying to balance capability with budget, and would love to hear real-world experiences. actually my workshop space is pretty tight, so I'm planning to pair whatever machine I get with a compact industrial table - if anyone has space-saving setup tips, I'm all ears! (And just out of curiosity - has anyone here used a post bed for upholstery projects too? I'm wondering how it would handle thick hides if I ever wanted to tackle a vintage loveseat restoration down the line.) Really appreciate any insights you can share - this is a big investment and I want to make sure I get it right!

-

Scoutmom103 started following Stitchman Servo Motor (The Missing Manual)

-

sarayoung joined the community

-

@MML Glad to hear the needle positioner is working for others too! I added a reply to the manual that shows how to access the hidden menus. The most useful piece so far is being able to set the upper bound on max speed. 🐎😀

-

Stitchman Servo Motor (The Missing Manual)

friquant replied to friquant's topic in Leather Sewing Machines

Hidden / Admin Menus After making the original post, I found a video on how to access the hidden/admin menus. To view/edit the hidden menus: 1. Hold P while press "-" 2. Enter number "2013" by pressing "+" "+" "P" "P" "+" "P" "+" "+" "+" 3. Save by pressing "S" 4. Now you are in programming mode with hidden menus enabled Thank you to youtube's @kuchkosol126 who made this youtube video for showing us the hidden menus: https://www.youtube.com/watch?v=Ksw97IGThsg (admin) P-01 (Upper bound on Maximum Speed) This limits how high the user can set their maximum speed Useful!! (admin) P-07 (unknown) default: 1100 range: 800-2000 (admin) P-08 (unknown) default: 0 range: 0-1 (admin) P-09 (uknown) default: 0 range: 0-1 (admin) P-13 (Strange things) When I enabled P-13 the motor would rotate in reverse direction for a quarter stitch, then quickly go forward again. default: 0 range: 0-1 (admin) P-14 (max current) default: 0300 range: 050 - 1000 (I suspect this is non-functional I tried setting this to 050 but my the pulley still slips for me instead of the motor limiting the torque) ### (admin) P-17 (unknown) default: 1 range: 1-3 (admin) P-18 (Set Admin Password) This allows you to change the admin password default: 2013 Thank you to youtube's @kuchkosol126 who made this youtube video for showing us how to set the admin password https://www.youtube.com/watch?v=hrwzXAHG6qc -

What project are you working on? 5-6 oz rawhide is pretty heavy. When it fully soaks up water it can double & sometimes almost triple in thickness depending on how you long you let it go. Search this company "TRAHIDE". I have never dealt with them but they do have an extra heavy hide that is 6-7 oz.

-

veg tanned leather, no matter the animal, is softened by adding oils such as neets foot oil. This will darken it also but will enable you to tie knots. I would, if I were you, attempt to get samples of the different leathers you are wondering about then do some testing to find what will work. you might think about latigo leather also.

-

I just got it to work! @friquant’s mention of setting P-15 to 0 (it’s 1 by default) makes it work for me to always have the needle stop in the NPS’s programmed position (the range of the NPS’s light being on). On the manual @friquant put together, P-15 set to 0 seems to tell the machine to listen to NPS and the needle position. I’m not sure if without the speed reducer it would work with the other setting. It shows Er01 on the screen most of the time, but it’s consistently working. All you need to do is: Hit “P” & “+” until you get into program mode. Hit “+” until you get to “P-15” Hit “P” to go into the setting. At this point you’ll see it show “1” by default. Hit “-“ to bring it down to “0”. Hit “S” to save the setting. Use the “needle up setting” Good luck!

-

Good to know. It seems like NPS with the stitchman servo motor and a speed reducer is not possible. If anyone finds a way to get it to work, please let me know! My only motivation to have one is that with a speed reducer the wheel is much harder to move by hand, so it’d be nice. I do agree it’s not necessary at all with a speed reducer. I only wish the engineering was a bit better. The NPS knows the needle is not in the correct position, so i don’t understand why it would not tell the motor to keep going until it’s in the correct position (with the light on). Does anyone know how it’s working under the hood that it’s not agnostic to revolution size? @friquant, would you know? Thanks.

-

Let me start by saying my machine doesn't get an awful amount of use. The short answer is no but that's because I haven't tried. I usually use it on a slow setting and I find it easy to get the needle where I want it with small movements of the pedal or the handwheel. Maybe I'll have another go at it sometime later but at the moment I've other stuff on my plate including a very poorly dog. I will say that I'm impressed with the machine. I've just stitched both sides of a 60 inch strap on 20 and it didn't bat an eyelid. Can't say that of other machines in the past.

-

Holy smokes! I need that hat! I’ll put it on my “want to do list.”

-

New sewing machine! probably too much for what I need.

