-

Posts

1,771 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Bob Blea

-

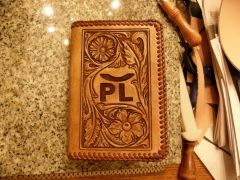

From the album: PL Ranch Notebooks

Here is one of the small 3x5 spiral notebooks with the same ranch brand and a small floral design. See more notebooks like this at my Etsy shop: https://www.etsy.com/shop/CandBLeather?ref=si_shop -

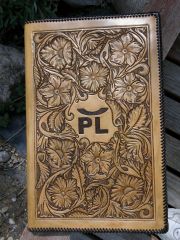

From the album: PL Ranch Notebooks

A full sized legla notebook with basket weave across the back. -

From the album: PL Ranch Notebooks

This is a closeup of the front cover of the legal sized notebook. The design follows the Northwest Style of carving, which is a little different from Sheridan Style floral carving. See more at my Etsy shop https://www.etsy.com/shop/CandBLeather?ref=si_shop-

- floral notebook

- northwest floral leather

-

(and 1 more)

Tagged with:

-

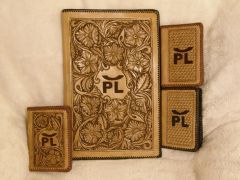

From the album: PL Ranch Notebooks

The large notebook is a 8x14 size legal sized notebook. The smaller notebooks hold 3x5 spiral notebooks. The ranch brand in the center was done to look like an actual brand. One of the small notebooks has a floral design similar to the legal sized one, and the other two are basket stamped. There are more items like this on my Etsy site: https://www.etsy.com/shop/CandBLeather?ref=si_shop -

How about hair barrettes? Or I've seen leather napkin rings. Might be able to make watch straps out of them too. Bob

-

I think it turned out pretty awesome too! Bob

-

What Are The Basic Tools For Sheridan Style Work?

Bob Blea replied to iknowshaun's topic in Leather Tools

Glad I could help Shaun. By the way, I got my bargrounders backward. I bought the #27 first and just recently got the #30 which is bigger. Also, I was assuming that you had a few basic Tandy tools already, like a camoflage and mules feet. They do perform some important jobs too. They add details to the vines and flower petals. I've been getting by with my Tandy camoflages and mules foots, but I had some older Tandy tools made back when they still had good impressions. If you don't have any of these tools, you might want to add them to your list. Like Bruce said above, all the tools on the recommended list has their use. Also, if you can get a copy, order the book 'Sheridan Style Carving' by Bill Gardner and Clinton Fay. It's a great book that shows how this style is done by masters. They show you step by step and they show you all the standard tools and how they are used. Bob -

What Are The Basic Tools For Sheridan Style Work?

Bob Blea replied to iknowshaun's topic in Leather Tools

Hi Shaun, and welcome to the forum. I do a lot of floral carving, and I highly recommend Barry King's tools. They will make Sheridan style floral carving much less frustrating for you. As far as a recommendation for starting out, the most important tools you will want are the bevelers. I started off with a number 1 and 2 checkered beveler, and have added smaller ones and smooth ones over the years, but I still primarily use those sizes. The beveler is the tool you will use the most so it's worth it to have good ones right off the bat. Traditionally everything in Sheridan style is bargrounded, and Barry does have a wide selection of sizes. I bought the #30's first, and I only bought the 3 hole and 5 hole bargrounders. I work small and tend to have small background areas so these small bargrounders work for me, you might want a little bigger size like a #27. However, it's OK to use a background tool to matt the area (like the Tandy A104) and it's a lot easier. Bargrounders can be frustratingly hard to use well. Undershot bevelers, or Lifters as Barry King lists them, are almost essential too, for that scalloped look that Sheridan style gets on the flower petals and leaves. I bought one initially (think it was his #2) but later got the next size smaller too. Pear Shaders and Thumbprints are close to the same thing, but the Thumbprint is shaped a little differently and it traditionally what is used in Sheridan style. I think I have the first four sizes of horizontally lined thumbprints from Barry, though I started off just with size #1. Many carvers would tell you that you should have a variety of sizes of thumbprints to match the size of the flower petal scallop you are using it in, but you can get almost the same effect if you learn to walk your tool a bit. Starting off with just the one size can be made to work. Thumbprints are designed so one end is a bit smaller than the other, so by tipping the tool you effectively get two different (but close) size shading tools. When you buy the next size thumbprint below a size #1, you get two sizes of thumbprint below the #1, if that makes sense. I would also recommend getting at least one of Barry's veiners. They are much thinner than the standard Tandy ones and (IMO) leave a much better impression. If you can afford it, I also recommend getting a center shader and leaf liner. Both of these tools are important to getting the look of flowers and leaves that you see in Sheridan style, particularly the center shader. It's used to bevel around a flower center stamp and gives a great look of depth to the flower center. And, if you have room in your budget, good flower center stamps make your work look better. Again, Barry has a wide selection of them. To me those would be essential carving tools, but there is one other thing I would recommend: a good swivel knife. The swivel knife is the basis of all the rest of the carving and if it's not sharp and easy to use, the rest of the carving suffers. Barry makes a good knife, but you can also get one of his swivel knife blades that will fit in a Tandy knife, so that could cut down on your costs. A Barry King blade will hold an edge better than the Tandy one, so just getting that blade would probably make your life easier just like having his bevelers would. I know this sounds like a blatant ad for Barry King, but I don't work for him, just have a lot of his tools. I think the world of them and wouldn't be able to do the carving I do without them. And, he's a great guy to do business with. This is just my opinions, and others will probably differ. Bob -

