All Activity

- Past hour

-

This is kinda what I use. https://www.walmart.com/ip/Equate-Self-Adhering-1-Elastic-Bandages-2-Count/804779067?classType=VARIANT&athbdg=L1102&from=/search I actually use vet wrap which is used for horses and 4 inches wide. I just cut one inch strips of it. Same stuff. JM2C, Jim

- Today

-

I'm looking for information on this leather cutter I bought from an old cobbler's estate sale. Is there a special use for it? It has an approximately 34 cm deep throat and 20 mm gap on the jaws. There is a long handle, so it can deliver a lot of cutting force. It has a swivel base that can rotate 360 degrees around and pivot 90 degrees forward or back. The maker logo is so worn I can't make out the name. All info appreciated. Thank you.

-

Singer Industrial Sewing Machine Screws

catskin replied to shoepatcher's topic in Leather Sewing Machines

I am only telling you my experiance. I used a metric thread gauge and it matched exactly. Then I took one screw that there were 2 alike and tried a metric nut on and it fit just as good as on the metric screw. SO, if that worked here it might work for some others on at least some screws. These were from machines that had never been touched. Some were from a machine my mother bought NEW almost a 100 years ago. If you look at and read the link you sent me you will see that what I said is true. it SAYS MANY of the singer screws match other systems. SOME do not. -

gear for 29k machine metal workers please read

catskin replied to catskin's topic in Leather Sewing Machines

Private message sent. -

How to ease when sewing leather on a 1341?

joetroba replied to joetroba's topic in Leather Sewing Machines

I am working on sewing the finger stalls on a baseball glove. Two pieces make up the back of a finger so there is a welted seam directly down the middle of the back of the finger. The two pieces that make up that seam are sometimes not equal length to create a "3d" curve in the back of the finger. I hope that makes sense, kind of hard to explain in words. My initial assumption would be that they would have to be the same length and the actual curve cut into the piece creates that "3d" curve. But I have also been told that it is normal for those pieces to be different lengths to create that "3d" curve. So maybe I am chasing the answer to an incorrect statement, and they both should be equal lengths. Just looking for any advice or clarity. And if anyone has done this before or something similar with another type of project. -

How to ease when sewing leather on a 1341?

Constabulary replied to joetroba's topic in Leather Sewing Machines

not sure what you mean... Is it that your last stitch is probably to long and not hitting the 1st needle hole where the seam began? If so then you can shorten the stitch with the reverse lever and hand crank the last stitch - if you know what I mean. -

How to ease when sewing leather on a 1341?

AlZilla replied to joetroba's topic in Leather Sewing Machines

What are you making that the three pieces wouldn't be the same length? 4 ounce leather really doesn't have any stretch that would lend itself to easing unequal lengths, at least as I understand easing from doing it with fabric. I'm going to move this to the Leather Sewing Machine sub forum. -

Thanks again everybody. MERRY CHRISTMAS to everybody. WUTA 3.85. I bought these from PacoLeathercraft on Etsy.

-

It was an experiment to see if it could be done and how well it did it. As to why - I could lay out a whole sheet of leather on my laser bed and cut out the body and score several different tooling patterns very quickly while I did something else. And they'd be just as accurate as a clicker. You dont lose any skills as far as tooling goes because the scoring only replaces the transferring of the pattern to the leather. You still have to follow up with your SK, and tool it out as normal. It just gives you another tool in your box to create different affects as well as it can increase your productivity. The downside is now you have to deal with some charring on the edges which throws a little curve when trying to bevel and burnish.

-

I've been using electrical tape. Probably because I'm an electrician and I have plenty around here.

-

Beautiful work!! If you don’t mind me asking, what stitching chisels do you use?

-

Singer Industrial Sewing Machine Screws

Constabulary replied to shoepatcher's topic in Leather Sewing Machines

not sure where how you figured that but I have different experience (I´m living in a metric country). Maybe someone overcut the original threads on your machines. Nothing really metric I´d say: https://www.singersewinginfo.co.uk/technical/parts/screw_threads/ -

Singer Industrial Sewing Machine Screws

catskin replied to shoepatcher's topic in Leather Sewing Machines

I realize this post started a long time ago. BUT, I have worked on 29k and 31k15 machines and much to my surprise, haven't found a screw yet that doesn't match a metric size. Both thickness and thread pitch. Get a metric thread gauge and see if the ones you need match. -

I am looking for some help learning how to ease a seem when sewing leather on a 1341. Specifically, a welted seam, where I have a stack of 4 ounce leather, 4 ounce 3/16" welt and 4 ounce leather. Each of the 4 ounce pieces have a curve but the seam lengths could be different, but I need start with pieces even and end with pieces even. I have done this with pieces that are the same length but having trouble with the ones that are not the same length. Thanks

-

Just adding SOLD as the next comment is all you need to do. Then a moderator picks it up and moves to old/sold and locks it so it can't be commented on further.

- 5 replies

-

- landis model 25

- landis

-

(and 2 more)

Tagged with:

-

Hi, Jup - a VFD is the way to go in your case. Just remember though - in Europe most all 3-phase motors run on 380 Volts. But you can change their configuration so they run on 220 Volt 3-phase. If you want to run a VFD from 220 Volt sigle phase - you will have to also adapt to 220 Volt 3-phase which means that you have to re-arange the brass bars in your wiring different. Wiring for 380 Volts will have the bars connecting U and V and W connected to each other in line. To run 220 Volts you have to connect R to U and S to V and T to W. Only takes a 1/4 inch drive ratchet with a 7mm socket/nut. Best ya get someone to show ya how it´s done properly. VFDs from Chinesistan ya can buy via EBAY for around 80€ - best buy one that exceeds the current draw of the motor. Greetings from Germany Tigweldor

-

@Zol, Thank you for your interest in the machine and for sharing the link. The machine has already been sold but unfortunately I have got less than zero idea how to move this post to Old/Sold. @Northmount - would you mind to bother with this, like, again..? You seemed to have some magical powers last time. Or does a "SOLD"- kind of comment suffice for any of the moderators to step in and close the topic? Thank you guys for your support and Happy Holidays everyone Cheers, Grace

- 5 replies

-

- landis model 25

- landis

-

(and 2 more)

Tagged with:

-

Floral scrolling step by step

LakeOtter replied to FrenchMich's topic in Floral and Sheridan Carving

I don't want to irritate anyone bumping an old thread but I was doing a deeper study of variations on scroll work and really enjoyed this that was posted 3 years ago. It's another I've chosen to download the pics just to look at in a personal, private study gallery of my own, as inspiration and variety. Thanks to FrenchMich -

gear for 29k machine metal workers please read

Tigweldor replied to catskin's topic in Leather Sewing Machines

Hi, This is what it looks like : .https://www.college-sewing.co.uk/81869-hand-wheel-shaft-gear-singer-29k.html Got one from a 29k51 that I can send you for free except you pay for the postage. Used to work in Regina for GE Railcar Repair as a weldor - back in the days when the Apollo MC was still in existence. If ya think that I´m trying to gyp ya - I can provide refs that this ain´t the case - only through personal message though. Greetings from Germany Tigweldor -

Looks like a table-mounted bobbin winder could be a 3:1 speed reducer if you added a tiny pulley to the spot where you normally mount the bobbin.

