-

Posts

361 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Matt T

-

Add another one to the list: http://www.ebay.com/itm/20mm-Handmade-Horween-Leather-Watch-Strap-Chromexcel-/121215051146?pt=US_Watch_Bands&hash=item1c38fae58a

-

looks like it could be for embossing a belt. Or maybe an ammunition belt.

-

You know, just because someone is selling something, doesn't mean people are buying. I doubt that many of these will sell.

-

Anyone here use 3d design software to aid in construction of complicated projects? I have used solidworks in the past, but I don't know if there would be something more appropriate for this type of work. Something where I can design, and then generate printable patterns?

-

Need Black Ostrich

Matt T replied to camano ridge's topic in Gun Holsters, Rifle Slings and Knife Sheathes

You can get some smaller hides on ebay for around 200 bucks. The guy that sells them is in Israel. http://www.ebay.com/itm/Genuine-Ostrich-Skin-Leather-Grade-4-Hide-Black-9-70-FT-/350921989150?pt=LH_DefaultDomain_0&hash=item51b4949c1e -

The edge paint looks very similar to angelus by itself, just that you can smooth it out with the iron since the wax melts. I have problems with it melting too much if I have too many layers.. not sure if that is how it is with the french paint too. As for the iron in a fire, it just seems like more hassle to me, but I haven't tried that. I would go the electric route unless you don't have access to electricity at a craft show or something.

-

There have been discussions in other threads about electric tools to heat and form the edge of a chrome tanned piece that's been covered in edge paint. Well, those machines seemed too expensive for what you get, in my opinion. I came up with a way to do this on the cheap, and want to share. The tips I used can be found here: http://www.ebay.com/itm/261192091318?var=560190215322&ssPageName=STRK:MEWNX:IT&_trksid=p3984.m1439.l2649 What I did was used a die and tap set to thread the rods on these tips, and attached them to a soldering iron. The soldering iron should be between 15-25 watts. My soldering iron can switch between 15 and 30; 30 practically burns the paint away, and 15 is just enough to do the job. I will probably try a 20 watt iron in the future to see if it is a better temp. Edge paint: I didn't feel comfortable paying the 100 dollar shipping fee to get the Beraud paint from France, so I had to get creative here as well. I noticed there was an expiration date of only 6 mos to a year on their paint, so I figure there must be some organic compounds, or an emulsion that coagulates after some time. I figure it is a carnauba wax emulsion, and possibly some casein What I am doing is creating a carnauba wax emulsion with 50% wax / 50% water, and then mixing it with angelus paint at a ratio of around 9 paint / 1 emulsion. Seems to be working well so far, and the wax enables the paint to melt and form better. If any of you experiment with the paint, please share your results and any other helpful hints you find along the way!

-

Any Idea Whats Wrong With My Skiving Machine? See Video Link.

Matt T replied to Dresden's topic in How Do I Do That?

This was happening to me, even with the edge guide. The reason is because the blade is not sharp enough. You need to sharpen it with the grinder and burr tool (and continue to do this on a regular basis). But Ferg is right, you should put the edge guide on also. -

Small Wallet

Matt T replied to hunio's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Wow, really looking nice! Where did you find such thin leather? And do use a heating tool to finish the edges, as discussed in other threads here? -

Thanks Ferg!

-

Yeah, the grinder is built into the machine for this purpose. I am not sure how I would go about honing it, or that it is necessary for this type of machine.

-

How To Create A Wallet Template For Consistent Pieces

Matt T replied to leatherorpleather's topic in How Do I Do That?

I trace around with a pen and then cut with scissors. For straight pieces I use a metal ruler and a rotary cutter. -

What is the price per square foot or square meter? That could also be an indicator, if it is very low. Oh, and I wouldn't touch this stuff with a ten foot pole; just my two cents..

-

I just got my skiving machine, a consew dcs-s4, and I notice that if it's not sharpened frequently, the blade will pull the leather and mutilate my piece. My questions for those experienced with this type of machine: 1) How often do you find yourself sharpening? 2) How long do you grind the blade for? 3) How hard do you press the grinder into the blade? Sparks fly all over the place when I do it - is this too hard? I also use the sharpening rod on the inside of the wheel when I sharpen, in order to reduce burrs.

-

tell him you need a bolt of the material, and see if he agrees... lol

-

-

Yes, something like this: http://www.ebay.com/itm/KINGSLEY-HOWARD-HOT-STAMP-STAMPING-MACHINE-FOIL-3-x-100-3-ROLLS-YOUR-CHOICE/290740201796?rt=nc&_trksid=p2047675.m1851&_trkparms=aid%3D222002%26algo%3DSIC.FIT%26ao%3D1%26asc%3D18060%26meid%3D2383699171258327404%26pid%3D100005%26prg%3D8304%26rk%3D3%26rkt%3D5%26sd%3D221306518061%26

-

It's a Hot Foil Stamping machine, and the stamp will need to be custom milled by a machine shop. This might work if you aren't doing large quantities: http://www.ebay.com/itm/Custom-leather-wood-stamp-brass-stamp-compatiable-with-soldering-iron-/130845339889?pt=LH_DefaultDomain_0&var=430177519379&hash=item1e76fd70f1

-

Pacific Trimming - Low quality hardware, but good for buying Riri zippers in specific lengths.

-

I'd be willing to bed that there is a form behind that leather, that remains in the end product. The leather is probably pushed/stretched to the form and attached with glue.

-

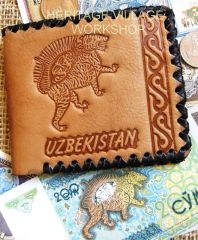

Old Uzbekistan symbol - "Sher Dor " on leather wallet

Matt T commented on scraft's gallery image in Our Leatherwork Galleries

- 1 comment

-

- handmade wallet

- leather handicraft

-

(and 2 more)

Tagged with:

-

It's not impossible.. maybe it will stretch and you will have to add another hole, not the end of the world.

-

I like the idea, but I have a feeling it will dry up and get stuck after a bit of use. I use a broken awl, and apply a little at a time. A miniature screwdriver would work as well.

-

Hi edd, where do you live? I was given a quote from beraud and the prices for the paint are reasonable, but the shipping to the US would be 100 bucks. I am using the rebranded fenice paint from Tandy, and it works well enough that I may just give up on the idea of getting the beraud paint.

-

Is this what was ordered? http://www.beraud-sas.fr/index.php?page=shop.product_details&flypage=flypage-ask.tpl&product_id=162&category_id=110&option=com_virtuemart&Itemid=31 Thanks, Matt