-

Posts

5,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

It is a darning machine - not even a sewing machine. If it is in the state as it once left the factory it does not even have a feed dog (for feeding the material) or a stitch length adjuster so It will not produce a seam with constant stitch length at all but we have not seen your particular machine yet. Maybe someone reworked it in the past.

-

Cowboy CB4500 or SIECK type 441 K

Constabulary replied to JustCurious's topic in Leather Sewing Machines

The above info sheet seems to be from the original 441 manufacturer JUKI The linked Sieck 441 K looks like the Cowboy CB 3200 and not like a CB 4500 Neither SIECK or COWBOY are manufacturer of sewing machines, they just put their own label (brand name) on Chinese made sewing machines and they are free to give them a name of their own choice. The price on the SIECK website is w/o VAT - add 19% for German VAT. -

obviously a 227R - maybe from a different batch. Also check SEIKO CW-8 or Consew 227R - basically all the same machines.

-

Maybe the racks & pinions in the gear box are worn or maybe the hook tip is worn. Are you sure you are using the right needle system 332 LONG (not 332)? Make sure the long grove of the needle is facing left.

-

claes Help! Claes 8345 ( Metro Spezial / Pfaff 9345)

Constabulary replied to Arsura's topic in Leather Sewing Machines

some years ago I visited their factory and bought some smaller spares while I was in the area for picking up some machinery (for sewing & wood working IIRC) - very nice folks there indeed! -

Justification for buying a real Durkopp-Adler.

Constabulary replied to leerling's topic in Leather Sewing Machines

Maybe worth checking with Global Sewing Machines and see what they have. They are NL based (Haarlem) and also have used 441 machines as it seems: https://globalsew.com/product/juki-tsh-411-normal-new/ Or maybe SIECK in Germany: http://www.sieck.de/en/machines/sewing/saddlery-sail-maker-heavy-duty-materials/arm-type-machines/?produkt=6832 EDIT: Looks like the Global Juki 441 are just drop feed - anyway - maybe worth checking with them. -

Justification for buying a real Durkopp-Adler.

Constabulary replied to leerling's topic in Leather Sewing Machines

College Sewing or Trojan Sewing in the UK are quite good sources for parts for certain Chinese / Japanese / Taiwanese made machines. But since BREXIT importing things from the UK became more expensive. -

New Member and mystery machine

Constabulary replied to piningforfjords's topic in Leather Sewing Machines

No Singer serial number IMO - I´d say Consew 226 or Seiko STW-8B -

Can´t find my digital caliper but yes, the 45K needle bar is ~0.9-1mm wider so a drill press will help

- 14 replies

-

- and many more

- singer 153w

-

(and 4 more)

Tagged with:

-

IIRC the 45K and 132K foot bars have a slightly larger diameter but I can check that later today. Anyway - if you have a drill press you probably make the adapter work. If the standard Singer feet will then work with the 45K / 132K is another story. You for sure have to modify the feet as well f.i. to allow the use of larger diameter needles. Keep in mind the standard feet are rather narrow and the feed dog on the 45K / 132K are rather wide. So the foot thing is trial and error IMO but the adapter it self can be modified I´d say.

- 14 replies

-

- and many more

- singer 153w

-

(and 4 more)

Tagged with:

-

Question is why do you want to adjust the foot height? I never do that on drop feed machines. I once set my foot bar top the max. foot lift and then I´m done. I only adjust the foot pressure. But maybe I do not understand your problem with the foot height. Maybe you mix up something. You can adjust the walking foot height on triple feed (aka walking foot) machines related to the material thickness. But on plain drop feed machine (like 45K25 and 31-15) there usually is no need to do that.

