-

Posts

5,801 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

No - that's a different screw the screw I mean is internally. its a large slotted screw. The red arrow points where the hole is & and on 2nd pic where the screw is. You probably have to rotate the hand wheel to see it. Not my machine its a pic from the www. This is mine I restored it in 2016. Different subclass but basically the same machine and it works perfect ever since. https://leatherworker.net/forum/topic/72789-singer-45d91-restoration/ Have you noticed the question above? When the machine is in reverse (lever all the way up in the slot) is the feed dog touching the needle plate in the longest stitch length when turning the hand wheel?

-

Maybe it´s because of wear. Is your limiter screw present (see red circle)? First I would check if the screw that attaches the stitch length adjuster / reverse lever to the casting is tight. You reach the screw through a hole in the casting right under the top shaft / behind the hand wheel. You probably have to remove the hand wheel first. Also, when you dialed in the longest stitch length is the feed dog touching the needle plate in reverse when you rotate the hand wheel? Post some pictures of your machine please.

-

I make a turn when the needle has risen and I leave just the needle tip in the material (needle eye visible) and I lift the foot just enough to give the material free like 2mm above the material so I have no tension release. On my 111G156 I also have adjusted my tension unit the way that it releases very late meaning it only release when the foot lift lever is in its upmost position. That ensures I have no tension release when seeing very thick materials. If you are using a foot lift pedal make sure your foot does not rest on the pedal. My 2 cents here.

-

keep in mind - the UK no longer is in the EU so for everything you import from the continent or elsewhere you have to pay 20% VAT + tax on top. I don´t know the 669 but I assume the binder brackets are the same as for the 69 https://www.college-sewing.co.uk/parts-by-machine/durkopp-adler-parts/durkopp-adler-69-parts?p=4 I would check with College Sewing, they sell KH binder and stuff as well. When the UK was in the EU I ordered everything from them (I´m in Germany). When ever I had a question I was in touch with Justin -->> Justin[at]college-sewing.co.uk

-

Needle and thread for my Singer 29-D-58

Constabulary replied to zzrguy's topic in Leather Sewing Machines

BTW - often the Singer "D" machines from Wittenberge, Germany have a decal instead of a brass badge. But the decals are often rubbed off. However the decal looks like this bras badge here and says "Fabrik Wittenberge". -

Needle and thread for my Singer 29-D-58

Constabulary replied to zzrguy's topic in Leather Sewing Machines

Not Persia - I´m sure she said Prussia The German Singer factory back then was built in Prussia (Kingdom of) but K.o. Prussia is history since the German revolution in 1918 (to make it short but story continued). Nowadays it is located in the Federal State Brandenburg. Before loosing too many words this may be of interest for you: https://www.singersewinginfo.co.uk/wittenberge Some of the factory buildings still exist and I have visited the location in 2019 and posted some pics in the below linked thread: -

