All Activity

- Past hour

-

Typical gc2605 conversion to non-binding machine

AlZilla replied to TakashiOkada's topic in Leather Sewing Machines

Turn Closed Captions on, go to settings and tell it to "Auto Translate" to whatever language you wish. -

Typical gc2605 conversion to non-binding machine

friquant replied to TakashiOkada's topic in Leather Sewing Machines

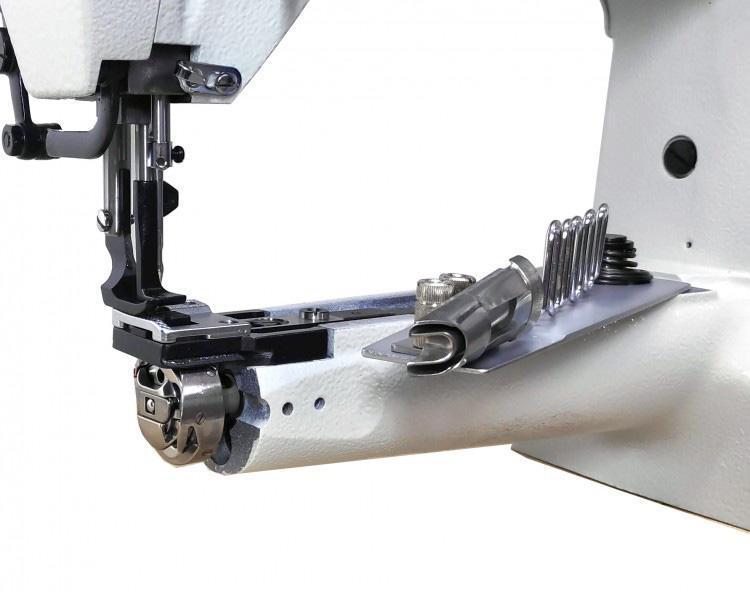

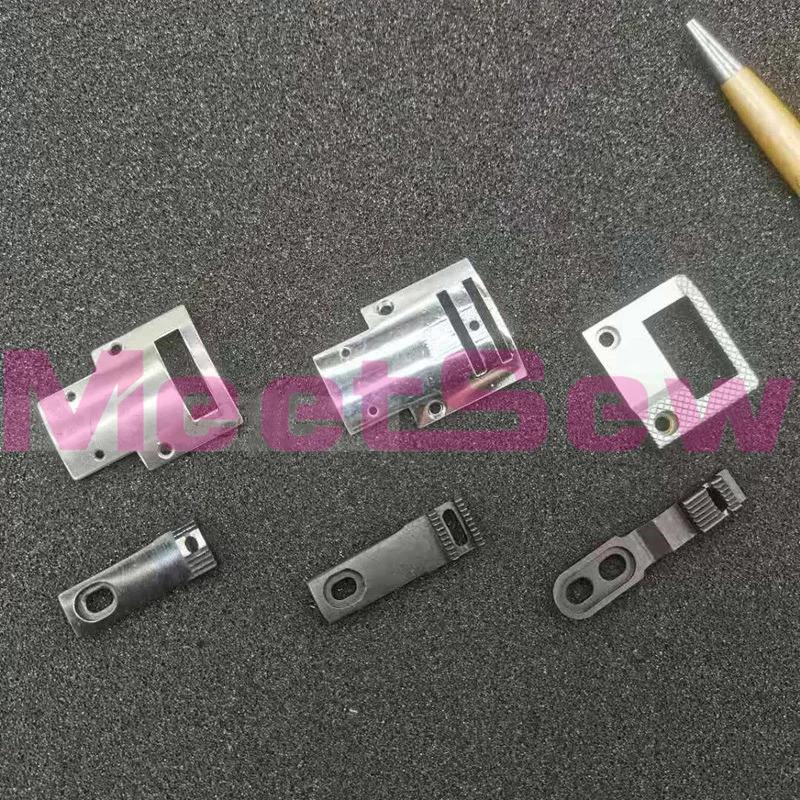

Three interesting points from that video: The feed dog on the binding machine that he bought has no vertical movement. He wanted to convert it to being a standard machine. It appears that he bought a new feed dog and throat plate for it. In general it works as a standard machine, but the feed dog only goes forward and back. (No vertical movement) He made his own cover plate to replace the binding cover plate that it came with. (The long metal plate that's about 250mm x 30mm that he mentions about 6:55 into the video) He abosolutely loves his swing-down edge guide 😀 - Today

-

hello, it's me again. I was about to buy the typical 341 you guys recommended to me for 1900$ but then I found an interesting triple feed binding machine in the used market for 400$. it's a typical gc2605. this is the picture of the actual machine for sale, it even has the half table and all! there's a similar model, it's the typical gc2603, which has normal throat plate more suitable for general leather sewing. apparently it's the same machine but with different plates, picture below. the end of both arms seem a bit different. these are the plates for each model. screw holes don't seem to match more pics from the internet for reference according to this picture, both 2603 and 2605 are essentially the same machine? this is a video of a guy with a gc2605 speaking russian (i think) and he's saying something while holding the plate I want to put in the gc2605. can anyone who speaks russian tell me what he's saying?

