-

Posts

5,801 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

a singer 111w - subclass unknown but since it has no revere it may be 111w155

-

Junker & Ruh Sd28 Instruction Manual

Constabulary replied to celticleather's topic in Leather Sewing Machines

There you go SD 28 Junker & Ruh Outsole stitcher Parts list and manual.pdf -

https://www.consew.com/View/Consew-Model-227R-2

-

well, it´s not impossible to buy and run American made sewing machines only - you have to look for them, maybe travel, and sometimes have to rebuild them. But they for sure al will be vintage. I for a reason only use vintage Singer sewing machines (made in the US, UK and Germany). But when it comes to certain spare parts China is the only source for spares (at least for me living on the other side of the pond + BREXIT). Some parts are interchangeable with non Chinese Brands (always a big pleasure for me to figure that) like some older Dürkopps and CLAES are based on Singer - even some Pfaffs are using Singer based parts (very few but still)... But thats a different story If you want SEIKO machines look for a SEIKO dealer in the US (scroll down here) https://www.seiko-sewing.co.jp/en/worldwidenetwork/ But I´m not sure if all SEIKO´s are still made in Japan

-

I´m sure when the machine does not clearly state made in Japan - then it is is not made in Japan. Buy a Dürkopp-Adler and it most likely will be made in the Czech Republic in the Minerva Plant (top Quality BTW). Even some JUKIs come form China I have read somewhere. China not my preferred "source" for goods but as mentioned before - you cannot run away from it. And I bought a lot of CHICOM sewing machine spare parts and have to say the quality in most of the cases was really top - way better that expected for the price.

-

Leather Supply Companies - Good and Bad?

Constabulary replied to Gulrok's topic in Leatherwork Conversation

If I had to "redesign" the logo, I would do away the Est. 2022 (to early as Klara said), I would use stars with peaked tips instead of rounded and I would use a more pronounced, lets say ribbon type banner like this or similar: https://www.pngmart.com/de/image/138917 -

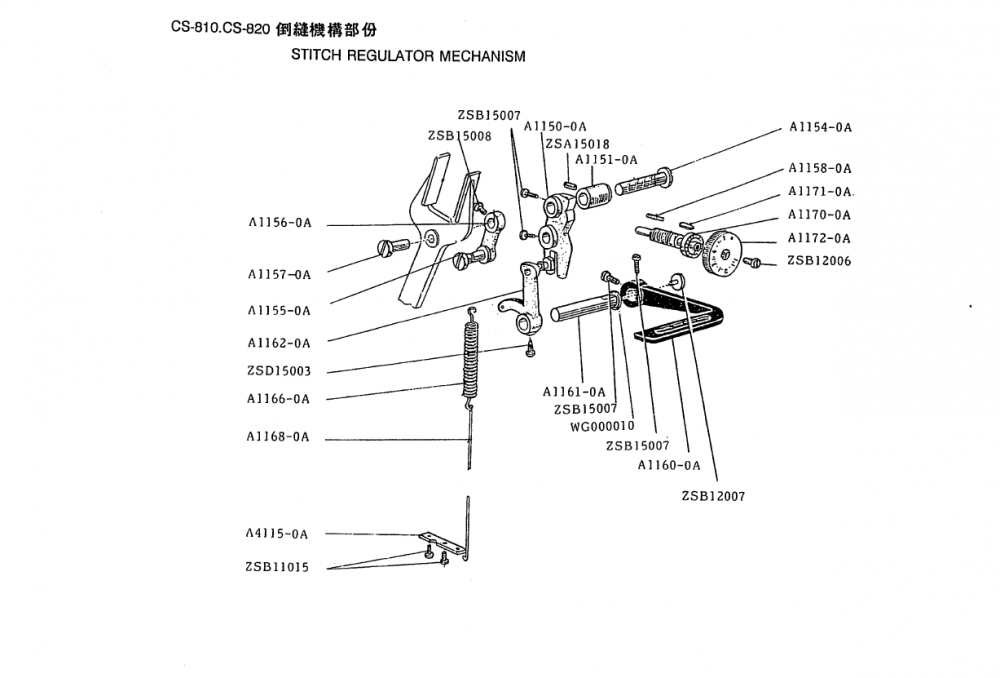

when looking at the parts list I would say no, not ex factory. If the return spring was a pull up spring it would be easier. But maybe you can drill a hole in the table plate )maybe with a little metal tube inside) on the right side of the machine and attach a wire to the reverse lever and foot pedal - see 2nd picture. I´d make the wire on the reverse lever detachable so you can tilt back the machine when needed. Just an idea.

-

when your Pfaff is using 134-35 - why not setting up both machines for that needle system? You only have to stock 1 needle system (it´s cheaper on the long view) and don´t have to worry to mix up needles (it happens). BTW College Sewing has 134-35 LR in 180 and 200 https://www.college-sewing.co.uk/needles/groz-beckert-industrial-needles/134-35-groz-beckert-needles/134-35lr-groz-beckert-needles https://www.college-sewing.co.uk/needles/schmetz-industrial-needles/32-10-134-35-schmetz-needles/schmetz-134-35lr-leather-point ARMASTORE in Latvia has 134-35 LR in 180 at a super price for 100 needles: https://armastore.eu/134-35-rtw-lr-singer-needles-pack-of-100 Other than that STRIMA in Poland has 135x16 with DIA tip in 180 and 200: https://de.strima.com/items?query=135x16

-

I´m pretty sure Toledo Industrial Sewing Machine (CowboyBob) can help you out - see above post. @ Bob my 212G has no spring stop on the TU - I have the curved metal spring stop on the casting.

