-

Posts

5,801 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Balance wheel rotation direction of singer 45k14

Constabulary replied to ddiuni's topic in Leather Sewing Machines

So far all fur sewing machines I have seen run clockwise meaning truing the hand wheel away from you. KGG already mentioned it - see section HINTS (page 7) In operating the machine always tum the wheel from you. you also have a hint on top of page 6 when operating the machine the balance wheel should turn from you. You can change the the rotation direction of certain sewing machine motors. Your Singer motor looks like what we call an "Anlasser Motor" in Germany. I think you have a stack of metal prongs in it that make contact when you push down the lever on the right / the foot pedal. The more prongs make contact the faster the motor runs. But it also could be that is has some sort of rheostat. On most motors of this type you can change wiring and instructions for that are inside the motor near the wire terminal plate or the stack of metal prongs / the rheostat. But to be honest I never have touched this type of Singer motor so I do not know for sure here. -

They are out of production for a long time and even if you find the parts (you never know) they may cost more than the machine is worth when restored. Maybe a 2nd machine for parts would help but they are quite rare. Anyway - since you are in NZ checking with MARFAR in Australia may be an idea. They sometimes pop up when I´m looking for parts. Maybe they have old stock they do not have listed in their webshop. Just a guess. https://marfar.com.au/

-

Please post pictures of your machine. If possible one pic from the left side with removed face plate please.

-

Did you read the manual? Maybe not correctly threaded. Please post some pictures of your threaded machine and one view from the open slide plate that covers the hook.

-

Can I modify the singer 45k56 like 45k25 and use it?

Constabulary replied to ddiuni's topic in Sewing Leather

You should post some pictures of your machine so we know how it looks in its current state. Do I get you right - you want to convert the 45K56 jump foot machine into a 45K25 roller foot machine? If that is the case you may need an OEM Singer or Adler roller foot that slides onto the presser foot bar and you have to remove the parts the govern the jump foot mechanism (IIRC). I´m ot sure if after market version of this kind of heavy duty roller foot do exist. But you may need some other parts as well. It would help if we could see your machine - please post some good pictures. -

I can´t help but just today I read in a Pfaff mechanics instruction manual (for Pfaff 332) that ex factory there is a 10% difference between F and R stitch length in order to not pierce (damage) the thread of the forward stitch. This has nothing to do with your machine but from my observations there very often is a difference between F and R stitches on different machines - maybe for a purpose? Not sure how different the machines are internally but externally the Pfaffs often have the same stitch length lever so maybe this is an idea for you: https://www.youtube.com/watch?v=wtT7QejY2eQ

-

CobraClass 4 Bobbins -- Will THESE fit?

Constabulary replied to MacB's topic in Leather Sewing Machines

or compare measures from the offer with your bobbins -

Singer 136w100 stitch length gears

Constabulary replied to johnnysingerfan's topic in Leather Sewing Machines

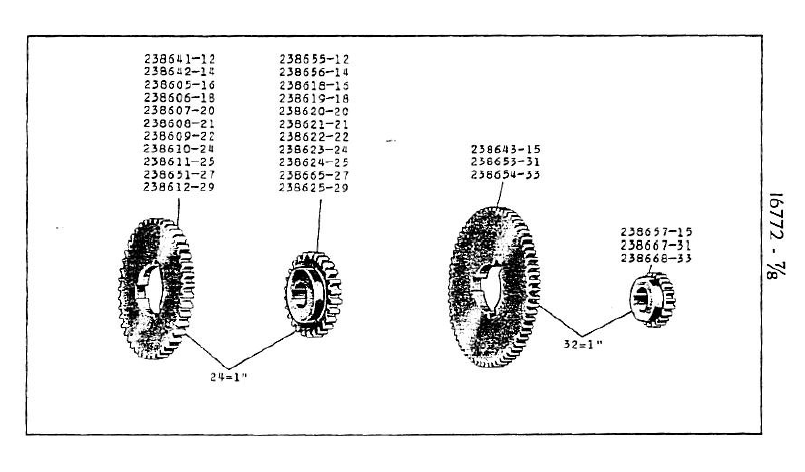

I once owned a 110w which is the flat bed Version basically. Cool machine but way too short stitches for what I do. You will find the gears in the parts list of your machine but I honestly doubt there will be gears for 4-5mm stitches. This is an extract from the 110w parts list. Not sure if the gears are the same in your machine so this is just meant as an example. I think the stitch length (stitches per Inch) is the number behind the part numbers. -

Just a guess - It may have happened that they sorted screws into the wrong bin. I once ordered screws for the 29K71 paddle spring on the needle bar and received screws for the 29K72 hook spring. You never know - this happens. Since they have the screws and the needle bars too ask if they could check if their screws fit their needle bars cause you think an error could have happened while sorting the screws. The needle bars of the Adler 67 167 69 169 and so forth should all be the same.

