All Activity

- Past hour

-

Thanks Bruce I appreciate it. This should be a sticky.

-

Coffee is dripping, kettle is boiling, my dog is enjoying her Christmas breakfast, and I'm just waiting for my sweetheart to get up. Merry Christmas!

-

Hope everyone is having the best Xmas they can whilst sparing a thought for those for whom Xmas will never be great again. And let's hope that 2026 will be a productive year.

- Today

-

Merry Christmas everyone!

-

Merry Christmas everyone!

-

It's 6:39 here, and I have just finished putting some cinnamon rolls together for the family when they wake up...you know those real gooey upside-down ones lol.

-

Merry Christmas!

-

Inadequate knife sharpness, or too much moisture. Ugly "drag line"

JDFred replied to LakeOtter's topic in How Do I Do That?

If you’re keeping your blade vertical to the work, which it looks like you are since I don’t see any undercutting, it is probably too much moisture. I’ve never had any success with the fridge method of casing it always comes out too wet for me. -

Thank you. It’s the first time I’ve made anything other than reins out of harness it skives and punch holes in it a lot easier than veg tan. Probably from all the oil and wax in it. Have a Merry Christmas. Thank you. I got the lace idea from the one I was coping measurements from. My mother in law saw that and really liked it also. Have a Merry Christmas.

-

Very nice work. I agree with Tom about the lettering. If the tapering was unintended just claim you designed it like that, it looks really good.

-

Merry Christmas, everyone!!!!!!!!!!!!!!!

-

Melissa Adams joined the community

-

Thank you very much for the response.

-

truebluehickbilly joined the community

-

Turned out nice. I like how you laced the brow band on the crown.

-

That's a nice adjustment system. The shuttles on my walking foot machines have a thin steel plate that can be bent in or out to limit the position of the needle. However, in my experience, the needles seem to almost always get pulled away from the hook and deflector shield. It would probably have more protective effect on larger needles, like #22 and up than on thin needles, like #18 through 20.

-

Happy Christmas everyone!

- Yesterday

-

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

kingsley machine Kingsley Hot Foil Stamp Machines

Northmount replied to Chris Wronski's topic in Miscellaneous/Other

Chances are your files are too large. Resize to 800 pixels in the longest dimension. If your files are too large to post here due to file size restrictions, you need to resize your files to fit. Please use jpg or png format files as they load automatically when the thread is opened. Follow this link for some helps and suggestions. https://leatherworker.net/forum/topic/15122-how-to-post-pictures-on-lw/?do=findComment&comment=551171There are lots of Apps, software, and online tools available on the web, or even built into your device to enable you to reduce your file sizes. 800 pixels in the longest dimension is quite adequate. Smart phone screens and many monitors don't display high res files in high resolution. People that live on the fringes of the internet appreciate smaller file sizes and high res photos may take from 10 minutes to hours to download. -

Inadequate knife sharpness, or too much moisture. Ugly "drag line"

dikman replied to LakeOtter's topic in How Do I Do That?

Sounds like your blade is sharp, I reckon it's got too much moisture in it. I had a similar thing when I wanted to try something in a hurry, I dunked the leather in a bucket of water and started cutting not long after and had a similar result. I think the excess moisture makes it too soft and causes the leather to "grab" on the blade. -

