All Activity

- Today

-

Very nice. A lot of thought and hard work went into making these.

-

Has anyone noticed the attractiveness of the bottom stitches to be machine-dependent?

-

Unknown Chinese servo motor controller manual needed

friquant replied to Einherj's topic in Leather Sewing Machines

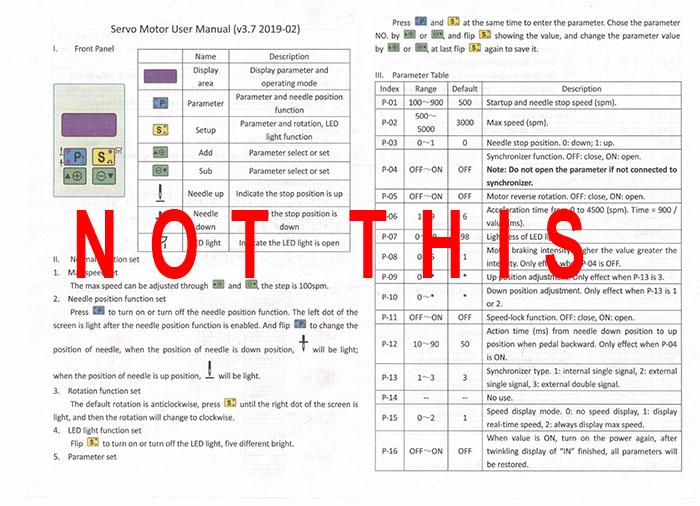

You did your homework, showing us what the ranges and defaults are for each parameter. At a quick glance that menu looks like the "Stitchman" -

Yes, the Cobra does come with a reducer which does allow for slower sewing and greater punching power due to the increased torque provided by the speed reduce. The cost for a 3:1 speed reducer, at least in Canada, is about $100 CAD. I have never owned any of the Cobra equipment but from my experience I had for a very short period of time a Consew RB206-5 that I hoped to replace my Juki DU-1181N with as it was supposed to be similar to the Juki DNU-1541S. It wasn't good enough to replace the Juki 1181N so I sold the Consew. Bottom Line, do an honest test using a sample of your stuff on both machines. You may have to send a sample to a vendor. I could not find a weight for the head of the Cobra 18 listed so you may want to call them keeping in mind the Juki DNU head alone weights 80.46 lbs (36.5 kg). kgg

-

Watch some of Makers leather supply videos. Aaron does some videos using the class 18 cobra.

-

I am going to buy another machine the two in contention are the Juki 1541 and the Cobra class 18. Your right similar machines. The cobra has a reducer on it that allows a very slow stitch. The Juki does not. The Juki has a beautiful back side stitch, however, I do not know about the class 18. So this is why I asked. I want a machine that front and back stitch looks good. Why, because I may make a notebook, the person opens the notebook and sees both sides. I want both sides to look nice. I have a cobra class 4 and with this machine there is a notable difference in the two stitches. I hope I have made it clear.

-

Internship and maybe a new start

Sheilajeanne replied to Tove09Tilda's topic in All About Us and Off Topic

I had a friend in HS who was very bright, and loved biology. She went to university, and eventually got her Master's degree in microbiology. Upon graduation, she got a job with the Ministry of Health. She found herself doing the same lab tests over and over and over. She also realized that eventually she would get promoted to a more interesting job, but government bureaucracies are not at all flexible, and promotion would be very slow. She quit the job, went back to school...and became a lawyer! Several of my HS classmates also became lawyers, but she was the only one who worked in criminal law as well as the other, less demanding legal fields! At the time, it was unusual for a woman to be a lawyer, and even MORE unusual to find a female in that particular field of law! -

