-

Posts

5,801 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Manual for my global post bed machine

Constabulary replied to miker's topic in Leather Sewing Machines

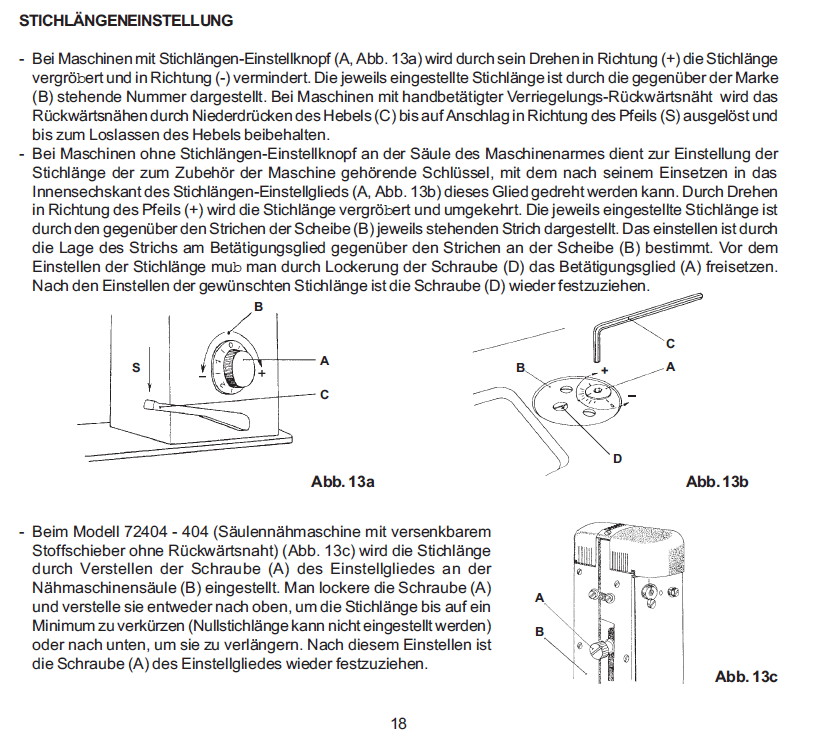

I found something: You have to loosen Screw D before you adjust the stitch length and tighten again when done. -

Manual for my global post bed machine

Constabulary replied to miker's topic in Leather Sewing Machines

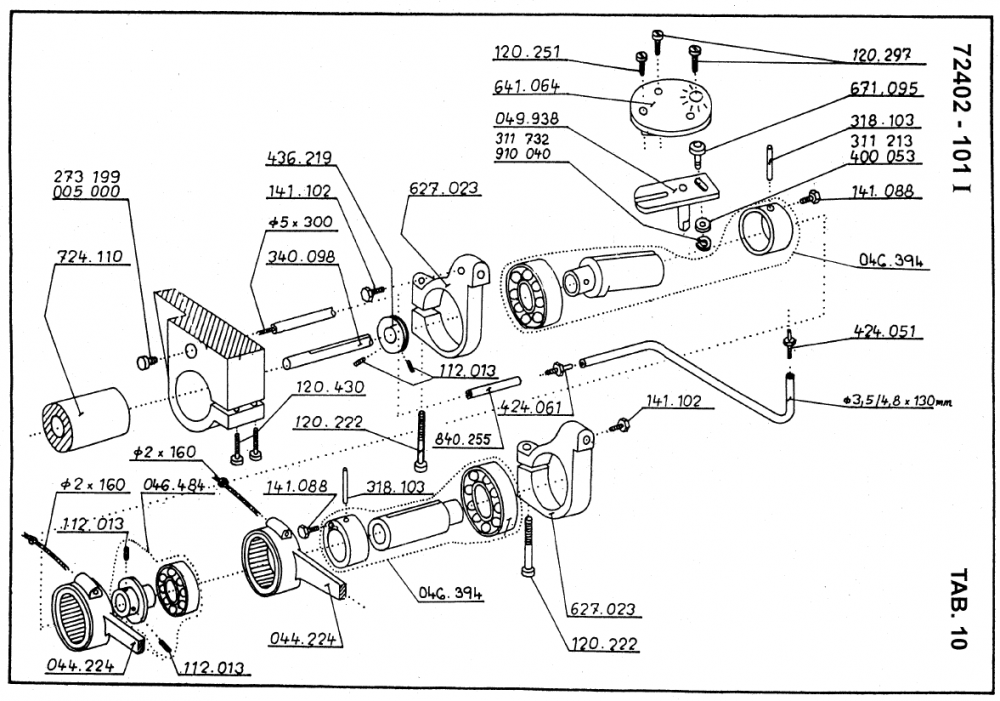

see above post, I just edited it. Maybe the parts lists help to figure the function. Or maybe the REXEL Co. can provide a manual. I´d check with them. This is from a list I downloaded -

Manual for my global post bed machine

Constabulary replied to miker's topic in Leather Sewing Machines

I would tilt back the machine and check what the allen key is doing... EDIT: You can download parts lists here. Maybe they help you to figure the function. https://rexel-com-pl.translate.goog/content/33-katalogi-minerva?_x_tr_sl=auto&_x_tr_tl=de&_x_tr_hl=de&_x_tr_pto=wapp -

you will not find many oz measures in the EU. Grams per meter or square meter is more common. https://www.esvocampingshop.com/de/outdoorstoffe-zeltstoff/baumwolle/ https://www.stoffkontor.eu/stoffe/canvas/ https://www.stoffe-zum-leben.de/köper-canvas-segeltuch-zeltgewebe/

-

So how much speed reducer reduction will this motor / needle positioner now accept? 1:2, 1:3 or even more? Does it matter how big the motor pulley is? Usually these motors comes with ~75mm pulley but most LW swap it to 40-50mm pulley. I´m just a user but not an electronics geek so this question may sound stupid (maybe not). Is there (probably) a way to adjust the "reduction acceptance" (I have no other word, sorry) in the motor management menu? That would be a great feature.

