-

Posts

5,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

For me it looks like the needle bar is set way to low. Are you sure you are using the same needle system / same length needle as before? If so then something is seriously wrong. In the pictures the needle tip is where the feed dog supposed to be mounted. So how does it get there - only reason is a too long needle or a too low set needle bar. Not speaking about the needle hook timing but thats something you should check. I guess you have a proper manual for your machine so the needle hook timing should be mentioned in it. Here is a JUKI 341 manual (same machine) Juki LS 341.pdf

-

No one knows what a certain dealer has in stock so its either trial and error or you buy from a dealer who provides the bobbin measures. The 9033 is quite a standard bobbin that fits for a lot of different Pfaff machines. This looks promising to me: https://www.etsy.com/de/listing/809301592/cutex-pack-of-28-metal-bobbins-9033-for

-

111G and 111W are basically the same - 111W was made in the USA and 111G was made in Germany. So what ever you find for the 111W works for the 111G as well.

-

that depend on your machines subclass and the size of the needle hole in the throat plate and how the whole machine is set up but reg. the Pfaff website the current 1295 takes 110 - 150 needles so 138 should be possible and maybe (maybe !!!) 207 but thats something you have to try. Earlier models may not exceed 138 but again it depends on how the machine is set up. https://www.pfaff-industrial.com/en/portfolio/sewing-machines/post-bed/pfaff-1295 Needle thread chart: https://www.tolindsewmach.com/thread-chart.html

- 2 replies

-

- industrial sewing

- pfaff 1295

- (and 4 more)

-

The purpose of left stand sewing machines

Constabulary replied to Constabulary's topic in Leather Sewing Machines

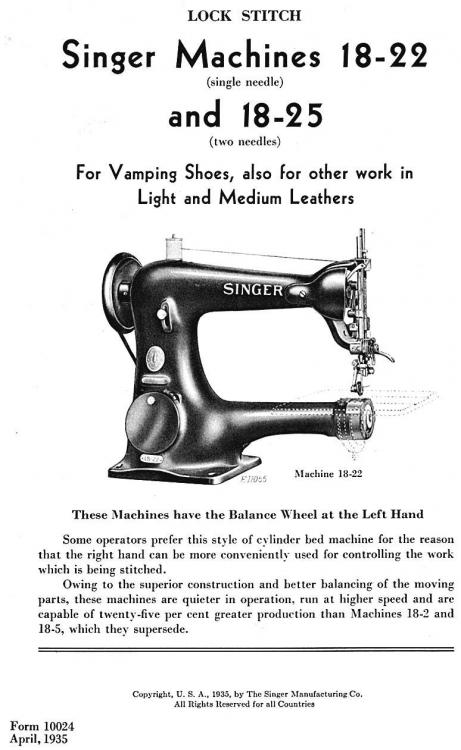

Some info that I found in a technical description of a Singer 18-22. Looks like left stand machines exist because of "operators preferences" but not because of "sewing technical reasons". Thats at least how I read it. -

Schmetz explains it better than I could: https://www.schmetz.com/en/industrial-needles/needle-compass/round-points/ https://www.schmetz.com/en/industrial-needles/

-

B is medium weight material. To Pfaff specs this means needle NM 80 - NM100 but I´m sure you can use 120 as well (just try) and maybe a more coarse toothed feed dog compared with the A Model. So nothing special for heavy duty. S is for the zz needle hole width (4.5mm). Don´t let sub classes on the tag mislead you. It´s a plain 138 garment / tailor sewing machine with 4.5mm Zig Zag. As far as I can tell a tension spring and nut are missing as well as the 2 thread guides on the face plate and on the needle bar. 138 came with different needle bars. I think the thread guide here was just a piece of bent wire held by 1 screw on the needle bar but I´m not sure.

