All Activity

- Past hour

-

Thanks Constabulary ! Do you know if uses 135x16,135x17 needles ? One of the first things I found said machine uses 16x74 and is a obsolete needle system, then it says 16x2 and 16x1 is the modern equivalent and another AI mode thing said 135x17 is same needle system as 16x2 system ,so that gets me confused . Hope to find manual to study before I drive 50miles to see. Traffic here is no joke 😩

-

Way cool machine- really! I owned one but it did not suit my needs. I would not buy one again. Why - because why in the world should I pay $25-30 or one (1) needle? Chances are high that you break one and you better have a few spares on hand. Know what I mean? Depending on what you want to sew I would look for a an other model.

-

I had both 34K and 51w (still have it). Is sold the 34K cause I found the 51w and I do not look back. 34K is a bullet proof design, it was built to last but mine had a too tall post and I figured parts situation for the 51w is still good but even for the 34k you still find some new parts that the machine share with other Singer models. If I had too chose again I would always go with the 51w but you don´t always have choices. 34K´s also came with shorter post but sometimes you have to take what pops up on the used machine market. If you are looking "just" for a post bed machine then look for "810 Post Bed". It is more or less based on the 51w. This was my 51w project (1st model 51w):

-

The 17U model was made in Japan the 123 subclass has smaller diameter arm compared with other Class 17 machines and it is using Singer 15 type bobbin cases and bobbins. Apart from the hook / bobbin you should be able to use any other 17U model manual you find online. The subclasses usualy just have minor differences but the main machine often is the same. Check if needle plate and feed dog are present and in good order and see that the machine is complete in the hook area - see parts list for that or post more detailed pictures.

-

With servo motor and replacement handwheel and servo pullies to give speed control and extra torque. Will do a stitch at a time. Forgive the video quality and sketchy use. I haven't touched this machine for a very long time. Located in Chatham, Kent, UK. Pickup only. £850 Durkopp 239 with converted handwheel for extra torque and slower speeds..

- Today

-

I moved your post to Leather Sewing Machines. You are more likely to get some feedback here.

-

Thanks for your replies. To my inexperienced eyes the oval looks ok. My thought is the screw that holds the piece in place and the area of the piece that the screw comes in contact with are both worn down. There’s now way to tighten it enough currently that will have the feed dog move correctly. I can’t see any loose movement in the shaft the dog attaches to though that doesn’t mean there isn’t. It’s pretty dirty in that area. Im planning to go by the shop this week and talk with him some more and maybe mess with it some more. Is there anything else you would recommend I should look at on this machine? Do you have a recommendation for a source for parts for the machine, specifically the screw and feed dog? Thanks again, Jonathan

-

Incredible work. Thanks for sharing.

-

Hi everyone, came across this machine Singer 17u123 , just the Head is available, but can’t find out much about it? Looking to purchase but need to find out what and if needles and bobbins are available . I wanna sew light leather stuff and Canvas with it . Need manual to make sure machines all there. Sorry still struggling with adding pics . Don’t wanna buy another boat anchor. Also only thing comes up for manual is a 17-23 ,, and I can’t retrieve/open to see machine .. very odd . Thanks for all info .!!. Metalhorseman

-

Hi all. I make smaller sized bags as a hobby. Currently my only machine is an old mint Juki Ls 341 (gray color model) and I really like it. I want to add an old beautiful Singer 51w wheel feed post machine to my collection. I can't seem to find one anywhere for sale. Are there online vintage machine dealers that anyone knows of I could contact? All I need is the machine head in nice condition. I really want a Singer 51w model or maybe even a 34k, mainly because I like old machines and love the look of these singers. Thanks for any info!