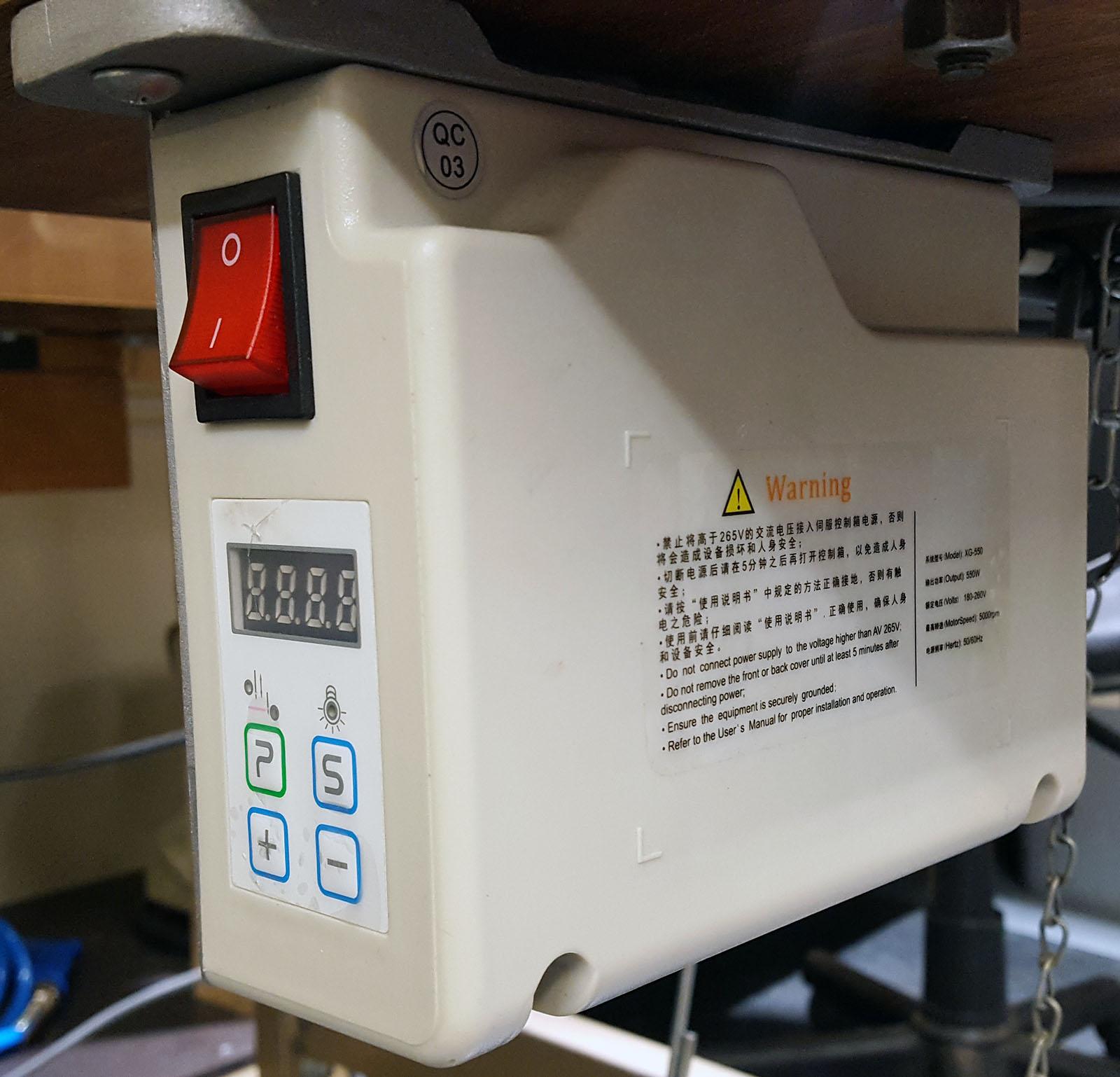

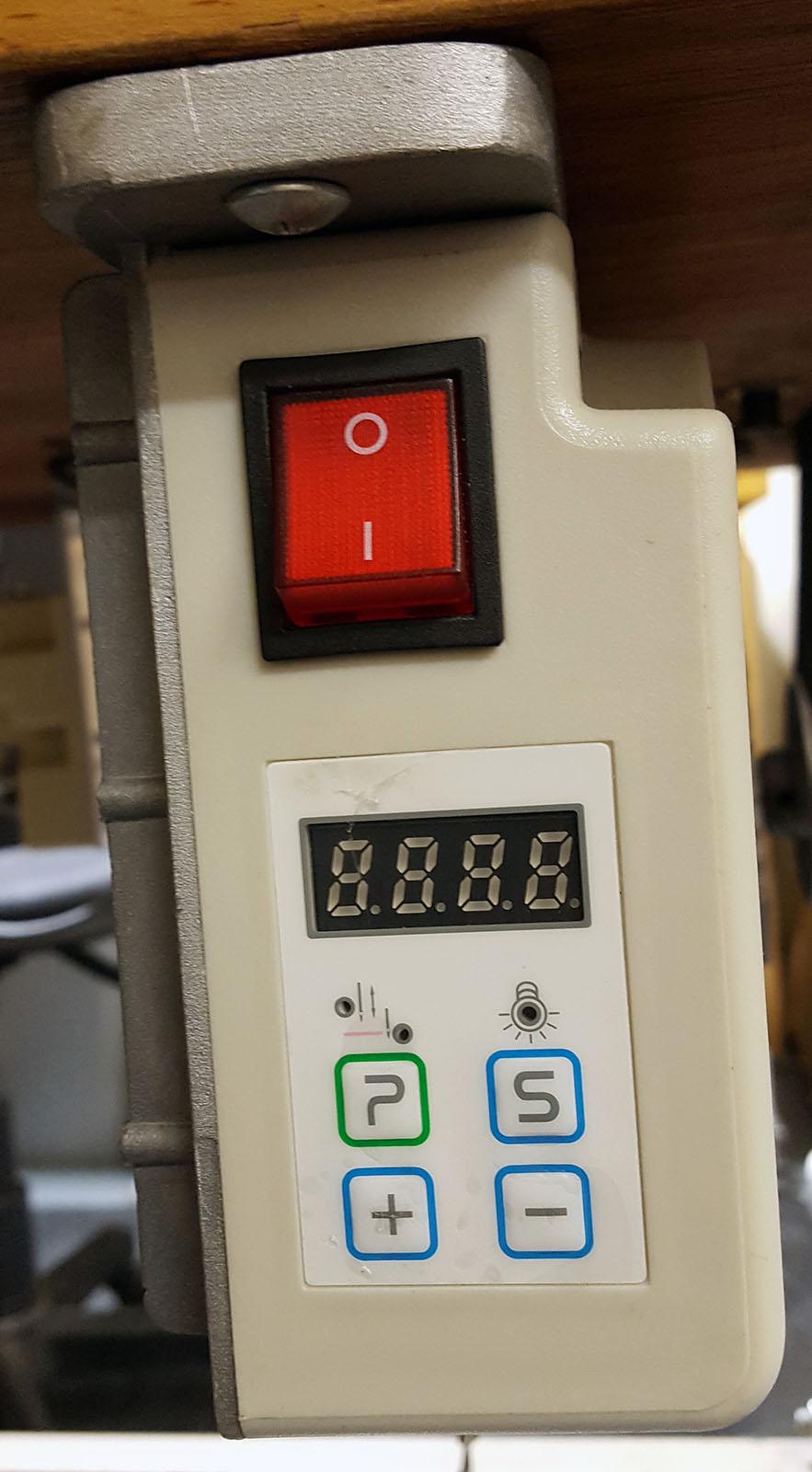

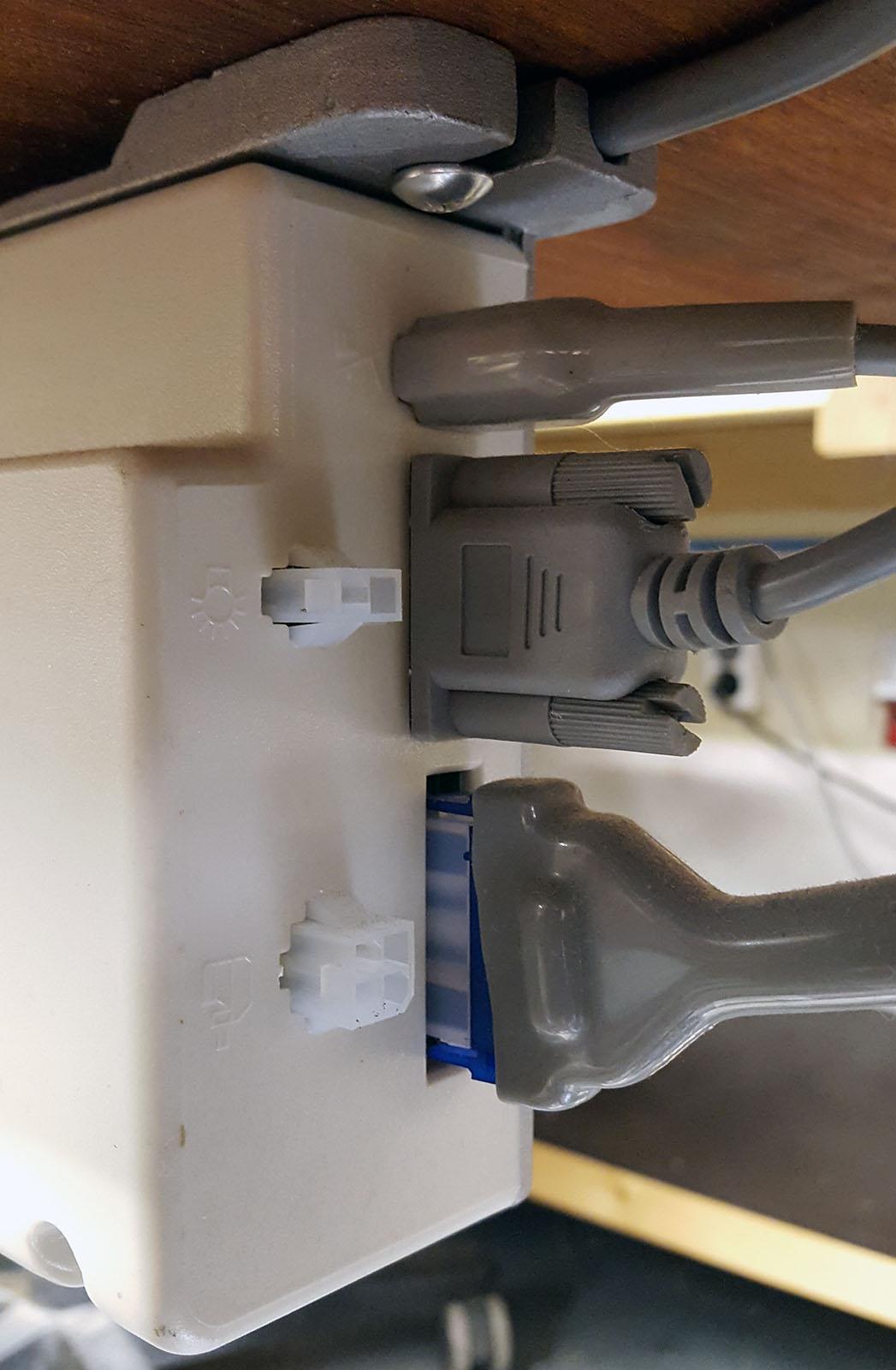

I am looking for the manual for this Chinese servo motor controller. I want to install a syncronizer, but the parameters on the controller do not match the ones on the manuals I have found online. I couldn't find any model number on the controller to do a proper search either. Here's what I found about the parameters by testing: You enter the parameters menu by pressing the P and + buttons at the same time. You browse the parameters list by + and - buttons. You enter into a specific parameter by pressing the P button. You increase or decrease the parameter with + and - buttons. You exit the menu with the S button. P-02: range = 0 - 1, Reverses the motor direction P-03: range = 06 - 18, increments by 1, current setting 12 P-04: range = 200 - 800, increments by 50, current setting 200 P-05: range = 0500 - 4000, increments by 50, current setting 2000 P-06: range = 000 - 999, increments by 1, current setting 000 P-07: range = 0800 - 2000, increments by 100, current setting 1100 P-08: range = 0 - 1, current setting 0 P-09: range = 0 - 1, current setting 0 P-10: range = 0 - 1, current setting 0, if set to 1 it seems to be some auto sew setting where the machine runs for about 6 seconds, then pauses for a while and repeats. P-11: range = 0000 - 9999?, increments by 1, current setting 0000, I only tested that it goes over 1000, but since it increments by 1 it would have taken forever to go to 9999 P-12: range = 001 - 120, increments by 1, current setting 005 P-15: range = 0 - 1, current setting 0 P-16: range = 0200 - 4500, increments by 100, current setting 1000 Let me know if you need more info or photos. Thank you.