Help identify Dürkopp cobbler machine

Constabulary replied to Lasse's topic in Leather Sewing Machines

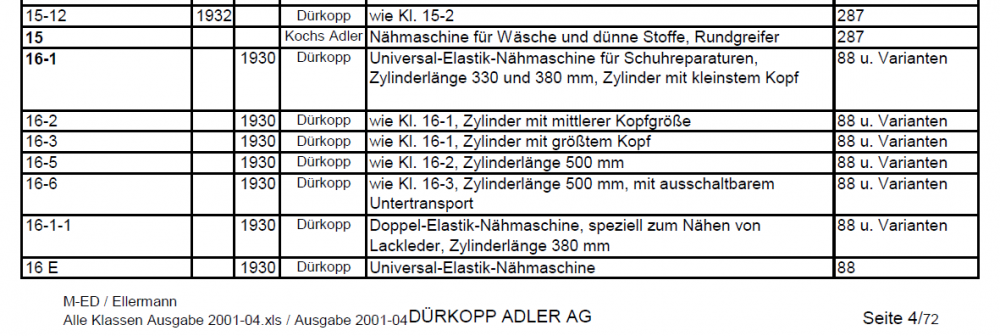

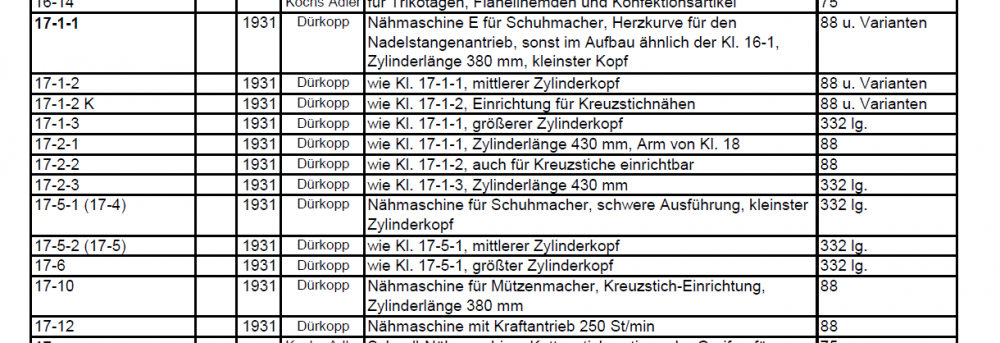

I have a class 17 parts list and the gear driven winder is shown in the list so I guess certain sub classes have this type of bobbin winder. I haven´t seen a model 16 either (meaning one that is clearly marked as model 16) but the historical list of Dürkopps & Adlers clearly shows a Dürkopp model 16 as cobbler machine. Maybe (maybe!!!) we ID some class 16 as class 17 cause differences are not known and the 16 has many similarities with the 17. But as long as there is no clear model number mentioned on the casting I only can guess. So I really do not know... Maybe SHOEPATCHER knows more Extracts from the list: -

Major difference IMO is just the casting. On the later model they covered whole mechanism on the rear side whereas it is visible / easier accessible on the earlier models.

-

Help identify Dürkopp cobbler machine

Constabulary replied to Lasse's topic in Leather Sewing Machines

What I can say for sure it is not a Model 18 cause the 18 had a static boat type shuttle (see link in Wiz´s post) I would say Dürkopp 17 (elastic / oscillating shuttle) however Dürkopp also had a Model 16 that they did not continue in 1930 so it could be a 16. Meaning it could be a predecessor of the Model 17. But to be honest I do not know the differences in particular. But the later 17 had a different needle plate and tension unit - not sure if that alone makes yours a model 16. -

Needle and thread for my Singer 29-D-58

Constabulary replied to zzrguy's topic in Leather Sewing Machines

Wiz, no 29D58 could be correct - because some 29 models were made in Wittenberge, Germany prior 1945. But they are the the exact same as K models made in Killbowie, Scottland. Usually the German made Singers serial numbers (prior 1945) start with a C. -

my spool holder has no bearings and is not causing drag issues. It´s an old ADLER all metal made model and the spool core is sitting on a tube that spins around plain round shaft. Never tried something else as it always worked well. College Sewing in the UK has some tape racks: https://www.college-sewing.co.uk/accessories/chair-stands-table-tops/tape-racks Maybe worth checking with them because of binders. Maybe they know a source in the UK for custom made binders or can even offer one that suits your needs (don´t know). https://www.college-sewing.co.uk/folders-attachments

-

these Co´s are in Germany: https://www.np-z.com/sonderbau https://www.grau-apparatebau.de/produkte.html BTW - Dürkopp Adler is offering attachments / special solutions too: https://www.duerkopp-adler.com/products/specialized-solutions They have a catalogue: https://www.duerkopp-adler.com/fileadmin/dag/Media/Doc/Branches/additional_equipment_catalogue_2021.pdf But I´m sure they offer other special solutions too but they wont be cheap

-

You need a presser foot set that suits the needle plate (throat plate) and feed dog. Binding with 1mm thick leather is special - leather is causing more friction between the binder and the binding material (leather tape in your case) than f.i. nylon or cotton webbing does. You need a binder that suits your chosen biding material. And that is the main problem. Most (not all) binders you find online are not really meant for using thick leather as biding material but it depends on the binding material thickness (because of the friction). Right angle (90°) raw edge binder are causing more friction than 45° binder or inline binder. When the friction between binder and binding material is too high you will have a stretch effect and that will ruin your project. Maybe its worth considering thinner leather tape like 0.5mm or so. You can try to find cheap binders online (trial and error) or check with attachment companies like Atlanta attachments (or similar Co´s in the UK) and they will make a proper binder that suits your chosen binding material and your machine but that will cost you big $.