-

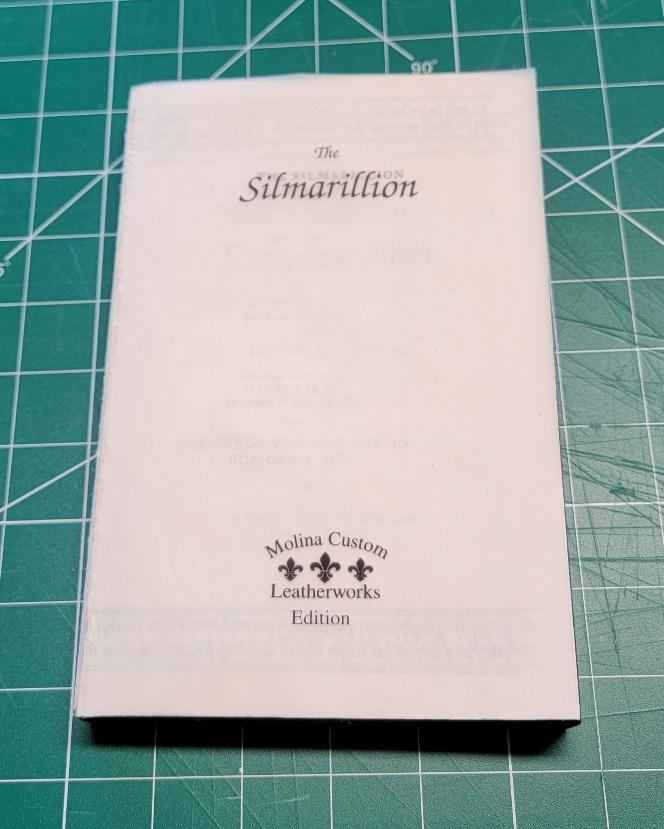

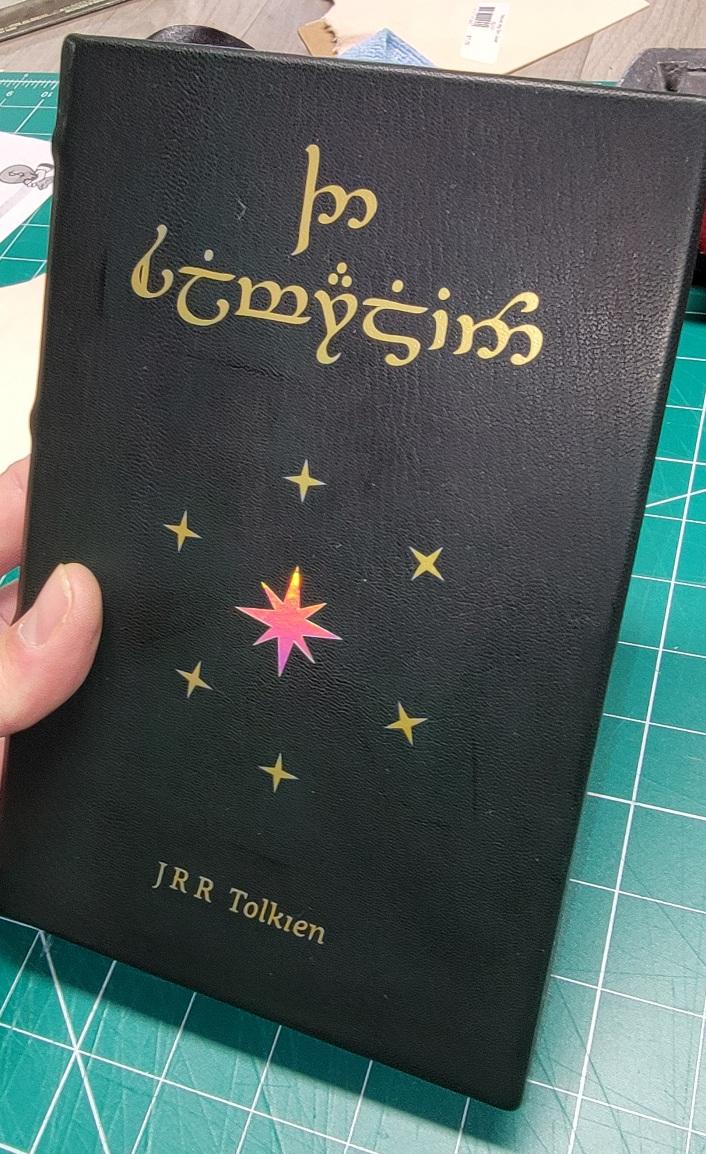

That looks spectacular! Fantastic job, the black and white dotted edges and marbled pages looks like a lure to a bibliophile - whispering: I hold great secrets that you secretly yearn to read. Will it reside on your own bookshelf, or is it a Christmas gift to some lucky person? Brgds Jonas

-

that is the coolest work Ive seen for ages, man. You did a fantastic job!!

-

Pedersen 308 / Junker & Ruh SD 28 leather machine needle alignment

kgg replied to Einherj's topic in Leather Sewing Machines

I guess "reasonably priced" is a relative thing. Each needle at $28.57 AUD ($26.23 CAD) and I thought paying $4.50 CAD for 794S size 250 was expensive. kgg -

Yes, this project took a lot of time and effort multiple revisions and refinements and even then, perfection is always a moving target. We’re planning to add more patches on the front panel to balance the design and fill the empty space you see. This duffle bag was created for a client who approached us with a custom request. We’re a small custom patch business, and projects like this often come through word of mouth and referrals. The bag features premium leather patches, carefully embroidered and applied to achieve a bold, high-end finish.

