-

Posts

7,378 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by JLSleather

-

Gravity and age are inevitable, unavoidable. Being sucked into paying for useless crap is a choice. Stopping work again this morning to find out just why I get all this credit card crap, insurance "offers", and "pre-approved" refuse. I swear I'm on every "do not call" list, "do not write", "do not offer", "do not spam (electronic OR paper), ..... it should basically require a court order to even say "hi" And yet they do .... Yeah, I want some more credit, so I can buy some more crap, ... yikes- who are these people.. and are they stupid, or are they just hoping that I'm stupid?!@##!

-

Tha's funny. But ya gotta be my age to know that it's funny

-

Skiving/splitting and finishing an entire side

JLSleather replied to theoregoner's topic in How Do I Do That?

Well, HO is like W/C in the sense that you can order leather in about any weight. HO from the tannery is quite consistent thickness, actually... when they say 3/4, they MEAN 3 1/2 oz, and when I order 7/8, I GET 7 1/2 oz. Very firm, very level. Now, if you got some HO somewhere else, and want it split, that's a service I have repeatedly wondered why nobody seems to offer. You can get leather cut, clicked, sewn, and dyed, but apparently splitting isn't "the in thing". Most of us wouldn't have a machine large enough to split entire sides (or the space to put one, quite often). And some are of course so terrified of competition they'd likely wet themselves at the thought of doing something beneficial for another crafter ... -

I'm not seeing a length-wise seam. Matt is correct -- one piece.

-

That works.. thanks That's only $2 over "dealer" price, and without the minimum order.

-

Do you not know, or are you just not willing to say? Uhhh.. never mind...

-

What's the shipping look like over there? I hesitate to sign up for yet another site, but there's one I want, provided I'm not going to find out the shipping is $10+ ...

-

Bigger is better. The tables I use now are getting a bit soft, so I'll be replacing them once I move. Depends on the size work you'll be doing, of course, and the room you have available. My buddy has a 30'x60' shop with 14' ceilings.. which is a bit much for me Still, I like a cutting table 8' x 4' ... which allows me to lay out an entire side of leather to view / cut. 2x4 frame covered with 3/4" plywood (you could likely get by with 5/8" plywood). Screwed down to teh frame, and the whole thing held up with 4x4 posts (5 of em - one in the corners plus one half way down one side). Then another "shelf" about 10-12" off the floor - this can be a framework as above covered with heavy cardboard, or better yet light plywood covered with heavy cardboard. Cover teh top with 1/8 masonite (comes in 4'x8'). Drive a finish nail in opposite corners to retain it. This will let you cut leather for a LONG time before it's scarred up... at which time you just pull the two nails, put on a new sheet (cost about $5) and go back to your business. The bottom shelf holds more sides of leather - off teh floor, off the ground, and out of direct sunlight. Now, you can't do this for $119, so HF starts to look quick n easy, but I think you'll want bigger soon. Note my cutting table looks a bit like this, but i have 3 other tables plus a "rack" for hanging chrome leathers ....

-

Pancake holster construction

JLSleather replied to JLSleather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Yep. My buddy Robert made holsters for 10 years before he ever used a pattern -

Sweet... now there's two of us who occasionally make a mistake

-

Pancake holster construction

JLSleather replied to JLSleather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

'50/50' or curved, I stitch them both on a machine before forming -

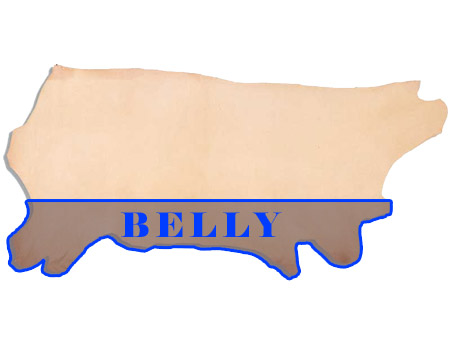

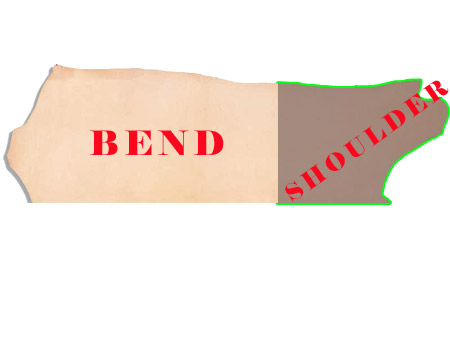

That is a bend, which is a back MINUS the shoulder. Take a cow, cut it down the middle, this is a 'cowhide' or 'full hide' cut that in half down teh spine for two "sides" Cut off the belly section and call it a "back" (side minus belly) AND..the difference between a 'back' and a 'bend' is removing the shoulder, leaving the bend. This is THE best part of the hide for belts, being the most dense (strongest) part of the leather.