-

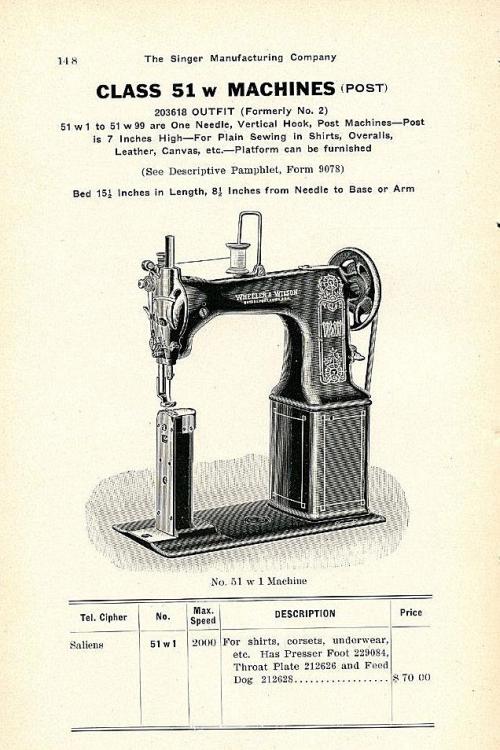

Singer 51W SV 2 Post Bed Machine Restoration

Constabulary replied to Constabulary's topic in Leather Sewing Machines

-

Pfaff 145 H3 Squeaking Handwheel

Constabulary replied to ethereal's topic in Leather Sewing Machines

I would remove the V-belt on the machine pulley and try again. Still squeaking? If not maybe then its the motor brake or the V-belt. You know how the motor brake works? -

Left Stand Singer 45K Variant → Singer 145K1

Constabulary replied to Constabulary's topic in Leather Sewing Machines

-

Left Stand Singer 45K Variant → Singer 145K1

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Update. Its assembled again. Not entirely happy with the paint but well, it looks better than before. I just striped the paint of hand wheel and added a Singer badge. Presser foot was missing now it has a new one and I replaced the spool pin with a new chromed one. Upper tension unit is replaced too and I added a new thread guide. -

Old factory sewing machine stand, or not?

Constabulary replied to trash treasure's topic in Leather Sewing Machines

-

Old factory sewing machine stand, or not?

Constabulary replied to trash treasure's topic in Leather Sewing Machines

yes, stands like this were used by Singer, Adler and so forth. I have one from a Singer 7 but but just the 2 outer parts. This will be my kitchen table one day (kicking this around for 3 years or so) But it would not surprise me if they were used in other plants as well. I shot these pic in 2016 when I visited a Museum in Bielefeld (Home of Dürkopp, Adler, Phoenix and other sewing machine brands) -

Improve Look Of Back Side Of Stitching

Constabulary replied to Kcinnick's topic in Leather Sewing Machines

overstitcher.... you learn something new everyday. That really is interesting. Will check them out... Thanks a lot for that hint. -

I think that may be the 45K25 that came with a roller presser. AFAIR the 21 was a plain presser foot. I think you are right - my bad

-

so you do not get #10 into #13, right? It pretty much is the same on all rotary hooks (vertical and horizontal). I would hold #10 (bobbin case base or basket) by the small center post push it slightly against #13 and either rotate the hand wheel or the bobbin case basket it self until it falls into the race then rotate a bit more and the bobbin case should be in place again. Can be a bit fiddly... The needle hook timing should be mentioned in the manual. You can download it here: https://www.consew.com/Resources/

-

depends on condition, if motorized, if with stand or just the head, what accessories are included... some pictures may help. The 45K21 came ex factory with a roller foot. If it is included it is worth $80-100 alone.

-

Problem with reverse stitch tightness on Singer industrial

Constabulary replied to AlainaZ's topic in Leather Sewing Machines

I would check the foot bar height, make sure it has full contact with the needle plate when lowered. I would also check the height of the feed dog (maybe set too low?) and the condition of the under side of the presser foot as mentioned before. My 2 cents- 6 replies

-

- industrial machine

- tension problem

-

(and 1 more)

Tagged with:

-

The 26 is based on a Nakajima / Juki 341 AFAIK so this could helpful if Leather Machine Company has none: Juki_LS-341N_Engineers_Manual_compressed.pdf Nakajima-321L-341L-Parts_compressed.pdf