-

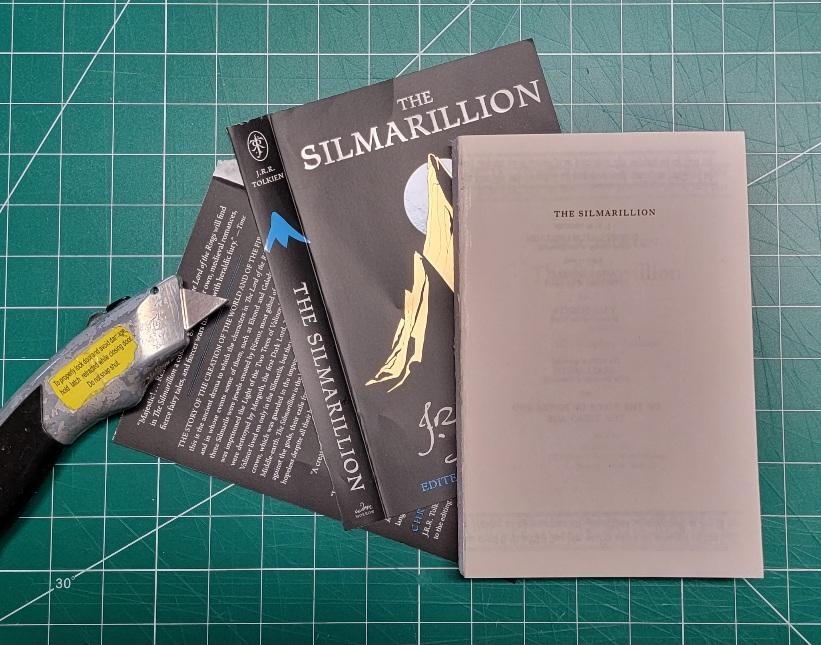

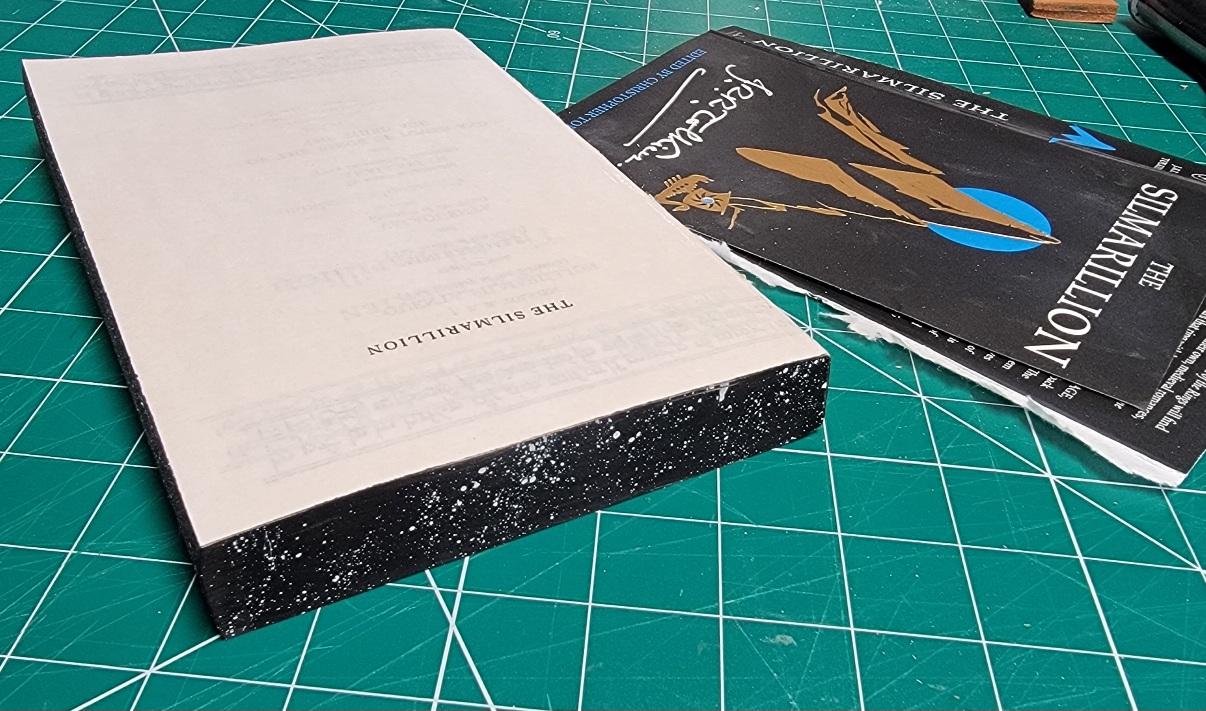

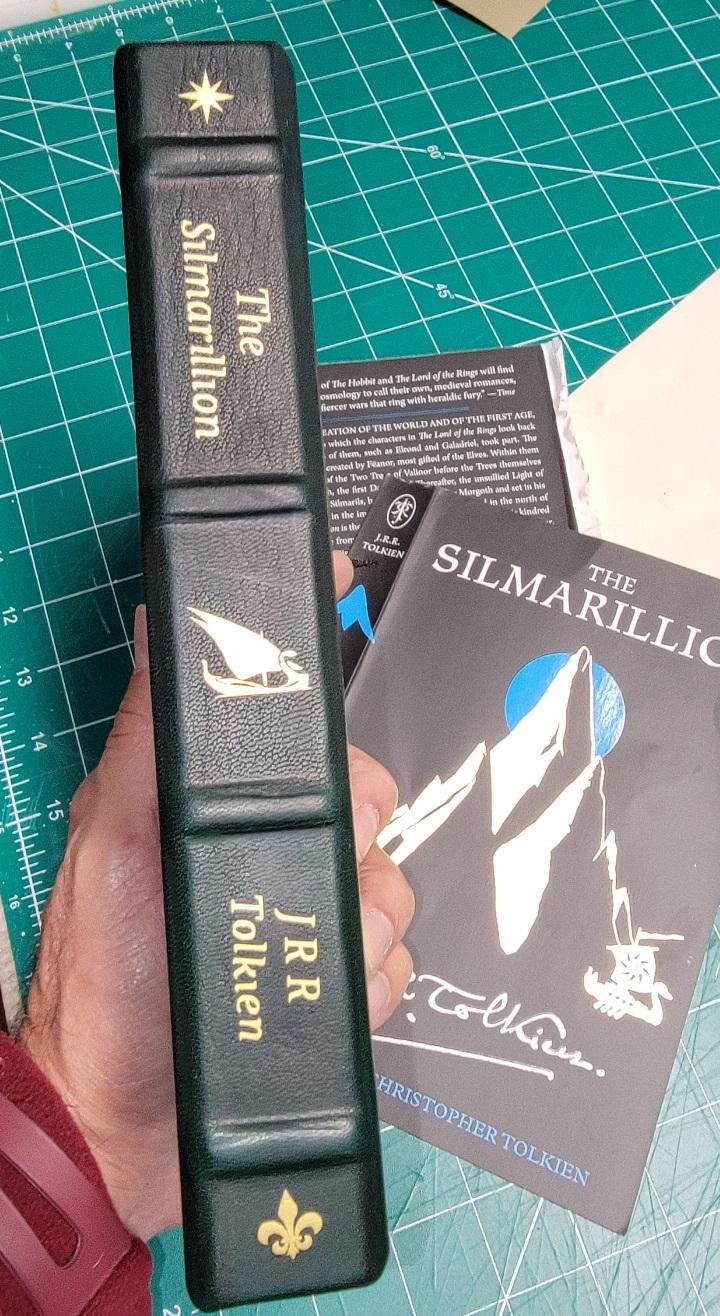

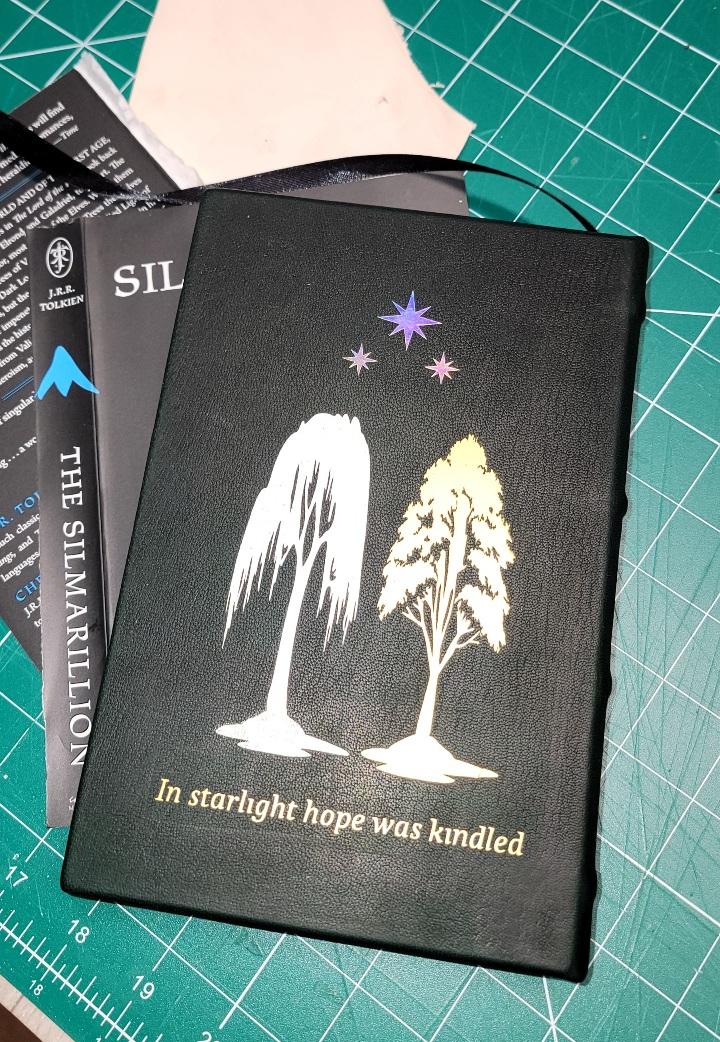

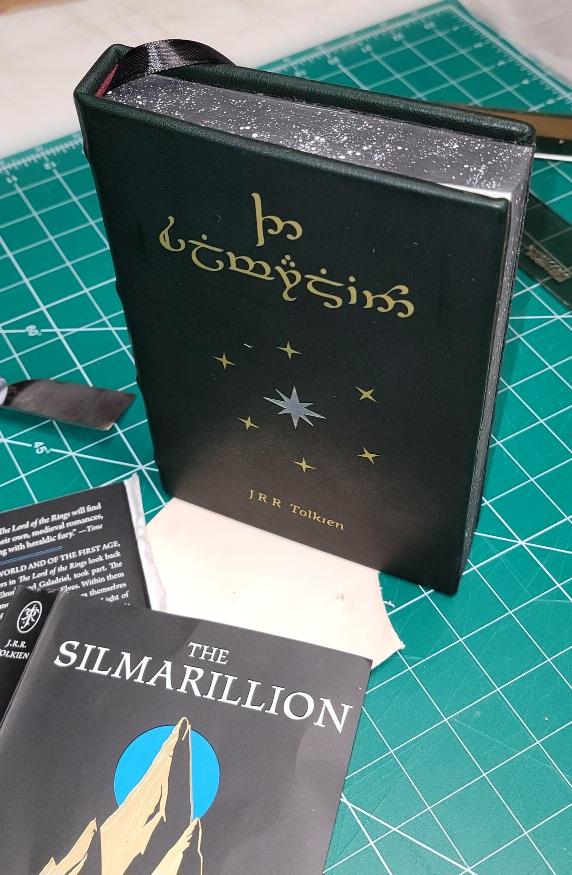

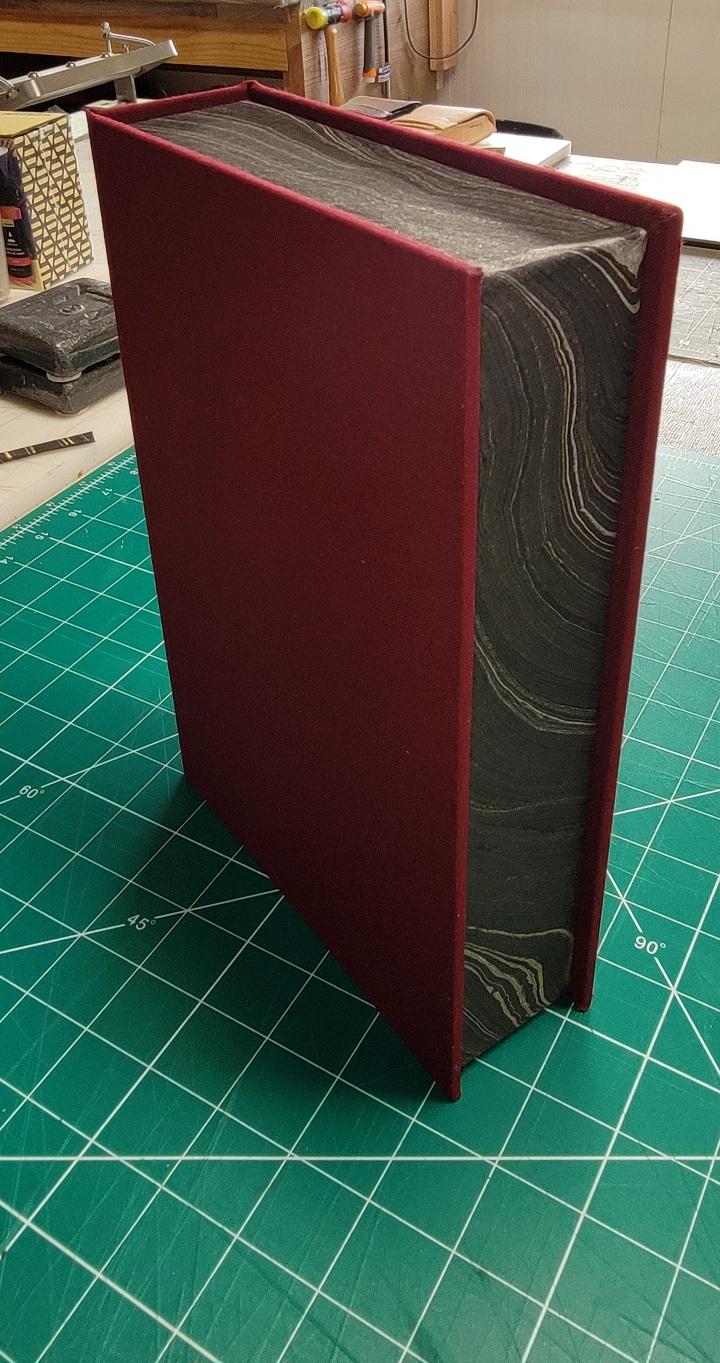

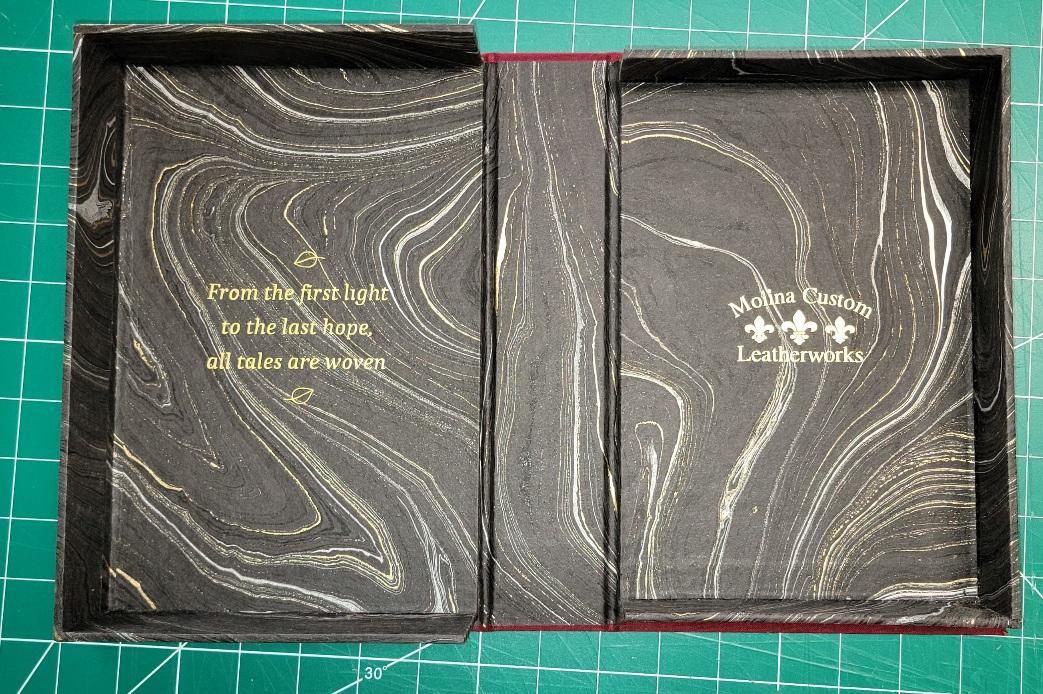

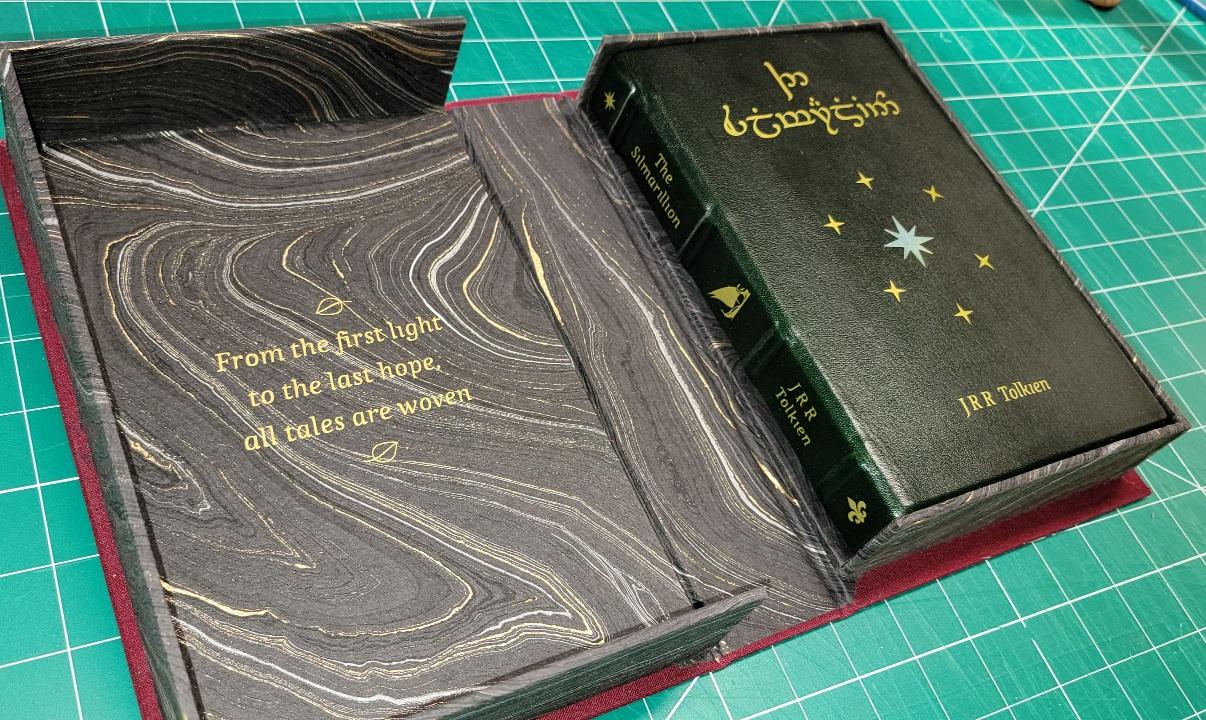

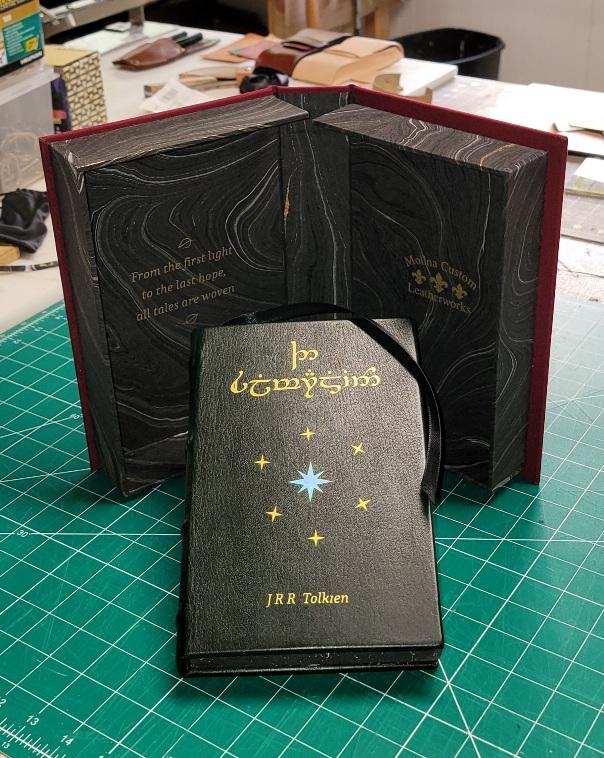

I started a book rebinding project. It's going to be JRR Tolkien's The Silmarillion in a clamshell box and after the holidays I'll do a box set of The Hobbit and Lord of the Rings trilogy. I started by tearing off the paper covers from the text block. I painted the page edges black with white specks. I added a vellum title page, a black silk ribbon, burgundy headbands, and black marbled end pages. For the cover I used 2-3oz vegran goat hide. I gave it 3 coats of Fibing's green Pro dye, .095" binder's board. For the cover art I used gold and holographic heat transfer vinyl (htv). I sealed it all with a few coats of a mix of Resolene and carnuba wax. The clamshel box I used .095" binders board, burgundy book cloth, black marbled paper, and the art was htv.

