-

Posts

7,378 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by JLSleather

-

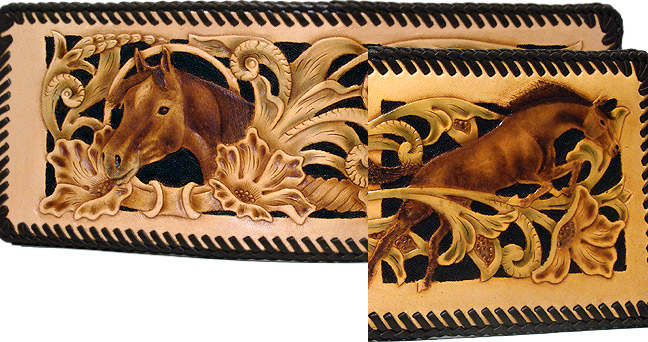

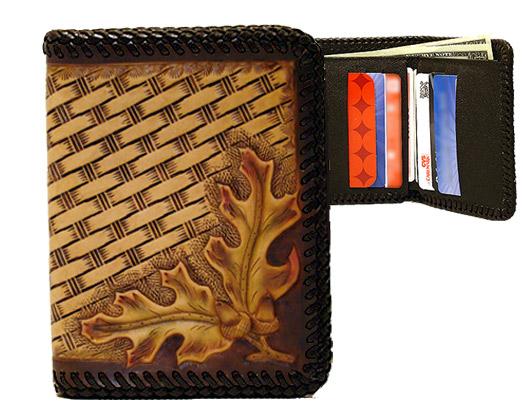

Your leather still a tad too wet -- but you CLOSE Let a bit more of the water come out, and you'll get richer definition without doing more work I'm not a fan of antique AT ALL, but I certainly dont EVER recommend it on "figures". Maybe if it's kept to the floral areas. These were done from those old Stohlman patterns, all from his "top 20" book for wallet designs, in 3/4 oz cowhide. No antique paste used on any of it - main (base) colors applied with an airbrush, and then depth added with STohlman's "dry brush" technique.

-

I like the design That DOES look snug. Part of that is likely the full-length site channel (which I generally don't do) though teh Glock is clearly a newer design as well. GOOD news is, you'll know where you want the next one narrower, or wider, or looser ... etc. Your leather, at least on the back panel, looks like it may be a bit dry (lacking oils)? Still, you pulled off the look - how does it carry? Pulls okay? Cant be sure from the pic if your thread is a bit smaller than I generally use, or could be just the geometry of the needle you used causing that look. I like the LOOK of 277 thread in a holster, but I'm confident that 207 is certainly enough strength. Is that elephant?

-

1st oak leaf! How ugly is it?

JLSleather replied to DieselTech's topic in Floral and Sheridan Carving

well, uhm... yah. The worst thing you did to yourself here is ALL THAT BACKGROUND. It's a bit tough to keep an even surface with that large a background. It can be done, but often looks nice without going to all of that. Consider just a light "accent" around the design, and leave the rest natural. -

I LIKE IT - "just enough" design without being over done.

-

Schmetz leather-needles.pdf this is jsut one brand, but you get the idea.

-

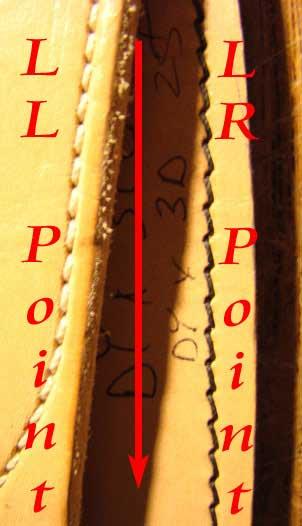

Well, yeah The point is 'twisted" the other way from the "LR" needles, and not the same as the (very popular) "D" or "S" needle. I got a pic here sumares... RED arrow shows direction of sewing, meaning the way it sits here is the way it went in the machine, top of the pic away from you. These are sewn with the SAME size thread and the SAME 6 stitches per inch. Done this way to show the difference in teh LOOK of the finished project. I LIKE the very straight, very tight results from teh LL point. The LR point tends to be less deep, and has that angled, almost 'lacey" look I've always found a bit "girly". The belt above with the official Colt buckle set was FOR a girl, so. ... there's that Note how much deeper the stitch is pulled on the LL, even though no groove was made and the tension was not changed. Somewhere around here there's a whole thing about needle geometry.. see kin I find it....

