-

Posts

7,378 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by JLSleather

-

Rubber Bushing For A Holster

JLSleather replied to steelhawk's topic in Gun Holsters, Rifle Slings and Knife Sheathes

You can get them a number of places, or f you just need a couple -- from about any auto parts or hardware store (vacuum hose). -

My very first leather holster

JLSleather replied to carguy4471's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Yep -- these things are usually made to seal the bag, deliberately intending to PREVENT moisture escape. I've never used one, but I would think that could become painful... towards the back side of a guy... -

My very first leather holster

JLSleather replied to carguy4471's topic in Gun Holsters, Rifle Slings and Knife Sheathes

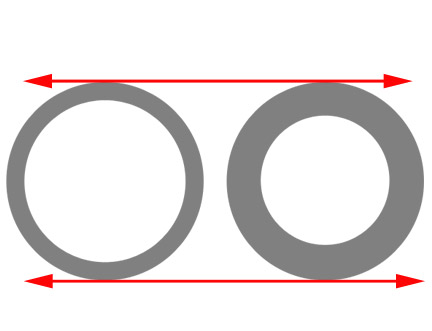

What? We didn't like that example? Alrightey then... Try this... teh measurements on the holsters are the OUTside of the leather. In a perfect world, the INside of the holster would match the OUTside of the firearm. And the patterns are drawn to accomodate the OUTside of the gun, WITH the leather thickness specified. If you use leather noticeably heavier, it's much the same as using a thicker walled pipe. You can order 3" pipe, but the wall dimension (leather thickness) will dictate what fits through it. The two circles are the same size on the outside, but the thicker the material, the tighter the inside becomes. -

My very first leather holster

JLSleather replied to carguy4471's topic in Gun Holsters, Rifle Slings and Knife Sheathes

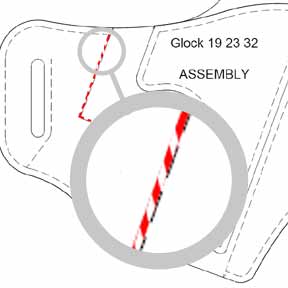

I see we're still getting comments on this. Now, you KAINT be still on that "first holster' like the title says Just a 'sidebar' about leather thickness with my patterns (and this is about MY patterns -- I have no idea how them sensitive folks do it): These are made for a fairly narrow range of thickness. But should be fairly easy to 'adjust' and 'recover' for using a different thickness if you like. One guy - I think just to 'rib' me about it -- likes to use 8/9 for about everything. Fair enough, but keep in mind that pattern is intended for 7/8 leather, or 8 MAX. So if your leather is 9 0z, not a huge ordeal -- but you might put the line on the leather as normal, and then stitch down the outside of the line, instead of down the middle of the line. That should give you enough room for a similar fit. I'm talking about this (the red is your awl) .... -

Hand stitching type? (not saddle for sure)

JLSleather replied to mayorblurps's topic in Sewing Leather

Good for you! Don't take anybody else's word for it -- TRY it and then you'll know. More people should take the "show me" attitude (we'd have less 'knowing' and more "doing" for starters ) -

Including the j-frame - 58,587 downloads. Shucks, you'd think they'd be more pics around here ..

-

Hand stitching type? (not saddle for sure)

JLSleather replied to mayorblurps's topic in Sewing Leather

This is a myth, and not even a particularly good one. I have a copy of stohlman's sewing book around here somewhere, and all due respect to Mr. Stohlman,.. TRUTH is: I have -- on more than one occasion -- made a mistake of some sort, and needed to remove the stitching put in by machine. After cutting the top AND bottom threads, I can tell you that it does not "fall out" or "unravel". Fact is, removing the thread -- though done by machine -- is a pain in the back, and requires that each stitch be "unlocked" .... not a 2-minute deal! -

Probably silly question

JLSleather replied to Mattsbagger's topic in Gun Holsters, Rifle Slings and Knife Sheathes

CAN be, but not necessarily. I've seen holsters with both belt slots AND loops (removable) so it would be used either way. -

IWB holster fitment issue

JLSleather replied to badluckleather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

-

IWB holster fitment issue

JLSleather replied to badluckleather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

You're asking that rig to "come around" in the front, but that sittch line is a stress concentration point, causing it to bend at what has become its weak point. Now... how to fix ... If'n it was me, I'd try adding a stitch line (which I think is where Ron was going with it) PLUS swapping those "clips" for one another. Meaning put the front one on the back and the back one on the front. Which it would seem would work better on an IWB anyway Lemme see kin I mock up a pic... -

I'm not getting it, either. I'm not sure how you would know, actually. I can see the benefit (NEED) for having sides from the same tannery batch, but from the same cow ... From the same run should give you consistent color (as much as is possible). Only thing that would be gained by getting both sides from ONE hide is perhaps buying the full hide (not cut into sides) which may give a little better "cutting economy".

