-

Posts

1,212 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Gregg From Keystone Sewing

-

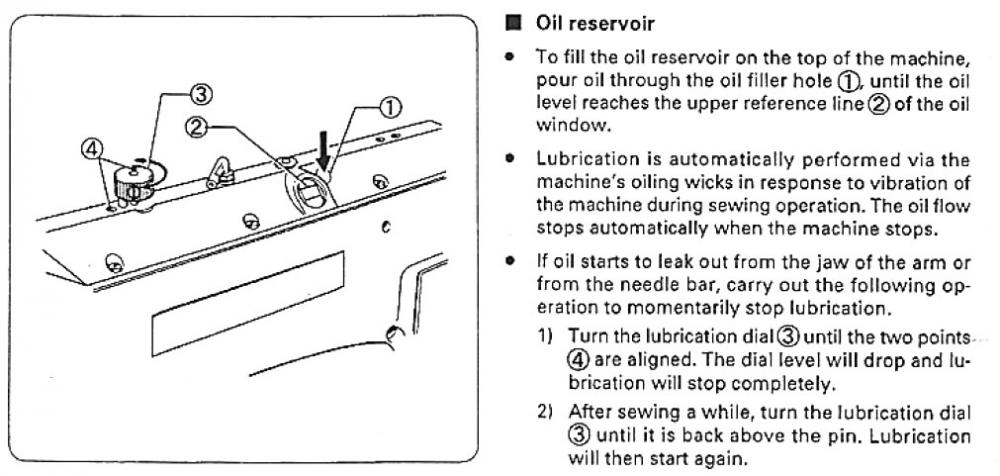

See attached, this is from the Seiko book for the same oil mechanism. If it works, and I can tell you has never been a service issue then it works. It may be a keeping up with the Jones or marketing type of stuff, but if I can oil one hole instead of nine, then I'll take it!

-

New to industrial sewing machines Juki LU-562

Gregg From Keystone Sewing replied to jshep's topic in Leather Sewing Machines

Nice -

Very interesting, I didn't know that Singer was first with that type of spring/weight upper arm oil reservoir on some 211/212 subclass machies. I thought it first appeared on Seiko machines such as 255RB, 333RB, or 339RB type machines. This most commonly called 'centralized lubrication', meaning that it's not automatic, but that it will help spread oil as the machine operates by lubricating one point that will carry oil through usually oil wicks.

-

Oh dear, another machine.....

Gregg From Keystone Sewing replied to dikman's topic in Leather Sewing Machines

Sold in the USA by Consew, this was sold as a model 206RB-3, the -4s were white. This model -3 was one of the very best Consew 206RB models in the series. Foot lift at the knee lifter is 9/16", same for all 206RB-3, 4 and 5s. All Consew 206RB subclasses and Seiko STH-8BL subclasses use the same hook, bobbin, and bobbin case. -

Good Morning from artic Michigan

Gregg From Keystone Sewing replied to momster's topic in Leather Sewing Machines

Wiz, Check the parts books, this machine in question here is not a top bottom feed machine; it's a true compound walking foot, four motion, with top, bottom, and needle feed with alternating presser feet. Uses common Singer 111W walking foot type presser feet. -

Need Some Help With This....

Gregg From Keystone Sewing replied to RoamingGnome's topic in Leather Sewing Machines

It's a Consew model 28, Seiko Copy of the Singer 78-3. I've got a few on the shelf here. Consew model 28 Owners Manual: CLICK HERE Consew model 28 Parts Book: CLICK HERE -

dang....another JUKI LU 562 issue

Gregg From Keystone Sewing replied to mixmkr's topic in Leather Sewing Machines

Nice, I enjoy seeing people helping out people around here, that's what it's all about. -

Pfaff 1245 706/47 Manual

Gregg From Keystone Sewing replied to Adriancg's topic in Leather Sewing Machines

Didn't think I could make somebodies day with this one, but I scanned and uploaded, click the link below; Pfaff 1245 Old Case Owners -

Consew 277RFS Compatibility/ Parts

Gregg From Keystone Sewing replied to WoodsideCo's topic in Leather Sewing Machines

