-

Posts

5,801 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

What exactly is the struggle with the thread? reg. stitch length - check this Video:

-

Machine is definitely a keeper. Well - I´m not 100% sure but the tension unit looks like one from a Pfaff 138. That does not mean your tension unit does not work with the machine but I think its not the original tension unit. Adler tension units look different they look like this: and yours has 2 tensions (thats for double needle machines, sewing tucks and so on) and seems you run the thread through both of them - thats basically wrong. Try to thread your machine a different way - go from the thread guide on top of your machine directly to your tension unit and thread it as shown in this picture and try again sewing.

-

Trying to figure out the basics

Constabulary replied to spectre6000's topic in Leather Sewing Machines

This is one of the most useless threads in the whole sewing machine section. I´d suggest deleting it as there is no sense in it tat all. Or at least close it with an Admin´s comment at it´s end. -

we also have dealers in Germany like Sieck.de or Frank Brunnet who sell Hightex (Cowboy) machines http://www.fbn24.de/epages/64180611.sf/de_DE/?ObjectID=34606502&ViewAction=FacetedSearchProducts&SearchString=441 Frank Brunnet also sells on Ebay and accepts offers: http://www.ebay.de/itm/Cowboy-Hightex-CB-4500-leather-sewing-machine-Sattlermaschine-/222356209782?hash=item33c5768076:g:3rIAAOSwstxVW6ak Since GB is still a EU member you don´t have to pay any custom fees.

-

Nick - can´t help you with details but I wonder if you already have a price for this machine incl. tax.

-

I could only tell you what google tells me - guess you have seen this Video already. It explains a lot.

-

Where are you located? Maybe some one can recommend a good dealer close to you. Hard to tell from a distance what going on with your machine. Post some pictures and a video if possible. My 1st guess would be the needle and hook timing. Maybe it´s just the needle bar that needs and adjustment in hight. Or maybe the hook tip is too far away from the needle or the hook tip is worn.

-

Not sure what experience you have with sewing machines but generally all sewing machines should have consistently perfect stitches when properly set up. But there are of course the factors of needle and thread for the right material. Thats usually up to the operator or the dealer when you give him order to set up your machine for a certain sewing operation. I can sew long meters of consistent stitches with all of my sewing machines. They would be useless if they can´t do the job. But I of course have to adjust top and bottom tension when sewing different materials and or different thickness and find right needle and thread combination. When you buy a machine from a dealer it should be perfectly set up since you pay him for that! When you buy form a private seller always test the machines with your thread your needles and your materials - when ever possible. Make sure you have the manual with you when you buy an unknown machine from a private seller.

-

Who uses a Pearson #6

Constabulary replied to T Moore Medicine Hat Saddlery's topic in Leather Sewing Machines

Well, I have sewn max 20mm leather with it - test wise - thats the max. I was able to get under the foot when a needle guide is installed. I never will sew leather of this thickness regularly. I just hand cranked it and needle went through the leather like butter. I have not the most experience with this machine but some pro´s are, the needle feed only since you have no feed dogs marks on the bottom side and the adjustable presser foot - you can move the presser foot back and forth approx. 10mm. Also these machines are easy to work with. I have restored mine - totally stripped it, cleaned it, painted it and put it back together and it sewed right away. I had to adjust just thread tension a bit. You also can adjust some of the wear parts like the needle bar. These machines will probably last for ever if we have no nuclear strike. I think folks who are using machines like the #6HM are not using them just because of these features. I think it also has a lot to do with the historical aspect and tradition of leather work and / or just the joy of using vintage machines in general. Modern machines like the 441 clones are for sure more comfortable to use but as I said before - you cannot beat the joy of using vintage machines like this. For me it is a totally different thing sitting in front of a + 100 years old fully functional harness maker machine that generations of leather works / harness makers have used before I put my oily fingers on it. I have to admit I have not used a 441 yet but I have used and tested many other sewing machines of different classes but the older machines always had this certain something you sometimes cannot put in words. Maybe just the joy of seeing, feeling and hearing these old machines when working sometimes combined with a certain smell. Don´t know - maybe just passion for vintage machines? Maybe others can tell you more.... -

Who uses a Pearson #6

Constabulary replied to T Moore Medicine Hat Saddlery's topic in Leather Sewing Machines

I have a BUSMC #6HM but atm barely using it. Also have an BUSMC A1 - just recency acquired (if asking for BUSMC machines in general) -

pressor foot mods. Post any that you have done

Constabulary replied to Gregspitz's topic in Leather Sewing Machines

I see you are using titanium needles - are they really so much better? -

Cast Iron Again - Pearson & Bennion / BUSMC A1

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Yes I have the chip. Its just a cosmetical issue. I´m using the larger pulley anyway so I will try some JB weld. Mechanically the machine is in excellent working condition - zero issues. Meanwhile I have a heavier foot spring installed so I will try to sew some leather in the days to come. I just love the clicking sound it makes njaahahaaa old cast iron is freakin addictive -

When you replace just the long rack it could be that it does not play well with the other parts of the gear box. When the gears / racks are in "good" condition they have a flat tip when they are worn the have a sharp tip. But there is of course something in between. I have replaced a pinion bushings on 29K´s twice and both were extremely (!!!!) tight. I heated the gear box and hammered it out with a big punch. Not sure if they were just badly gummed or heat shrinked. The new bushings did not fit very well as they were a bit oversized so I had to sand them down. That something I don´t like to do again as I feared to ruin the gear boxes.

