All Activity

- Past hour

-

Do u have the same skiver?

-

FEIT DCL-8500N : Stump for Tilting Machine Head

friquant replied to friquant's topic in Leather Sewing Machines

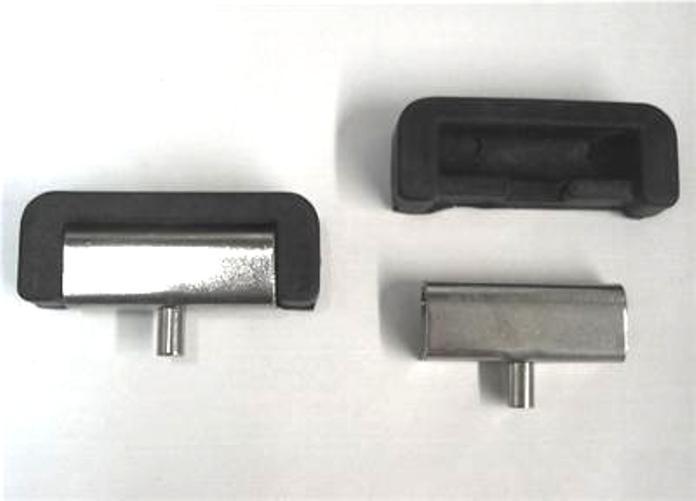

Anybody care to measure the distance from the hinge line to the tilt stump on their machine? My working hypothesis is that a tilt stump too close the the hinge axis will lift the machine off its hinges. For reference, this is the hinge type on the table. I have not personally owned this style of hinge. It appears that even with the machine head tilted back, the hinge can still be pulled straight out of the table. But I suspect that is true of this other style as well: -

Well if anyone needs a scanned copy, or the actual books, they can message me details.

-

Cowboy 3500 Running when Powered On

Constabulary replied to KYCat's topic in Leather Sewing Machines

Guessing - most likely a motor problem. I guess the machine has a servo motor so I would guess the lever of the accelerator unit or the hall sensor is loose / has moved and is probably stuck in the "run" position. Please post some pictures of your motor and the accelerator unit and lever where the it man rod is attached and maybe a video showing the issue (please not just 5 second video or so" upload it to YT and post a link here. - Today