-

I think it looks fine . . . you definitely put a lot of time into it for sure Sometimes it is the time spent that helps the maker say to himself "Good Job" when he can look at it knowing it is done. What is the bag for? May God bless, Dwight

-

@Einherj. The needle has no adjustment apart from the stitch length . Where the needle is fixed is solid and cant move therefore i conclude you have the wrong needle . The current wear marks could be as a result of deflection of the needle when re -stitching through existing holes like when doing a repair . However don't sweat it because new needles are available from here . https://www.leffler.com.au/pederson-needle-hvy-for-308-machine/ . This is the only source i know of . They are in Australia and they are reasonably priced . Become a member for a good discount . The needles are quite tough and last a while but i don't know for how much longer they will exist so get a few as spares . I occasionally sharpen mine with a small hand held diamond file . If stitching sole leather wet the leather beforehand.

-

1925 Harley JD Seat Restoration

Mulesaw replied to Irishleather's topic in Motorcycles and Biker Gear

Looking really good! Here's a similar seat that was fitted with new leather. It is a project I would really like to try, but I haven't got any bikes with that style of seat. My reasoning for 6 strand is that a seat lives a pretty rough life, there is plenty abrasion from the drivers legs and there is sunshine, rain and dust, all which is hard on the stitching. Brgds Jonas -

Yeah, that hat has some character, now. My dad used to cut 4 air holes in his hats. His looked much like yours. Also from greasing the tractor then driving a good coat of dust on it. LOL The round hat clip looks good. Using a caribiner is a good idea for it. I'll try the bar magnets first to see how they do.

-