- Yesterday

-

I cut the fingers off an old pair of leather gloves and slip one on my finger. I cut off the end so my finger pokes out. Sewn quite a few holsters and gunbelts, Works for me.

-

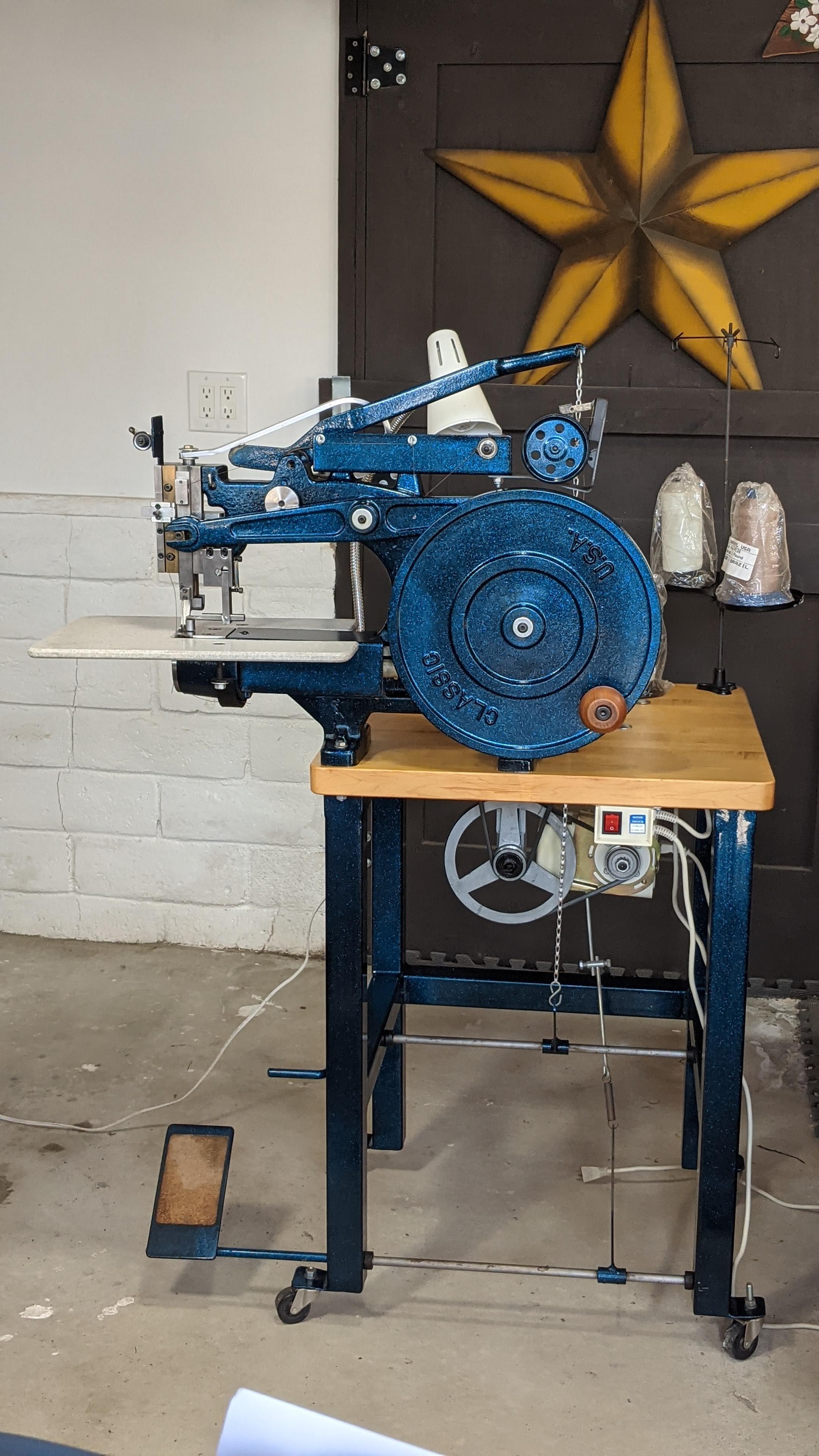