-

What machine are you using that you need such a big needle size in 135x16? Are you sure the machine can handle the thread thickness you need for a 180 or 200 needle? Anyway - as an alternative needle try to locate 134-35 needles with leather tip - same shaft size but just s a bit shorter than 135x16. Only thing you have to do is lowering the needle bar.

-

Bob, I´m not sure but the weren´t just the Japanese made 211 (211U...) equipped with the check spring stop on the tension unit. Not sure though but my needle feed 212 has no spring stop on the tension unit I have the curved piece mounted to the casting I recall that I added the curved metal spring stop to the two 211U566 I worked on cause I did not find one with an "integrated" spring stop.

-

It´s not an OEM part, do not expect OEM Quality and when I look at the Amazon reviews - seems sometimes they do not fit. I bought this one twice (not OEM quality either) and both fit an work (at least on the 211U566 I worked on): https://www.ebay.com/itm/143413567310 But you can get just studs from good sewing machine dealers too but I do not know how much they are - can´t be much. Don´t know which is bent but tension stud is 201224 and regulator stud is 201199. If you buy them from Ebay I would buy new nuts too and when possible from the same dealer - or check with a known sewing machine dealer.

-

Searching for a 3/8” gauge set for Mitsubishi LT2-230

Constabulary replied to pgc's topic in Leather Sewing Machines

https://www.tolindsewmach.com -

Searching for a 3/8” gauge set for Mitsubishi LT2-230

Constabulary replied to pgc's topic in Leather Sewing Machines

I don´t know how your machine looks or how it is setup (maybe with bells & whistles?) but usually you can raise the presser foot bar. The position of the screw holes may look different cause the needle plate is wider at the 3/8 plate. Hard to tell from the picture but the feed dog height should be measured from the bottom side of the screw hole and not from its bottom end. But again I only can guess cause I´m not in front of your machine. Keep in mind that you have to move the two hook saddle sideways when using the 3/8 gauge. BTW - this was my Singer 212G141 project. -

Searching for a 3/8” gauge set for Mitsubishi LT2-230

Constabulary replied to pgc's topic in Leather Sewing Machines

that to me looks like a plain 212 set, foot looks a bit different but I would give the 212 set a try. They do not cost much on Ebay or so. EDIT: when I look closer I think the needle plate underside is different - I guess because of the thread trimmer knife. BTW - the needle plate may have a longer cut out for the feed dog. The 212 I have just has 5 SPI and I guess your may have a longer stitch length. Not sure though. But that could make a difference too. -

Searching for a 3/8” gauge set for Mitsubishi LT2-230

Constabulary replied to pgc's topic in Leather Sewing Machines

can you post a picture of your gauge set so we know how yours looks like and compare it with a 212 gauge set. maybe it´s just a minor difference and the 212 set can be modified. Just a guess. -

Maybe I do not understand your setup (no offense). So you run a compressor to air power a vacuum pump that sucks up the leather remnants? If it was me I would use a electrical vacuum cleaner like one of these 30-40 bucks ash / oven vacuums. Know what I mean? I think thats more effective - or not? https://www.lidl.de/p/parkside-aschesauger-pas-1200-f5-18-l/p100335698 Or a cheap wet / dry vacuum https://www.lidl.de/p/parkside-nass-trockensauger-pwd-12-a1-inkl-3-teiligem-saugrohr/p100348045 You may find them in local classifieds for 1/2 the price or so.

-

Maybe its me but I do not understand the relation between compressor and vacuum pump for a skiver - isn´t a vacuum cleaner (kind of) what you need to suck up the leather remnants? Maybe one of these ash or oven vacuums is what you need.

-

For me it looks like the needle bar is set way to low. Are you sure you are using the same needle system / same length needle as before? If so then something is seriously wrong. In the pictures the needle tip is where the feed dog supposed to be mounted. So how does it get there - only reason is a too long needle or a too low set needle bar. Not speaking about the needle hook timing but thats something you should check. I guess you have a proper manual for your machine so the needle hook timing should be mentioned in it. Here is a JUKI 341 manual (same machine) Juki LS 341.pdf

-

No one knows what a certain dealer has in stock so its either trial and error or you buy from a dealer who provides the bobbin measures. The 9033 is quite a standard bobbin that fits for a lot of different Pfaff machines. This looks promising to me: https://www.etsy.com/de/listing/809301592/cutex-pack-of-28-metal-bobbins-9033-for

-

111G and 111W are basically the same - 111W was made in the USA and 111G was made in Germany. So what ever you find for the 111W works for the 111G as well.

-

that depend on your machines subclass and the size of the needle hole in the throat plate and how the whole machine is set up but reg. the Pfaff website the current 1295 takes 110 - 150 needles so 138 should be possible and maybe (maybe !!!) 207 but thats something you have to try. Earlier models may not exceed 138 but again it depends on how the machine is set up. https://www.pfaff-industrial.com/en/portfolio/sewing-machines/post-bed/pfaff-1295 Needle thread chart: https://www.tolindsewmach.com/thread-chart.html

- 2 replies

-

- industrial sewing

- pfaff 1295

- (and 4 more)