-

Simple little holster for the small S/W revolvers available for download (Merry Christmas!). Fellas, if you paid for this one, say in the last month or so, send me a message about which one you'd like for your FREE replacement... kaint have one guy paying when the other guy gits it free .. http://www.jlsleather.com/diy/holster-patterns-diy/

-

Prefered Holster for 1911

JLSleather replied to Dorado's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Yep, me too. I ASK when a customer orders a holster, what belt they are wearing (or perhaps they need one). I can "get over it" for 1/8" over, but I don't run 1 1/2" belt through 1 3/4" slots.... anybody who has ever needed to pull the pistol QUICKLY knows what we mean by "wiggle" "move" or "rock". Right there with ya again. Seems like about 14 oz-ish works real nice like. -

Well, yah--- that's what I said. The speed and circumference of the pulley is the same at all times, so the "tension" on the belt is constant (after start-up). In teh "straightaway" ... there is tension, and in the bends, there is both tension and compression. And regardless of the direction (grain in or grain out) of the leather, the bend radius -- the part actually doing the "curve", is not the middle of the leather. BUT, the "tension" on teh belt is constant -- not increasing. Once it reaches full speed, the tension is not increased. Still, the belt will fail over time, even though the tension is not increased. But the question -- to get back to the original -- was concerning leather of the SAME thickness, either 1 layer or 2 adding up to the same thickness. Personally, I think : 1.) Big Souix makes a great point above about putting holes in leather (or anything really). 2.) This entire thing will go the way of that thing about Photoshop "brushes" for stamping tools.. lots of words, no action.

-

Your conclusion seems backwards. The compression forces are "negligible" damage to the grain (pulley) side due to the flesh side's lack of resistance to stretch. In short, the outside stretches more, so there is less compression of the inner radius fibers. Or, to say the same thing another way, the grain side is less prone to stretch (increasing the compression if you put it on the outside). We've all known about this for a good while. Making a belt? Then most know that you need to moisten the grain of the leather to make the bend. BUT, the sueded side is bent all the time with no apparent damage -- apparent the key word here. Basically, the test you quote confirms that the grain layer is "stronger" (less likely to separate willingly).

-

Hand stitching type? (not saddle for sure)

JLSleather replied to mayorblurps's topic in Sewing Leather

So, you WANT that? Okay... each his own. I wouldn't let 'em go on about how it's "theirs" or "proprietary".. I can show you that same 'stitch' in leather books from the 70's ... Some of the girls used to call it a "rope stitch", because it was done for ever using latigo lace along the edge of handbags (Tandy kits were ALL like that for a while). The girl in the picture isn't anywhere near old enough to know anything about that. But, the girl in the pic may have nothing to do with that cutesy shop. 30000 sales since 2013 shows how fast a fool and his money are parted Oh, found it... these books (Vol 1 and 2) both show how to do that little thingie... https://www.leathercraftlibrary.com/p-1727-ideas-for-leather-projects-vol-1-1923.aspx -

Cell phone holster. In case ya needa pull it QUIK

-

Belt slot punches.....

JLSleather replied to carguy4471's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Yeah, you got it. -

At last, someone who understands (and admits) the harm done by pokin' holes where they don't needa be nun That second row o' stitchin' on that fancy go-ta-meetin' holster is basically a tear line.. like scoring concrete .. Hey, I make quite a bit o'the 'shiny' stuff, but I'm in with ya on the put no holes where they don't needa be.

-

Yeah, I get those. Usually, I just "pass" on them. If teh design doesn't work, then I just say that. If they want to fix it, fine. If they want ME to fix it, there's a charge for that BUT, most people decide to 'pass' at that point.. some because they hoped to get that done free, and some because they don't like the idea that if I design it, then the design is mine. I have a family of designs for holsters for the Boberg pistols (there's only 3 models). I designed those for and at the request of Robert from mecopocketholsters -- and they are his to do as he sees fit -- I dont' sell, borrow, barter, or give them out. But he was my buddy, and I dont' know that i would do that for anyone else ...

-

Welcome (sorry, forgot about this thread and jus' saw this! )

-

Chief has a point, actually. From a technical view, the grain layer is the strongest part of the leather, so 2 grain layers would be "stronger". More important, two layers together "pulling against each other" is "stronger" much in the way a braided rope is stronger than a single fiber -- the fibers aren't actually "stronger" (the tensile strength of the fiber would be the same) but the ASSEMBLY is.