jimi

Members-

Posts

1,418 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by jimi

-

yes sorry rotate.

- 29 replies

-

- cb3200

- thread fraying

-

(and 1 more)

Tagged with:

-

i take it your foot is on a round bar ?? might be wrong?? if so loosen the screw or screws to slightly move the foot to the right?

- 29 replies

-

- cb3200

- thread fraying

-

(and 1 more)

Tagged with:

-

yes the walking foot with the hole. can you move it to the right a bit?

- 29 replies

-

- cb3200

- thread fraying

-

(and 1 more)

Tagged with:

-

so did you try moving the foot slightly to the side??

- 29 replies

-

- cb3200

- thread fraying

-

(and 1 more)

Tagged with:

-

could it be the needle is fraying the thread when it passes through the foot , rubbing against the hole in the foot?? looks real tight in there.?? just a thought??

- 29 replies

-

- cb3200

- thread fraying

-

(and 1 more)

Tagged with:

-

with constabulary. almost 100% sure this is for releasing the tension on the thread when the foot is lifted up, then you can pull your work away and not bend the needle.

-

leather backpack First leather backpack

jimi replied to DarkGoku's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

great job, looks very cool.- 14 replies

-

Now that was lucky.. haha a tool nut with a mill and lathe. you could do wonders with that lot in your workshop. that is great that there are no marks left by the foot. as this is the goal with leather. i imagine if it does not fit in the hole and pulls on the thread instead you probably risk getting slipping at one point and possibly some stitches longer than others?? Hey Al how´s things.. i haven´t forgot about the pictures.. will send them tomorrow and you can have a laugh at my stitching hehehe..

-

-

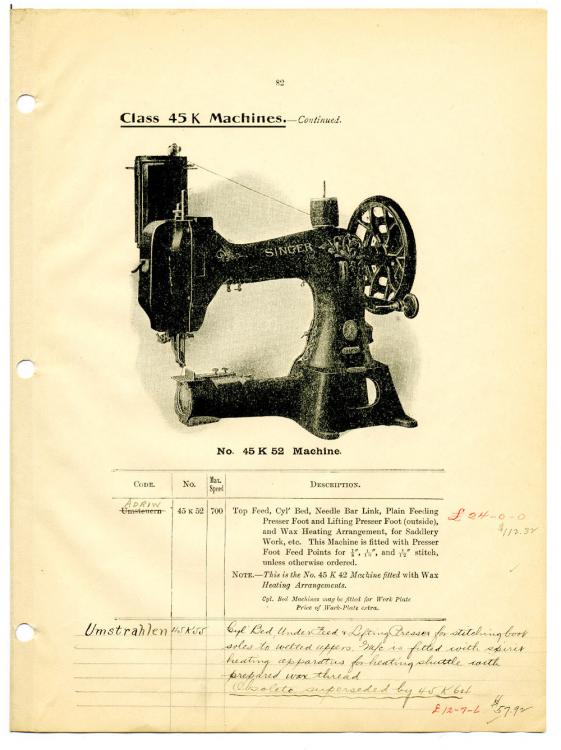

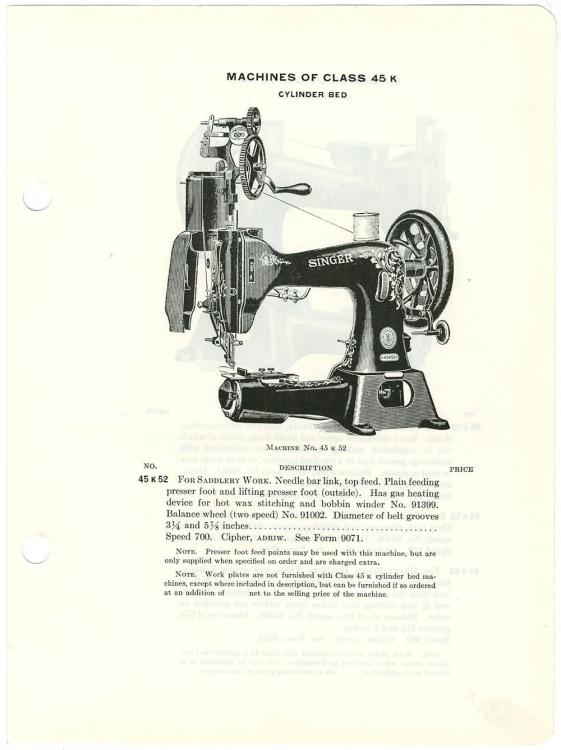

your welcome, yes sometimes i overlook things in the posts too..haha. your machine would have been probably furnished with a wax deposit for the thread, that is why i asked if the top tension assembly was present as this was mounted on the wax deposit. also the front foot looks to be different from the ones furnished with these machines but then again i could be wrong. is there any numbers or simanco on it?? as long as it works that is the point. here is a picture of one similar to yours. as you can see the front foot is different. i am not 100% sure but it looks as if it might have been used for setting the stitch under the surface also?? as it is in front of the needle. we will have to wait until an original turns up to find out.