-

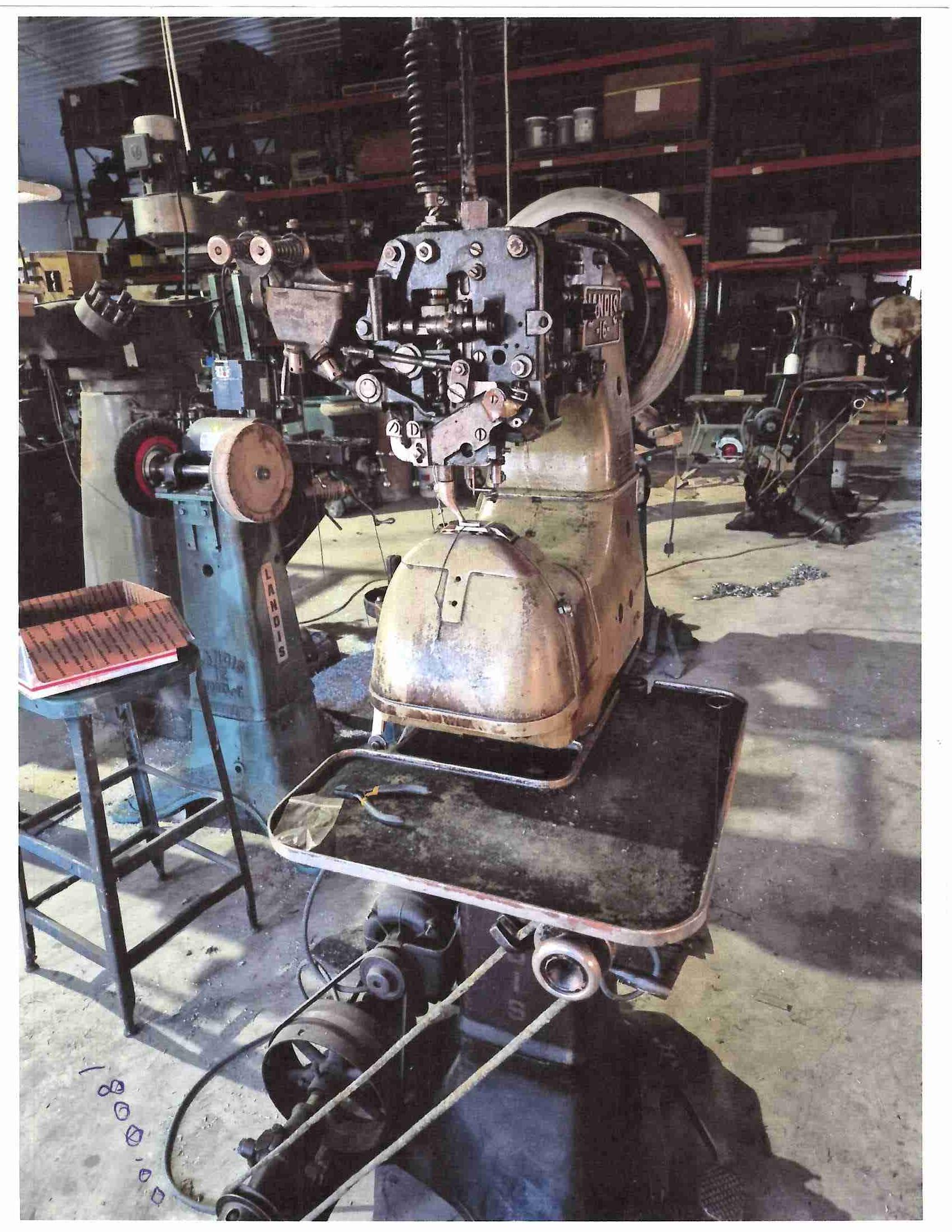

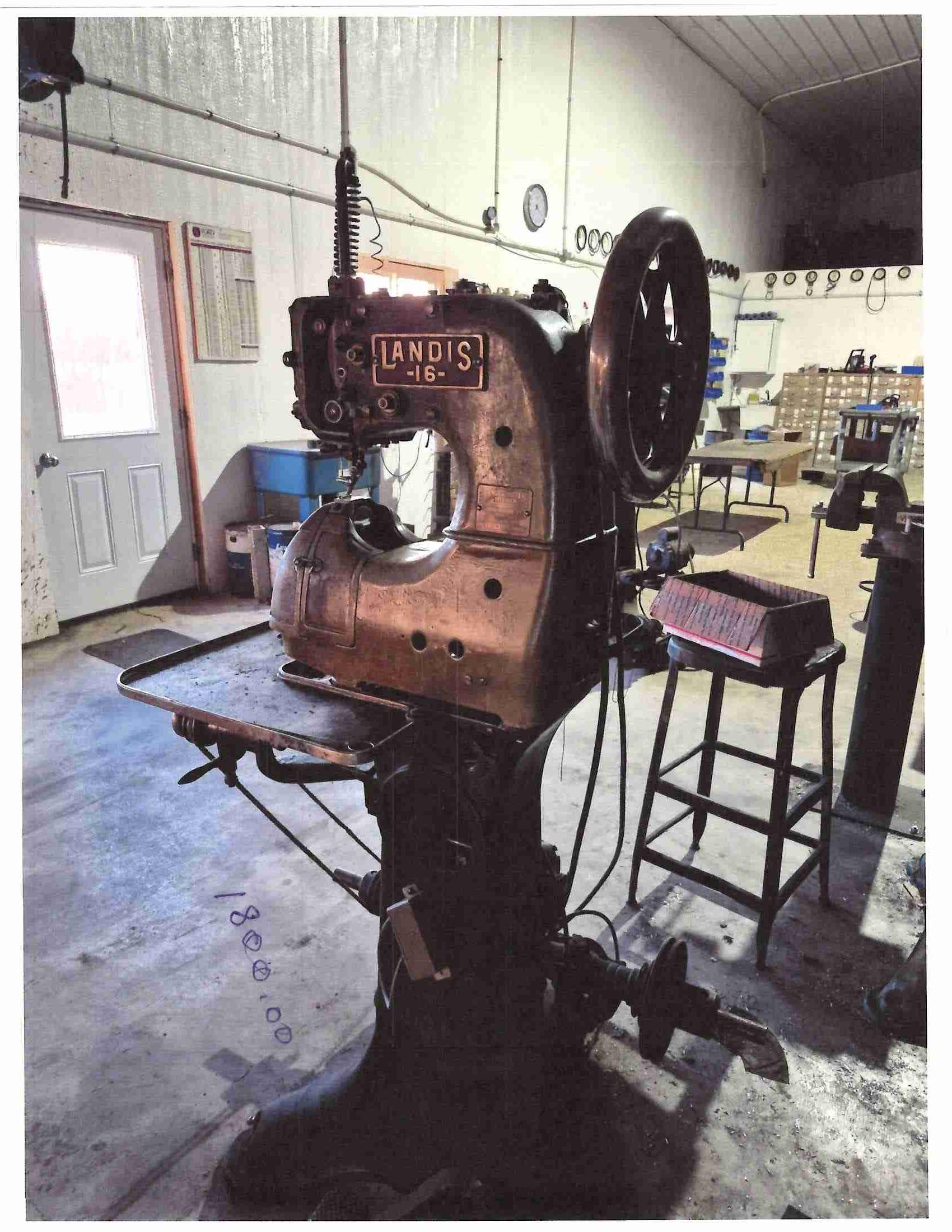

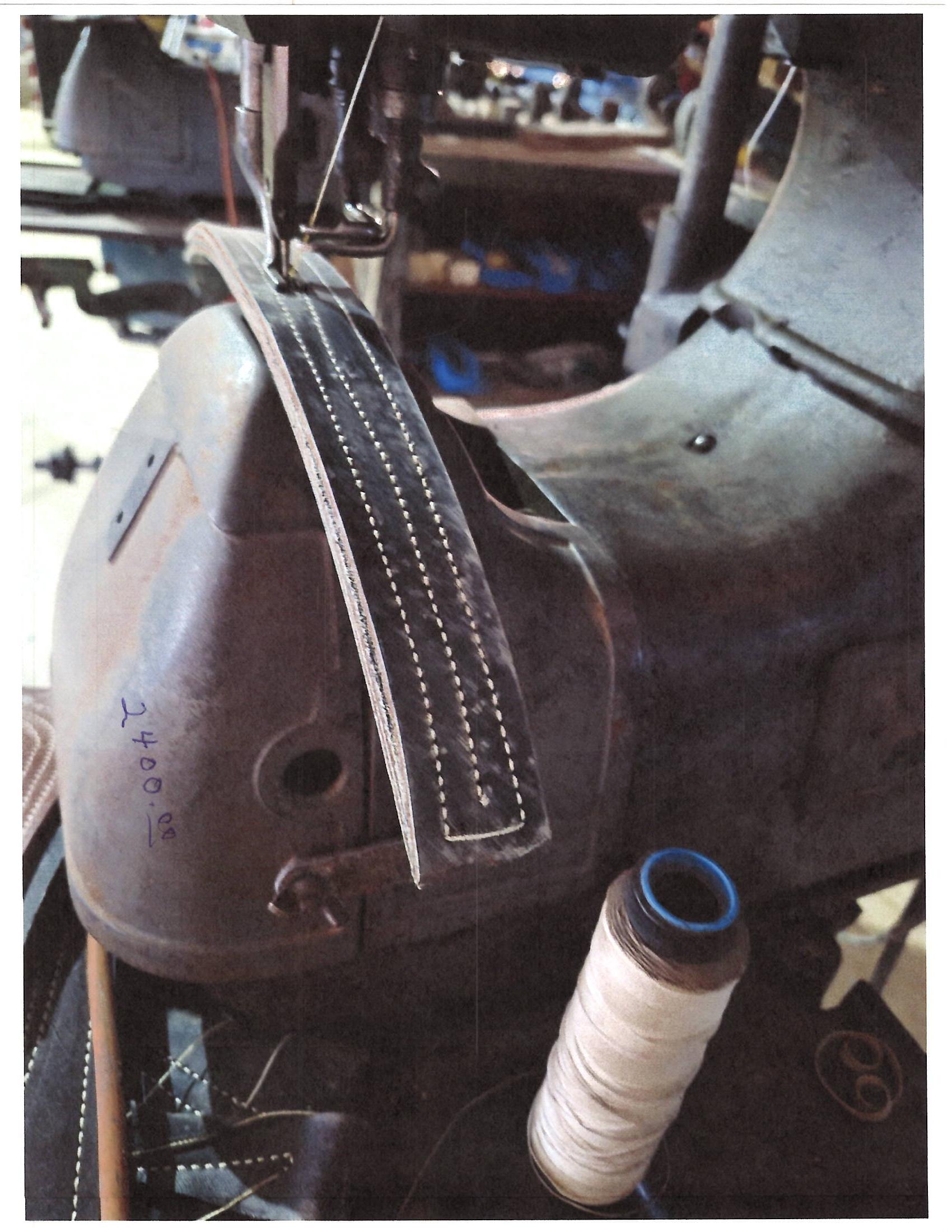

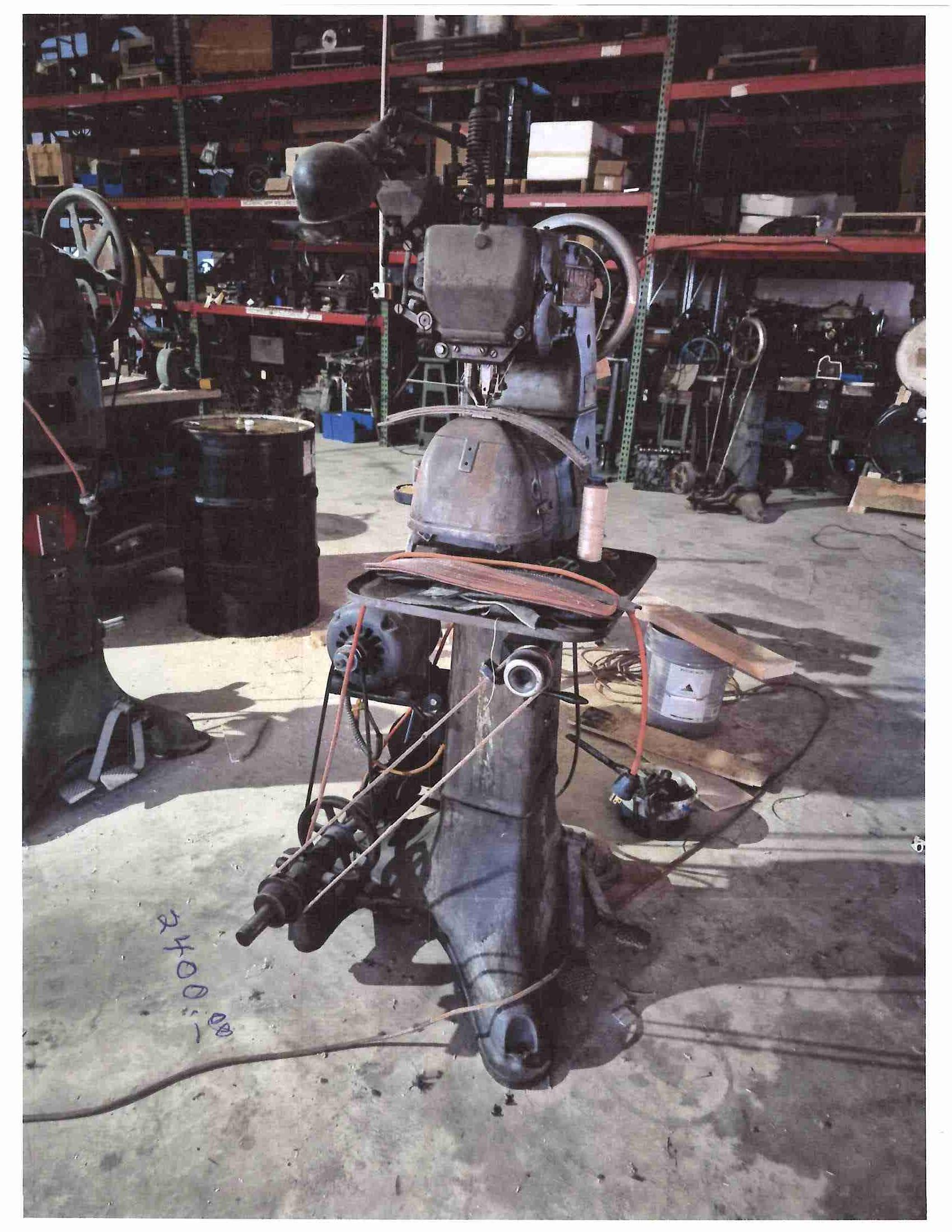

Hi I talked to Eli today over at Landis Machine Co was making sure he received a check that I sent him for a part for my Landis 16. I am posting this on here for Eli. He said he has two Landis 16 for sale he went through these machines and they are ready to sew and he is selling them for one of his customers. I told him to send me the photos and I would post them on here for him. Eli is a really good guy and one of the only people that has parts and can fix these old Landis 16. I sent him my Landis 16 and she is sewing a