-

claes Help! Claes 8345 ( Metro Spezial / Pfaff 9345)

Constabulary replied to Arsura's topic in Leather Sewing Machines

System 81 also is LA X 81 https://www.frankfordleather.com/needles/groz-beckert-claes-81-needle.asp Or check https://www.shoesystemsplus.com -

w/o knowing what is worn we only can guess. I love the old 45K´s very much but to be honest they had their time and better machines are out there nowadays. Not saying they are useless but it depends on the job and the money you can spend. I´m still using my 45D91 and I`m still pleased with it and I do not have the output that would justify a CB3500 or even CB4500 . What are you sewing with your machine? However they still make clones of the 45K - its the GA5-1 / Cowboy CB105 / Cowboy CB2500 and it is well possible that some parts are interchangeable but I never tried this.

-

Separate 45k21 from table + spare part question

Constabulary replied to Redbeeerd's topic in Leather Sewing Machines

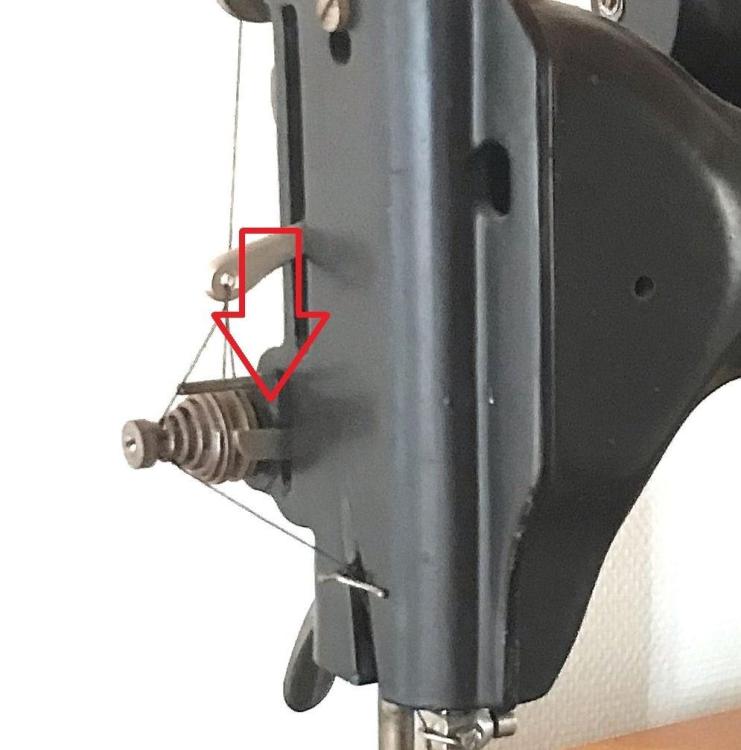

The Singer 45K jump foot system foot cannot be added to machines w/o jump foot. Well, maybe - if you have enough milling machinery and so forth, money, time and patience. Quick try for an explanation: The 45K jump foot is controlled by a notch on the cam that also controls the thread lever the 45K21 (afaik) does not have this notch so you have to to pull the top shaft to replace the cam or the whole shaft . There is a piston (kind of) sitting in the top side of the casting and the notch is pushing up the piston at the moment the foot is at its rear position then the foot releases and is jumping to the front. The 45K58 has a flat top on the casting head where the piston is mounted whereas the 45K21 doe not have this flat top. Then the 45K58 has a leaf spring on the rear (just like the Singer 29K4 f.i.) and that requires a special mounting which the 45K21 machines do not have. Not speaking of possible the differences in the casting on the rear side to accommodate the moving foot bar and differences in the face plate.... This is just what comes to my mind... BTW The check spring indeed is broke or missing. College Sewing in the UK has them: https://www.college-sewing.co.uk/parts-by-machine/singer-sewing-machine-parts/singer-45k-parts You either need just the inner part with the thread loop or both parts. -