-

Yeah, i can see that one , thanks. in the parts list 91092-91102 there are the different sizes that was available and probably in those days you could ask them to make you one up for a specific job. but as these machines are so old, if it did not come with your machine then it will be pretty hard to find these feet. that is one thing overlooked with these older machines. just for the normal feet for the 45k21 etc. it is very hard to find original parts like feet needle plates. and when it comes to accessories like binders etc.. then even more difficult. if you look at the parts list for the 45k89 etc.. you will find an array of accessories which were available but seem to be non existent when you ask people about there machines and what came with them. best thing would be to make them up yourself or get a friend to mill some. they do not seem all that complex to make.

-

sorry buddy, but your pictures are too far away to see anything. so did it come with one foot?

-

here is another link talking about the 45k52. maybe you saw this one already??

-

Thanks for the pictures, nice to see the old machines. did you get anymore feet with the machine or does it have just the one? looks like it is all pretty much their. is the top tension unit and the disk opener present?. as you see in the parts manual this came with the feet which have the two prongs or teeth on the toe, this was to mach up with the stitch length. as this was the way it fed the leather through you would have changed feet for different stitch lengths, this way leaving no visible marks on the top side. at least if you need a new needle plate you could do one up easily. but i can´t see the stitching on the collar?? in the picture above it seems like the thread is not resting on the post above the wheel tension unit?? strange?? regards jimi.

-

Hi There, here is the parts book for your machine. could you send some pictures of your 45k52. regards jimi.

-

19th century Hugo Werteim shoe patcher

jimi replied to RichardPorley's topic in Leather Sewing Machines

Hey Richard, way to go mate. well done, that is looking great. -

HOW TO: Polish solid brass snaps and solid copper rivets

jimi replied to howlback's topic in How Do I Do That?

Yep, that looks like what he has done. -

I Agree with dikman, i would say the best solution would be to weld it. at one point you are going to have to unscrew and tighten up that corner again if you ever disassemble the stand so a weld would seem better.

-

Hi there, this machine was fixed with JB weld and is working just fine. it does have SS rods inserted but the weld paste is as solid as a rock, or at least it seems like it to me. i have it on the legs on the floor at the moment and can move it around no problem. it was also tapped for the screw which holds the bottom rod on, as it broke right there, and that is also tightened up and working. or if someone can tig weld with some SS rod then probably better. this 45k was not soldered as it might have deformed the bed, so that is why i JB welded instead. hope this helps, but as Dikman said better seeing the part broken if possible in a picture. regards jimi.

-

Which machine for attaching shoe uppers to insoles?

jimi replied to Elennah's topic in Leather Sewing Machines

well there is a lot of different classes of 45k but the basic 45k1 or 21 would sew the leather in your picture. where you might be limited is with the type of foot for side clearance etc.. if you look up singer 45k here on the LW forum i am sure you will see some different types. there are ones that are for darning sacks and have no feed underneath, better not look for that type. -

on desktop,right click on picture-edit-resize-pixels- example 1225, then change to 725 or whatever - save.

-

if you look up singer 45k on the net the GA5 is a copy of that. check to see if your needle is in the right way first. or it may also be a wrong combination of needle and thread size?

-

Which machine for attaching shoe uppers to insoles?

jimi replied to Elennah's topic in Leather Sewing Machines

Oh ok. i do not think there are nº3 needles made anymore, just 4 and 5. if you needed a nº4 plate best to ask people when they are selling their machines as sometimes they will sell these parts alone. if you are looking for a multi tasker then an old working 45k type machine would probably sew your thin soles no problem (as in your picture). or a second hand triple feed like the cowboy or 441 type clones. -

Which machine for attaching shoe uppers to insoles?

jimi replied to Elennah's topic in Leather Sewing Machines

Hi, well the 45k89 in the picture would sew your leather as in the picture. if you start adding more sole etc.. then it might not do the job as well as an outsole sticher would. that is what i would say you would be looking for. although Singer did make the 45k68,69 and 71 for stitching soles, which is similar to the one in the picture but not exactly the same. if you are near Germany then look for a Frobana or a Gritzner outsole sticher. another option would be the Rafflenbeul MS55 or 200 which is a needle and awl type machine but also compact in size like the Frobana and Gritzner, and it feeds with the needle and not with teeth. in the UK i think similar was the Simplex and a victor. the needles for these first two machines are €9-10 ouch, i mean each. and uses left twist waxed linen 6-8 cord thread normally. if you can do the job as in your picture you might be able to pick up a cheap 45k and if it works then no swearing as an added bonus... here are a couple of pictures, i have just done this afternoon one on the 45k25. the other was done on the frobana. hope this helps. this was with the 45k25 this was with the frobana frobana 45k25 -

they are not what you would call a quality buckle. but for some projects would be fine. here are more pics. each bag weighs about 1kg. or if you want just a handfull make an offer. one bag is looking stained and could be the metal underneath or maybe the chrome is not that hot, but the other two bags seem ok. they have probably been sitting around for years in the bags?? . by the way i forgot to mention if anyone was wondering, the other buckles are not 5 euros like the biker ones. i am open to offers if you are interested in any of them.