beautiful stitch. Give him a call if you are interested. The one machine is $1,800.00 and the other is $2,400.00. Here is Eli contact info. I was not sure where to post this one. Landis Machine Co 6373 Country Road 400 N. McLeansboro IL 62859 for pickup. Phone # 217-543-3464

-

yeah - keep that old cast iron alive - I seldom went wrong with that! 😉 I love my 51w but the 2nd type as yours would be even more preferred but I love mine too. Singer crazy me is. 😁

-

@FDC Sweet!

-

It is my understanding that the fridge isnt doing anything for keeping moisture in. Its the bag. The fridge just delays molding. If youre doing a project that you'll have to come back too a bag should suffice fine. If it will be a few days then I'd stick it in the fridge. Peter main has a bigh sheet of tempered glass he uses. He would wet the leather and stick the glass on top and it would stay cased as long as he needed it too right on his bench. I believe this works because Moisture isnt lost much through the edges but the grain. Thats just my theory though

-

FEIT DCL-8500N : Stump for Tilting Machine Head

kgg replied to friquant's topic in Leather Sewing Machines

This a typical location for the "tilt stump". Typically just made of plastic, pressure fitted into a hole drilled into the table top and meant as a temporary rest. The machine " slithered off the table hinge and into the drip pan " indicates to me incorrect / damaged hinge and or hinge installation. I have never had a head slip off and with my stubby fingers I am also titling my flatbed machines back to install / remove bobbins. kgg -

I have a fairly new (2years) CB3500 that hasn't gotten a lot of use recently due to health issues. I've finally felt like doing a couple of projects and when I was going through the maintenance points I simply turned the power on and the machine takes off. The foot petal is 'up' and the arm in the motor is 'up' where there should be no stitching. There's a grinding noise coming from the motor when I turn the handwheel so it's not in the head unit. Any ideas on what caused this and how to fix? Thanks!!!

