-

Posts

5,807 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

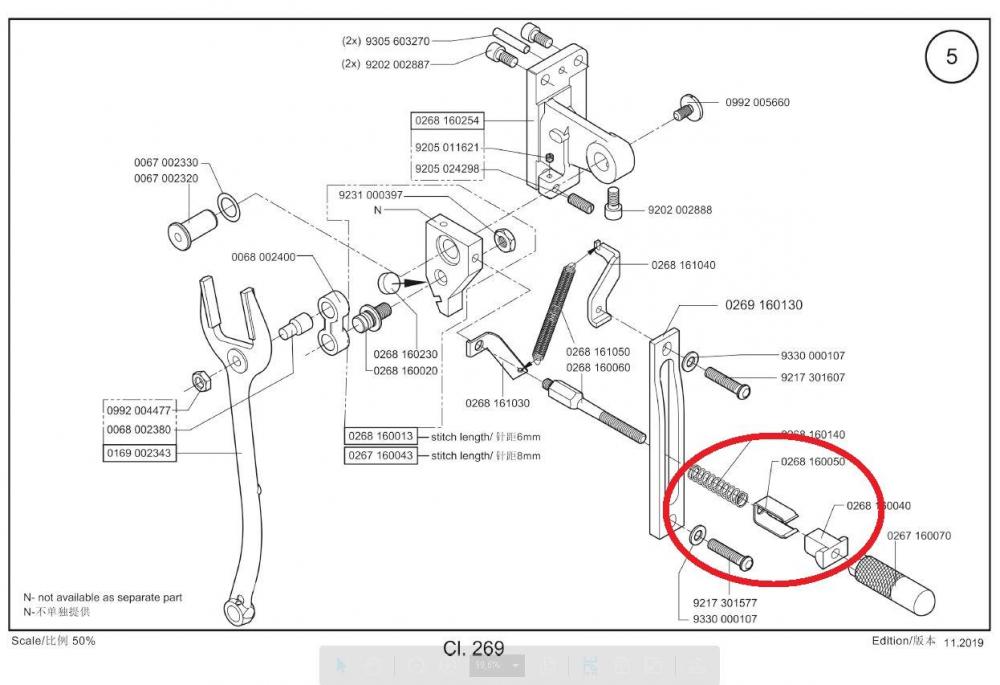

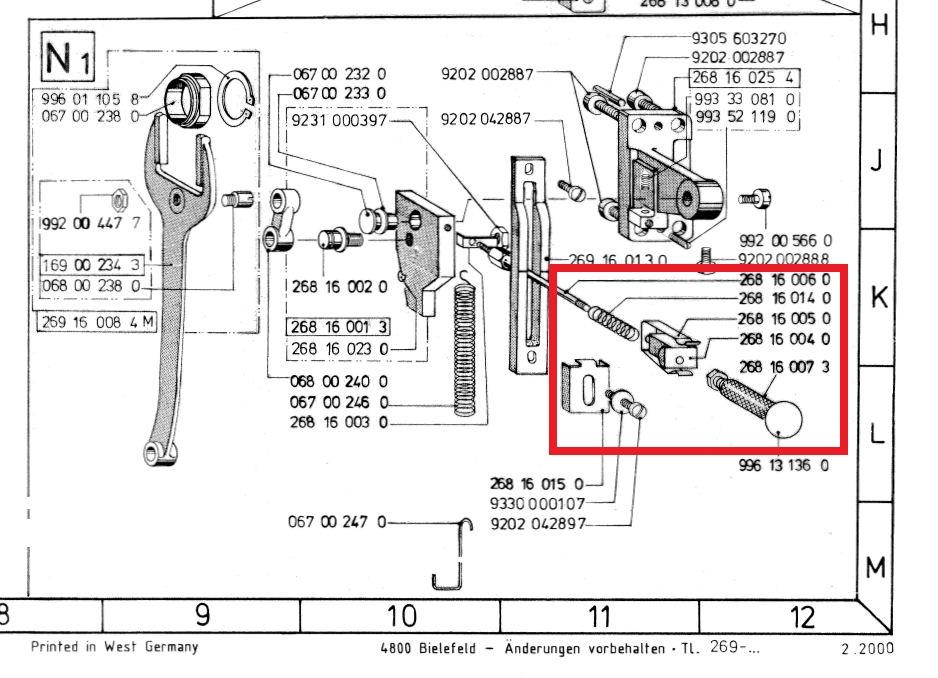

I´m not an Adler expert but when I look at your picture and cross check the parts list of a 269 - I would guess your stitch length adjuster is not correctly assembled. Just a guess.... Cross checked the older parts list as well: You may also check the orientation of part # 268 16 004 0 - you (maybe) have to rotate it by 180° but I do not know the design of this part but f.i. on certain on Pfaff machines the orientation of this part matters!

-

Unfortunately no - it is from the machine in your picture The screw is 34mm long from underside of the knurled head to the rounded tip. The threaded part is 25mm-26mm long. EDIT: Outer diameter is 8.5mm

-

That screw is a stop screw and the nut locks the screw. The screw has a ball tip. I´ll post measures later...

-

Dürkopp 17 Patcher - Sunday Morning Barn Find

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Yes, every single part! -

Can you identify this Singer 29K model?

Constabulary replied to Flipbou's topic in Leather Sewing Machines

I would guess 29K33 small bobbin (has a leaf spring on the rear - notice adjustment screw for the spring) or a 29K30 with large bobbin (could be cause it looks a little wider around the needle plate) - but all just -guessing. -

Dürkopp 17 Patcher - Sunday Morning Barn Find

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Broke the hook but I think I have a replacement, however it may work with out the tab too. Will check... I split a screw while turning the screw driver - no idea how this happened But I´m almost done with the head but still needs some work and maybe some adjustment. Added new longer thread spool pins. I forgot to "electrolyse" the hand wheel... so that's next. I just put it on for testing. -

https://www.college-sewing.co.uk/catalogsearch/result/index/?needle_size=5644&q=214x+needle 216x1 is approx the same but is slightly different in the tip area. They were used with Singer 132K and the like

-

Other things that affect hook timing, Singer 111W

Constabulary replied to AlZilla's topic in Leather Sewing Machines

You mean the needle bar height or needle to hook distance?? From my experience when you read the 111w manual you have the right order of what to do first. -

Has my bobbin mechanism 'shifted'?