-

Troubleshooting Pfaff 145 thread breaking

Constabulary replied to ethereal's topic in Leather Sewing Machines

You are aware that you have not installed the needle plate in the video, right? Without the needle plate in place it will never work correctly. -

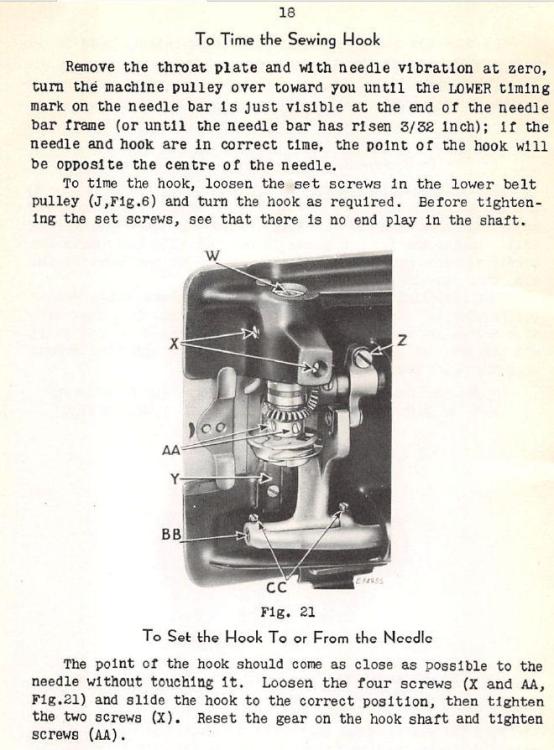

The timing is the same as for the Singer 107w or 143w cause they are using the same hook. Difference is that the 307G2 has the hook drive gears covered in a grease filled gear box but thats not relevant for the timing. Hope this helps: Also check this thread - as I said before the hook is the same on 143w and 307G2:

-

Help me! Do I need to know the brand and model?

Constabulary replied to Jpmaringa's topic in Leather Sewing Machines

I think Singers UFA / 29 was the earlier model but I don´t know if a license was sold to Adler but I don´t think so. -

Help me! Do I need to know the brand and model?

Constabulary replied to Jpmaringa's topic in Leather Sewing Machines

my records say the 30-15 is a small bobbin machine and 30-17 is large bobbin. -

singer 51w28 needle bar conversion

Constabulary replied to Cihowe's topic in Leather Sewing Machines

Hope this helps: https://leatherworker.net/forum/topic/96574-singer-51w56-needle-bar-conversion/?do=findComment&comment=659864 -

Dürkopp 17 Patcher - Sunday Morning Barn Find

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Thats ONE story - I also have heard that they stopped making this machine before the war cause it was too complicated (too many parts) and the competitors (Adler 30, Singer 29K...) were cheaper to produce. I don´t know - maybe the truth is somewhere in the middle. -

Dürkopp 17 Patcher - Sunday Morning Barn Find

Constabulary replied to Constabulary's topic in Leather Sewing Machines

@Pharvey Hard to tell from the distance... See the large slotted screw next to the long handle? Try loosening a little bit, maybe it is too tight. Just a guess. If it does not help post some pictures from the rear and the right side of the head. It is the 1st Class 17 I have been working on but I managed that it is making quite long stitches - longer than 5 SPI actually. -

Help me! Do I need to know the brand and model?

Constabulary replied to Jpmaringa's topic in Leather Sewing Machines

I meant 29K72 But as WIZ said, post a picture of the shuttle to be sure it is a large hook machine. I could be "downgraded" to 30-15 - you never know... -

Help me! Do I need to know the brand and model?

Constabulary replied to Jpmaringa's topic in Leather Sewing Machines

Basically a short Arm version of the Adler 30 - usually the short arm is named 30-15 BUT the 30-17 should have a LARGE shuttle hook but with short needle (no high lift). A rare machine but in case you need parts most parts of the Adler 30-1 and 30-7 should work with your machine. The large hook and bobbins is the same as for the Singer 29K71. The machine seems to be a quite early one cause it has no quick release for the hand wheel which allows to wind the bobbin w/o running the whole sewing mechanism. -

@Stevens6 this is a manual for the 29K71 which more or less is the successor of the 29K51 - the two machines are very similar but not identical but it will work for your machine. https://leatherworker.net/forum/applications/core/interface/file/attachment.php?id=135841 Hope this helps

-

The springs should work!

-

It is a darning machine - not even a sewing machine. If it is in the state as it once left the factory it does not even have a feed dog (for feeding the material) or a stitch length adjuster so It will not produce a seam with constant stitch length at all but we have not seen your particular machine yet. Maybe someone reworked it in the past.

-

Cowboy CB4500 or SIECK type 441 K

Constabulary replied to JustCurious's topic in Leather Sewing Machines

The above info sheet seems to be from the original 441 manufacturer JUKI The linked Sieck 441 K looks like the Cowboy CB 3200 and not like a CB 4500 Neither SIECK or COWBOY are manufacturer of sewing machines, they just put their own label (brand name) on Chinese made sewing machines and they are free to give them a name of their own choice. The price on the SIECK website is w/o VAT - add 19% for German VAT. -

obviously a 227R - maybe from a different batch. Also check SEIKO CW-8 or Consew 227R - basically all the same machines.

-

Maybe the racks & pinions in the gear box are worn or maybe the hook tip is worn. Are you sure you are using the right needle system 332 LONG (not 332)? Make sure the long grove of the needle is facing left.

-

claes Help! Claes 8345 ( Metro Spezial / Pfaff 9345)

Constabulary replied to Arsura's topic in Leather Sewing Machines

some years ago I visited their factory and bought some smaller spares while I was in the area for picking up some machinery (for sewing & wood working IIRC) - very nice folks there indeed!