I would say not bad at all. My only critiques could be just a matter of style. First, I think you have too much background in your design, but that may be your style and the effect you want. I also think your flowers look small in comparison to your circles, but again that may be the style you are looking for. Also from a flow standpoint, the flow around the lower left corner and the center flower seems to cross over itself in a figure eight. Generally people try to avoid this sort of cross over, but again that doesn't mean you shouldn't do it if that's the effect you were looking for. Or maybe I'm just mis-interpreting what you've drawn there at that cross over. I would recommend defining your border around the floral area. On the bottom it looks like the leaves are going lower than the floral elements, like they are falling off the design. Bob

-

Photo Album For My Little Girl

Bob Blea replied to MADMAX22's topic in Books, Journals and Photo Albums

Very cool idea. I hadn't started working with leather when my oldest was born seven years ago and had just started learning when my second son came along. Might have to make then each a photo album like this. I really like the idea, and yours turned out great. Congratulations on the beautiful daughter! Hope she is letting you get some sleep! Bob -

Grab And Go Hair On Hide Clutch

Bob Blea replied to DoubleC's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Very nice Cheryl, what does it look like inside? Bob -

Very cool. I know nothing about chaps, but they look great to me. Bob

-

Antique Box Under The Gun

Bob Blea replied to arbalet12's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Your work is always inspiring! Bob -

What a great idea! I've got two of those kind of block planes. Think I need to try and get that blade really sharp. Thanks for posting this. Bob

-

I've had lots of problems where I work with Blackberry's running down because the cases they were in were too tight and it was pushing buttons. At times we had to disable the side buttons for the camera to get them to stop. I would definitely recommend a looser case. Bob

-

Boy, that is a tough one. I have problems with that too. Chuck is absolutely correct that it takes practice, as much as anything we do when carving leather. The shading from the thumb print does make it harder because that leather is compressed and much denser than the unshaded leather next to it. I don't think I would recommend much re-wetting if you don't have to. Re-wetting will take a little of the burnish out of your thumb print or shading, and a lot of extra moisture could cause you to loose some of the relief you have carved. In order to make good decorative cuts I have to warm up first. I need to practice whatever the cut is going to look like first on some scrap. The first couple usually don't look that great. Also, make sure your swivel knife is very sharp and well stropped before you start. Having a sharp swivel knife makes all the difference in the world. Hope that helps, Bob

-

Hi Jaysouth, and welcome to the forum. I'm actually wanting to make a tool roll something like what you have made. That's a very traditional way of storing stamps. Yours looks pretty functional, and that's probably what is most important. Good job! Bob

-

Wish I could go but just a little too far away... Bob

-

Any Styles Other Than Floral & Sheridan?

Bob Blea replied to SouthernCross's topic in Floral and Sheridan Carving

You are also seeing a lot of the traditional western floral toolers migrate towards the scroll work used by engravers. They have used scrolls similar to the vive work in western floral, for many years, and it does create some very different effects. Bob -

Hello Nicklas, If you have an airbrush you could use that to put your first coat of resolene down. After that is applied it should be sealed enough to hold the antique in place. Bob

-

To answer the original question, it is paint. They even say that in the item description. I would use acrylics and then seal it with resolene. Bob

-

Tooled Side Of Legal Bag

Bob Blea replied to Tim Schroeder's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Very nice work incorporating all that. Well done! -

Thank you Bob, for posting this article. It makes me want to find some type and try doing this. Bob

-

Long Time Waiting! First Seat Finally Done

Bob Blea replied to Cyberthrasher's topic in Motorcycles and Biker Gear

I think it looks great. Nice job! Bob -

Photo Bomb

Bob Blea replied to zorrow's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I've got a Shih Tzu that will do the same thing. She always thinks she should be right in the middle of whatever your doing. That is a great looking bag. Bob