Constabulary replied to Jacktheboatguy's topic in Leather Sewing Machines

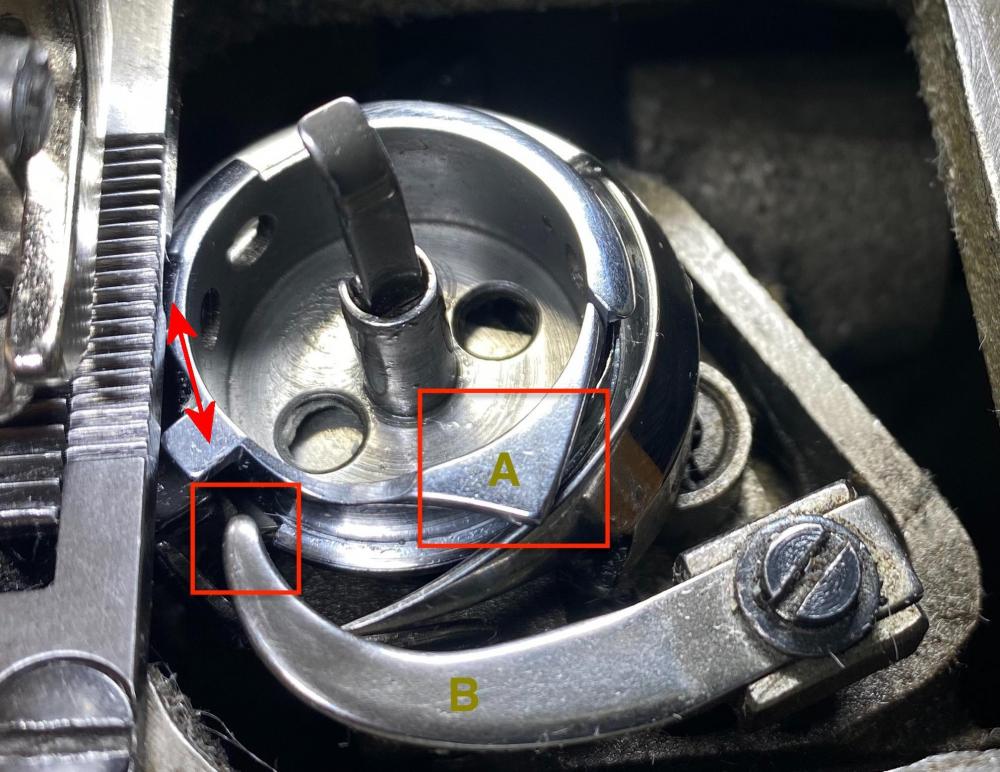

The bobbin case tab has to sit in the notch of the needle plate - see tips of the arrow. Remove the needle plate screws, rotate the bobbin case and put back on the needle plate. EDIT: Looks like you figured it -

Correct but depends on the work you have and last but not least your budget. My old bottom feed 51w works well for what I do but yes an improvement is always possible . I once owned a Singer 110w flat bed with wheel feed - I loved it but the stitch length was just too short (different story).

-

if it comes to double needle machines I would always choose a Singer based machines (Juki, Seiko, Cosew...). You will have a hard time finding gauge sets for the Pfaff 142 (if available at all) and you cannot use Singer gauge sets on the Pfaff. I have a 212G141 and love it. I don´t use it often but it works great. Maybe you are interested what I did with my machine: https://leatherworker.net/forum/topic/80209-singer-212-112-double-needle-converting-into-split-needle/

-

Pfaff 145/545 owners – Little help needed

Constabulary replied to hugocrafts's topic in Leather Sewing Machines

You need 2 screws one from the left the other from the right. Check the casting - you have 2 threaded screw holes. -

Pfaff 145/545 owners – Little help needed

Constabulary replied to hugocrafts's topic in Leather Sewing Machines

this is the cover for the "right side" gear box and will not fit the hook drive gears. Just google the parts number: 91-000 073-15 Screw is M3.5x9 If it was me I´d either order one from a dealer near you or tap a new thread maybe M4 or M5 or so. -

Singer 111W155 presser foot issue

Constabulary replied to Teradee's topic in Leather Sewing Machines

Check these 2 parts . 1.) is held by a set screw and is probably slightly offset EDIT: I´m a tad to late as it seems -

@MtlBiker Post bed machines can be very special. You have roller presser feet + bottom feed on "plain" post bed machine. Some can use regular presser feet too (or adapters are available) and some have fixed roller feet. In addition you can have permanent wheel drive (instead of a feed dog), then there are also motor driven roller presser feet (via a small drive belt). An then you can have needle feed option too and also triple feed (as on your 206). Not all combinations are possible and not all machine models are available with these features. As always - it depends on what sewing work you have. My Singer 51w is a "plain" one with bottom feed (drop feed) w/o reverse and set up for Singer type feet but I have an adapter so I can put on a simple roller foot to.