-

equivalent is the Singer 95 or 95K

-

When I bought my 212G141 (same style take up lever but with 2 holes) I figured the lower part (lets say the "slide tube") is bent. I had a hard spot when turning the hand wheel. It took a lot of time to figure that. I had to remove the needle bar rock frame and stuff and when the take up lever was out it was smooth again. Ordered a new take up lever from College Sewing UK installed it and I was back in service. I have no idea how this thing can bend but it was! Not sure if you have the same issue - hard to tell from a distance

-

Not sure what you mean with small stitches in regard to the edge guide... However it maybe be better to use a drop down guide which you can adjust sideways and in height. Like this one here: https://www.ebay.de/itm/143603133045 it mounts to the backside of your machine and you may need an adapter for mounting it (requires drilling and taping t

-

I have no 97 (unfortunately) but some Singer 7 and Seiko SLH 2 have a similar part - not sure if it will fit but I just wanted to give this hint: https://www.college-sewing.co.uk/35141-inner-presser-foot-seiko-slh2b-use-with-outer-foot-35096-genuine.html Maybe this helps - maybe not.

-

No thats why I put it in quotation marks. Sometimes folks that come from domestic machines (you never know) have a different view on sewing machines and the industrial sewing machine world can be different to what they have experienced so far (sometimes). I just wanted to give a hint where you can find information on old Singer industrial models.

-

Too many different questions fro just 1 thread I think. I run 2 750W JACK servos (same as yours but with more power), on both I have a 40 / 50mm pulley installed and also a 1:3 speed reducer. I guess yours still has the original 75mm pulley so I would replace the pulley with a smaller one (easy task usually). You find them on Ebay quite cheap (come from China) - BUT - these pulleys have a 15mm bore some JACK servos come with a 13mm and some with a 15mm bore. If yours has a 13mm shaft so can use a piece of 15mm tube with 1mm wall to adapt it. You can also make adjustment on the starting speed. 500rpm is the lowest you can set BUT the motor will actually start at 200rpm (shown in the display) - at least my 2 JACK servos do. cheap small pulleys: https://www.ebay.com/itm/323356609027 Motor speed adjustment: https://www.youtube.com/watch?v=hi09g49JksA Speed reducers can be DIY made from some simple parts or you can also buy them from certain dealers. Not sure what sources you have in France but in Germany you can get them from SIECK. They sell internationally and they speak English. https://www.sieck.de/en/machines/sewing/shoe-upper-sewing-machines/diverse-machines/?produkt=9237 But as mentioned before with a speed reducer installed the needle position will not work any more however the machine can be run very slow then and you don´t really need a needle petitioner. But depends on your preferences. I don´t need the NP. Find more info about all kind of speed reducers here: https://www.google.com/search?client=firefox-b-d&q=speed+reducer+site%3Aleatherworker.net%2Fforum https://www.google.com/search?client=firefox-b-d&q=speed+reducer+site%3Aleatherworker.net%2Fforum Other than a speed reducer you can do what TOXO did (see above). Also a question of preferences but both speed reducer or larger hand wheel work well. The foot pressure on the 239 will be adjusted with a knurled screw in the center of the top of the machines - same as on Singer 111. The 239 Dürkopp has a lot in common with the Singer 111 but certain things are different. If you need a manual for your machine you can use the Singer 111G156 manual partially (as I said it has a lot in common but is not the same) - other than that I can send you a Dürkopp 239 manual in German language if that helps. Depends on your project. Usually a smaller bottom thread is used when you have problems with centering the thread knot in the center of the material but IMO thats a very rare occasion and mainly is when you sew thicker or dense (or both) materials but it depends. In lets say 90% of the cases I use the same thread size top and bottom. I rather go up with the needle size than using a smaller bottom thread. It just depends... Usually the needle entry hole (on the top side) looks better / cleaner than the needle exit hole (on the bottom side) so it may depend on your project. But I would generally sew from the side where the seam is visible on the finished product.