Not so technically, if you really want OEM parts, they should be from Seiko, Japan, who clearly manufactured this machine and is and was sold under Seiko model number LSC-8BV-1. It's still a new, current Seiko model. Parts from Consew will work great as well, and some of the names of people already mentioned on this thread are aware of this as well and are more than capable of helping. -

Efka Variostop 3-Phase motor spins backwards

Gregg From Keystone Sewing replied to Uwe's topic in Leather Sewing Machines

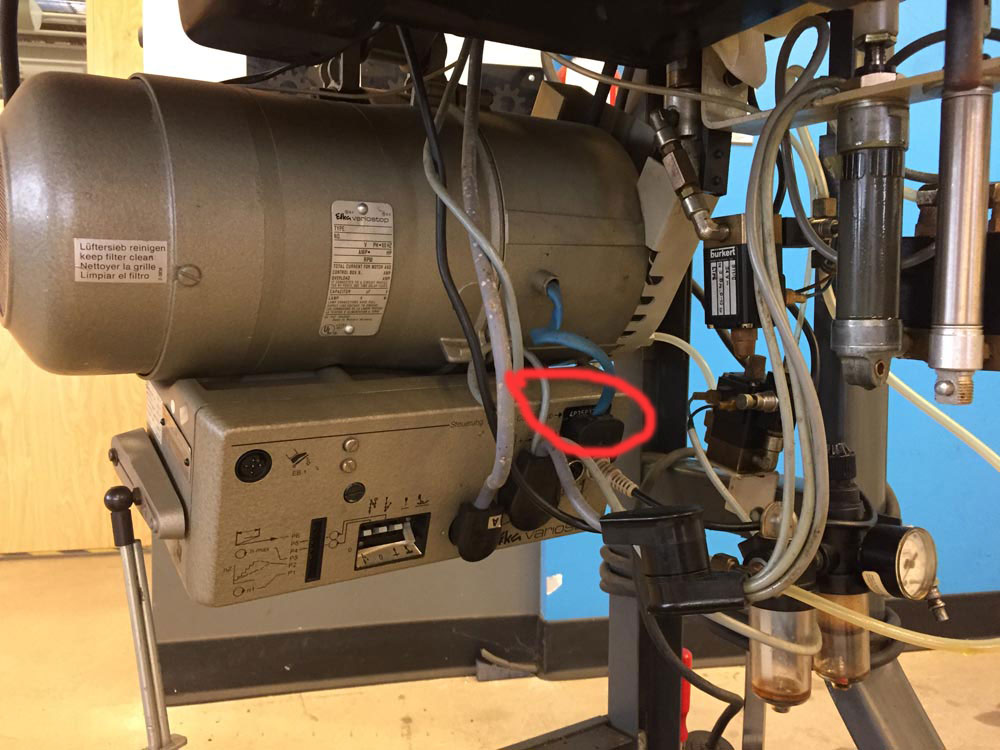

What's the model number of the control box, this may help us locate an owners manual for you. See attached image. -

No idea if they are the same folks doing the work, Mitsubishi has some good people too. I usually inform our customers who is doing what where, but not 100% in every case, especially if we are using them as a cog in the repair spectrum; the fact is some really don't care at all, and just want us to fix it for them through us.

-

Efka Contact in Germany

Gregg From Keystone Sewing replied to Yanni's topic in Leather Sewing Machines

It's none of my business, but Efka America has great service and support, for sure. What was the motor issue, if you don't mind me asking? -

Step up from Singer 107w1

Gregg From Keystone Sewing replied to mixmkr's topic in Leather Sewing Machines

People have to see this machine to believe it; Machine head is 300LBS, throw of needle is 1" to each side of center. Check out the parts charts, the hook saddle, that's huge, shifts side to side as the machine operates. It's really interesting. -

Step up from Singer 107w1

Gregg From Keystone Sewing replied to mixmkr's topic in Leather Sewing Machines

It's funny, after reading I was looking up information about a Singer 122-1, an absolute beast zig zag from Singer mfg. and flat out forgot that I posted about it on a thread here on Leatherworker.net -