Separate 45k21 from table + spare part question

Constabulary replied to Redbeeerd's topic in Leather Sewing Machines

Just what I can tell from the picture: Machine appears to be in very nice condition overall, however, I do not see a presser foot and the needle hole throat in the plate is damaged and the machine seems to be not correctly threaded. I´m not sure if the check spring is there (or broke) cannot tell from the picture. At least the thread is not going through the check spring - thats why I think it could me missing or is broken. It´s not a walking foot machine. It is a plain drop feed machine. -

Separate 45k21 from table + spare part question

Constabulary replied to Redbeeerd's topic in Leather Sewing Machines

The 45K machine has an oscillating barrel hook but no rotary hook. Hooks are available on Ebay as well but College Sewing indeed has some 45K parts in stock - not many though. But in case you will order from them order make sure you buy a the 2 components of the check spring as spare - better too have than to need. I would also buy 1 or 2 thumb nuts for the tension units as well (same reason). If you cannot find the parts enter the parts number form the parts list BTW the 45K tension unit on Ebay (for GA5 machines) do not work properly - guess how I know. If you have pictures of the machine please post them so maybe we can detect missing / broken parts. -

Google is your friend (sometimes) here is a download link for the manual: https://ismacs.net/singer_sewing_machine_company/industrial-manuals/17-22&17-23-manual.pdf Pictures will help to visualize your machine issues.

-

Help with old Singer cylinder arm machine

Constabulary replied to Metalhorseman's topic in Leather Sewing Machines

The predecessor is the Singer 107w50. I think it shares a lot of parts with this machine. Yours just has a more modern casting. I think it is late 1950´s -1960´s made. The predecessor flat bed version of your machine is the 107w1, 107w2, 107w3 and the like. The flat bed machines for sure share some parts with the cylinder arm version a s well. I´m almost certain that the instructions for the 107w50 will help you a lot with your machine. https://www.manualslib.com/manual/364298/Singer-107w50.html?page=6#manual -

How to make a USGI M1916 leather holster?

Constabulary replied to Tango99's topic in How Do I Do That?

-

How to make a USGI M1916 leather holster?

Constabulary replied to Tango99's topic in How Do I Do That?

I have these Mil. Spec. pattern files. Do not recall where they came from - not sure if they help you. I have more but cannot upload them - files are too big -

Advice on Singer 34K11 or Adler 5-6

Constabulary replied to Gryning's topic in Leather Sewing Machines

do you have a picture from the left side / the face plate so we can see if parts of the tension unit are missing. -

Part needed for a Singer 21w180

Constabulary replied to stitchbystitch's topic in Leather Sewing Machines

do you need just the hook or the hook + hook saddle? If just the hook I probably have an idea but you have to remove the hook from the saddle first so that I can see the bottom side. -

Don´t know where you come from but I restored my 29K71 with parts from College Sewing and they were all fine except the shaft for the front drive (no drilled pin hole). But bit by bit I replaced all non OEM parts with OEM Singer parts but thats a different story. The encircled thingy IMO is parts of the darning device.

-

Advice on Singer 34K11 or Adler 5-6

Constabulary replied to Gryning's topic in Leather Sewing Machines

Wiz, the 34K11 subclass it the much heavier subclass in the 34K range. The upper arm and hand wheel are from the 45K and it has a larger hook than the other 34K's (like 34K5 or 34K1 or the like). It is using the 214x2 / 328 needles. -

Yet another request for identifying

Constabulary replied to Redbeeerd's topic in Leather Sewing Machines

Very similar to Singer 96K.

.thumb.jpg.4c73c6a3a58a9bb647aeb12f04650a61.jpg)

.thumb.jpg.d138195a6e10e3169cb80fc1cfd82b5f.jpg)

.thumb.jpg.0e3714f2e78a9f064a0548113b5a4607.jpg)

.thumb.jpg.eb462aa5b9338fb1ce59005ee89e409a.jpg)

.thumb.jpg.2cc28bd28fe0374be53973e9adb3e5d5.jpg)

.thumb.jpg.0ecbfac75993bef5719032902668ddb4.jpg)