-

Trying to figure out the basics

Constabulary replied to spectre6000's topic in Leather Sewing Machines

Seems you don´t understand. There is no such list existing as there are literally several thousand different sewing machines on the market. Used, new, some 100 years old. Dozens of brands are existing and dozens of other brand are long time gone but the machines are still out there and are in use but no one knows all machines. But if you want to spend some time checking out Singer brand machines check the ISMACS Comprehensive Singer Sewing Machine Model List - that's probably the closest but thats just Singer - there are dozens of other manufacturers. http://ismacs.net/singer_sewing_machine_company/model-list/ Scroll down here - a list of approx. 60 manufacturers and I´m sure not all are listed. http://ismacs.net/singer_sewing_machine_company/home.html So maybe you can put together a list when your list is done feel free to post it here. I´d say when you have a certain project you want to do come back and ask what machine you need for the certain project. -

Trying to figure out the basics

Constabulary replied to spectre6000's topic in Leather Sewing Machines

If you are unsure what you need and the answers here are not what you expect then check with a sewing machine dealer. They for sure will tell you what type machine you need for your project(s) when you explain them what you want to sew. You probably can test sew some of their machines. -

Pfaff 335 w/ 135 Thread Having Tension Issues

Constabulary replied to drawingonblank's topic in Leather Sewing Machines

The 335 usually is a binding machine and not necessarily set up for heavier leather work. Just from looking at the picture I´d say you have to reduce the bottom thread tension and / or try a heavier tension spring in the top tension unit and / or try a needle 1 size bigger. Or try a thinner bottom thread. Are you using a leather needle or round point needle? I guess you bought the from Atlas Levy, right? They should be able to supply a heavier top spring. Just some suggestions... -

Cast Iron Again - Pearson & Bennion / BUSMC A1

Constabulary replied to Constabulary's topic in Leather Sewing Machines

small video - sorry not much space to place the cam properly - so my dirty fingers are in the way a bit. Thanks Steve but I have an original manual. I actually had it before I bought this machine. I once bought it along with some BUSMC #6 HM parts I needed for restoration. In the Video I use a 180 needle (metric) and some 207 cotton thread Just checked the stitch length - seems to be approx. 4 SPI at max. - a pretty good score for a vintage machine like this I agree but its really a pity -

Cast Iron Again - Pearson & Bennion / BUSMC A1

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Seems the machine once had an accident, a few parts were slightly bent, a piece of the pulley was dented and finally fell of (still have that chip) and I had to reproduce the foot pressure thing as it was totally bent and thread was damaged - no way to rescue it. I have filled the worn screw heads with hard solder and cut some new slits. Unfortunately I damaged the decal - I remember the owner said the machine was used as decoration on the window sill and shop window for decades (machine has not sewn for the fast 50 years he said). Maybe the permanent sunlight and my efforts of cleaning did not play well together. Really sad but I hate looking at / working with dirty filthy machines. So thats the price I paid. Machine is sewing again but I need a new foot pressure spring. The old one was badly rusted and broke and the current one is too weak to sew leather with, for webbing its okay. Some more pictures: -

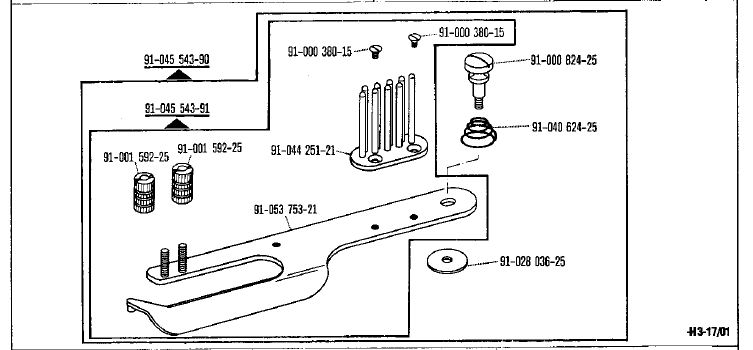

This it the original 345 bracket it belongs to LW member TROX - I hope Tor does not mind showing his picture here: And picture from the Pfaff sub class list There is also a DIY variant another LW member made but I prefer out of the box solutions when ever possible - however the DIY works well, see his YT video

-

I was hunting high and low for a synchronized binder bracket for my Pfaff 345 and finally found one more or less in front of my door. It is for the 145, 545, 1245 flat bed machines but actually fits for the cylinder bed 345 w/o problem. Only difference is that the original 345 bracket has a slanted panel towards the operator and this one has a flat panel but does not bother at all. I bought it at www.rimgm.de for 88€ + shipping - I know Kwokhing also has them but I only needed this particular bracket so I think it would have been more expensive to order it in HK since I don´t have to pay hight shipping and custom fees. This bracket is actually made in Italy and quality is quite good. Its made of 1/8 steel - so really sturdy! Comes with all parts you need for attaching it to the machine + a special screw driver thingy. It has a kind of quick release. The pivot stud can be left on the machine. Just wanted to share this since these Pfaff synchronized binder brackets seem to be hard to find on the web.