I've been watching this thread grow in frustration as people discover the weaknesses of the various servo motors they've purchased, only to find that most were wanting in either slow speed torque or starting speed. I see plenty of reports of high torque servo motors that start with a jerk at anywhere from 50 to 200 rpm. People owning analog, brushed servo motors get a smoother startup from zero, but the torque is so low that a speed reducer may be needed to get the machine to turn over. I want to tell you a story about an analog servo motor that I used to buy for my heavy leather stitchers, and even my walking foot machines. It was called the SewPro 500GR, which was sold by Toledo Industrial Sewing Machines, back in 2012 through about 2016, or maybe 2018. The motor had replaceable brushes (with spares included), a fully adjustable brake lever, and, wait for it ... a built in 3:1 speed reducer. That motor could power almost any sewing machine that was smaller that the 441 clones. It powered my cb4500 via a 3:1 speed reducer, mainly to add punching power at very slow speeds. I drove all over my walking foot machines from zero to its maximum speed without any jerks or hesitation. The motor was reliable and sold like hotcakes. Then, one day the employees went of for lunch and never came back! They shuttered the factory! Poof, gone! For a few years, enterprising folks learned that they could print out gradients onto transparent plastic wafers that replaced the original solid wafers that were moved across the light beam or photocell receiver. The gradient wafers allowed the digital servo motors to start at such a slow speed that it was virtually unnoticeable. The trick was keeping the gradient wafers affixed to the moving control lever. Eventually, we just stopped using those motors and switched to analog motors fed through speed reducers. I personally prefer to use analog servos with either 2:1 or 3:1 speed reducers, rather than a digital servo that starts at a noticeable speed bump. I sacrifice the top speed that I don't really need in exchange for low speed torque and a very smooth startup.