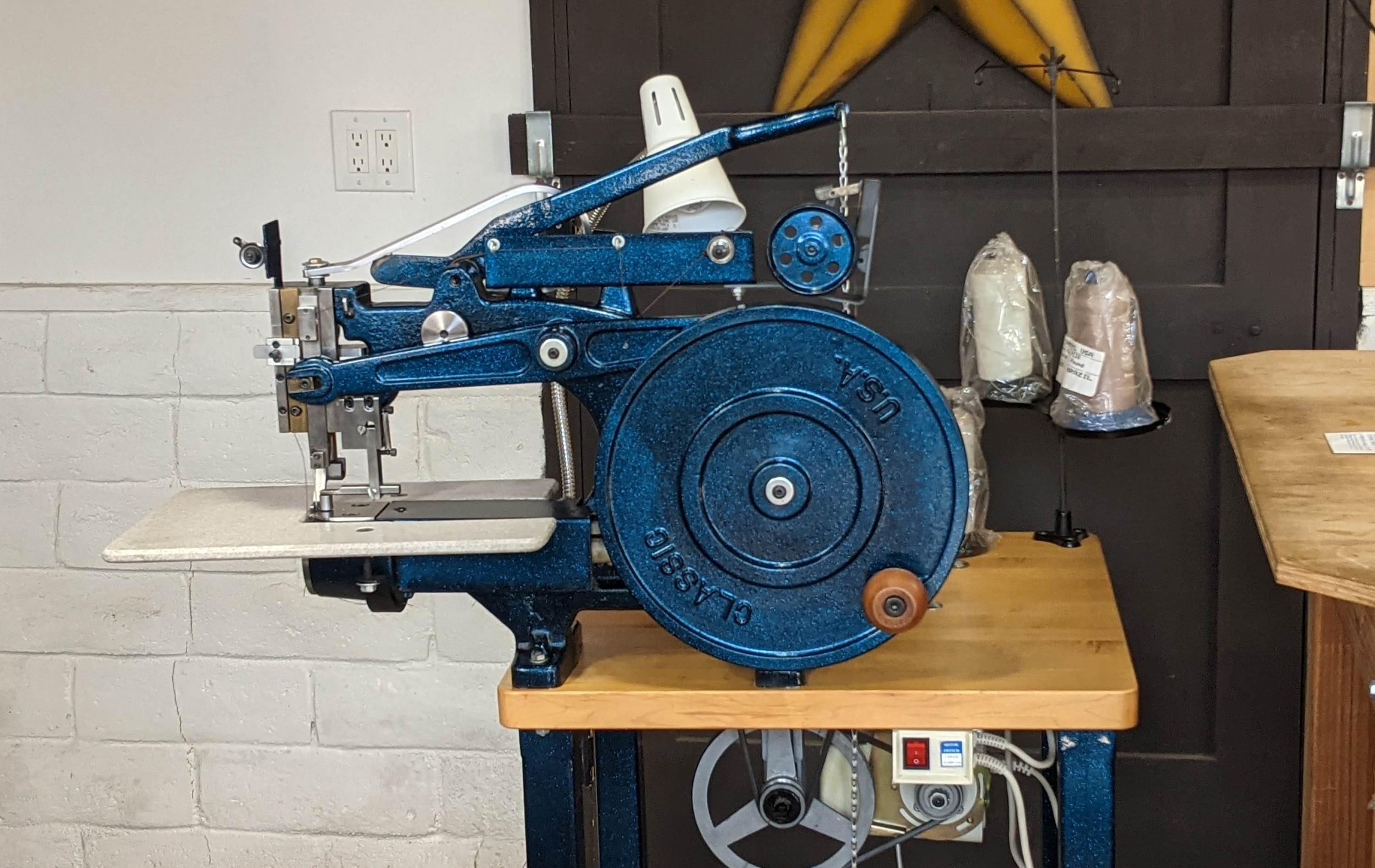

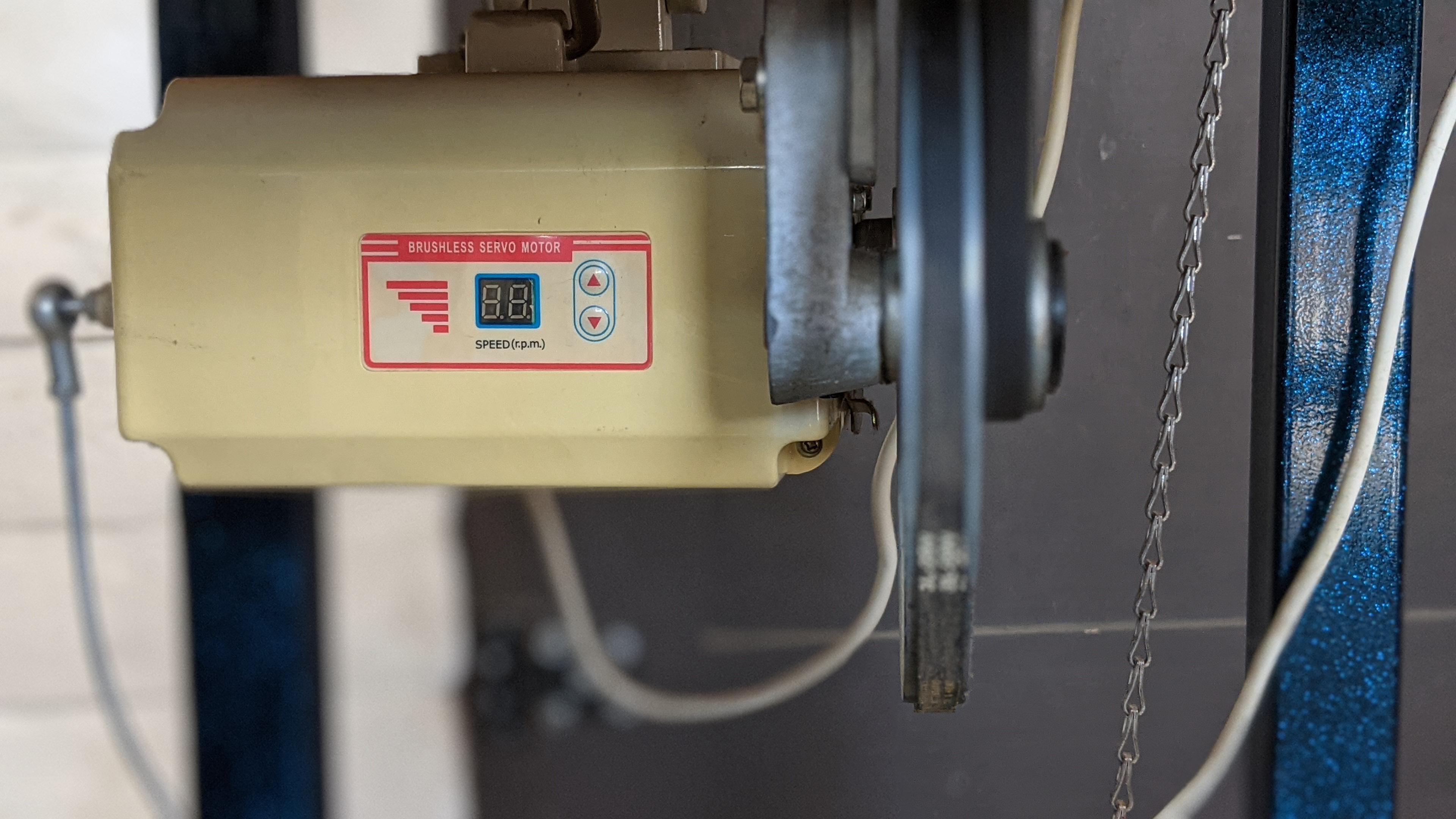

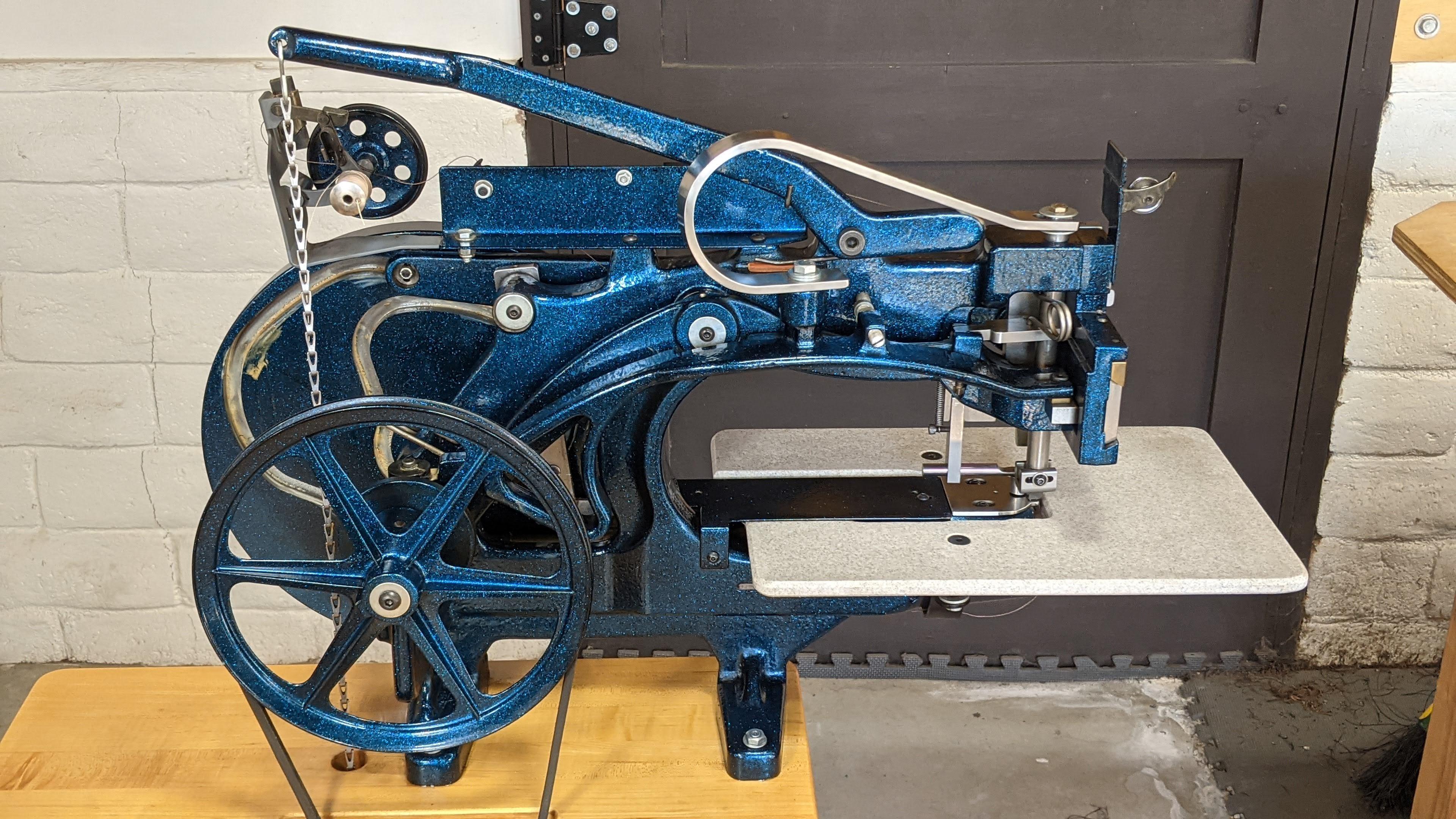

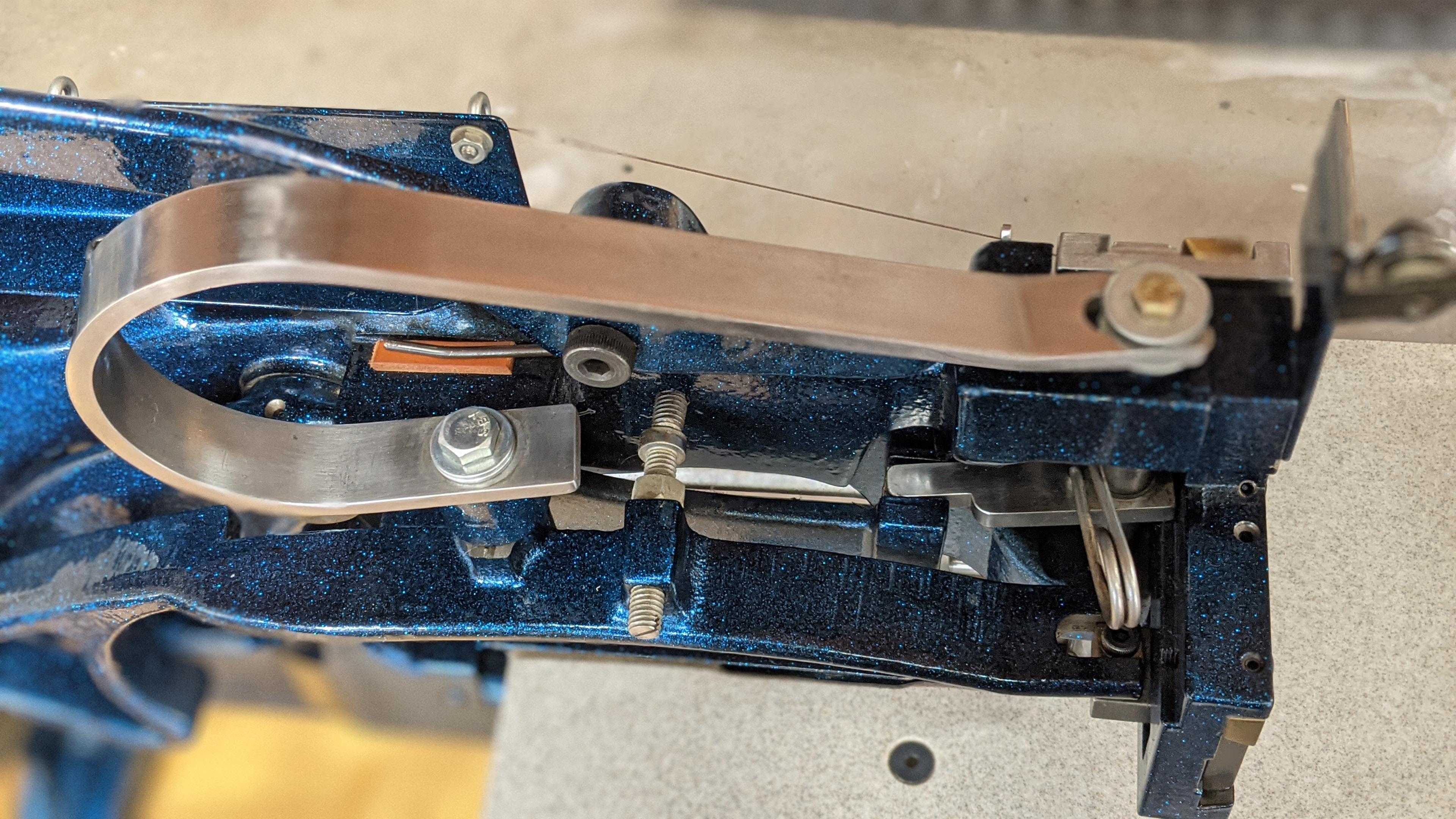

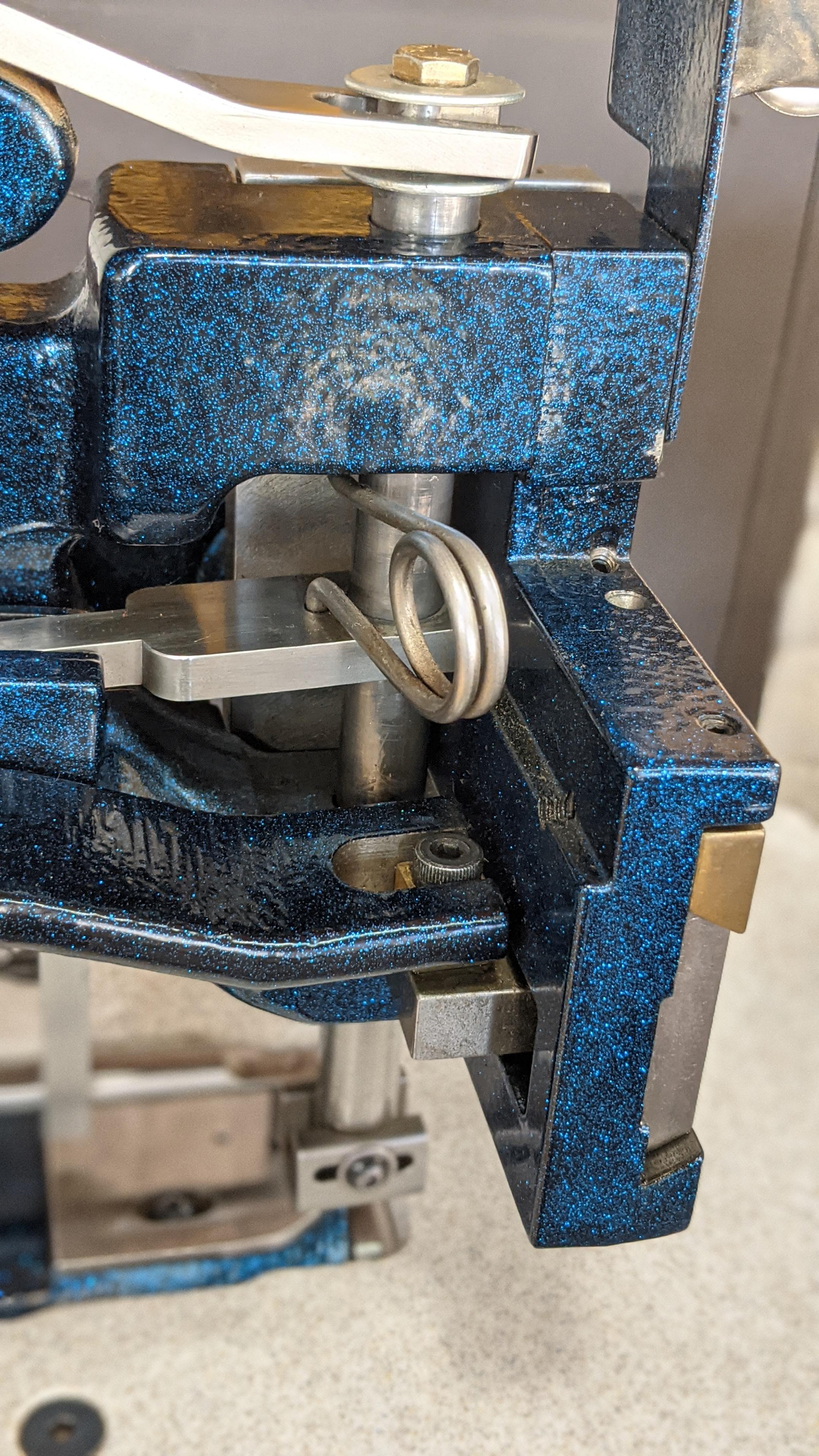

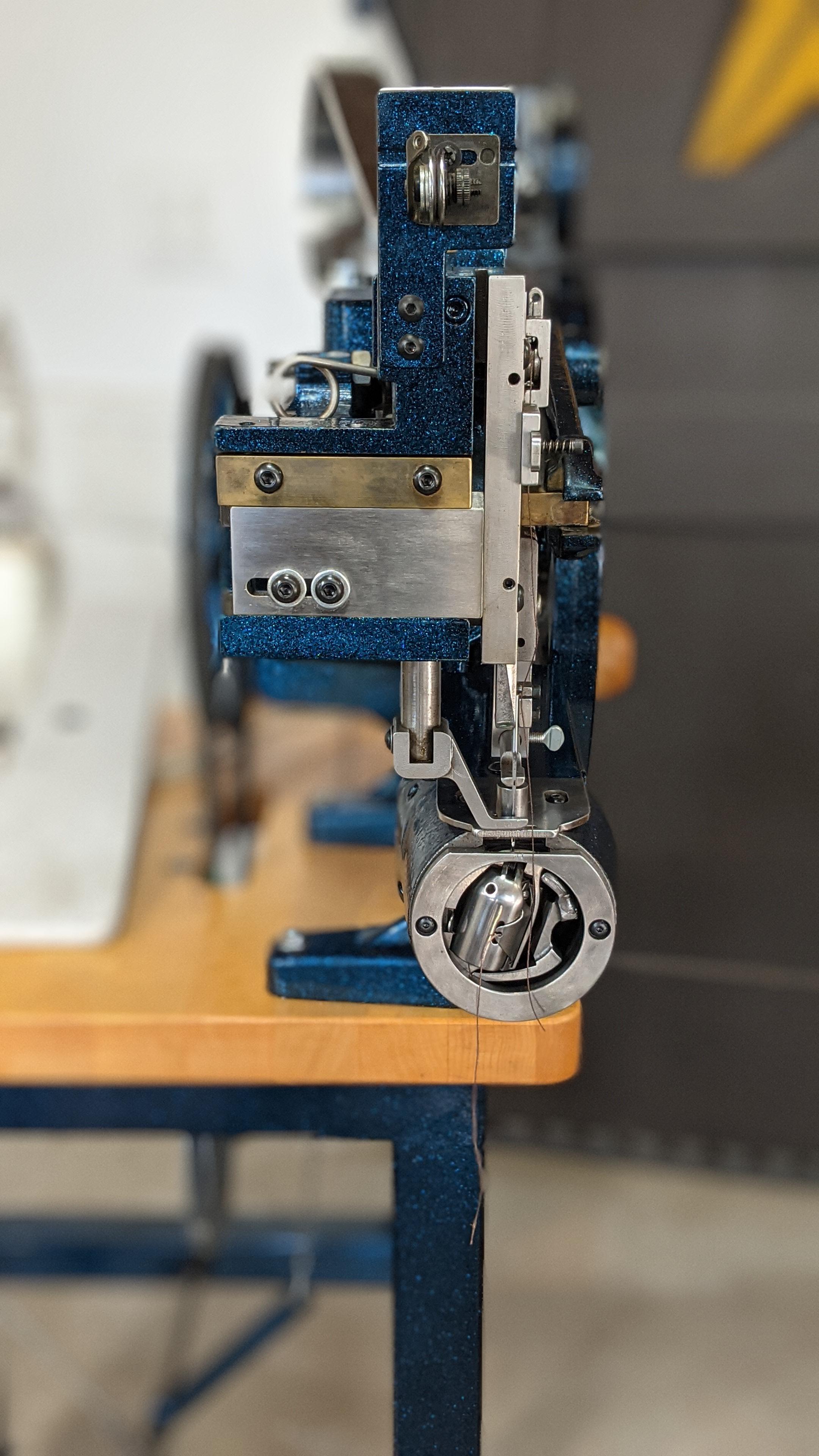

