-

Posts

5,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Main difference btw Adler 67, 167- gk373

Constabulary replied to dudumoko's topic in Leather Sewing Machines

67 has a standard hook (smaller size) and the 167 has a larger hook but is smaller as on your former Juki 563. 267 is the newer version of the 167 - basically. 267 has a different casting. Not speaking about the sub-classes, just the basic machine. -

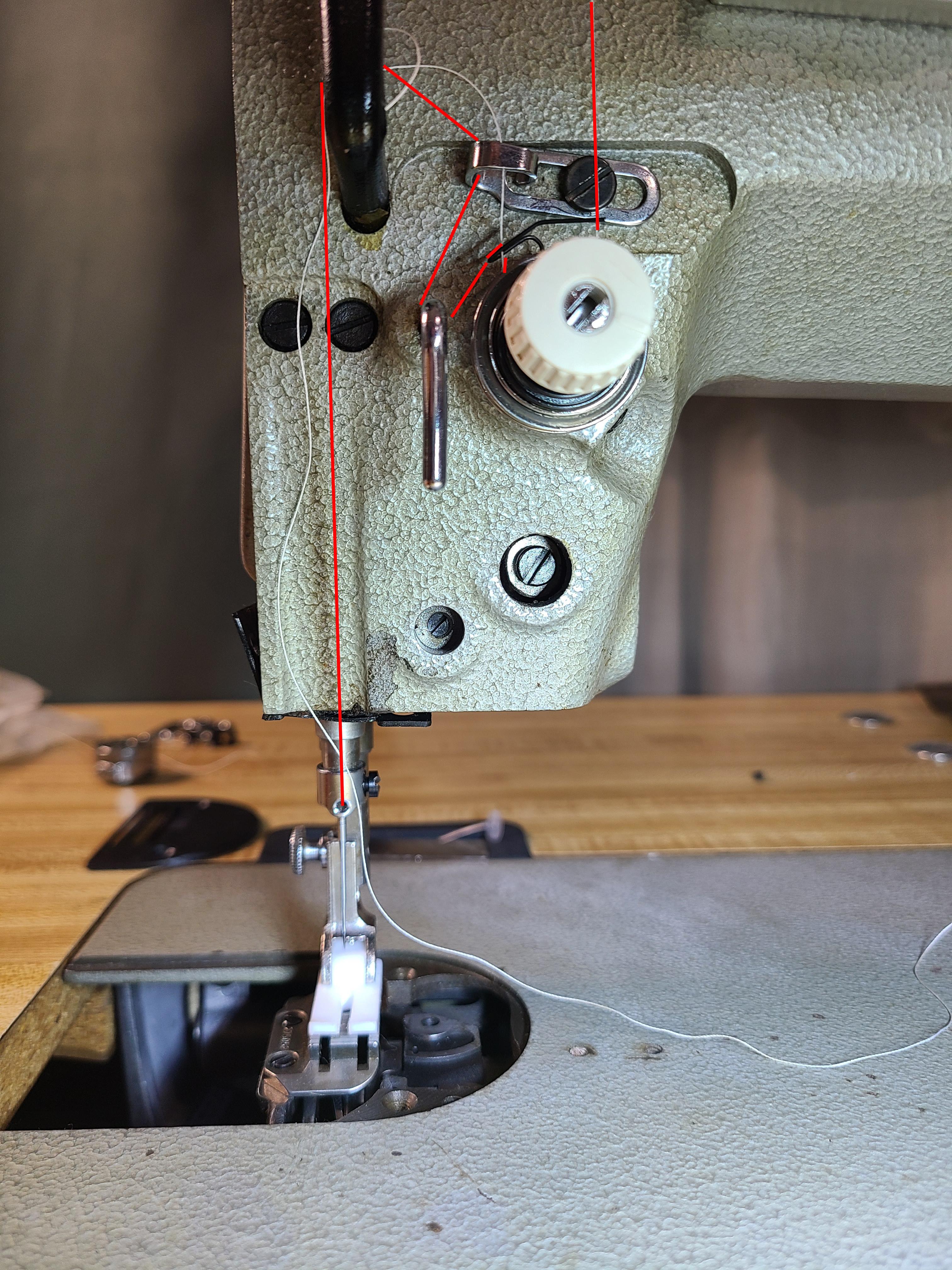

I would guess your foot is for a plain strait stitcher. What number has it? Needle feed feet usually have a longer slit. You can extend the slit on yours with a file or dremel (or similar) or buy a needle feet foot. F.i. check the College Sewing UK Website, they have a section for needle feed feet but should get the feet elsewhere too: https://www.college-sewing.co.uk/parts-by-type/needle-feed-lockstitch-feet.html BTW your top top thread path is wrong, you have left out the hook.

-

sewing some straight seems on scrap leather with a thin needle and thin thread and producing a quality leather goods with maybe a size 22 needle and 138 thread are two different things. If a certain machine is capable to sew leather depends on the product you want to produce, the type and thickness of leather you want to use and the needle and thread size you want to use and o course the overall thickness you want to sew. Thin needles with thin thread will most likely punch through all kind of leather (guess why syringes have super thin needles) then double or triple the leather and and try again. Then try making a proper product. All sewing machines have their limitations.

