-

Posts

699 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Sanch

-

-

Just a couple of recent holsters

Sanch replied to Boriqua's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I prefer not using a machine also. Anyway nice work. -

Just a couple of recent holsters

Sanch replied to Boriqua's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Nice clean-looking work! Two things number one I would like to see the backside of the iwb number two what machine are you using to sew these? Or are you hand stitching? Either way very nice! -

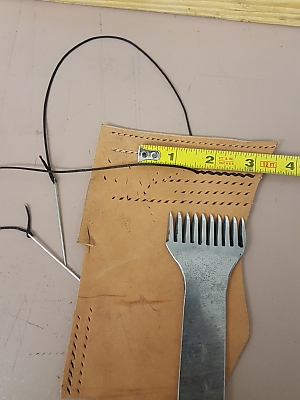

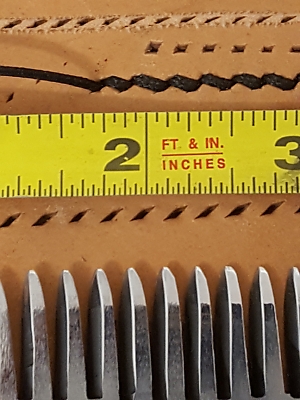

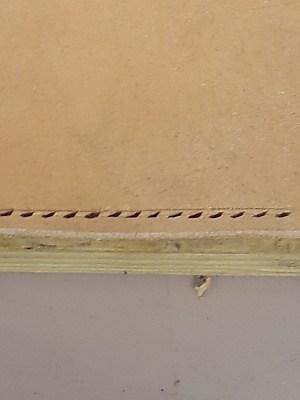

Okay so here's my final attempt I don't think I'll be spending any more time trying to make these things I would say that this last attempt is passable the holes look good I ran some stitches through it as you can see they came out pretty good but after having tried a couple of times now I think I will just save some pennies and buy some or stick to my stitching awl. So if I am counting this correctly I ended up with 6 SPI which for me is fairly good. Anyway here are the end results the two prong is not quite up to par but I enjoyed having fun making Sparks. first pic is in process of making them the bolts is there for size reference. and here are some shots of the holes that they produce and a close up and a shot of the stitching. I did not catch the thread when I ran that Stitch.

-

quick search no results.

-

yup, still thinking it's doable I spaced 2 cutting blades on my angle grinder yesterday it's just about perfect I cut out a new trial and will continue to pursue it as time permits.

-

thanks it gets the job done when I use it!

-

lol! would've likedto make it out of stainless but the Delrin scrap was readily available yours looks better than mine

-

yup got one of those too it's how I cut the lace for my avatar

-

mine was free! it doesn't see alot of use but when I does its nice!

-

lmao never discourage me brudda!!

-

ok so taking all in advisement yea the holes are too close for my liking and definitely not something i would put on anything I make. now having said that I will say this it would take longer to set up a mill to do this than it would be worth cause if I do make a "real" set meaning if I put the time into them I will only make one set, and they will be well planned and thought out. I do make knives so this was just playing around! anyway haven't decided.Thanks for the replies! OH and keep in mind 1 hour total time with an angle grinder LOL!

-

fantastic! I made a similar one but in Delrin!

-

Okay so I have spent the last 45 minutes playing around with a piece of the L6 steel that I have and here are the results. yes I realize that I totally missed the stitching Groove! as you can see this thing looks like a comb and it looks very very crude it took me longer to cut the piece of Steel out of the parent blade then it did for me to cut the teeth. as you can see the holes came out in somewhat of a diamond shape and very close together they are actually 7 SPI. Now for the nitty gritty, would I entertain making some of these vs buying them and would I, should I pursue this? I'm not too sure. So I had to experiment it was fun and it burned up a total of 1 hour of my time. The steel is so hard that I wouldn't even spend any time heat treating and tempering if I did decide to go forward with it. Anyhow thanks for looking and as always comments and questions are welcome.

-

And now I can honestly go back to work the Jaws are covered! I will also ask once again if I could get a moderator to move this thread over to the tools section please!AWESOME THANKS FOR THE MOVE!!! MODS ARE KING OR QUEEN!!

-

thank you sir!

-

thank you sir! at moderators I am requesting this be moved to the "tools" category please!

-

Proper style wallet

Sanch replied to Mattsbagger's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

very nice work! -

Waiting on the flat black paint to dry, then onto assembly. Then I will figure how I'm going to cover the jaws. and here's another angle okay so the paint dried and I got it done except for wrapping the Jaws here it is as always any comments questions are welcome. and with the Jaws angle down a little and finally with the Jaws angle down all the way for storage.

-

The blade thickness is 1/8" the handles will be twisted square stock I believe to be wrought iron. even if it's just mild steel it'll do not knife scale type but that's a fine idea. if my "blades" come out good I may just do that. I failed to mention that's no regular circular saw blade. it's a saw mill blade 20" diameter

-

still in the fab stages not ready to wrap the jaws till I get the seat frame set up. as to mounting it to a table I've already have one that does that and it served me well but I wanted the freedom of a dedicated stitching horse with 7" wide jaws.

-

Okay so here is an update of my new stitching clamp I'm just about done with the jaws, and now comes the fun part making the seating arrangement here are a couple more pics keep in mind this thing is made out of metal so it may look dainty around the jaw area but it's not here's a pic of the spring actuated clamping device and one more showing the knuckle that it's attached to which will be welded to the seating arrangement

-

really hmm. we'll see what I can do

-

looks like the idea I had was on track so far except I'm gonna do 2, 4, 10 and try for 6-8 SPI. but it's gotta wait till stitching clamp is worked on...but here is a pic of the parent steel