-

Posts

1,212 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Gregg From Keystone Sewing

-

Wanted : Singer 111W drop feed

Gregg From Keystone Sewing replied to chouinardragon's topic in Leather Sewing Machines

Singer 111W100. I'll take your answer off the air...(I'll send you a PM). I didn't want to hold back on releasing a glamour shot of this gem. -

Need help Identifying this Consew machine

Gregg From Keystone Sewing replied to tecbuddy1's topic in Leather Sewing Machines

I got you covered, it's a Consew 166R class, see attached. Consew166R-166RB-Brochure.pdf Consew 166 Parts Book -

Wanted : Singer 111W drop feed

Gregg From Keystone Sewing replied to chouinardragon's topic in Leather Sewing Machines

I may have something, let me poke around. Price sounds about right. -

Help with Singer 236 Needles

Gregg From Keystone Sewing replied to pgb123's topic in Leather Sewing Machines

-

Why not just contact Yamata in the US? Yamata Home page USA

-

7-34 Motor recommendation ?

Gregg From Keystone Sewing replied to idahoderrick's topic in Leather Sewing Machines

Singer 7-31, -33 and -34 do not have a foot pedal operated foot lift, only the hand lever. We have put some cylinders for presser foot lift, but it's not pretty but has worked. Electronic solenoids work well, up to a point. See link for video of 24V solenoid with SP-1100 motor These solenoids can be of course used with the Efka motor's 24V output for foot lifting. As for speed control, I make up these speed control dials mounted external from the control box. I can set the machine from say 50rpm up to maximum 800 and everything in between to limit the upper limit of maximum speed of the motor. Speed control example video -

CONSEW STW 8M manual?

Gregg From Keystone Sewing replied to MacRae's topic in Leather Sewing Machines

Consew 226R is same as Seiko STW-8B. These have reverse. STW-8 is same as Consew 225. These are direct copies of the Singer 111W155, part for part, screw for screw. No reverse. Consew Owners Book, 224R, 225R, 226R.pdf Here's another one, very good information. USNavySinger111WConsew225REPAIR.pdf -

7-34 Motor recommendation ?

Gregg From Keystone Sewing replied to idahoderrick's topic in Leather Sewing Machines

Seiko SLH-2B-FH-1 Demo with Efka DC1550AB321 with speed gate Here is a setup I've done many times over at this point and offer. It's a Seiko SLH-2B-FH-1 with an Efka DC1550AB321. Motor provides needle positioning up and down. I have a speed gate switch that will limit the upper speed limit to say 200RPM down from 800rpm so the machine will not get away. This is the switch you see me using. I also use a potentiometer for this as well giving it even more control, but not on this setup. The Reverse is by foot pedal or hand lever, and works well. What does not work well is the presser foot lifter pedal from a mechanical standpoint; you have to stand on the foot pedal and put lots of pressure. This is where the air cylinder lift shines. Heel back on the foot treadle at the end of the sewing run, and the needle and presser feet lift up so that you can easily remove the work from the machine, as well as stop with the needle in the work in the seam, lift the foot and turn the work with a half heel back. Also, this has a needle cooler setup not demonstrated here that will run when machine is in operation and then shutoff automatically. -

7-34 Motor recommendation ?

Gregg From Keystone Sewing replied to idahoderrick's topic in Leather Sewing Machines

7 class machines need a lot of low end torque to get the handwheel moving. The handwheel on a 7 class is 22lbs. or greater and required a lot of low end torque just to get the thing moving, and then we have to penetrate the material, that can be very or extra heavy compared to some leather or canvas jobs. As far as speed, the large diameter handwheel slows the machine down a lot. And you can get a Consew clutch motor from us directly or drop shipped, with any pulley size available that you want. Most servo motors in the "$200" or range are not up to this task at all, and even if working are not reliable under this load for production. I could be wrong. We pretty much to do same thing with skivers that we sell, clutch motor for them as well. -

Help with Consew 206RB-3

Gregg From Keystone Sewing replied to HeidiJSetzer's topic in Leather Sewing Machines

This came up just a few weeks ago on another thread here; CLICK HERE- 4 replies

-

- leather sewing machines

- getting started

- (and 5 more)

-

7-34 Motor recommendation ?

Gregg From Keystone Sewing replied to idahoderrick's topic in Leather Sewing Machines

I would use a 3/4HP motor, good common example is a Consew NS-614 (P24) CLICK HERE for their product page. The 6000SM is a motor we work with, and NOT a good fit for this machine, at all in this case for this machine. -

Paint match Consew Grey?