-

There is 332 and 332LG / 332 LONG which is longer than 332. 332 is for the 30-1, 30-15 and so forth and the 332LG / 332 Long is for 30-7, 30-70 and so forth with a higher foot lift. Alternatively you can use 135x17 and 135x16 needles on your machine (I do this on my 29K71 which is using the same needles as the 30-15). The nomenclature 332 and the longer 332 Long can be confusing especially when the needle tip is left twist (LL)

-

Let me try to explain. You have to close the needle plate. Hold the thread in your have and pull it up slightly when the needle goes down and when the needle comes up again a bit again no longer pull the thread then a loop will be formed which then is caught by the hook. If this does not work then you needle-hook timing most likely needs adjustment or you have to practice. Watch the movement of the needle you will notice the needle goes down, then it comes up a little bit (maybe 2mm or so) and in this moment the thread loop is formed and the hook can catch the top thread loop...

-

They are no longer available - even in the land of Pfaffs and Adler 😉 IIRC in the German Sewing Machine forum we had a lady who managed to install new upper and lower gear + an "of the shelf" timing belt on a 153 or 189 but that's was a hell of a process IIRC. However there is a replacement kit but its not cheap and IMO not worth the money considering for what kind of machine it is for. https://www.ebay.de/itm/176815412544 If it was me I´d look for a Pfaff 262 or similar.

-

when the motor is behind the machine you may have problems tilting back the machine for service / oiling.

-

What is this "Man-Sew" device on a Singer machine????

Constabulary replied to Constabulary's topic in Leather Sewing Machines

I have Singer pinking shears that I have used maybe twice sooooo I really do not need a device for that. But I know what you mean. 😁 I know it´s better to have than to need but... no... Fortunately it is 100km away from me. I have to reduce this sewing stuff + machines anyway. I´m about making one table for all my (4) arm machines. I´ll post pictures when I´m done. Tinkering... again. 😅 -

What is this "Man-Sew" device on a Singer machine????

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Thanks a lot. Now that I know I do not need it... I want it 😂 *kidding* -

just wondering for what purpose you need these information. 5.2cm is not the overall length of the needle, it is the length from end of the shank to the upper end of the needle eye. Just as side information the 328 is a bit special cause the shank diameter increases with the needle size.

-

Vintage Durkop Sewing Machine

Constabulary replied to colonelsaxton's topic in Leather Sewing Machines

that was probably me but I no longer have this machine. -

Are all Juki 1341 clones created (somewhat) equal?

Constabulary replied to 6ixStitcher's topic in Leather Sewing Machines

well, thats just my opinion. Others may have a different views on that. 😉 -

Are all Juki 1341 clones created (somewhat) equal?

Constabulary replied to 6ixStitcher's topic in Leather Sewing Machines

IMO there not as many sewing machine factories in China as you find sewing machine brands online so IMO most of the so called clones come from the same factory. If you want your own brand name on machines you can order that if you buy enough of the "hardware". Maybe there are a few different factories but who really knows that. And IMO the machines are fairly equal the differences probably are in how they were set up. Some clones may have features that others do not have. In earlier times this was called sub class. In your picture you see that certain machines have installed different "devices" like machine mounted bobbin winders, direct drive motors of a knob for adjusting the foot lift height and so forth so have an eye on that. But IMO it is not possible to tell quality differences by just a brand name - there are just too many brand and there is not a "pool" of experiences when it comes to buying sewing machines directly from China in relation to brands - if you know what I mean. However - buying directly form the "manufacturer" can be a gamble as you never know if they come ready to sew and set up as you would expect it from a local dealer. But we have members here who bought directly and the machines arrived properly set up. But in the end the responsibility in on your side and claiming warranty issues may be not as easy as when you buy from a local dealer. If I was in need of a brand new sewing machine I would buy directly from China. Why? Mainly because you have dozens of videos online how to adjust these machines and I do not have the big $ and output that would justify buying from a dealer so yes, its a gamble but IMO the risk is not very high. Times have changed and IMO the quality of the Chinese products have increased and the Chinese have learned customer service and the latest feedbacks here are not bad. But again it´s a gamble. However. I´m a big friend of used / vintage equipment and I do not see that I`m in need buying something new. So it depends on your situation (time / money) and if you are willing / able to tinker a bit here and there. For my purposes I can deal with used / vintage equipment very well. -

IIRC they have once sold this video on VHS - not sure though. If they put it up for sale on CD-R I´m sure a lot of folks would like to buy it.