-

AND ... you can also "pre-punch" on the smaller machine - just end up with smaller holes (which likely doesn't matter). Incidentaly, on VERY heavy projects, I have been known to put a large diamond point needle in the drill press and "poke" the holes that way. Leave the spindle off, make sure your diamond point is oriented correctly, and use an overstitch wheel or similar to set even spacing. I used the pic of the little purple Sig holster for a reason. This one shows one case where I didn't want the parts sewn "just yet". The stiffener panel is sewn on as usual. Then the holster is folded into position, marked, and sanded for evenness. BUT... tehn the holster is "poked" around the outside edge for stitching, without thread. This is done because that holster is OPEN ENDED. It is fully lined (with natural cowhide) and incorporates a tensioner screw so she can set her own ease of removal (for this purse gun). Thus, it's sewn together ONLY in the little "rectangle" area to the right of the pistol and under the grip. Without the long version, lets just say this was the only way to do this and keep the stitching continuous.

-

MOST of my holsters are 277 thread, with a 24 needle (with an LL point), and 6 stitches per inch. A few pics here, just for reference. 207 thread, #23 LR point needle, 6 per inch #69 thread, #18 needle (on the consew 206), 9 per inch 277 thread, #24 LL point, 6 spi Zoomed in detail on Sig P938 holster - natural leather with natural thread, pic says the rest.

-

Are you personally carrying? No need to post here - kinda defeats the purpose of "concealed" - but send me a message with your model if I have a pattern I'll send it, first one free

-

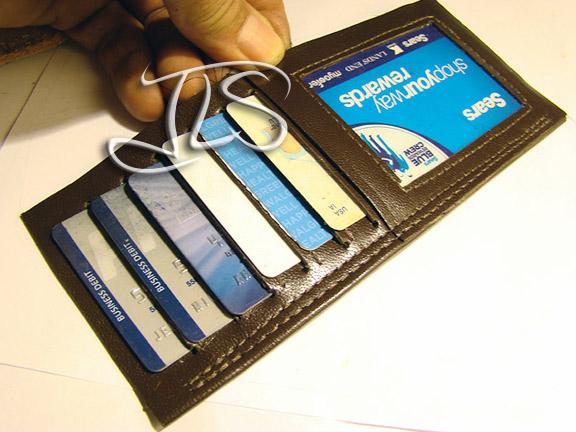

346 is great .. for pulling your truck out the ditch and snow I like 277 for holsters, and often use it on belts when they're meant to be "matching". For a belt, like a belt, I like 207 thread is more than plenty. The consew 206 is a reliable little machine, sews VERY well with thread size from 42 to 138. I got mine to do 207 now and then, but usually not. I had one of these machines, BIG mistake letting go of it. I used mine for everything from wallet liners (like 1.5 oz chrome tanned leather) to zipper gussets (4/5 oz veg cowhide with zipper tape) to the full wallets (3/4 oz veg cow with multiple layers of lining leather). All the way down to 42 thread for some liners, 69 thread for others, and 138 to sew the wallet together. AND, I ocassionally "cheated" when doing a holster project. Without going into the "why" of it all, SOME projects I wanted HOLES but not SEWN WITH THREAD just yet. So I rubber cement the piece together, turn OFF the machine, and HAND CRANK the wheel to "poke" the holes. Keeps em aligned and evenly spaced. Then went back and HAND SEW the thing together with heavier thread like a 277. No time right now to detail all of that, but sometimes I want it held together but not YET sewn. For great info on ALL of this... the consew (or equivalent) AND the '441' machine, contact Bob. He'll steer ya right https://www.tolindsewmach.com/ 866-362-7397

-

thanks the drawing was done from a 3.8" bbl (yers prolly 4.5"?) and withut the add-ons.

-

cool - let us know here how close this is, so other folk know it's good to use

-

Somebody got a xdm .40 print this and lemme know 'f its close.. XDM40sketch.pdf

-

anybody making pocket holsters these days? Would like to get some patterns uploaded to Cutesy, but need to lnk a bit of hardware for some. I mean like these....

-

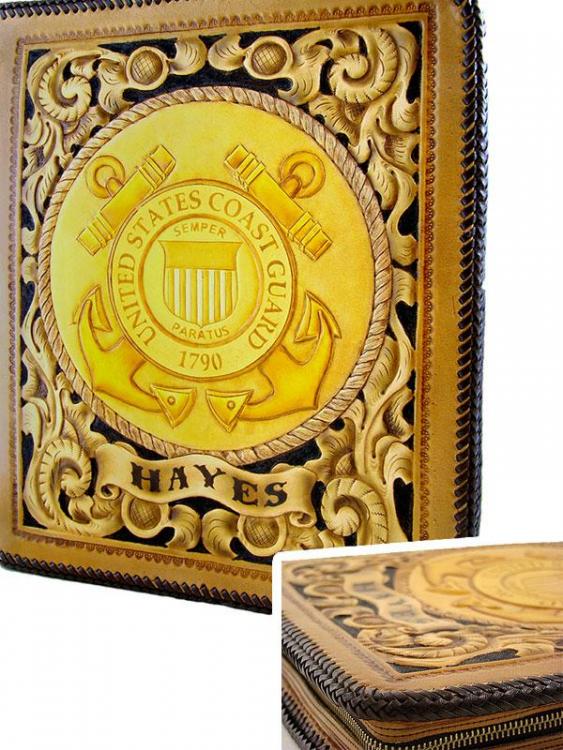

Lacing is one of those "sitting on a comfy chair with the feet up" applications, when time allows me to do it that way. It's about the ONLY time I ever have a tv on These were triple-loop laced, which is even more time consuming than the double-loop generally used on wallets. LOTS of lace, too. Dont even remember the linear feet of lace, but its a good bit. Figger the distance to be laced would be like around 80" depending on teh details of the design (compared to a wallet, which is about 25").