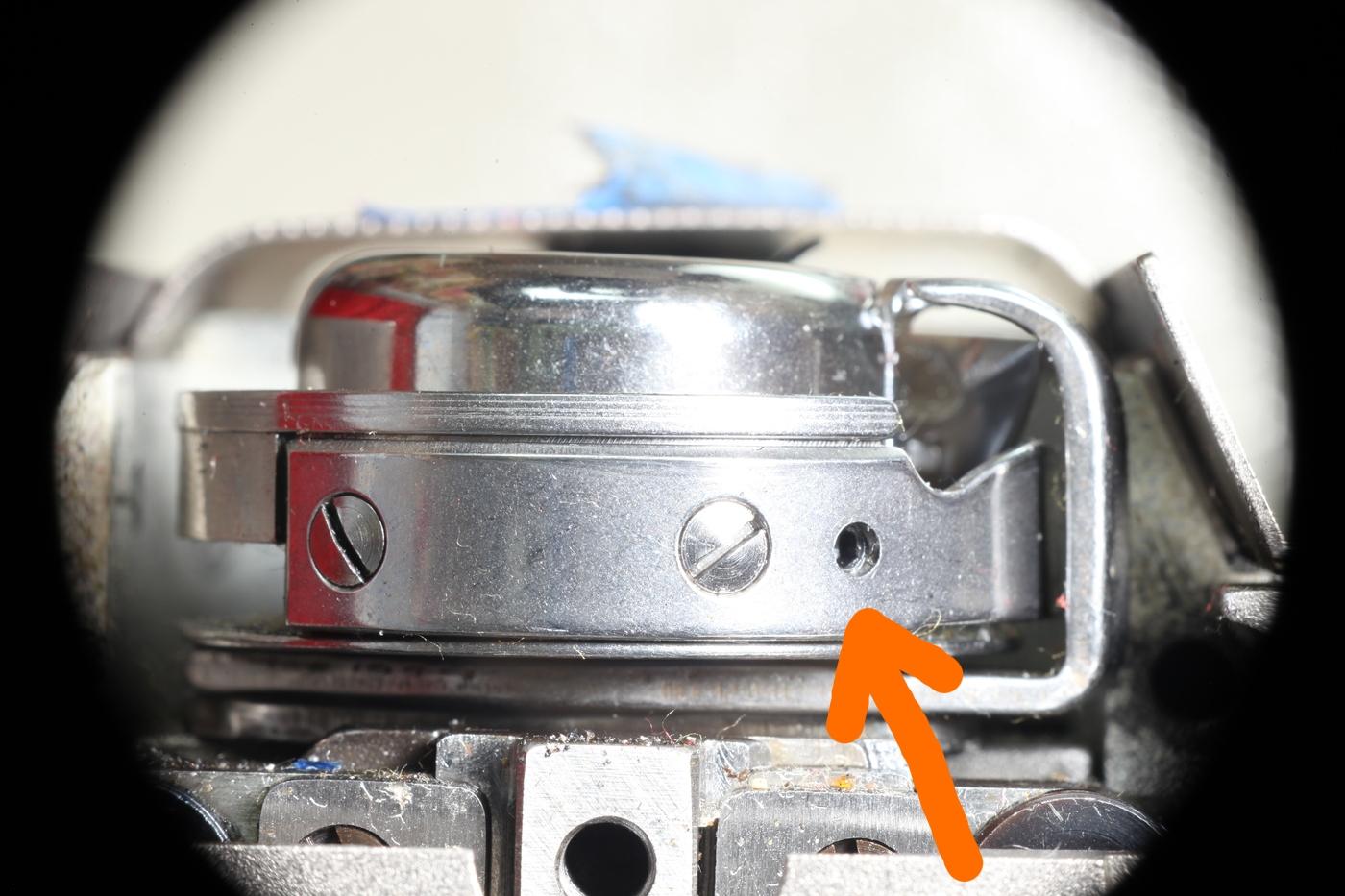

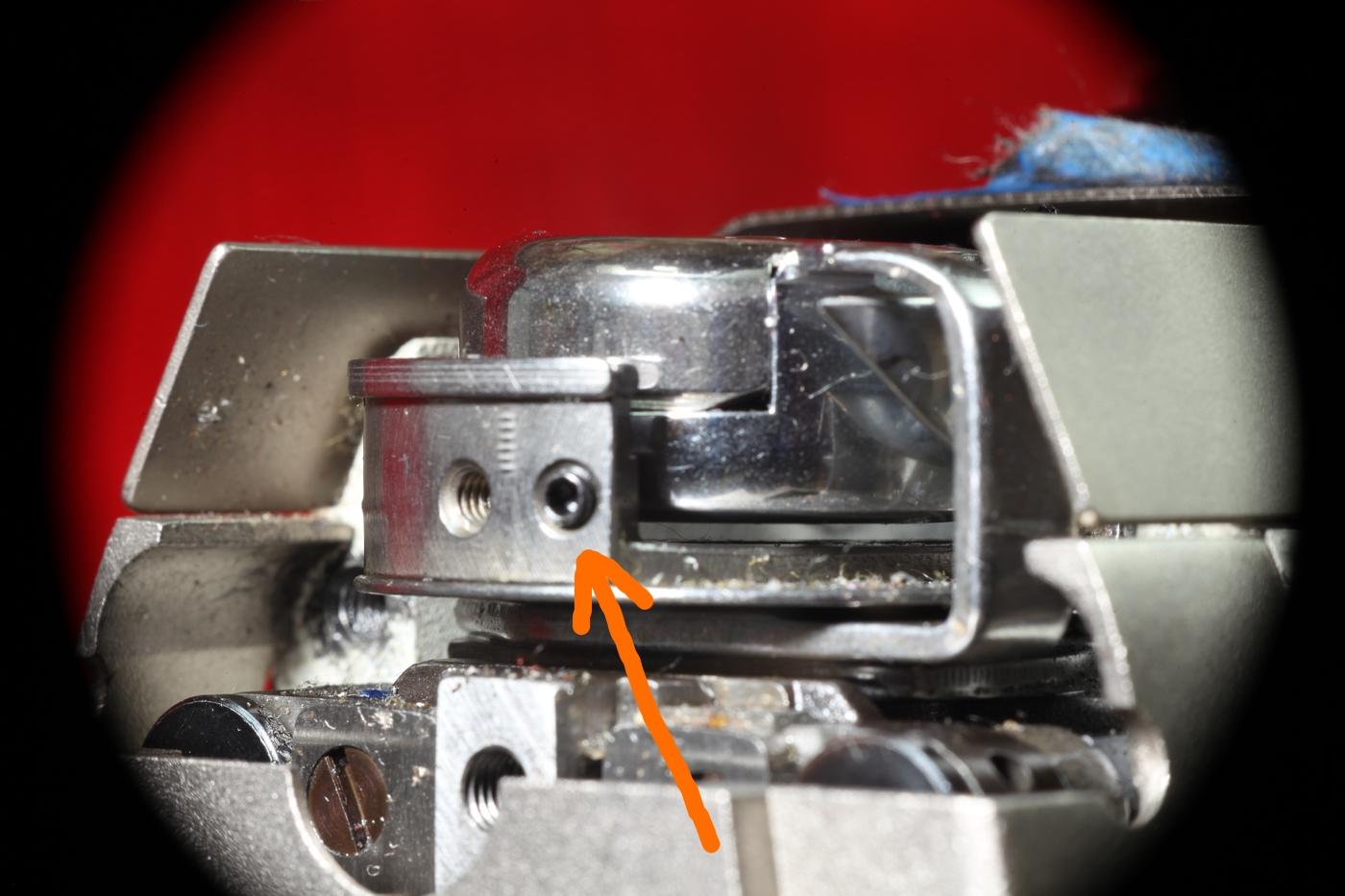

I hadn't noticed this before, but I think it's an adjustment screw for the needle guard. (Jianglong 341) Looking closely, I could see a hexagonal shape behind the round hole. 1/16" (1.7mm) hex wrench seems to fit. Or from a different angle: Here I removed the needle guard and you can see the set screw that sits behind it: I've been wanting the needle guard to be stiffer anyway. (What good is a needle guard that just gets out of the way when the needle comes by?) Using this adjustment screw will mean there is a support closer to the bulge in the needle guard, so I expect it to flex less when the needle presses against it.

-

That looks really nice. I like harness leather bridles. Randy

-

Thanks for the compliments. The young man can play, so I hope the strap can keep up. He's getting really popular thanks to TikTok. I don't understand, but I guess I'm too old. I think the font appearance is an optical illusion since the strap is curved over a post. The letter height is within 1/16" but the width may vary. If they are tapered, it certainly wasn't intended. Randy

-

I just answered your email and came here to see this. I can expand a bit on what I didn't cover in my reply there. Straight edgers - generally flat bottom and cut a flat profile. I mostly sell them to makers of English horse tack. Round edgers - several styles that cut a rounded profile, concave bottom surface, some have a convex shape to the top edge and some are flat on top. usually a longer life with they are a blade style edger and easiest to maintain. My favorites. Cowboy edgers? - may be referring to Western edgers aka bent-toe edger - fairly easy to maintain, curved profile from the side. As they sharpen back the cutting edge goes back further and further around that corner and the angle you hold them at lowers. Bisonette edgers - hole in a flat blade and can theoretically cut on a push or pull stroke. How often do most people need to pull? Pretty rare. Harder to maintain and sharpen without widening the cutting edge. My wife likes them a lot. I sort of do but never saw any huge advantage. Finest edger, fine edger, Gomph Common edger - these have a V shaped fork in the tip. rounded profile, fairly easy to maintain, can trim linings close to a stitch line, sharp tips and are sometimes called "finger stabber edgers". Common edgers - lots of versions and several edgers get lumped as common edgers. Some of the vintage unmarked ones from Osborne were referred to as common edgers. rounded profile, easy to maintain, easy to widen out sharpening unless you are careful. Gomph called their "fine edgers" as "common edgers". French edgers - flat profile, can be used for edging, skiving edges, and if they have the right profile will gouge channels too. You asked in your email about tight inside curves - the turnback edgers will do that - short lifespan and tricky to sharpen. A round edger with short toes and narrow sides will do inside curves too.

-

Just seen this on YouTube.

-

@Curious Observer If making bags will be your specialty, start making plans to obtain the industrial sewing machines that are best suited to that work. Number one would be a cylinder arm walking foot machine. It should have at least 10.5 inches clearance to the right of the needle. With this type of machine you can sew completely around a bag from the outside. This is great for installing zippers as a last step. You can even use it to hem pants! Number two might be a post bed machine with a roller foot. If the post is tall enough, you can use it to sew along the bottom of a bag. This machine is also great for assembling hats, or sewing patches onto hats. Number three could be what we call a "patcher," which is a cylinder arm machine with a foot that rotates in 360 degrees that pulls the work in any direction. While the bobbins are small compared to standard industrial sewing machines, their narrow noses can sew deep into areas that other machines can't access. You're already working on getting a flat bed walking foot machine. It will handle sewing seams that lie flat.

-

That's a beauty! What caught my eye immediately is the way the vine is woven around the flowers to create a criss-cross appearance, and how you decreased the size of the letters to complement the shape of the point. Lots of neat details. Thanks for sharing.

-

Excellent work! I hope their guitar playing keeps up with it