-

I made a set a few years ago. 12x12x4 Funny how I never seem use them? They just sit here over the back of my couch on display. I planned to hang them over the seat in my truck but figure someone might break my window to steal them?

-

I don't understand your question. Are looking to purchase this class of machine or ???? As a note the Class 18 is a clone of the Juki DNU-1541S and if you want quality build and stitch wise by a Juki but they are going to be expensive. If you looking to buy a machine what are you planning on sewing, thread size, thickness of material??? kgg

-

Great job Phil. Must've taken a while.

-

This is what I would consider a medium-large size. It's 8" wide, 9" tall with a 4.5" (cut size) gusset. Randy

-

Thanks for the compliments. Nothing is attached to the belt. Everything slides on, so you can move items where you want. However the pockets on each side are all sewn and riveted together. I think I have enough leather left to build a smaller tool pocket if he wants to change it out. Randy

-

Wow! Wish I had one of these when I was in construction!

-

Newest creation, hope you enjoy IMG_0891.mov

-

I screwed up on my last post, should be a cobra 18. If anyone has one can you show me the back side stitch. Looking for something that has an attractive front and back stitch.

-

first pancake holster

Thadrick replied to Thadrick's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks guys. I got bored after that holster and started a cowboy style holster for my Lil GP100 and made it half way through the project before realizing I made a rooky mistake. I made it left handed. Couldn't help think that if I was making a pancake style I wouldn't have mattered. -

I have two spot setters for sale. Wm. Brown Holster Co. text or call…970-200-6328. Bill

-

Outstanding work!

-

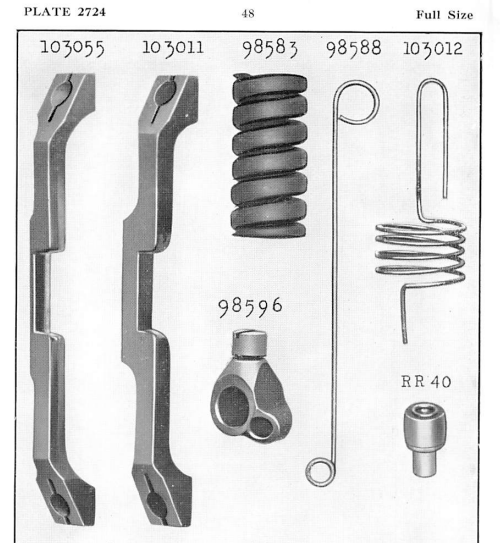

Download for a 133K manual but not exactly for the 133K13 but it may help: https://leatherworker.net/forum/topic/56667-singer-133k-information-wanted/page/6/#findComment-546077 the 2 parts on the left are positioning fingers and you notice the gap, right?

