All Activity

- Past hour

-

Thanks everyone for your taking your time for suggestions & insight!!! I am going to order some different needles and thread. If the skipped stitches continue, I will do the suggested adjustments. I am snowed in for the next couple of days. Please consider this thread PAUSED for the next week until needles and thread arrive and adjustments are made!!!

- Today

-

Yes, you can still get them in brass. Oddly enuf, my #1 son's belt needs a new buckle and all he finds are brass ones, which he doesn't like Shame to say it but try Temu

-

-

Remove the two endcaps from the left end of the cylinder bed. Turn the hand crank and you'll see the vertical feed cam in action. You can loosen the setscrews in it and rotate it to taste. In terms of order of operations, you will want to adjust the vertical feed cam first. (Probably such that the feed dog is at its highest point when the needle is at bottom dead center.) Afterwards you would adjust the eccentric that moves the rock frame (such that the needle arrives at the throat plate at the same time as the inner toe)

-

I really like this, nice work and a light bulb just went off , great idea! Thanks for sharing.

-

You might want to post a pic so we know exactly what you need.

-

I am going to make my wife a two prong mechanics bet. However, the reason why is she’s allergic to most metals pretty severely. The cheap one you see on Weaver and whatnot are nickel. Her worst one. I saw a post on here from 2011 that somebody made these out of brass. Anybody still make two prong mechanics belt hardware from brass?

-

Info on machine. Looks older and huge.

bruce johnson replied to bigsig11010's topic in Leather Sewing Machines

As Wiz said - American Straight Needle. Old, heavy, and no new parts available. The guy who taught me a lot about tools repaired and restored a lot of the old needle and awl machines in this area. His advice to me was to never buy a needle and awl until he was gone. He'd worked on his last one. He said when if I did buy one, get a Landis 3 and second choice a 16, Champion deep throat next, and run away from the Americans. Sam had a shop in Canada for a while. He had a pretty good story about a guy who moved up to that area. He tried to sew some saddle skirts on an "ol' wore out loose straight needle sloppier than the back end of a gummer Holstein cow". The skirts got chewed up and that guy vowed to hand sew the rest of his life, and according to accounts - did that in fact. You may have read about him doing this. -

very nice work.

-

https://www.ebay.com/itm/297964725790?mkevt=1&mkpid=0&emsid=e11021.m164380.l178263&mkcid=7&ch=osgood&euid=567cfffa39f64984bf7bf6ee8ea96a04&bu=43715962808&ut=RU&exe=0&ext=0&osub=-1~1&crd=20260124071500&segname=11021&recoId=297964725790&recoPos=1 This is Bob Parks "Creating Western Floral Designs", a hard to find book. I already have one or this one would be mine! Thought someone might be interested.

-

@JukiFan There are quite a few reasons for skipping but one very overlooked one is a wore our needlebar,from tightening the needle set screw over many years the hole gets enlongated to the left side forcing the needle to set @ an angle so the thicker your sewing as the needle goes in it will pull it away from the hook causing skipping.The test is loosen the needle set screw & note how far it moves left to right.

-

spring flowers and good food

chuck123wapati replied to chuck123wapati's topic in All About Us and Off Topic

Will Chedder brauts and tater tots work? I don't want to dishonor my clan, Montgomery. -

-

spring flowers and good food

Sheilajeanne replied to chuck123wapati's topic in All About Us and Off Topic

-

Here is a thread and needle matching chart that I had a hand in creating. Where two sizes of needle are shown, use the smaller size in thin or soft material and the larger in thick or denser material. When it comes to the accuracy of the thread sizes, trust the name brands over no-name spools. Name brands have some degree of quality control. Avoid the cheapest thread (e.g., off-brands on eBay or online Marketplaces). The thread chart includes the strength of each thread size. This is its breaking strength. That can be used to determine the best thread for a particular job. For instance, if you are going to seam a cover that will be pulled tight over an object, or otherwise subjected to stress along the seams, use one size larger that the smallest thread. It might be a little harder to totally hide the knots on the backside, but the stitches may hold up better. I usually use the largest thread that allows me to bury the knots. There will also be different compositions of thread available to you. Choose the type of thread that fits the material. If you're sewing denim, you can buy a type of thread called Denim Thread. It's washable and stable when washed and dried. If you're sewing indoor upholstery, buy bonded nylon. If the job is for outdoor use, like a porch chair, or an awning, outside banner, or a cushion on a boat, use bonded polyester thread that's UV resistant.

-

Info on machine. Looks older and huge.

Wizcrafts replied to bigsig11010's topic in Leather Sewing Machines

That is an American Straight Needle harness stitcher. The machine is from the early 20th Century and has a needle and awl. They were made to use waxed linen thread. It was made to sew along the edges of harness and saddle straps. If you remove the edge guide, it has a depth of about 4 inches from the needle to the body. Here is a video explaining how to thread it and operate it: https://www.youtube.com/watch?v=vgt0AUp3emU -

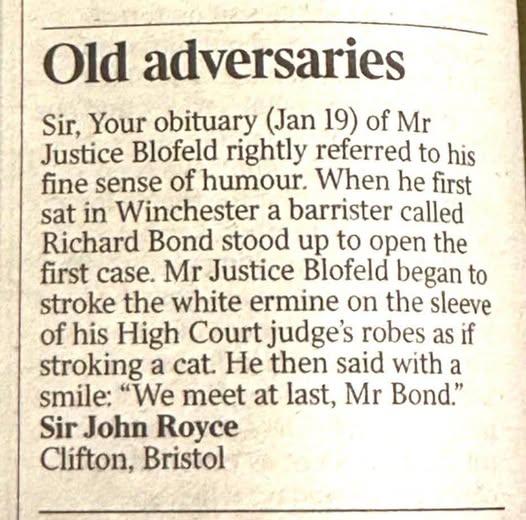

In this photo from the parts manual, see part #224113. It's a collar that clamps to the shaft to prevent play. But I'm not seeing such a collar in your video.

-

Unknown Chinese servo motor controller manual needed

friquant replied to Einherj's topic in Leather Sewing Machines

Ah that's cool. -

With the motor disconnected, and the bobbin cover plate slid to the right, you can watch stitches form as you turn the handwheel. Once you can identify what it looks like when a good stitch is made, and what it looks like when the thread jams, you can start to trace out how the jams are happening.

-

This machine is for sale in my area. Could anyone tell me anything about it? What kind of leather projects is it used for. It looks old and huge but then so am I so...

- Yesterday

-

good plan. i believe the axle of the handwheel is 12mm but ill take it of and measure it out and see what i can find. yeah ill learn the work the clutch. it takes time but also cool to learn. easy system for sewing machines instead of the servo motors stil have not found the problem with the tread jamming. see allot of videos, but either they show nothing or extremely to much XD

-

Unknown Chinese servo motor controller manual needed

Einherj replied to Einherj's topic in Leather Sewing Machines

I know. I didn't have a small enough tool handy at the time, but I had a soldering station. I was testing the P-06 some more, and it seems it is actually a limiter for the maximum number of stitches the machine sews while holding down the pedal. If I set it to 1 the machine does one stitch, if I set it to 4 the machine does four stitches, etc, no matter how long you push the pedal, that's the maximum number of stitches it does. You have to lift the pedal to do another round. This setting requires a needle position sensor, of course. When the setting is at 0, there is no limit. -

Unknown Chinese servo motor controller manual needed

AlZilla replied to Einherj's topic in Leather Sewing Machines

Thanks, @Einherj. The more of this that can be collected in one place, the better we all are.