-

Posts

1,212 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Gregg From Keystone Sewing

-

Here's the parts for Adler 30-1. To the best of my knowledge, every part is both available, and very expensive. Adler 30-1.pdf

-

Need Help With Adler 167-373

Gregg From Keystone Sewing replied to Dave84's topic in Leather Sewing Machines

Wow, that's a new one to add to my library, thanks. -

Source for blank feet/feed dogs?

Gregg From Keystone Sewing replied to hackish's topic in Leather Sewing Machines

I'll get on that, too. Give me a day or two and I'll report back on the setup.- 16 replies

-

- feed dogs

- walking foot

-

(and 2 more)

Tagged with:

-

Need Help With Adler 167-373

Gregg From Keystone Sewing replied to Dave84's topic in Leather Sewing Machines

All I have is the stated 12 page user manual. It's pretty weak documentation to say the least. -

Source for blank feet/feed dogs?

Gregg From Keystone Sewing replied to hackish's topic in Leather Sewing Machines

Hackish, That't called a bolt rope foot, nobody sells them, but can be made up by custom attachment guys.- 16 replies

-

- feed dogs

- walking foot

-

(and 2 more)

Tagged with:

-

Presser foot conundrum

Gregg From Keystone Sewing replied to Chayse's topic in Leather Sewing Machines

Darren, Chase, Constabulary, I've read all of your posts, good stuff. Glad to be part of the conversation. -

Source for blank feet/feed dogs?

Gregg From Keystone Sewing replied to hackish's topic in Leather Sewing Machines

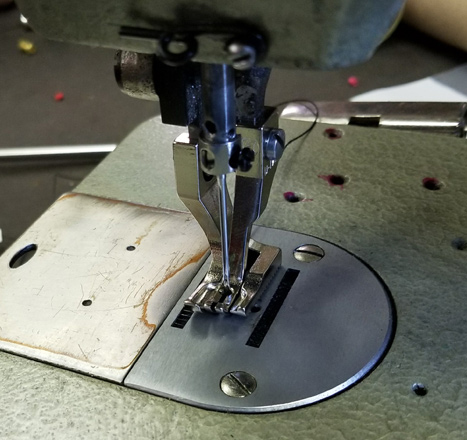

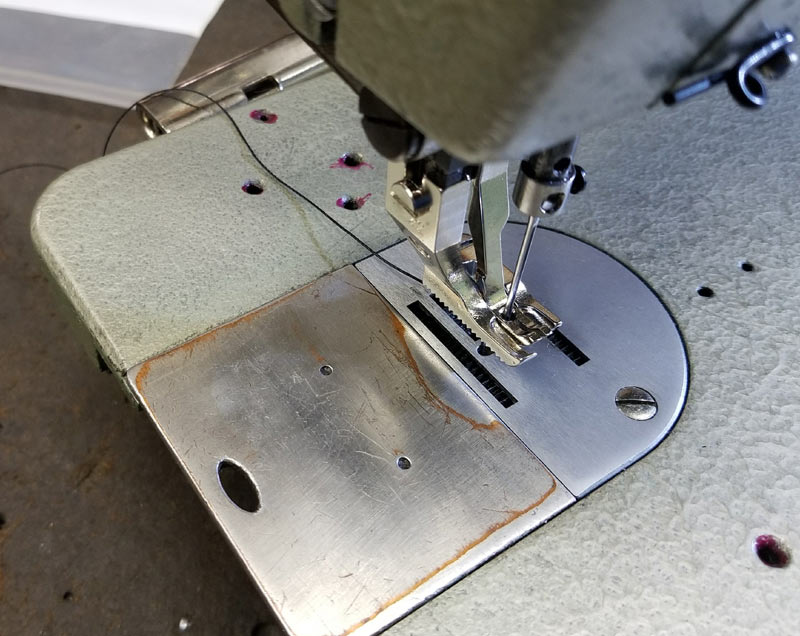

HA!! Success! This is a Consew 99, old guy, but same setup as a 146RB. Consew 205RB presser feet are installed. However, this combo with stock feed dog and plate is not that fantastic, and I have no idea if Consew 205RB needle plate and feed dog will line up correctly with this. If it does, we could really have something here. Going with a six row feed for zig zag I don't think is the way to go, as far as a straight stitch setup goes, but I didn't do that much playing around. The other thing is that a six row plate STILL has the zig zag long slot, where the 205RB has a much smaller hole. This is a big advantage when only straight stitching.- 16 replies

-

- feed dogs

- walking foot

-

(and 2 more)

Tagged with:

-

Source for blank feet/feed dogs?