Gregg From Keystone Sewing replied to tofu's topic in Leather Sewing Machines

Home Dept. has a hammer grey, a lot of the generic suppliers have gotten out of the paint business. -

Sewing Machines at Auction in L.A.

Gregg From Keystone Sewing replied to kgg's topic in Leather Sewing Machines

Nakajima 280L, then became Juki DNU-241, H, or HS. Discontinued and superseded now with DNU-1541,or with S for safety clutch model. They share many of the same parts and part numbers. All are made in Japan. -

Durkopp Adler 205-370 Handcrank

Gregg From Keystone Sewing replied to cdthayer's topic in Leather Sewing Machines

Great looking machine for sure. Any work that you put into it will be well worth it. Very desirable machine. -

SEIKO - What kind of sewing machine is this?

Gregg From Keystone Sewing replied to Seom's topic in Leather Sewing Machines

I can't find anything on this machine. I'm not sure Consew even brought this in.- 29 replies

-

- seiko

- sewingmachine

-

(and 2 more)

Tagged with:

-

how to change the length of the stitches

Gregg From Keystone Sewing replied to Chamod's topic in Leather Sewing Machines

One step forward one step back. I never knew that about the stitch length until you mentioned it. The stitch length regulator/incorporated safety clutch still remains a mystery to many people and is very easy to 'knock the machine out of time' when simply adjusting stitch length. It was not a great idea and didn't for sure improve on the 111W that also had both. Also the reverse mechanism has very heavy spring presser and you have to stand on it to push it down. That would get old fast. Singer also put a silicone lube for thread system incorporated into many of the 211 models and I've yet to see one ever working or really that is not broken. I do like the push button for the presser feet climb using a worm gear for adjustment, a lot like the modern large plastic dials found on many new walking feet machines. -

SEIKO - What kind of sewing machine is this?

Gregg From Keystone Sewing replied to Seom's topic in Leather Sewing Machines

I'll have to look through some old Consew and Seiko catalogs when I get back to the shop. Info does not seem to be on the web nor is it a new current model Seiko.- 29 replies

-

- seiko

- sewingmachine

-

(and 2 more)

Tagged with:

-

how to change the length of the stitches

Gregg From Keystone Sewing replied to Chamod's topic in Leather Sewing Machines

Machine is a Seiko, sold for a short time from Singer. You can see from the image that this machine Seiko embossed on the bed. If you look at the blue square, that's the stitch length regulator. There must be a push button that yo would press and hold down and then turn the handwheel forward or backward to adjust stitch length. Press and hold the button down until it falls into a slot lower and turn by hand, not under motor power. Singer Seiko 138B8BM Parts Book -

Just as another point of reference, based off of the speed chart, you can see that a 1725RPM motor with the correct handwheel and motor pulley combination can get up to and beyond maximum speed of a regular walking foot. With the servo motors coming on strong this chart is becoming old news. Speed Chart for Pulley Selections.pdf

-

Paid orders, buyer disappears - Etsy

Gregg From Keystone Sewing replied to alpha2's topic in Marketing and Advertising

Roger that sir. Our industry standard has been 50% down up front on custom equipment. When we get stuck with a custom sewing machine, often it's a machine that is valuable to 1 person, company or group. Nobody will ever pay for the labor, materials that go into a custom machine that absolutely positively no one other than the original buyer can ever make use of. -

Pfaff 1245 second hand

Gregg From Keystone Sewing replied to Gymnast's topic in Leather Sewing Machines

This is very difficult to answer. I think that if the machine is setup to work only with pneumatic cylinders or electronic solenoids or both, and or this machine likely has a motor that is 20 or more years older should be a concern. Even if the motor does work, can you get service for it? QuickRotan motors were used on a lot of those Pfaff models and can be a big issue to service or even find owners manuals with parameters, and I've tried. That's even before assuming that this machine is mechanically sound, or is it missing parts? Is the motor 3 Phase 220V, 1 Phase 220V or maybe even 110V single phase? A lot can go wrong here even if the seller is convinced that the machine is good to go, second hand sellers rarely can offer a lot of technical knowledge about equipment like this. Hope this helps! -

PFAFF 145 needle adjustment in feed dog

Gregg From Keystone Sewing replied to DanishMan's topic in Leather Sewing Machines