-

This machine would definitely do the job for you. The learning curve on my skiver was a bit steep but patience and lots of trial work. I'd label each control on the machine as soon as you get it as this helps when tweaking it!

-

I wanted a post bed machine for years but the price of a new 810 was a bit over the top for my usage/needs. Constant serching on used on-line apps finally coughed up a little gem - A Singer 51W59 withing 20kms of me. It was mine for $300.00 CDN. It took over 2 years but there it was! I threw away the table and set aside the clutch motor, bought a servo motor and controller and built a new compact table for the head. The head got torn down to the last screw and restored. It is a lovely little machine to use and look at and it lays down perfect stitches. I bet that you can find one as well, it just takes time!

-

That is a masterpiece! Beautiful design and execution!

-

True. About a third of my stamps are ones I've made. I usually only make ones that I can't buy. Why make one when someone else has gone to the trouble to make it? There are some I don't have the ability to make. Then I'll buy what's close.

-

How does this "tilt stump" attach to the table? Is there a nut under the table? Or do I pry the plastic cap off to reveal a bolt head and it screws out the top? This is a customer's machine, a FEIT DCL-8500N. The closest manual I have found so far is this one for the Artisan 8500N. I brought the head unit home with me for repair. But I'm convinced that the tilt stump is in the wrong place. It prevented the head unit from tilting all the way back. But after a couple minutes, the handwheel end of the head unit slithered off the table hinge and into the drip pan. Nobody was hurt in the process, but seems liable to happen again. My intention is to move the stump further away from the operator, and a maybe a couple inches left (from the operator's perspective) so that it loses its tendency to lift the machine off of the table hinge closest to the hand wheel. But I'll need to pack the appropriate tools to do so, and while I was there I did not manage to figure out how it attaches. artisan-8500n__similar-to-feit-dcl-8500n__manual.pdf

-

I’ve done both. Straps loosely rolled in a jumbo zip lock. Flat pieces left flat. I left enough air to keep the plastic off the leather surface. Initial case in the morning or evening, 12 hours to even out, then tool. If I didn’t finish then back in the bag. I didn’t see much difference in the refrigerator or not.

-

spring flowers and good food

chuck123wapati replied to chuck123wapati's topic in All About Us and Off Topic

Haven't heard from you lately. Are you lost under your AC? -

I agree you can't make 'em all, but you can make the easy ones with simple hand tools, save a bundle, learn a new skill, and have unique stamps no one else has.

-

Downside I think is getting the bobbin tension adjusted. The Juki style is where the bobbin is placed in the top half part of the bobbin assembly, threaded and tension adjusted while still in your hand and then dropped in place. Personally I like being able to adjust the bobbin tension this way as I can do a bobbin tension drop test. kgg

-

Thank you, making a few stamps also, background and border out of bolts. It is cheap to try and if it fails put it in the scrap metal pile. I do buy good stamps too, their is a skill to it and I don't have it. Simple things are fun who knows what happens though. I like the stacked handle. I wouldn't say fancy, more options.

-

Thanks Keith. Seems like a foolproof way to do it. I wondered if I was doing something wrong.

-

putting a belt in the fridge?

Dwight replied to LakeOtter's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I've never done that . . . and it would take a bunch of convincing to get me to do that. Stuff dries out in the fridge almost as fast as laying on the counter. For what stamping I do . . . if I have to shagnasty for a while . . . I leave it and hit it with the sponge when I get back. Works fine for me May God bless, Dwight -

That is correct for the Cobra Class 26 it does not have a Juki compliant bobbin assembly. Here is a video for the bobbin installation. kgg