-

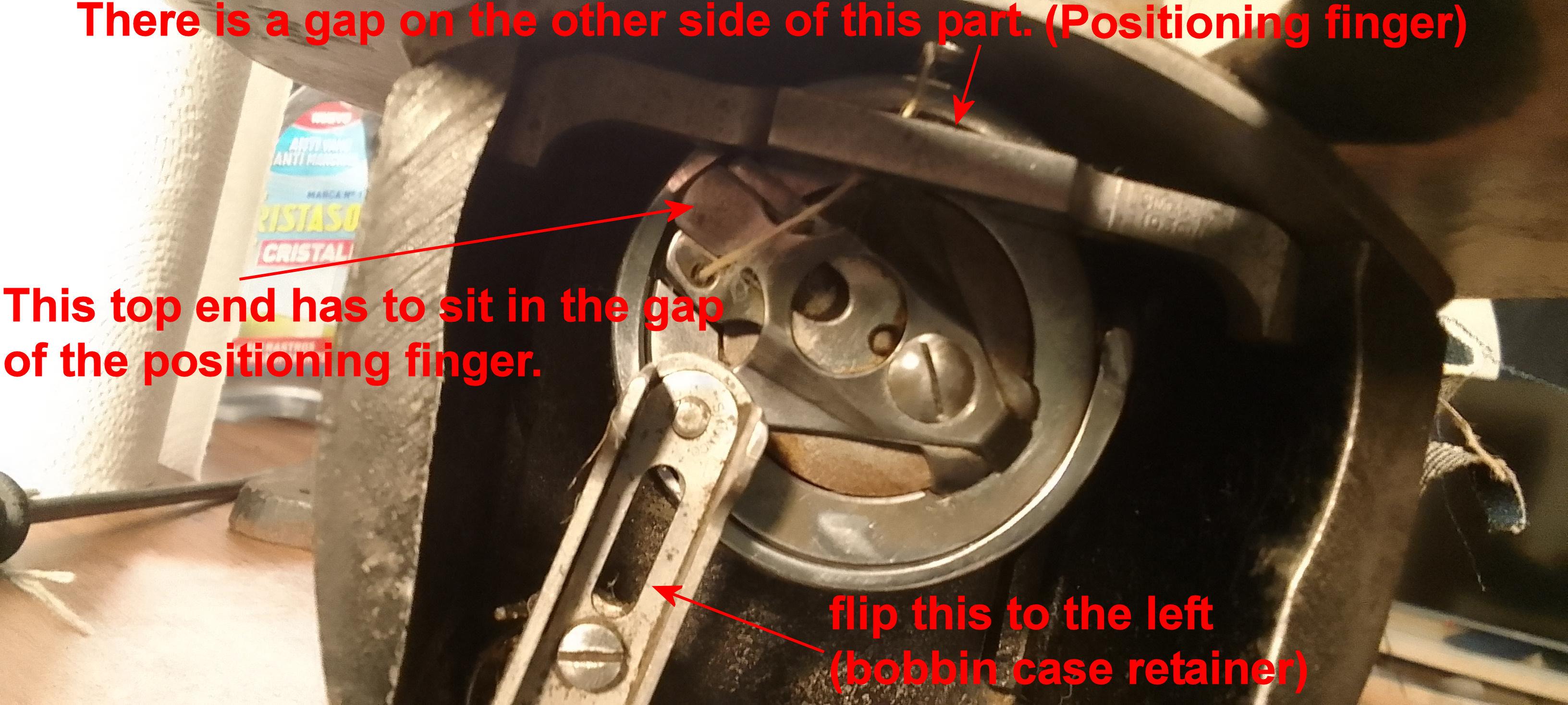

I guess you alreday have figured that is is a darning machine that ex factory is not set up for sewing operations. I once owned 133K3 but it´s long gone. There it a Bobbin case positioning finger that holds the bobbin case in position. You see it in your picture (that part is the "bar" above the hook / bobbin case in your picture). The top end of the bobbin case has to sit in the gap of the positioning finger (remove the needle plate and you have a better view on it and I think you will know what I mean when you see the gap). You only can insert and remove the bobbing case when the hook is in the right potion and you have to flip the bobbin case retainer aside before you can insert the bobbin case. EDIT: hope this helps

-

@pierre2171 I split this out into it's own topic so maybe we can get you some help. It looks like an interesting machine. EDIT: In fact, a search for 133k13 turned up a few hits. I'll leave you to sort through them. https://leatherworker.net/forum/search/?&q=133k13&search_and_or=or

-

What is a Cobra 13? Do you maybe mean a 3? I'd you have one you're dissatisfied with, maybe post a picture of the problem? Stitching problems tend to be fairly generic.

-

Nah, you couldn't have bought one that nice. The only way that gets better for me is if the pouches are modular. It's one of those bespoke things you can afford to have because you're a leather worker.