-

I haven't done the 'pancake' there, but I've made a good many of the "bucket' or 'envelope' holsters (some folks like to say 'western'). I'm gonna re-work it to put a little 'fancy' in there, but I'll send you something here shortly...

-

Did you get a back or a bend? Cuz IF it's decent leather, then $170 for a back is a good price. Keep in mind "they" (not just springfield) always say they're gonna hand select the best..blahblahblah Everybody else got the same story. Still, I have got some decent leather from them time to time. 18 is optimistic, really, I think you'll have a bit in there you'll want to cut out. But a little thought before cutting can make a difference.

-

Revolver holster patterns reduced by half 'til Thanksgiving (just what day is that anyway?). https://www.etsy.com/shop/JLSleather?ref=hdr_shop_menu&search_query=revolver+holster+pattern OH OH OH>.. I dont' do many "sales", so I never think about that really... but if you bought one of these in the last couple weeks and paid full price (thus missing the "sale") just send me a message and get the sale price (refund).

-

OOOPS>.. I got that backwards. Some of these patterns should maybe get pulled out a bit more often Turns out, I did have the blackhawk.. got it from Ray 'n' friends at bunkhouse tools, -- pattern came with the dummy gun (so not mine to sell/trade/give). Fit like a glove ... And maybe I kept the ammo carrier that girl wanted to go with it? I'll look around, but not guarantee ...

-

Yep - used to be that Osborne meant good toys. Not so much any more... As for where to get that "old" quality... I wouldn't know. Hit 'n' miss about anywhere really. And can't really take a recommend from around here too seriously either. I bought a set of the J Watt edgers that everyone was going on about. I found them to be "just okay".. they came ready to cut but do not hold an edge at all. And I have weaver slot punches that I'm considering giving away, soon as I find someone I don't particularly like

-

Not sure i understand the value of using a drill press for stitching holes, since an awl is far less expensive and takes less space (and can easily be angled as needed). But for those who want to do it that way.. why not just chuck up a sewing machine needle, or an awl blade?

-

Holster for M&P Shield

JLSleather replied to jstar61's topic in Gun Holsters, Rifle Slings and Knife Sheathes

We kaint see the back side Clip? Loop? Velcro? I like the compact design -

I used to have one of the 206RB5. Letting it go was not my best decision ever Still, that really is limited to 207 thread (max), but was darn reliable. Keep in mind that for actual knowledge, I would perhaps recommending a message to Wiz or Art here on the forums - either of whom has likely forgotten more than I know about various machines -- or give 'Cowboy Bob' a call (number on teh web site)

-

I've not used one, but everybody who bought the Cowboy 3200 has good things to say about both the machine and the dealer they got it from. Search that one on this forum. If I didn't have machines here already I'd likely give that one a go. There are others, too -- perhaps someone will chime in with more knowledge of various models than me ...

-

If you're doing belts / straps up to about 1/4" (which is WAY more than enough) you should be able to find a decent machine for maybe $1500-1800 (new).

-

Glad I could help Now, you want the mag carrier for that 1911 for the cost of shipping? I got one here on the desk (for about a month now) with a cosmetic "booger"... which you can have just for paying the shipping. It aint bad, it's what happens when you drop a drop of Fiebings oil dye on a mag carrier which already has finish on it (OOOPS!). Unwilling to pitch it out, unwilling to sell it as "new", and don't carry a 1911 Pic shortly... assuming you don't "need" a mag from me, but this would actually let you see some 7/8 oz drum dyed skirting from W/C

-

For efficient cutting of belts, you'd likely want either a bend or a double shoulder. A "bend" is a single back with the shoulder portion removed. Backs generaly aren't long enough to cut TWO strips, so that would be "trim" (not necessarily "waste") I use backs, since I can cut a belt from the bend section and the matching holster from the shoulder section. Tandy got a pretty good description of this: https://www.tandyleather.com/en/leather-buying-guide.html I ordered from RJF once.