-

Dürkopp 17 Patcher - Sunday Morning Barn Find

Constabulary replied to Constabulary's topic in Leather Sewing Machines

This machine is a bit different to what I have read in the Class 17 manual (of a later version I guess) so far . At least in terms of how to insert the needle correctly / timing. Usually you shove the needle all the way up in the needle holder tighten the needle holder screw and done. This machine is different. When I took it apart I noticed a very clear mark on the needle bar (very unusual for a patcher). Now that it is almost reassembled again I had to figure how to time the machine. It has an eccentric on the gear box (see earlier post) but it indeed ist not for timing it is for compensating wear on the racks and pinion and that is a great feature! I the hell was not able to figure the timing cause I shoved the needle all the way up (of course). I assumed you can advance or retard the shuttle driver pinion by 1 tooth or so.... but no - did not work. Then yesterday night I went trough my manual collection and hell I found an original manual (German Language) for this machine . Did not even know that I have one and since when - really no clue. Now it is clear what the mark on the needle bar is for. So, you have to bring the needle bar in a position that the mark is leveled with the surface of the top side of the head. Then insert the needle in the needle holder until the needle eye is leveled with the surface of the needle plate. And then the machine is timed right. Unusual but not a bad idea. But you have to know that cause all other patcher machines I ever had (yet) were different to this. Will post more pictures later. -

Ha - 2.5K is a lot - you can get the clones of the Mitsubishi PB 810 with reverse for approx 1.8k or less: If you ask me - they are all the same "breed" just setup slightly different (with speed reducer or not and so forth) or with a different name tab on or slightly different casting. https://www.google.com/search?q=810+post+bed+sewing&source=lnms&tbm=isch&sa=X&ved=2ahUKEwi56arjzOn7AhVQ2qQKHXRuAN0Q_AUoAnoECAIQBA&biw=1680&bih=878&dpr=1 https://atlaslevy.3dcartstores.com/Single-Needle-Post-Machine-Mitsubishi-Style-AtlasUSA-AT815_p_4422.html https://www.techsew.com/us/techsew-810-post-bed-roller-foot-industrial-sewing-machine.html https://sunny-sewing-machines.myshopify.com/products/thor-gc-810-post-bed-roller-foot-sewing-machine?variant=32410588938380 https://leathermachineco.com/product/cobra-5110-post-machine/ https://thorsewingmachines.com/index.php/product/thor-gc-810-post-bed-roller-foot-sewing-machine/ The dealer choice is yours. But I would probably look for one as local as possible. Maybe you can even pick up the machine or go to the dealer for testing. Looks like Sunny Sewing Machines is in Texas. Advantage of the 810 model is that certain spare parts are available fairly cheap. I have used some of the parts on my decades old Singer 51w sewing machine and they still work (but thats a different story).

-

Dürkopp 17 Patcher - Sunday Morning Barn Find

Constabulary replied to Constabulary's topic in Leather Sewing Machines

it´s almost fully assembled but still needs work - I´ll post pictures tomorrow. -

5 machines (fell in my lap, details coming)

Constabulary replied to Teradee's topic in Leather Sewing Machines

The 211 is a 212 double needle needle feed. The 68 looks like a button hole machine.... -

Dürkopp 17 Patcher - Sunday Morning Barn Find

Constabulary replied to Constabulary's topic in Leather Sewing Machines

-

Really? When I check google I find this for example: https://www.ebay.com/itm/402349074068

-

Dürkopp 17 Patcher - Sunday Morning Barn Find

Constabulary replied to Constabulary's topic in Leather Sewing Machines

alright - so black it will be Just primed the machine casting and some parts.... More pics in the coming days... -

Speed Reducer Mount made from Clutch Motor Mount

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Another ex clutch motor upcylcling thingy. This is the flange of a MORETTI clutch motor. It has two ZZ ball bearings with 15mm inner diameter so it works great for building a speed reducer. Not that I need another speed reducer but why not keeping it for a future project. Could come handy one day. Maybe for a box type speed reducer or for mounting it directly onto a stand. I wanted to cut cut it squared but ran out of cutting discs. -

Dürkopp 17 Patcher - Sunday Morning Barn Find

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Glenn, yet most parts were just dirty but not rusted. Dried oil + dust sometimes looks like rust. The parts turned out really nice! I´m not sure about the color for the casting. I have green in mind or just black as it was. -

Some basic info. From just looking at the machine it seems to be a Mitsubishi Clone of the Singer 212G140. A double needle machine with drop feed + needle feed and no reverse.