-

Dürkopp 291 parts are harder to find and accessories and parts are expensive it however is the newer machine model with a larger capacity hook. The advantage of the 226 is that is shares parts / accessories with the Singer 111w which are easy to find and cheap. Here is a source for 291 parts: https://www.college-sewing.co.uk/parts-by-machine/durkopp-adler-industrial-sewing-machine-parts/durkopp-adler-291-292-spare-parts.html Enjoy the prices ** kidding **

-

Singer 51W SV 2 Post Bed Machine Restoration

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Basically the 111d is German made prior 1945 and the 111w is US made. They share the same parts. So 111d or 111w does not matter what matters is the needle bar diameter. The 51w28 seems to be the same 1st model 51w as mine so you basically need a needle bar from a Singer 211 needle feed machine or 111w151 which also is a needle feed machine. Check this thread for more details: -

My life has changed (partially to negative, partially to positive) and I have to sell several vintage sewing machines (heads only) that have "piled up" over the recent years. I just have toooo many and especially too many I'm not actively using. All will be in sewing condition (depending on what you want to sew) but may need some adjustments, cleaning, or refurbishing. When ever possible I´ll make a quick video showing how it works / is sewing. I can ship overseas and I do proper packaging (I can give references. I have sold to several long time LW members before). Listing the machines will take some time. I have no triple feed /walking foot machines for sale. Most are patchers (CLAES, Singer, Adler...). Quick list of models (may not be complete): Patchers: CLAES 8346-30 CLAES 200-3 Adler 30-15 Adler 30-7 Singer 29K71 maybe a Dürkopp 17 w. medium hook (actually size of a large CLAES hook) Other machines: Singer 45D90 (with reverse) - same as 45K90 but German made prior 1945, parts are the same. Pfaff 138 (black) Dürkopp 207-5 with roller foot (similar to Singer 96K) Anker M with roller foot Pfaff 230 (early black with wider timing belt and NO plastic gears) Anker RZ List is not complete yet. I may have some interesting accessories as well (branded thread stands and so forth). ATM it is just too much to list. If interested send me a PM and I´ll figure shipping costs and I´ll give you a price for the machine INCLUDING insured shipping. Not included will be import import taxes, VAT.... you name it and all that depends on your destination - so that is all up to the buyer and not my part. I know I have to list prices and pictures but I work long time (incl Saturdays) and I may answer slowly so please be patient with me. So when ever I get a request I´ll post the pictures here and add a price. Bear with me - life is hard at the moment. I hope that works for you folks & the moderators. 😉

-

tooooo many pinned therads on page 1

Constabulary replied to Constabulary's topic in Feedback and Suggestions

suggestion: unpin these threads: What Exactly Is An "eps" (Electronic Positioning System)? Adler 467 For Venator Delete / relocate these threads as they are IMO no longer needed: New forum for 3D printers, engravers and laser cutters New Members, please read this before posting. Please list your location and country in your profiles the member location should be mandatory when signing up and the problem is solved (IMO) or increase the number of new post on page 1 of the sub forum -

check the parts list and try to figure what parts are needed but I honestly doubt you can do that and even if it was possible the parts will be crazy expensive.

-

Singer 153K103 Serial Number Problem

Constabulary replied to ChipinAZ's topic in Leather Sewing Machines

-

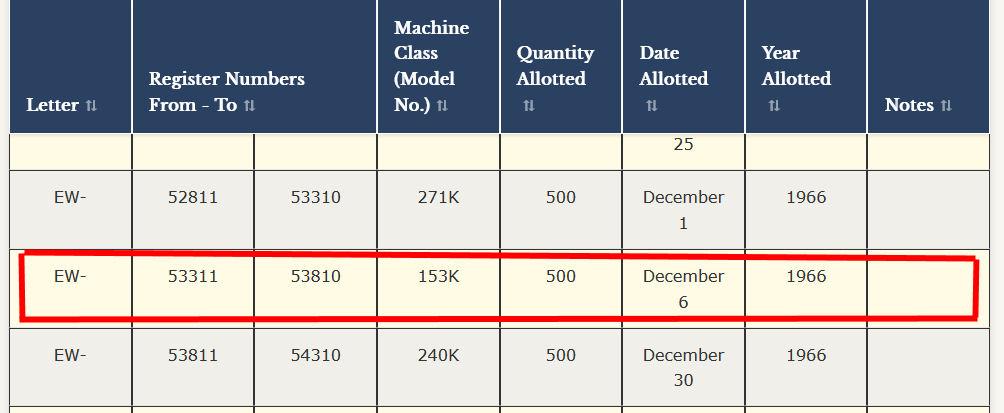

Singer 153K103 Serial Number Problem

Constabulary replied to ChipinAZ's topic in Leather Sewing Machines

The Singer serial number records are not complete I dont think anyone has a complete list. For some double digit prefix serial numbers records do not exist anymore (as it seems) EX prefix is around late 1965 so your machine for sure is a later date I think early to mid 1970´s onward and it is UK made. -

since the forum has been updated there seem to be fewer new posts / threads on page 1 in the "sub forum". Page 1 only shows one (1) new thread all others are on page 2. And if you ask me I'd say at least 1/2 of the pinned threads can either be delete (3D printer f.i.) or are no longer needed to be pinned (to make room for the new posts). Just my 2 cents. 😉

-

I at least can see that here is a thread guide missing. Have you cheeked the needle hook timing especially the needle bar height?

-

I have edited the pic a bit... ah... well... I´m not sure but is your bottom thread going trough the needle eye??? That would surprise me... But could just be the angle 🤔

.jpeg.63f0d01779fa0b34f2999382d0ef5bde.jpeg)