-

Leather Finishing Cream Suggestions

JLSleather replied to p51p28's topic in Leatherwork Conversation

I LOVE this stuff -- Great on everything from book covers to holsters. Sheen, protection, without turning your leather "mooshy". -

I use a pancake style compressor from BOSTITCH.. came with pneumatic nail guns from MENARDS of all places. Set regulator between 20 and 40 depending on the look you're after, and GO! Comes with a regulator, but I did add an in line moisture trap, and I drain the tank every so often Never any problems

-

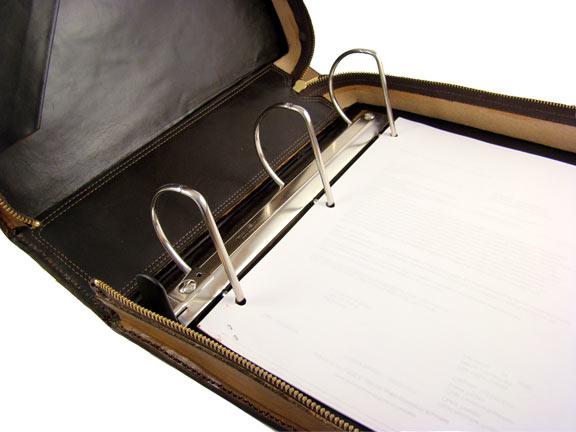

You can get zipper tape lotsa places. I have bot it at S-T Leather (out of st louis), tandy, hobby lobby, ... you get the idea. Most places will carry it in black and brown material. You'll need zipper pulls and stops as well - the pulls you might find individually, the stops are likely a pack of 5 or 10. I like the #5 brass ... is there another kind Two binders shown were for 3" ring binders - making them about 3.5" thick. The other was more of a "portfolio" type thing, requested by a gal for her father who was retired from teh Coast Guard. Just pockets for papers and a spot for business cards - his in the pocket and others he receives behind the pocket. Obviously, this type is more suited to a Bible cover. MY Bible, which is as yet uncovered (think cobler's kid no shoes) is like 9 1/4" x 6 3/" x 1 5/8" if I squish it together... maybe close to 1 1/2" thick. I keep saying "one day" I'll get round to making a cover I like OH YEAH -- the lining "innards" of both of these were done with kidskin from S-T Leather. Used to be product #L3777, not sure if it still is. You can get this in nearly the same look at a couple other places, but you'll pay considerably more. Same stuff I use to make wallet 'innards", as it's thin but still strong and looks very nice.

-

for a cheap, oily "notebook" which appears designed to sell "templates", that method might work. FOr a Bible, which is likely 1 1/4" or MORE thickness, you're going to want a leather ZIPPER GUSSET. Somebody probably does make zipper tape wide enough, but I wouldnt' expect any longevity out of it. AND, though it may seem obvious, always use a brass zipper - not that nylon stuff. These done as Stohlman shows in that book. Looks like a lot of words and drawings, but once ya lay it out in front of ya it aint that difficult Sew or lace as desired (triple loop lace used on the bottom two).

-

-

may not be the brush. do you have a moisture trap in the line? sometimes compressors condense moisture, and that's what makes em "puke" (plus the condensed water doesn't mix with the alcohol dye)

-

If you're making a VOLUME of rounded items, may be worth getting. OR, a guy could drill various hole sizes through a board, cut the board in half, add a hinge

-

Added pattern for single mag carrier, fits G43x, G48

-

Colt Mustang (Duncan's aluminum) Glock 19 Glock 21 Glock 30 Khar PM9 (with removable CT laser) Kimber SOLO Sig Mosquito Sig P238 (KnifeKits MultiMold gun) Sig P320 Full Sig P320 Compact Sig P365 SAS (Cook's) Sig P938 Smith Wesson 442 Revolver Smith Wesson 38 spl j frame Smith Wesson Bodyguard .380 (with CT laser) SMith Wesson M&P Shield 9 (same as .40) Smith Wesson M&P Shield .380 EZ Springfield Armory Micro 1911 .45 Springfield XDE-9 Springfield XDM-40 (3.8") Springfield XDS-.45 (3.3") Taurus Millenium G2 (Cook's) Walther PPK