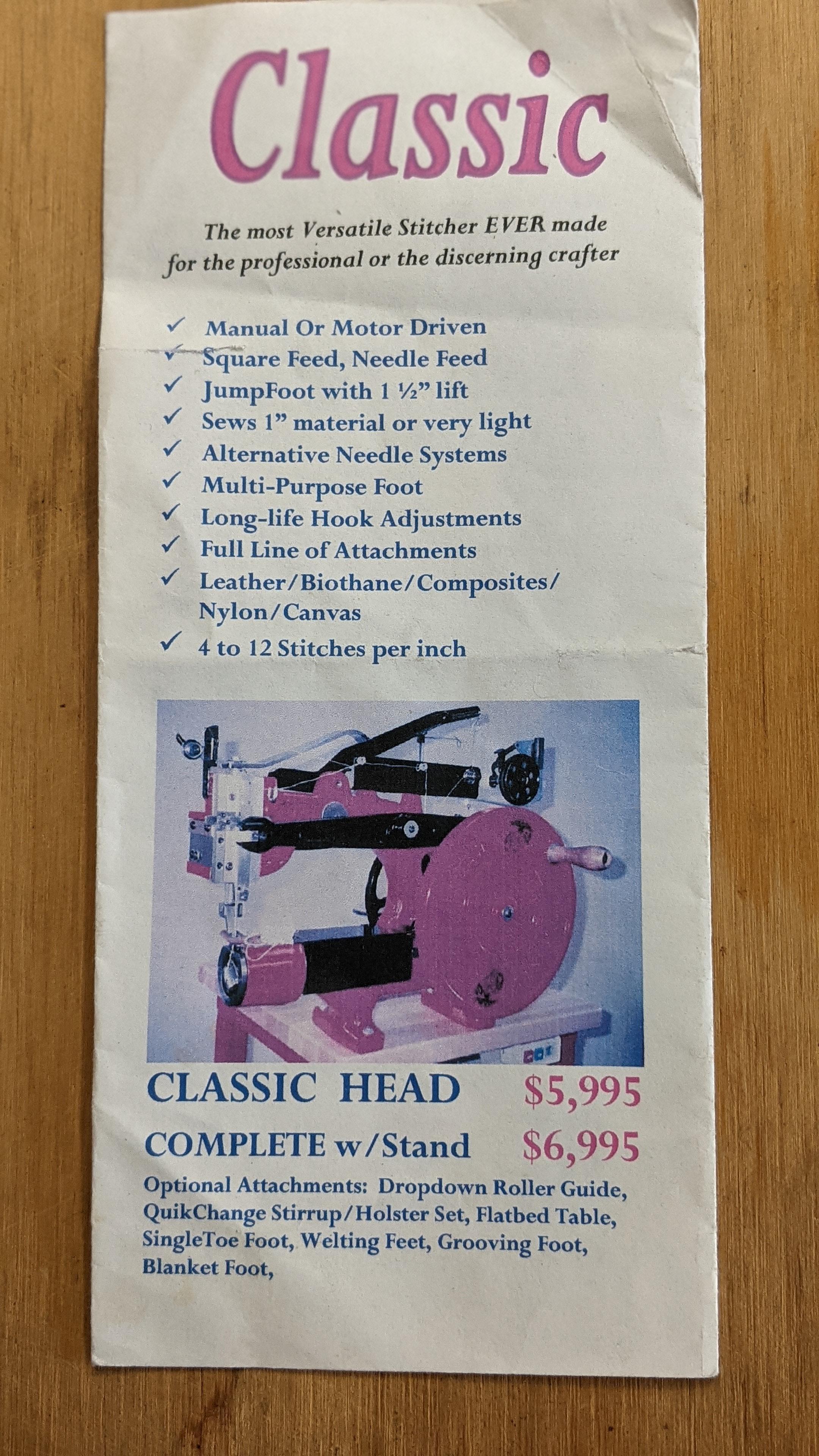

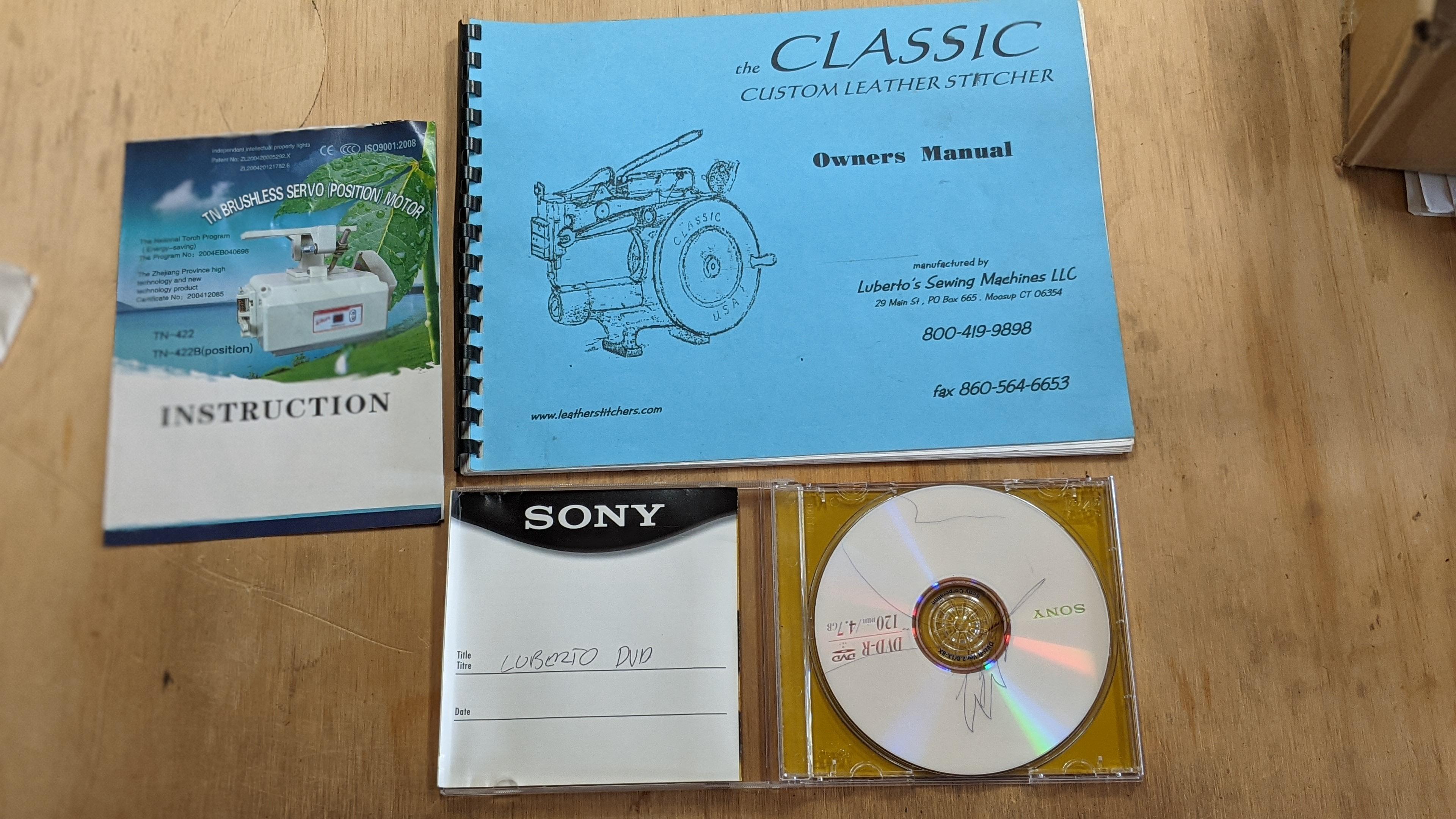

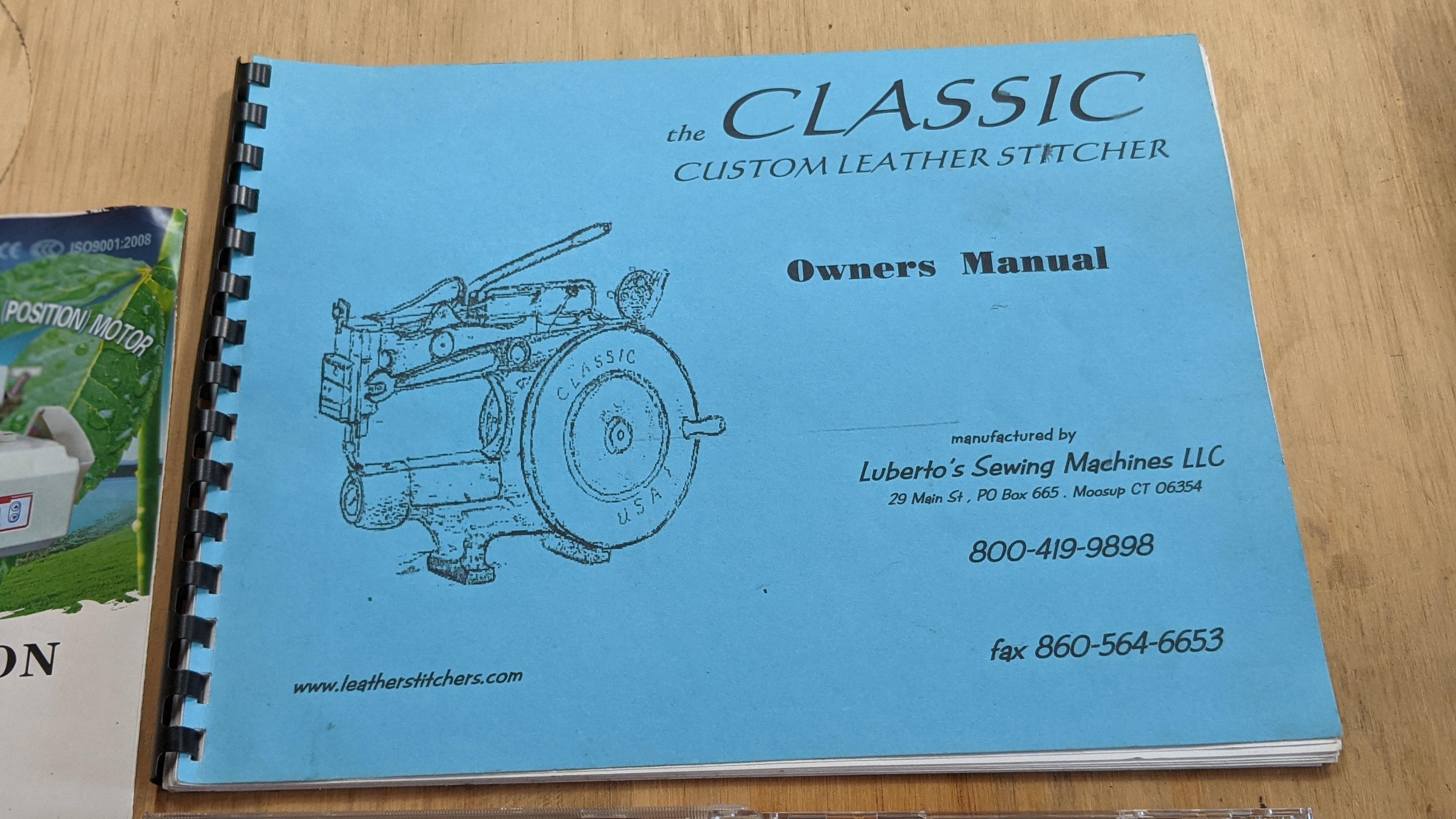

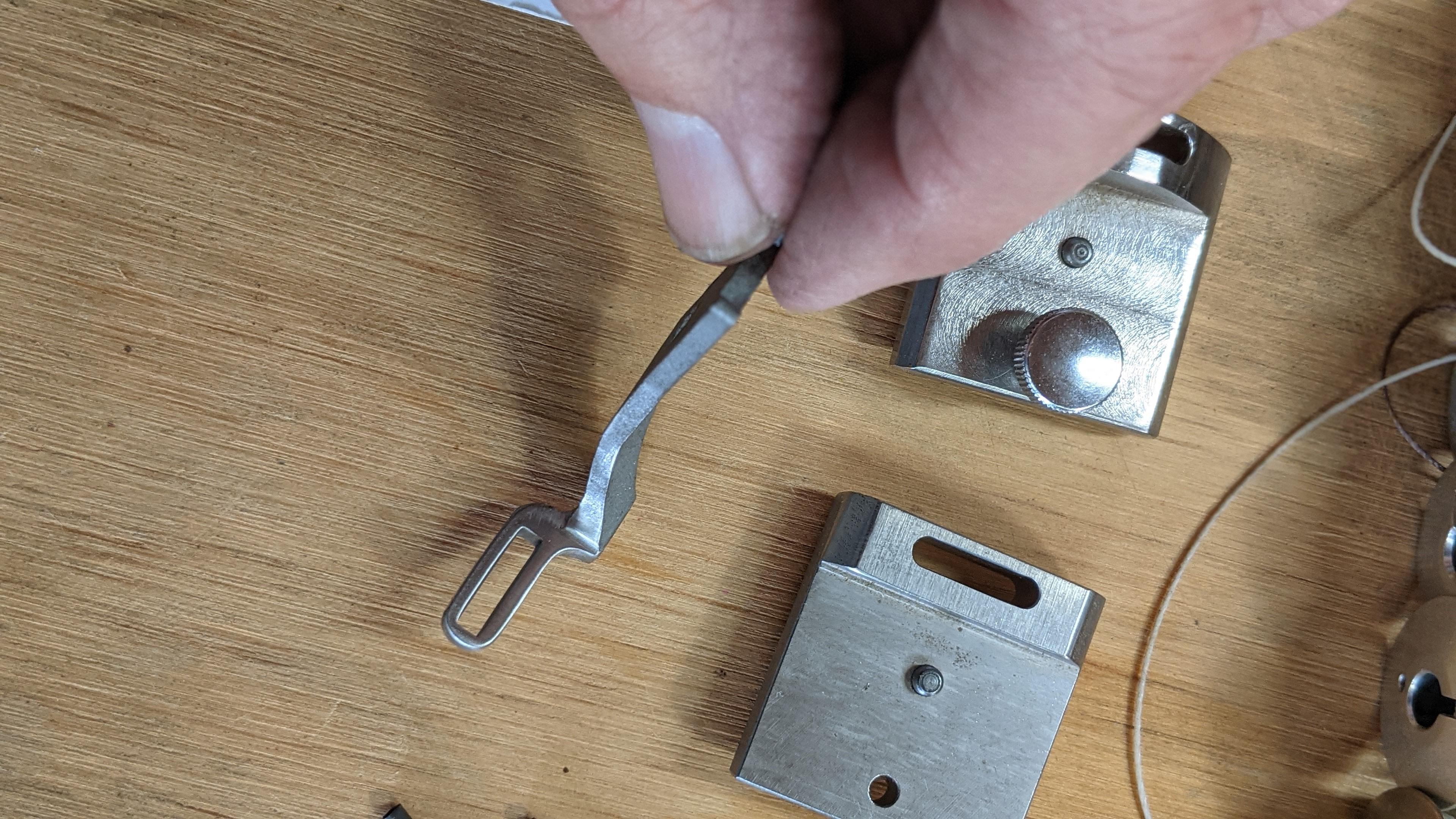

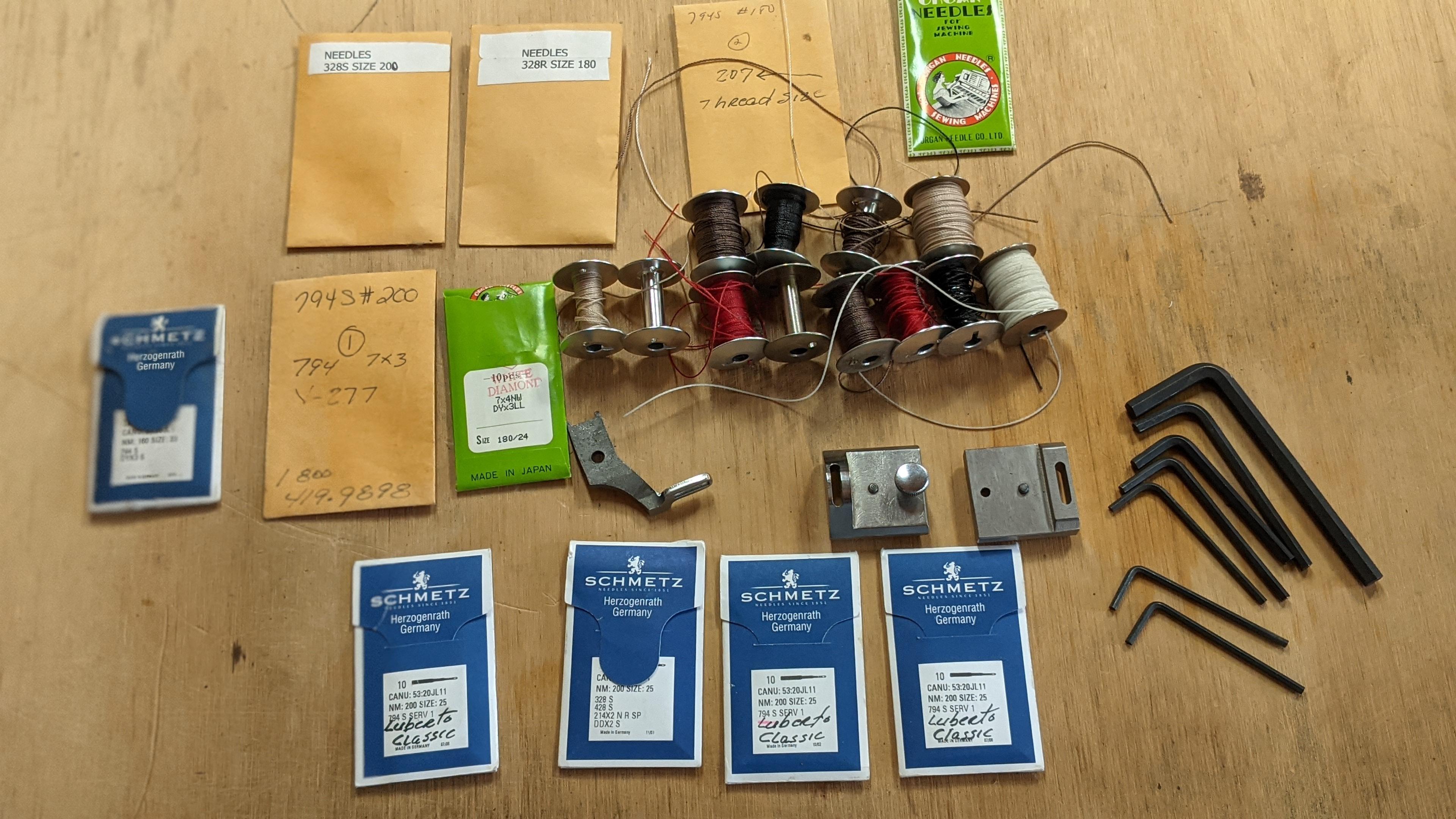

Luberto Classic Custom Leather Sewing Machine - Metal Flake Blue $4,000 OBO (Sold for $6,900 New) This awesome hot rod has been good to me, but sadly it’s time for me to let it go. This machine will stitch your thickest leather projects, it can sew over one inch of leather. It can be used by handcranking or electric servo motor. In great condition! Made in the USA. Includes many extras. - Flat bed attachment - Drop Down Roller Guide - Extra Presser Foot - Holster Plate - Stirrup Plate - Electric Servo Motor - 12 bobbins - A bunch of Schmetz and Organ Needles - Bobbin Winder - Work light - Handcrank Knob - User manual - Spools of Thread - Stand -Instructional DVD - Home Rip with child’s artwork on the inside-Still plays nicely. Location: Los Angeles California. Close to the Gene Autry Museum. Pick up only - No Shipping Available

-

I use athletic tape. Maybe that's the white tape Bruce mentioned. I tried band aids, but they weren't very effective. Randy

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)