Gregg From Keystone Sewing replied to hackish's topic in Leather Sewing Machines

Michael, We've emailed and spoken many times now; never once was it a waste of time. I've got 205RB presser feet, I've got a 146RB sewing mechansim,I'll check it out and report back. No idea what this will look like, never tried.- 16 replies

-

- feed dogs

- walking foot

-

(and 2 more)

Tagged with:

-

Presser foot conundrum

Gregg From Keystone Sewing replied to Chayse's topic in Leather Sewing Machines

Like my Dad would tell people, if you want to drive Mercedes and BMW, you are going to have to pay their prices for parts and their services. People don't see this until I present it like it's a car. Sewing machine analogies never seem to hit home. I can't agree more; some of the German machine's prices for parts are through the roof, to say the least. In fact that would be a nice way to put it. I read this like "I've got this awesome vintage BMW, they still make parts for it, but I don't want to pay their prices." Well, that's going to be a problem then. -

Source for blank feet/feed dogs?

Gregg From Keystone Sewing replied to hackish's topic in Leather Sewing Machines

Michael, I can help here, Consew has, by part number, 724 Feed dog, and 705 Needle Plate. By the book, these show up with standard factory machine setup. These are four row only. Consew 199R and 199RB uses standard 415 Feed Dog, and 139 Needle Plate. These are four row. Consew ALSO has optional feed and plate with SIX row (this would add two more to the front of the feeder and plate, same as back), Needle Plate is 139F, Feed Dog is 415F. All that said, it does appear that the needle plates and feed combos can be installed on either 146 or 199 models. I would want to make sure the six row works well with the upper feed on the 146RB, not sure as we have not done this yet. Uwe could be correct in that the manufacturing process could be such that they are not going to be able to provide blanks as you mention, but I'll leave that for you to decide.- 16 replies

-

- feed dogs

- walking foot

-

(and 2 more)

Tagged with:

-

Presser foot conundrum

Gregg From Keystone Sewing replied to Chayse's topic in Leather Sewing Machines

New standard stock foot is available, about $130US -

Need help with an idea

Gregg From Keystone Sewing replied to Windrider30's topic in How Do I Do That?

This was my first thought as well. -

V69 will work fine, but don't know for 100% if the under bed trimmers will cut that, or how well. First things I would check are the needle size, make sure you have a needle with an eye large enough to accommodate the thread, such as a size 18. Also, check the bobbin case tension, if it is set for fine threads, it may need to be backed off a bit. Other than that, should work fine, really unless something is wrong with the machine mechanically.

-

Help with Consew Machine?

Gregg From Keystone Sewing replied to sockyII's topic in Leather Sewing Machines

Bob, If you really want to get thrown for a loop, the GC0618 model, without the -1, is a completely different machine. This machine is pretty rare, and I've only seen one customer who had one. I think it's pretty old at this point also. -

Help with Consew Machine?

Gregg From Keystone Sewing replied to sockyII's topic in Leather Sewing Machines

Bob, It does appear to me that this model Mitzi YU360CTS (Among many other model labels that appear on this machine) is not anything but a machine made in the Highlead factory, thier model being a GC0618-SC-1 that is a true walking foot, top, bottom and needle feed with alternating presser feet. -

Welcome from New Jersey as well, I live over the bridge, but work in Philly. Book binding, or just simply sewing through paper, is a very tall order not many are aware of. The density of the paper being sewn can require a really capable machine. Good machine but certainly not limited to this task, would be like a Consew 733R-5 as a point of reference. This machine is not overkill for heavy capacity work. People may be surprised how limited a common walking foot for canvas and upholstery can be when performing book binding applications. Companies like Tenn. Attachment and others make up guides for these applications as well.

-

Pfaff 138 Parts Link Pfaff 138 Owners Manual Link Pfaff 138 Adjustment and Service Most suppliers will have quality generic presser foot, feed dog and needle plate, however, this is for the 4.0mm width or bight zig zag Pfaff 138 model; If you have the 6.0mm width zig zag or bight, you are going to need the genuine, and expensive, Pfaff feeder and needle plate.

-

How close to the edge of the arm will it sew?

Gregg From Keystone Sewing replied to Matt S's topic in Leather Sewing Machines

This is a very common question I get when talking about any cylinder bed machine. Most sales brochures offer the cylinder diameter in the specifications or somewhere else, but not usually the distance from the edge of the cylinder to the needle. I've seen some crazy mods to open up this space, to accommodate a particular good that needed to be sewn. Why hack away at working frame and components to do it. Makes sense if you need to do it. -

Finished this beauty...

Gregg From Keystone Sewing replied to RonM's topic in Archery Quivers and Bow Cases

Really pops, nice design, a real piece of art work. -

Both are very high quality Japanese built machines. The main difference is that the Consew 206RB was first introduced in the 1970s, and the Juki DNU-1541 Series is new, and current. But again both are very high quality machines, and parts for both are easy to get to date.

-

Consew 226 Reverse Stitch Length Adjustment

Gregg From Keystone Sewing replied to cdthayer's topic in Leather Sewing Machines

Consew over the life of the 226 model series had three frames. This is the earliest one, and may be from the 60s. This has the old style reverse, is what they call it, and that was a long time ago. I have books at my work computer. I'll post tomorrow.- 7 replies

-

- consew

- stitch length

-

(and 1 more)

Tagged with: