-

Posts

5,801 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

As far as I know the 132K / 133K needle bars are too short but yes they have the same diameter. The 132k / 133k have a longer internal top bushing therefore the needle bar is shorter.

- 10 replies

-

- spare parts

- needle bar

-

(and 1 more)

Tagged with:

-

I would go with the Pfaff but depends on the overall conditions of the two machines. What I like better on the Pfaff is the stitch length adjuster and the machine has no timing belt. It is shaft driven. "Around the hook" they are very similar. No one can guarantee you the Paff will sew better. That often is a question of how the machine is set up (needle hook timing, needle hook distance and so forth - also age and wear matters). I would test sew them both with the max. material thickness you would sew in your business and then decide.

-

You mean the Adler 165 or the 167? The 165 is a cylinder arm drop feed machine with barrel hook

-

I noticed you are from the UK - maybe worth checking with College Sewing or Trojan Sewing. BTW - I think the Singer 7 and Seiko SLH series are using the same diameter needle bar as the 45K but they are longer (better to long than too short). I would buy a matching needle holder too. But better check with College Sewing for details. https://www.college-sewing.co.uk/35022-slh-2b-needle-bar-seiko-genuine.html

- 10 replies

-

- spare parts

- needle bar

-

(and 1 more)

Tagged with:

-

I would check with a COWBOY dealer (f.i. Toledo Sewing Machines) if a needle bar of a Cowboy CB105 / CB2500 / GA5-1 will fit. I´m almost certain that it will.

- 10 replies

-

- spare parts

- needle bar

-

(and 1 more)

Tagged with:

-

Singer 29-3 Presser Foot Won't Rotate

Constabulary replied to AlZilla's topic in Leather Sewing Machines

I once "implanted" a modern bell crank lever in a ancient 29K1. Maybe this thread is helpful -

Singer Post Bed Identification?

Constabulary replied to AbelJojua's topic in Leather Sewing Machines

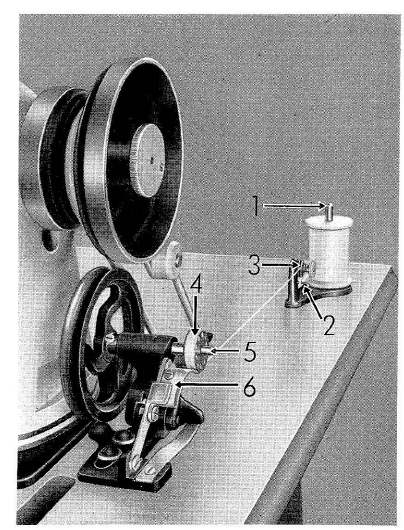

The type of bobbin winder you have usually comes with a spool holder with tension unit - like this: And it is more comfortable to use compared with the simple machine mounted one that came with the machine ex factory. Except the hook (same as large hook for 29K / Adler 30-7) and some tension parts (same as for Singer 16 / 17) you will have a hard time finding parts but these machines are so tough you barely will need any when you have it up and running. Look on Ebay. Sometimes folks rip apart machines for parts. I once needed a new needle bar and found one from a Singer 17 that worked: https://leatherworker.net/forum/topic/66729-singer-needle-bar-i-could-use-some-help/ So some other bits from other machines will fit for the 34K as well but you have to look them up and maybe compare parts lists but Singer 16 and 17 have certain parts in common with the 34K. If you haven´t found a manual for the 34K please send me a PM with your email address and I will send you a PDF. -

Walking foot won’t lower properly

Constabulary replied to theredhedsed's topic in Leather Sewing Machines

have you oiled the machine ever since? BTW - looks like it is not correctly threaded (top thread) sec. 0:05 - 0:008 (just saying) -

Pearson / BUSMC HM 6 serial numbers and dates list

Constabulary replied to Stewey's topic in Leather Sewing Machines

I once owned a DVSG / BUSMC #6HM some years ago but sold it to the UK to one of our LW members here. The serial number number was G-10522. The G prefix I think was added because it was a machine for the German market. DVSG is the equivalent of BUSMC in the UK. This was the restoration journey. I still have a range of detailed pictures of the finished and assembled machine which I can either post or send you by email if there is an interest. -

@Adekunle not sure if you read the latest comments above but maybe showing a video of when / in what situation the bobbin pops out will be helpful. For me it is hard to imagine why and when a bobbin pops out of an oscillating shuttle hook.

-

if vintage triple feed machines with reverse are what you are looking for the Juki 562 or 563 or Consew 226 may be of interest as well - just to mention a few... Other are Adler 67 or 167 and Pfaff 145 and 545 and Dürkopp 239.

-

The purpose of left stand sewing machines

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Not mine - Just for the records - Left stand post bed machine from GOERICKE, Bielefeld. What a beauty! -

probably the small curved leaf spring which holds the bobbin housing in the shuttle frame is worn or the screw that holds the spring in place is loose. Remove the shuttle hook from the machine and swing the bobbin housing aside and the check the spring and screw. Just a guess w/o having seen pictures.

-

knee lift is wrong on my cylinder arm gc2603

Constabulary replied to Lucie's topic in Leather Sewing Machines

post some pictures please- 3 replies

-

- instructions

- manual

-

(and 1 more)

Tagged with:

-

Looks like a drop feed Pfaff 34 or 134. The 34 has an oscillating hook, 134 has a rotary hook. Machine has reverse. No walking foot.

-

Durkopp 17-1-1 threading instructions

Constabulary replied to RogerChemel's topic in Leather Sewing Machines

maybe this video helps - if not send me a PM and I can send you a manual in English language. -

I have misread - you mean the shuttle (hook) not the shuttle race. There are large hooks and bobbins but they are not for the 45k. They f.i. came from Adler 204, or 205 and the like. I atm do not have a larger hook on hand but left is a 45K bobbin (approx 20mm dia), right the larger one (approx 24mm dia).

-

They are the same - if it appears larger then most likely the shuttle race is missing - but we have not seen pictures of your machine. I have a 91 subclass and the difference to the 93 (ex factory) is that the 93 comes with an extra roller foot IIRC.

-

Looks like a Juki 563 clone. Juki 563 are super reliable workhorse machines and have a super large bobbin / hook. Cannot speak for CHIKON but it at least is made in Taiwan as it seems. We have not seen pictures of your machine so we cannot judge it. Picture often tell more than words.

-

Binding Bracket vs Moving Arm

Constabulary replied to aslfkjaslfkjasflkj's topic in Leather Sewing Machines

Experience in therms of fixed or synchronized binder setups are different. I cannot speak for fixed binder position brackets but (1st picture) but I´m using a synchronized binder machine. And the bracket you show in the 2nd picture is governed by the special feed dog in which is a hole and a small "piston" (see red arrow) on the end of the extended left arm of the binder bracket goes into the hole. Thats the how it is governed. It has a spring loaded pivot point on the right and it be lifted and swing aside to easy access the bobbin / hook. The advantage of a synchronized binder is that you can bind smaller radius items cause the needle has always the same and very short distance to the binder. So it depends on what items you are binding but the synchronized binder is always (IMO) an advantage. Not saying other binders will not work. At the end the decision is your which you prefer and what items you are going to bind. But the synchronized version is IMO more flexible. My old and reliable Singer 108w20 has a synchronized binder and I love it. Having the right bracket for the job is one thing . The far more interesting "game" is finding the right binder for the binding material you wan to use! This can drive you nuts cause the binder and the binding material have to play together very well and you do not want much friction between binder and binding material. This is critical especially when using leather tape for binding. You find a lot of information on the binder topic here in the forum - do a quick google search: https://www.google.com/search?client=firefox-b-d&q=binder+site%3Aleatherworker.net%2Fforum%2F The information do not cover the Juki 1341 / Global WF 1575 in particular but the general information here are quite useful. If it was me I would buy the synchronized version but it will require a special feed dog and needle plate and a matching foot set. EDIT: text copied here: https://www.chholderby.com/industrial-binders/ I can´t explain the advantages of a synchronized binder any better. EDIT II: I once owned a Pfaff 345 with a very similar setup as for the Global WF 1575. Maybe some useful general information too - especially the video - see below thread. EDIT III: Since you are in the UK - maybe it´s worth checking with College Sewing - they have a wide range of binders. Not sure if they have the brackets but they have KH sewing equipment in general and they also sell JUKI´s -

this hook helps guiding the thread - nothing special just a "thread guiding device". Almost all rotary hooks have this in one or another style.

-

Without knowing your thread and needle size - I would try a 1 size larger needle

-

it has the hole in the casting from where you see the stitch length dial so it should a model with 2 push buttons. The 111 with stitch length knob near the hand wheel have 1 button in the bed but no hole. @Burkhardt here is a PDF of an old 111w brochure maybe it helps to figure the subclass (see box below picture). Looks like your machine is from 1940. Singer 111w Class Machine Brochure.PDF

.jpg.6422ae9ab716bec32f4be5da434696e9.jpg)