BenOrsonLeather replied to gordonl's topic in Leather Sewing Machines

I have a longarm in the workshop. Yeah, that sucker will practically sew through concrete. The issue I have with it is the foot lever to lift the presser bar! And I’m tall! I have to stretch my leg across the room to lift it! Hahaha! -

khyll started following Recommendations for very dense + soft leather?

-

I need some very dense and very soft leather, ideally veg-tan natural color so that I can dye it myself. It can be relatively thick as long as it's soft enough that I can tie knots with it. I'm thinking that moccasin bison might be what I'm after. I'm grateful for advice both on type of leather and suppliers that offer a good balance of quality and price.

-

Hook to Needle Distance: A Compromise

Michiel replied to friquant's topic in Leather Sewing Machines

I would try too see what’s happening when actualy sewing with tread and material (leather, canvas or what you are using) It can be hard to see, but if you can, and turn the machine by hand, you can see what is the problem if the machine forms a good loop in the thread the hook needle distance is not that important but if your thread is bad or the timing wrong you might get this. with some machines you can see it by sewing on the edge of your project and open the slide right of the needle sometimes you have to look from the underside. use a flashlight! -

BenOrsonLeather joined the community

-

Hello Where do you all get trucker hats and what type of trucker hats are used with.leather patches. Thanks

-

emmdom joined the community

-

@toxo Were you able to get the NPS to work with the speed reducer with one of the P settings? I have not been able to get it to work

-

pengkegu started following kellyswanson

-

Help Needed:About wiping the glue and edge paint

pengkegu replied to kellyswanson's topic in How Do I Do That?

I don't know what tool you use to apply edge paint. I'm used to using an awl. My method is: after covering it with paint, I hold the awl at a 45-degree angle downward and scrape the edge paint onto the leather. -

thank you for you sharing

-

friquant started following Hook: Off the Shoulder

-

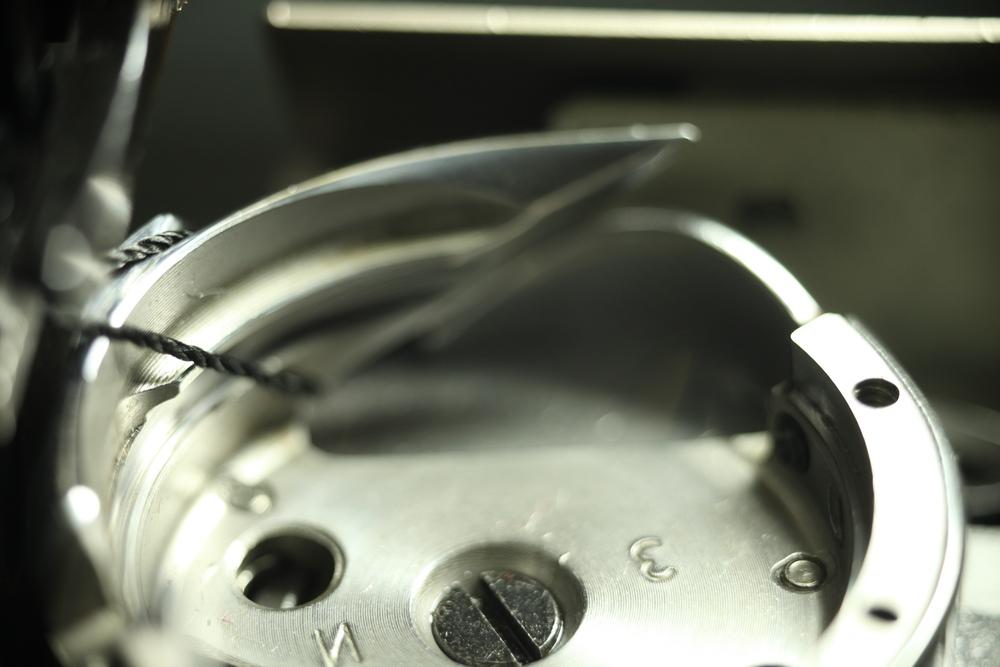

When a hook has a shoulder, does the thread need to ride in it? The hook on my JiangLong 341 (clone of Juki 341N) has a shoulder to it. When stitching forward, the thread rides in this shoulder. (See the first two photos) When doing long stitches in reverse, the shoulder did not catch the thread so the thread is lagging behind the shoulder. (See last two photos) The reason I am investigating this is to understand how the machine is so noisy when stitching long stitches in reverse. I have set the hook-to-needle timing and the hook-to-needle distance according to the juki manual. I have tried different positions of the latch opener. The latch opens the gate, but the thread does not go through it while it has the chance. Later, the thread gets yanked past the gate....yeek!

-

What's the thickest/heaviest weight Rawhide out there? Bovine or something similar. Been looking for some really heavy sides/double shoulders but can't seem to find anything over 5/6oz....Would like to find something heavier. Any leads/ideas?