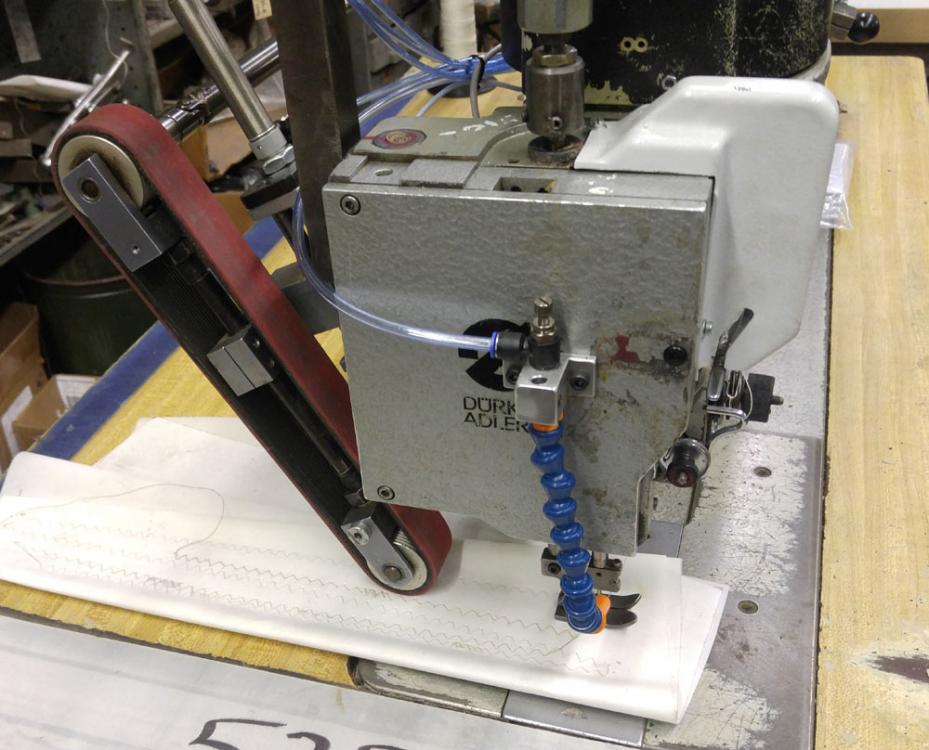

Reconditioned Jentschmann Adler 98-2-8 made in Germany, stretched to 30" of workspace, light to medium heavy single throw (Two step, one stitch) and triple throw (four step, three stitch) by means of a switch, New Efka DC1550AB321 220V single phase motor with V820 Control Panel, upper limit of speed control dial, Jentsmann GTR-1 belt drive puller. Puller, presser foot lift & backtack are actuated by solenoid controlled pneumatic valves, includes air gauges, filter, regulators, oiler, push to connect tube fittings. Price is $5,850 USD, store pick and machine demo is available, buyer pays for shipping, within US machine ships via commercial van line from our shop in Philadelphia, PA USA, usually about $300 range for shipping a machine like this.

-

- sail repair

- adler

-

(and 6 more)

Tagged with:

-

Step up from Singer 107w1

Gregg From Keystone Sewing replied to mixmkr's topic in Leather Sewing Machines

Mixmkr, Check out a machine I have, not inexpensive, but certainly an upgrade over the 107W1, but the same sewing capacity, check out the correct location for this machine, I'll post it on this MB under the for Sale, Machinery -- Sewing and Stitching, New and Refurbished to Like New -

Juki LU-563 floating stitch lever

Gregg From Keystone Sewing replied to keithski122's topic in Leather Sewing Machines

This is what I would look for 1st, feeder is bumping something. -

206RB Reverse stitch length

Gregg From Keystone Sewing replied to Dave4's topic in Leather Sewing Machines

I've been able to read a bit of this, and only now clearly understand the issue. Usually, I don't move on anything until someone brings the issue to my attention. I don't recall many of the 206RBs, 3s and 4s, that have this issue, but I can see where this would be a problem as in this case. Great fix, this is not easy at all to do, or to get correct without cutting, welding, and grinding many times until we get it correct. -

206RB Reverse stitch length

Gregg From Keystone Sewing replied to Dave4's topic in Leather Sewing Machines

That was my 1st impression as well! I have to come back and study this when I have more time, seems interesting to say the least. -

Aerostitch Problems again

Gregg From Keystone Sewing replied to BillinOK's topic in Leather Sewing Machines

What the heck is that?