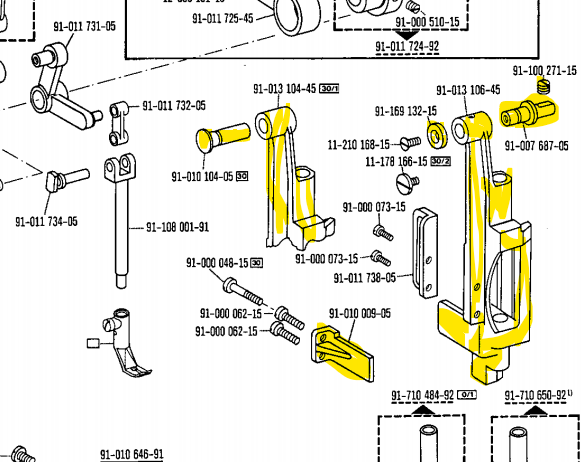

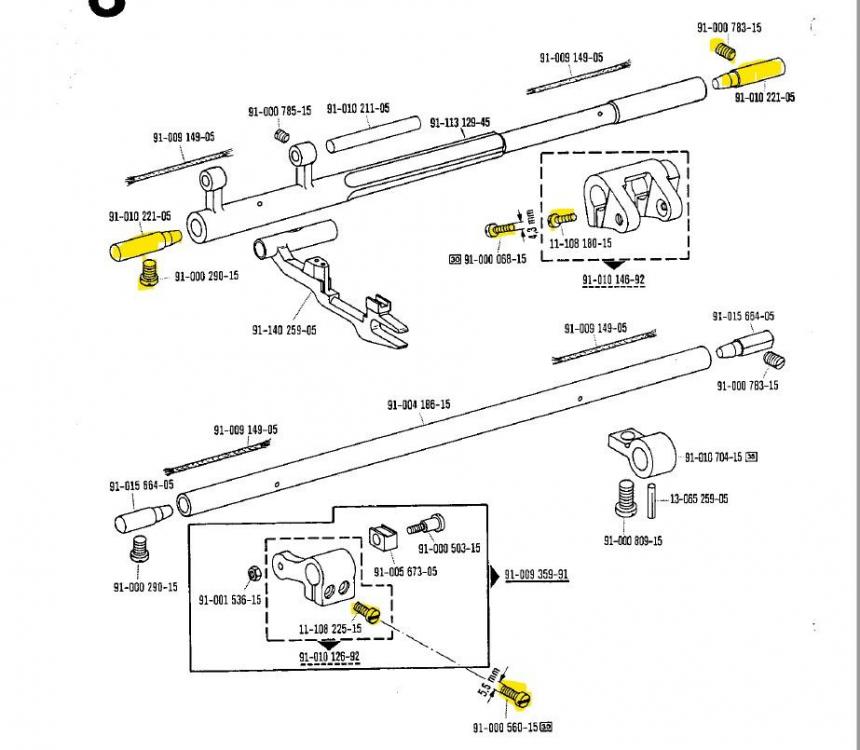

Yes sir, I guess he may have the wrong needle as well, or like you said of course. Say a 16X357 or even a household? Correct is 134-35 or a 190 from what I know. Also, maybe the washer 91-169132-15 is on the wrong size, pushing the needle bar rock frame 91-013106-45 or 91-013104-45? After that, darn maybe the arm and bed are misaligned, rare but I've seen it. Other than that I have no idea. Like said maybe a bent needle bar. Only way to know is to take it out and roll the needle bar on a flat surface. -

3,450RPM is considered high speed sewing motor, 1,725RPM is considered low speed. If you put a 2" pulley on a 3,450 motor for a walking foot...it will still be too fast. It will have very poor low end speed control. It's not about 'power'. A 1/3, 1/2 or 3/4 horse power motor are going to have the same level of control. When we used to put only clutch motors on walking feet machines, when we made a mistake by putting the wrong speed motor it was very apparent.

-

Paid orders, buyer disappears - Etsy

Gregg From Keystone Sewing replied to alpha2's topic in Marketing and Advertising

If you are at it long enough, these things will happen. I've had people come to pick up repairs that were parked at our shop for years. The walk in like nothing happened after we had long given up on them. And expect us to have their machine ready. Another woman came in and said that she put a deposit down on a machine over a year ago and wanted us to give her money back. Her explanation was that she was just coming out jail and needed to get her life back straight and that she wanted the machine but really wanted the money back as she could really use it. I feel she almost walked right out jail to our shop because she knew we had her money like we were a bank. Yes, we gave her money back in full for sure. Another one, and I mean with with respect, but it's just a fact that this guy on the other end of the phone sounded like he had one foot in the grave. He sent a deposit, and within a week or two we did everything we could to contact him. We had his phone and fax number (this was a while back) and the were eventually disconnected. We never did hear back from that guy.