-

Anyone taken a cheap servo motor apart?

dikman replied to AlZilla's topic in Leather Sewing Machines

Definitely pull it apart, we're all interested now to see what the problem is! - Yesterday

-

BOOT TOE BOX REPAIR QUESTION

tozafoot replied to Drummist's topic in Shoes, Boots, Sandals and Moccassins

I have used a small marble pestle to push out slightly dented toe boxes: can hold the pestle in place with one hand and hit the outside of the toe shape lightly with a small hammer (peen) to smooth out creases in the leather. Not sure about using heat to restore shape: I guess it depends what was used to make the rigid toe shape in the first place. When I make footwear with toe boxes, I soak veg-tan cowhide (~5oz) for several hours before pulling it into place on the last and nailing it on. No heat involved at all, only water, -

Hi, sorry for the late reply's. Thank you for the link, that was certainly cheap. That shape of roller is much better than the long one that followed my machine, much easier to adjust. Mine doesn't equals the shape of the stone roller anymore. I may customize it, cutting away half but the bearing needs to be replaced as well. I will order the one you have but is the hole tapered as on Italian machines (like on mine Alpha SM, FAV etc.) looks like you got a gap there, material thickness different maybe? Thanks Tor

-

Thanks, I already have the foot that Tom E shared a link about. But it has been worn a bit by previous owner, it came with my machine that I bought used many years ago. I guess I can make a new roller for it on my lathe. The roller profile do not longer match the profile of the feed wheel... difficult to adjust for splitting use. The minimalistic guide for turns and stiffer leather makes most skiving tasks in soft leather difficult. I really miss a decent guide. Thanks Tor

-

Thank You, I already have that roller foot that came with my Italian machine. Do Randall have this guide as well? The Italians are notorious difficult to deal with. Even if I'm much closer to Italy, I prefer dealing with USA. Now before Trump's tax are in play. Thanks Tor

-

SunStar KM-380 BL-B cylinder arm consistently leaking oil

kgg replied to Esket's topic in Leather Sewing Machines

The Sunstar KM-380 BL-B can take a max needle size of a #23 needle which basically means you can use a max size thread of V138 ( Tex 135, M20 ) thread in thinner leather. Here is a link to the machines specifications. ( https://www.manualslib.com/manual/970676/Sunstar-Km-380bl.html?page=8#manual ) Here is a link for thread to needle size: ( https://www.tolindsewmach.com/thread-chart.html ) kgg- 12 replies

-

- cylinder arm

- sunstar

-

(and 3 more)

Tagged with:

-

As a professional leather repair guy, I 100% agree with you. The majority of DIY attempts I've seen to fix stains on leather furniture haven't brought the expected results to people. Kristina, please share a picture of the couch, and I may be able to offer advice on how to fix it using tools/materials available at Home Depot. Thanks!

-

That's okay. As long as you know that people appreciate your work. 🙂

-

Sorry again for the repeated responses I didn't realize I was re-messaging you 😞

-

Sorry for the slow response, I didn't even know I had a reply. Sorry for the slow response, I didn't even know I had a reply. Sorry for the slow response, I didn't even know I had a reply. Sorry for the slow response, I didn't even know I had a reply. Sorry for the slow response, I didn't even know I had a reply.

-

🙂I'm sure your mother will love them. You can see the love you put into making them. The colors you have selected look so beautiful together.

-

A picture would really help. Some folks think they have leather when they really have fancy vinyl. Vinegar will often take an odor out of leather but I've never used it for stains. Upholstery leather is usually pretty resistant to staining unless it's ink. I wouldn't do anything to the stain without seeing how the chemical reacts on an inconspicuous piece of the leather, like underneath the couch. I'm pretty sure no matter what's going on, vinegaroon isn't the answer. ~J

-

Sweeet!! I'm sure she'll love all of them. Nice work!

-

That would be the thing to do. You have not mentioned the type of leather on your couch. Vinegaroon only works on unfinished veg tanned leather. Baking soda damages leather more than vinegar, so be careful. You could try those enzymatic cleaners that are available for pet messes to get the stain really clean but spot test first.. After that, there are many leather dye creams available online, on Amazon. They are usually advertised for shoes or bags but work well on anything. I tried them some years ago and the shoes I restored then are still going strong.

-

Anyone taken a cheap servo motor apart?

AlZilla replied to AlZilla's topic in Leather Sewing Machines

I didn't try it powered but I did hold a flat blade screw driver next to it and then slide it under. It doesn't show any wobble, at least at hand spinning speeds. A runout gauge is not in my bag of tricks. I might have to go tear it apart before the replacement arrives. I really don't want to run it anyway. No need of doing more damage. And I'm pretty curious. -

My older brother was a Joplin fan, We would listen to her a lot on our weekly skiing trips back in the 70s, lol. I could sing Bobby Mcgee right with you. I love her music Its a shame she left us.

-

Hi Uwe, I like the stand you have built for your Adler. I'm looking to build a couple of tables like that for some leather machines. Are the legs available online? Thanks Tor

-

Edward Reed joined the community

-

Years late, but BuckleGuy.com has a Mason Jar Wrap kit you can purchase and make the leather wrap yourself. Pick a chromexel leather since water doesn’t impact that leather (used to make boots / see Allen Edmonds shoes). All men should drink from the Mason! Lots of angry old guys responding.

-

Some of the youtubers we follow have neat toys to make processors better/quicker. One such item I drool over in the Campbell Randell Variable Speed Burning Machine. Chances of getting one in Australia are pretty minimal and if it was available, I would probably be hit with a 50% export Tariff ;). So I after some time on my CAD I came up with these. The sanding wheel is 89mm diameter and has a small flat area so the sand paper has a slight overlap and you don't feel a bump. I choose the diameter to suit strips cut from an standard sheet of wet and dry sand paper. Currently I am testing 180 grit and am extremely satisfied. The Dust collector is NOT my work. I blended a vaccy adaptor on Thingiverse (https://www.thingiverse.com/thing:2806410) to suit my needs. The burnisher works well. These are all printed in PETG and time will tell if the stand up to abuse. Both the sander and burnisher are driven by 1/2hp 3 phase motors with VFD to control speed. When I get this mounted in their (yet to be designed frames) I will share moer details. As always I am very open to comments and observations.