-

looks like a plain drop feed sewing machine but a blurry 7 second video is not very helpful to clearly ID a sewing machine. Do you have a link to the full length video? BTW I would open a new topic for this request cause this clearly is not a 441 type leather machine

-

You are using a fairly thick needle for a fairly thin thread as it seems. Check this needle thread cart for finding the right needle / thread size combination: https://www.tolindsewmach.com/thread-chart.html This is a GA5-1 Chinese made machine - basically a modern version of the Singer 45K Here is a manual and parts list, hope this helps : 06_Techsew GA5-1 manual.pdf Techsew GA5-1 Parts.pdf

- 7 replies

-

- neels saddlery

- tension problem

-

(and 1 more)

Tagged with:

-

Manual for my global post bed machine

Constabulary replied to miker's topic in Leather Sewing Machines

Global was probably the seller / distributor of this machine but not the manufacturer. They also sell used machines. I would assume a Minerva 72401, 72405 or something in between. EDIT: kinda like this one (scroll down): https://maszynyobuwnicze.wordpress.com/maszyny-szyjace-2/ -

Cobra class 4 reverse issues

Constabulary replied to StoneBuiltKnives's topic in Leather Sewing Machines

lowering the needle bar just a tiny bit sometimes helps EDIT: BTW maybe this video by LW member UWE helps to figure issues with reverse: -

Sewing leather onto polyester

Constabulary replied to experimentswleather's topic in Leather Sewing Machines

We do not know the robe or the size of the piece or thickness of the leather or what it should look like when finished but generally sewing a thin layer of what ever onto a piece of leather should be technically possible. Why not? -

We do not know how your machine is set up and if you have a circuit breaker on your machine or not. No matter what when you leave an (especially older) electric deceive plugged in I would recommend a circuit breaker or a power strip equipped with one.

-

How to remove/replace bobbin without removing what I'm sewing

Constabulary replied to CitroenLVR's topic in How Do I Do That?

So when your bobbin is empty and you replace it you have to pull up the bottom thread, right? How would it work w/o removing the work? EDIT: Huh - looks like the guy in this video does NOT pull up the bottom thread when he starts sewing with his 205RB (Minute 10:00 onward) https://www.consew.com/View/Consew-Model-205RB-1 Interesting - seems to be working. Not sure why but looks like it does. So when looking at the Video I would assume you just change the bobbin as shown and go on with sewing. Seems there is no need to pull up the bottom thread on this machine - for what ever reason. -

Tax and customs when buying from Goods Japan

Constabulary replied to ScottEnglish's topic in Suppliers

I´m late to the show here but in case you buy the goods on Ebay then (usually) Ebay charges you the VAT automatically and in some cases even the import tax and forward it to the Gov. Then your seller gets a code he has to write on the address label so the carriers know VAT / Tax is paid. Thats at least what I experienced. Like Ebay or not but when it comes to international purchases Ebay often the easiest way to buy goods from foreign countries. Check this: https://www.gov.uk/guidance/vat-and-overseas-goods-sold-directly-to-customers-in-the-uk -

guessing it is Tennessee Attachment Co. Inc. https://www.tnattachmentco.com

-

Interesting Mitsubishi Cylinder Arm

Constabulary replied to nycnycdesign's topic in Leather Sewing Machines

yes, looks like a darning machine. -

Weekend find : 45k25 plus accessories

Constabulary replied to Damas's topic in Leather Sewing Machines

Nice find! Roller feet are sought after and accessories are always priceless! I guess #5 is for folding leather strips for reins but I only can guess. Do you know in what kind of leather business this machine was used? Maybe the products they made can give an idea what #1 and #5 were used for. Maybe the 2 bits are custom made but when you browse through the parts list of other 45K machines (different sub classes means different accessories) you sometimes see obscure accessories so that probably is a good source to figure what you have. -

The speed reducer probably is the best solution for you. It ads torque and slows down the sewing speed. So at very slow speed you are still able to sew quite very thick materials (depends on your work and material if you need that or not). I have speed reducer on ALL my industrial machine tables / stands.

-

I do not recall everything cause it was some years ago when I restored. I´m sure everything was apart except the top shaft. I think when you remove the handle there is a set screw behind it... But not I´m really sure... Looks like your foot is stuck in the upper position have you tried applying more foot pressure?

-

sorry can´t tell from the Video - but some years ago I restored a Dürkopp 18 (no longer have it) but maybe you can see something in the pictures from my restoration or the pictures other have posted and the video in this thread: https://leatherworker.net/forum/topic/76826-dürkopp-18-patcher-restoration-long-journey/page/2/ https://leatherworker.net/forum/topic/76826-dürkopp-18-patcher-restoration-long-journey/?do=findComment&comment=517817

-

I do not know the the size but if it is easier just tap a new thread - I´d go that way if you have the tools

-

Its better when you post pictures of YOUR machine. Front and back and some more pictures of "around the head" so we can see the details better and if something is missing. If you can shoot a video and upload it to youtube it would be even better but not just a 5 second video, take your time and make a proper Video - if possible.

-

I have the leaf spring and maybe some other bits if needed. I`ll send you a PM. Your pics are small and I cannot see details very well but the racks and pinions should be aligned like this to work properly. This is from a Adler 30 but Singer 29K are similar.

-

Consew 146RB-1A pneumatic presser lift

Constabulary replied to ElFishbone's topic in Leather Sewing Machines

maybe you should post pictures of your machine and the "parts situation" cause industrial sewing machines are often set up / equipped in different ways.