-

But you have to be able or at least be willing to help your self solving some machine issues. Making something out of nothing is the biggest pleasure for me. 2nd what Shoepatcher said - basically both are triple feed machines and use the same type of hook. Advantage of DA machines IMO is that they offer a lot of special application accessories for their machines ex factory. At least they did in the past. Not sure what is still available for the 205 which is obsolete now AFAIK. BTW - Dürkopp took over Adler and the Co. is now Dürkopp-Adler so DA is not a clone of Adler.

-

you can also use round point needles for certain leather work. Especially for lighter leather. So basically any system 16 / 1738 / DBx1 / 287 needle will work in this machine.

-

@LatigoAmigo

-

Just noticed your "profile"... Yeah then rather an embryo compared with a landis #1 Singer 16 usually use System 16 needles - don´t care a bout the number behind the 16 too much, they describe the needle tip usually. Same needle is the system 287 or DBx1 or 1738 https://www.organneedle.com/industrie.php?p=DBx1&v=produkt&l=en https://www.sailrite.com/Needles-DBx1-Serv7-10-Pack-10 EDIT: I had edited my 1st post (see above)

-

there was a 16-26 on Ebay classified in Germany a while ago: https://www.ebay-kleinanzeigen.de/s-anzeige/singer-vintage-naehmaschine-model-16-26-sehr-selten-/2079646970-240-23414 IMO a plain class 16 with most likely just difference accessories ex factory (thats how the sub classes differ most of the time) so nothing really special on the machine it self but maybe others know more. A relatively "small" beast in the industrial sewin machine class - you most likely have not come across a Singer 45K or 132K yet In the "Singer Industrial World" you find a lot of information regarding the sub classes in the parts list of the models. If you can´t find a 16 parts list look for 16K Parts lists (same machine just made in the UK and not US)

-

Adler 4, 104, 5, 105 (jump foot versions) used similar feet but they are as rare as the Singer 45K feet. I had 20 or so different feet (Singer and Adler) but sold most of them some weeks ago cause I never used them. I have 5 left but I have no chance to check if they suit the 45K58 in particular cause some feet require certain feed dogs. I have two I could part with but said said not sure if they fit the 45K58. a left and right toe foot - kind of.

-

Looks like an Adler 199 Zig Zag garment / tailoring machine. Do not expect to find many parts. Machine is using a timing belt. If its bad or missing you are most likely screwed (if it doesn`t share the timing belt with other models but I don´t know). If you have pleasure in tinkering I would probably buy if for 30-50 bucks. Looks like hinges, V-Belt and bobbin winder are missing (if not inside the drawer). Maybe you can use the table and thread stand for another machine - just depends... I have a manual in German langue if it helps. Send me a PM with email address so I can send it.

-

@SewingFeatures are you an Amazon affiliate link spamer? "Brain MIller" sometime is Leon V. or Victor Fiori on linkedin or Eli Bawer on twitter or Victor Mosheyev on soundcloud - at least they share the same avatar picture Sometimes you find testimonials (f.i. Peter Kartscher) with this avatar picture too. Mods - please scroll down to the end of the linked site and check the disclaimer. We had similar link spamers in a German Forum a while ago.

-

sewing some pieces of 10mm thick leather together and producing a certain leather good are two different things. The 220 series usually have 20mm foot lift so 10mm should be no problem. I´d recommend to test the machine before buying. If the motor is too fast you probably want a new servo motor and maybe a speed reducer in addition.

-

basically it depends on the work you want this machine for / what kind of leather good you want to sew / produce. Meaning the question should be what is the right machine for what I want to sew (the right machine for the job)

-

Best beginner sewing machine for making leather goods.

Constabulary replied to RockyAussie's topic in Leather Sewing Machines

Will it? With 207 thread - maybe? Not defending Adler (really not) but the needle <-> edge of throat plate distance is a question of what throat plate and feed dog you have installed. Adler and Pfaff offered a wide range of throat plates and feed dogs - nowadays availability of these parts is the question or how the machine is set up and what subclass. BTW - since you have the DCS-246 and the Adler 69 - have you tried if the feed dogs and needle plates are interchangeable? Would not surprise me.