-

The hat came yesterday, used a little tape to shrink it, long oval seems to fit good. After wearing it a couple days it has shaped to my head and is very comfortable. It is show in the photo already dirty, hard to keep hands clean and run a farm. Put the hat on and had to grease the tractor, it is a tool much the same as the tractor. Thank you for the kind words, have had good teachers who I have not met in person. Your welcome. I got some yesterday and they work much better, this hat clamp used them.

-

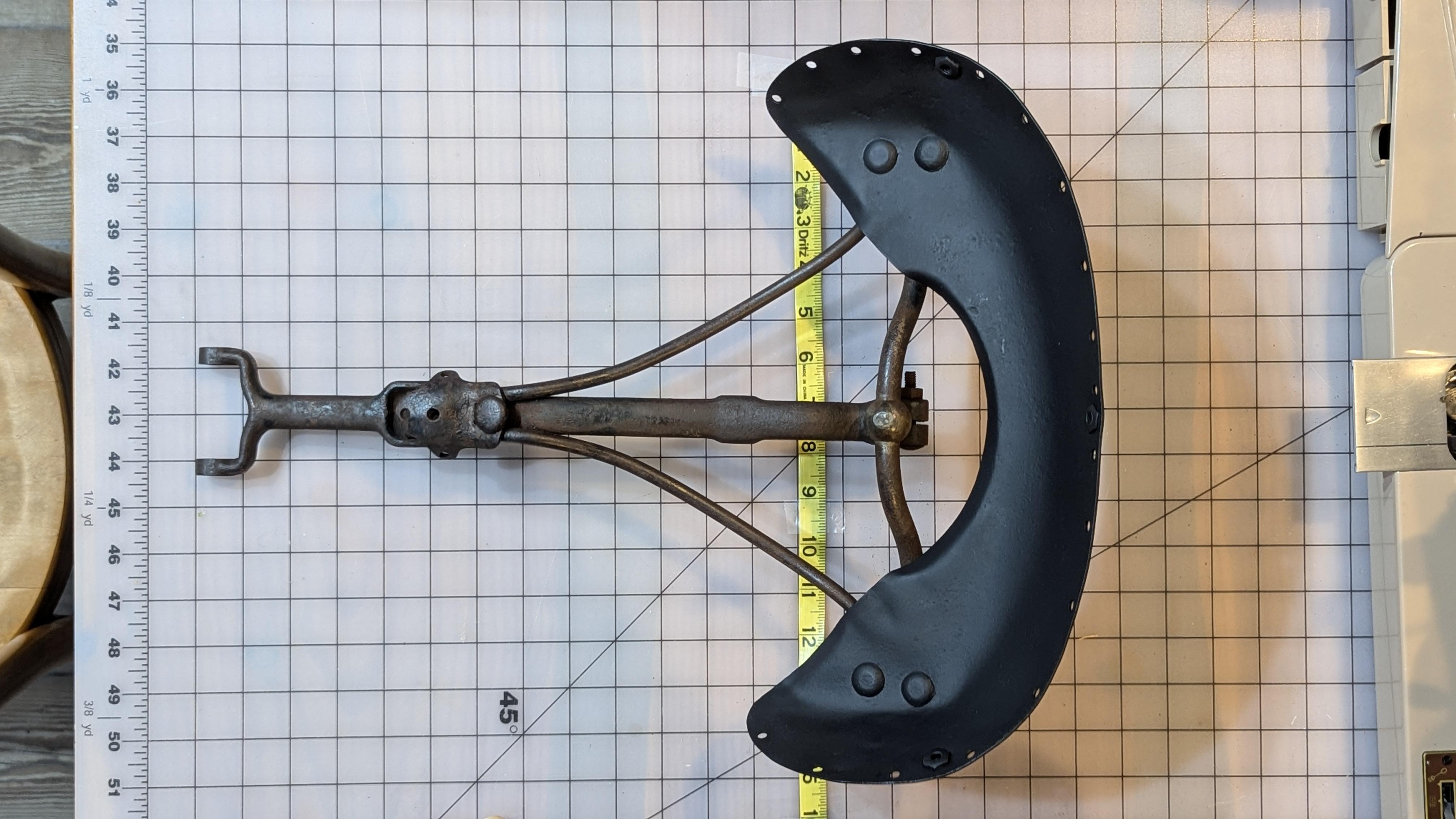

1925 Harley JD Seat Restoration

Irishleather replied to Irishleather's topic in Motorcycles and Biker Gear

Thanks! 6-strand linen! OK, this might be a test of his patience. Here is the frame and the first layer experiment. Found better rivets today, so those will be changed out. -

spring flowers and good food

Darren8306 replied to chuck123wapati's topic in All About Us and Off Topic

I bet that smells great! lol Last night I visited an underwhelming buffet restaurant, with amazing company That man is a hero! I hope he finds a twenty in an old jacket from the back of his closet. -

Thats a good idea. I'll do that tomorrow and let you guys know If that is the case.

-

You could do a bit of science here and move one tooth back to the original, to confirm that it's quiet in the original configuration and loud being one tooth off.

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)